Surface spraying device for sneaker processing

A technology of surface spraying and sports shoes, which is applied to spraying devices, liquid spraying devices, etc., can solve the problems of changing spraying effect, poor spraying effect on the surface of shoes, change of pressing range, etc., and achieve the effect of stable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

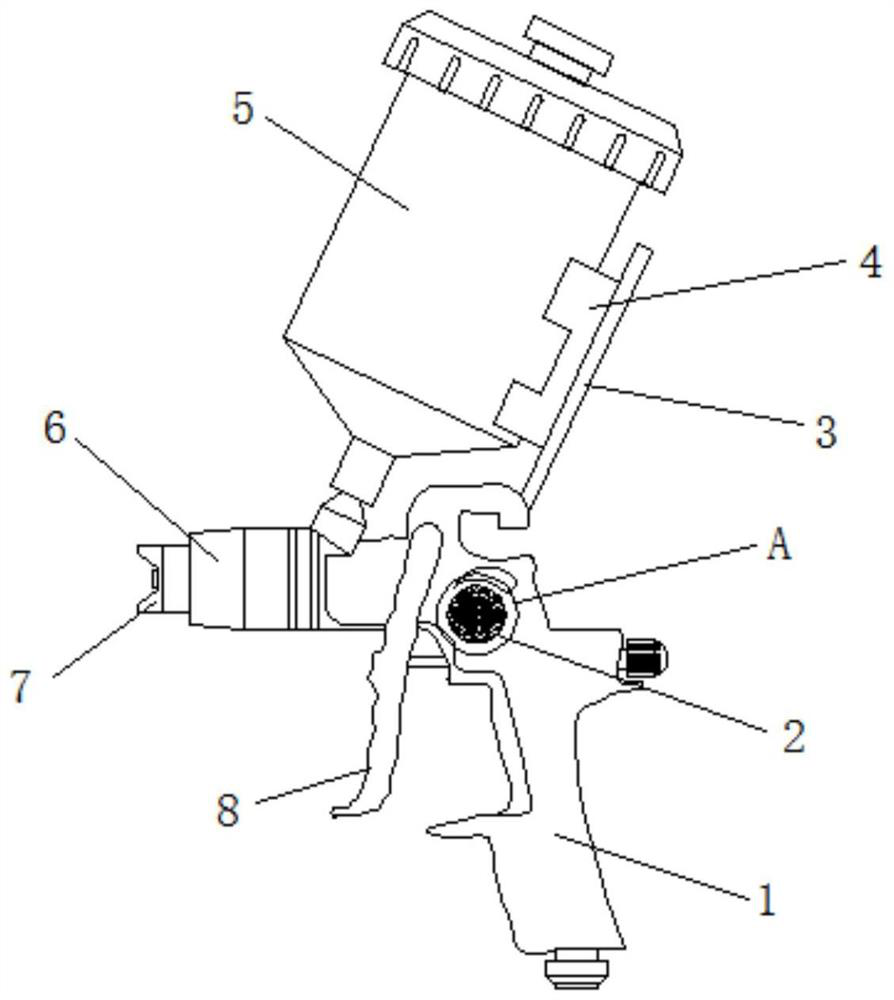

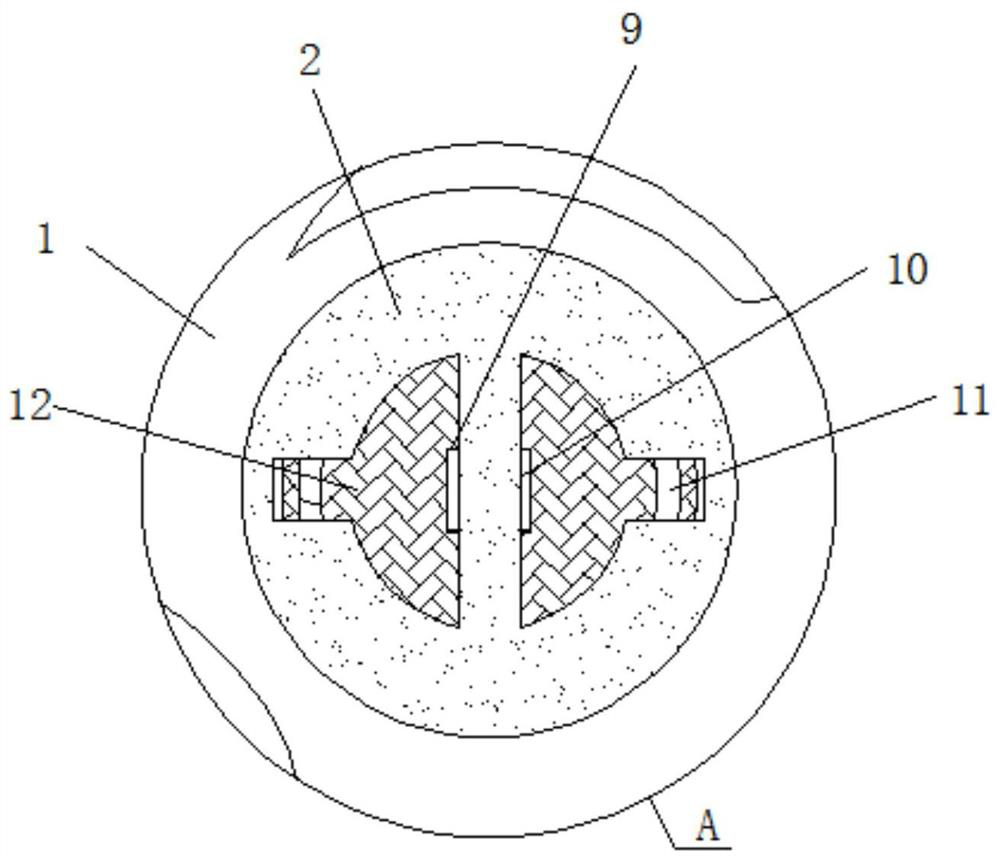

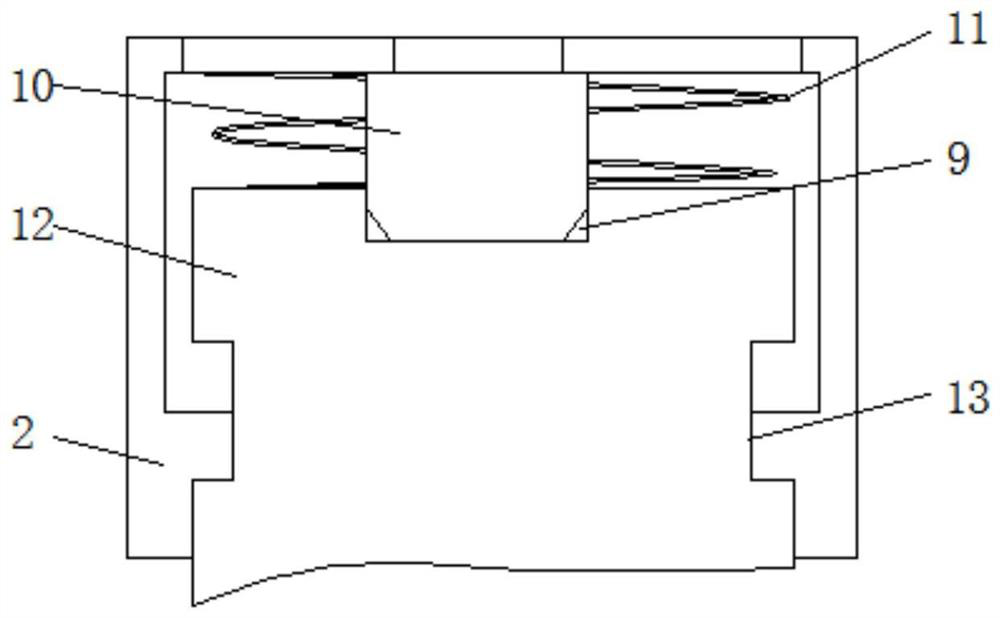

[0024] see Figure 1 to Figure 4 , the present invention provides a technical solution: a surface spraying device for sports shoes, including a gun body 1, the side wall of the gun body 1 is provided with an adjustment knob 12, the outside of the adjustment knob 12 is covered with a protective sleeve 2, through The designed protective sleeve 2, the protective sleeve 2 is installed on the surface of the adjustment knob 12 and can rotate freely, and then plays a role of protection and isolation for the adjustment knob 12, preventing it from touching and causing it to adjust the range of the trigger 8, so that the The invention is more stable in use, the outer wall of the adjustment knob 12 is provided with a groove 13, one end of the protective sleeve 2 is inserted into the groove 13 to connect with the adjustment knob 12, and the other end of the protective sleeve 2 is fixed with a connecting block 10, through the designed connecting block 10 , the connection block 10 is a squa...

Embodiment 2

[0028] see Figure 1 to Figure 5 , the present invention provides a technical solution: a surface spraying device for sports shoes, including a gun body 1, the side wall of the gun body 1 is provided with an adjustment knob 12, the outside of the adjustment knob 12 is covered with a protective sleeve 2, through The designed protective sleeve 2, the protective sleeve 2 is installed on the surface of the adjustment knob 12 and can rotate freely, and then plays a role of protection and isolation for the adjustment knob 12, preventing it from touching and causing it to adjust the range of the trigger 8, so that the The invention is more stable in use, the outer wall of the adjustment knob 12 is provided with a groove 13, one end of the protective sleeve 2 is inserted into the groove 13 to connect with the adjustment knob 12, and the other end of the protective sleeve 2 is fixed with a connecting block 10, through the designed connecting block 10 , the connection block 10 is a squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com