Lithium battery producing and processing mechanism

A processing mechanism, lithium battery technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of aluminum-plastic film bending, unfavorable product quality stability, deformation, etc., and achieve the effect of avoiding the danger of punching machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

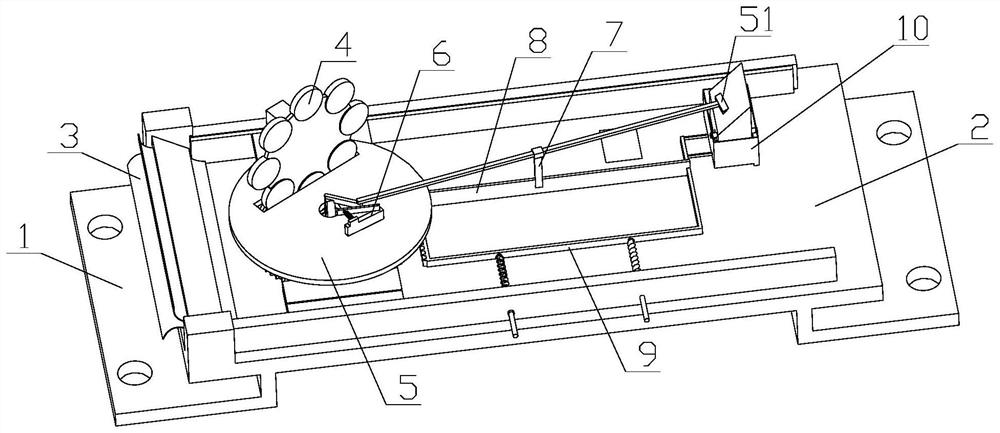

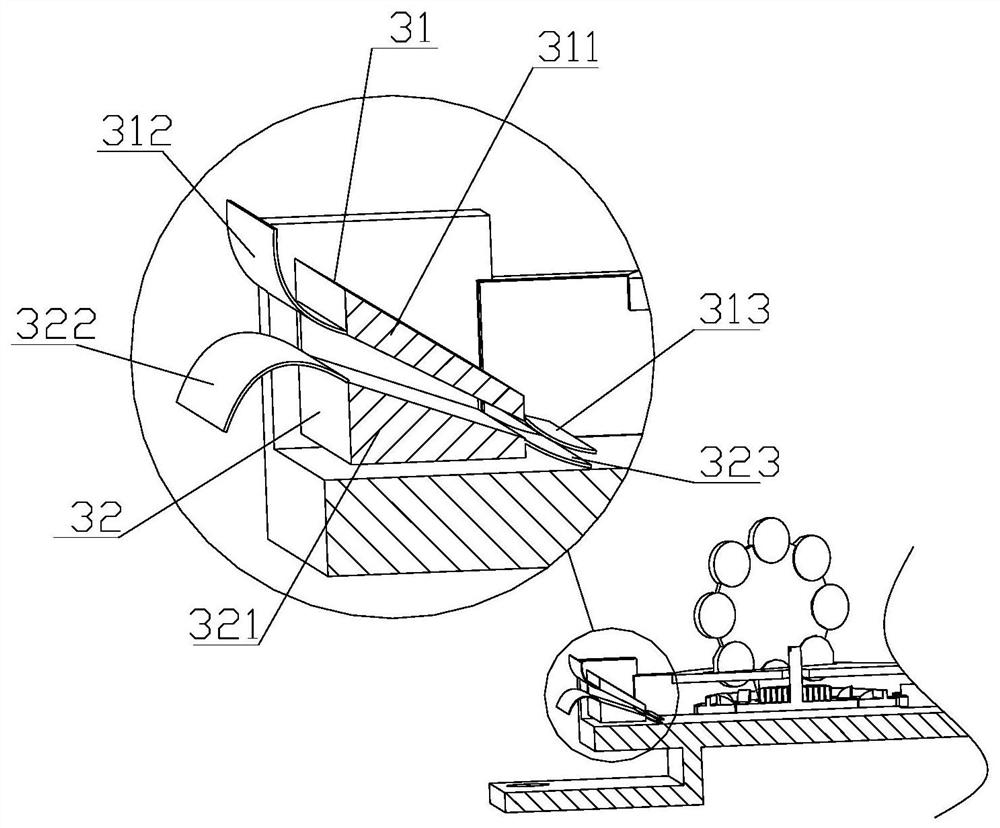

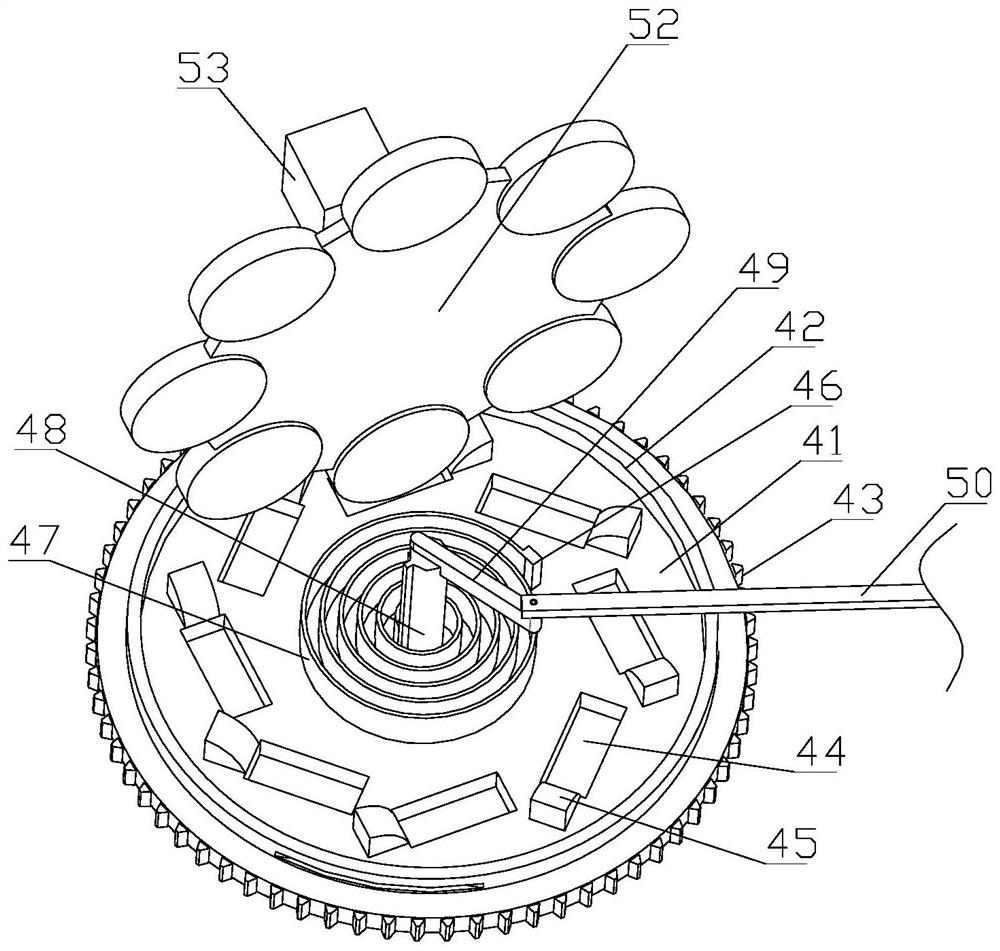

[0030] Attached below Figure 1-7 The present invention is further described with embodiment:

[0031] A production and processing mechanism for a lithium battery, comprising an installation part 1 and a support part 2, the installation part 1 is arranged on both sides of the bottom of the support part 2, and a connection position for connecting with a stamping equipment is provided on the installation part 1, The upper end of the support part 2 is set as the transmission surface of the aluminum-plastic film, and the both sides of the transmission surface are provided with retaining bars, and one end of the support part 2 is provided with a guide assembly 3 for conducting the aluminum-plastic film. One side of 3 is provided with a dialing assembly 4, a supporting plate 5 is arranged at the upper end of the dialing assembly 4, and a limit assembly 6 is arranged at the upper end of the supporting plate 5; one side of the dialing assembly 4 is slidably supported by a guide sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com