Unified characterization method for characteristic lines of gear three-dimensional error

A characteristic line and gear technology, which is applied in the field of unifying the characteristic line of the three-dimensional error of the gear, can solve the problems such as the difference in the actual performance of the gear, and achieve the effect of comprehensive measurement and evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention is described below in conjunction with concrete processing example:

[0052] 1. The basic parameters of the characteristic gear are shown in Table 1. The tooth surface point cloud data with errors on the gear is as follows: Figure 5 shown. Take tooth surface 1 as an example for data processing.

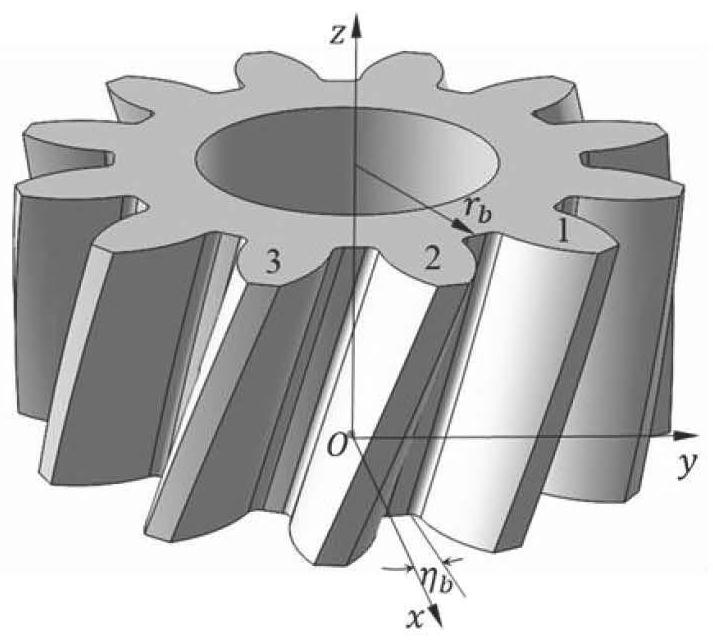

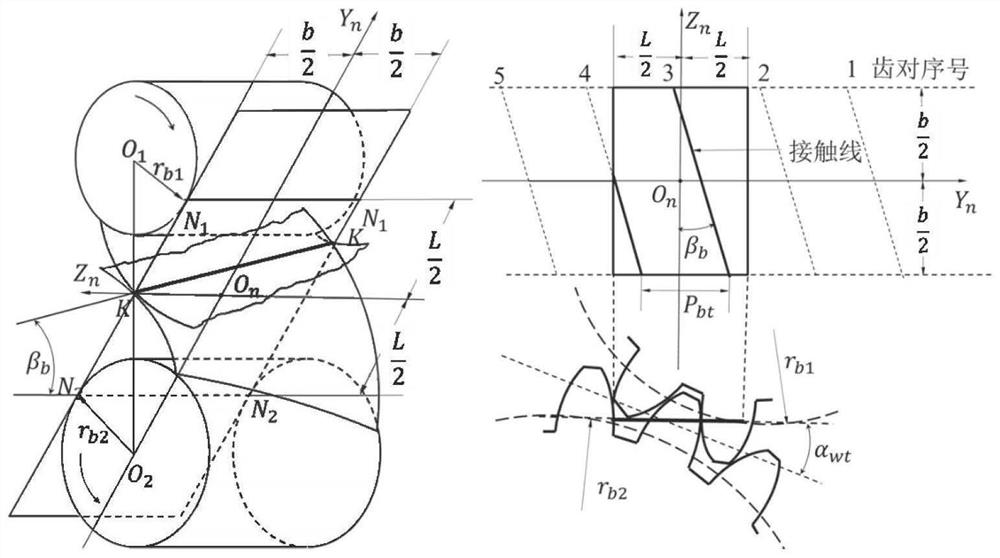

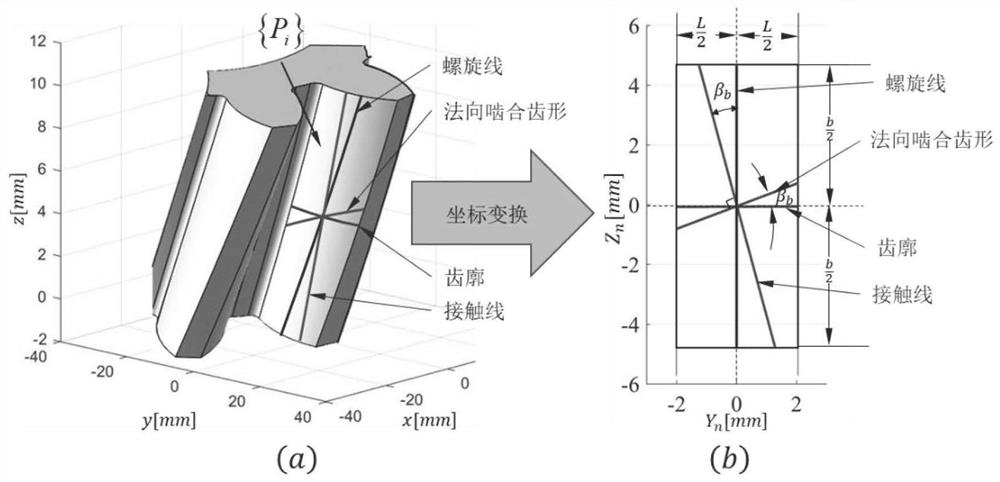

[0053] The position of the origin of the gear coordinate system is located at the intersection of the gear axis of rotation and the bottom surface, the x axis is located in the middle of the first tooth groove, the y axis is perpendicular to it, the x0y plane is perpendicular to the axis, and the z axis coincides with the axis of rotation of the gear shaft. When the gears mesh, the base circle tangent plane passing through the meshing line of the two gears is the meshing surface, and a coordinate system (Y n ,Z n ). Z n The shaft is along the direction of the gear axis, and the range is Y n The axis is along the development direction of the tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com