Distribution network live-line full-process operation robot

A working robot, a whole-process technology, applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problems of low work efficiency, hidden dangers, long operation time, etc., and achieve light weight, compact structure, and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

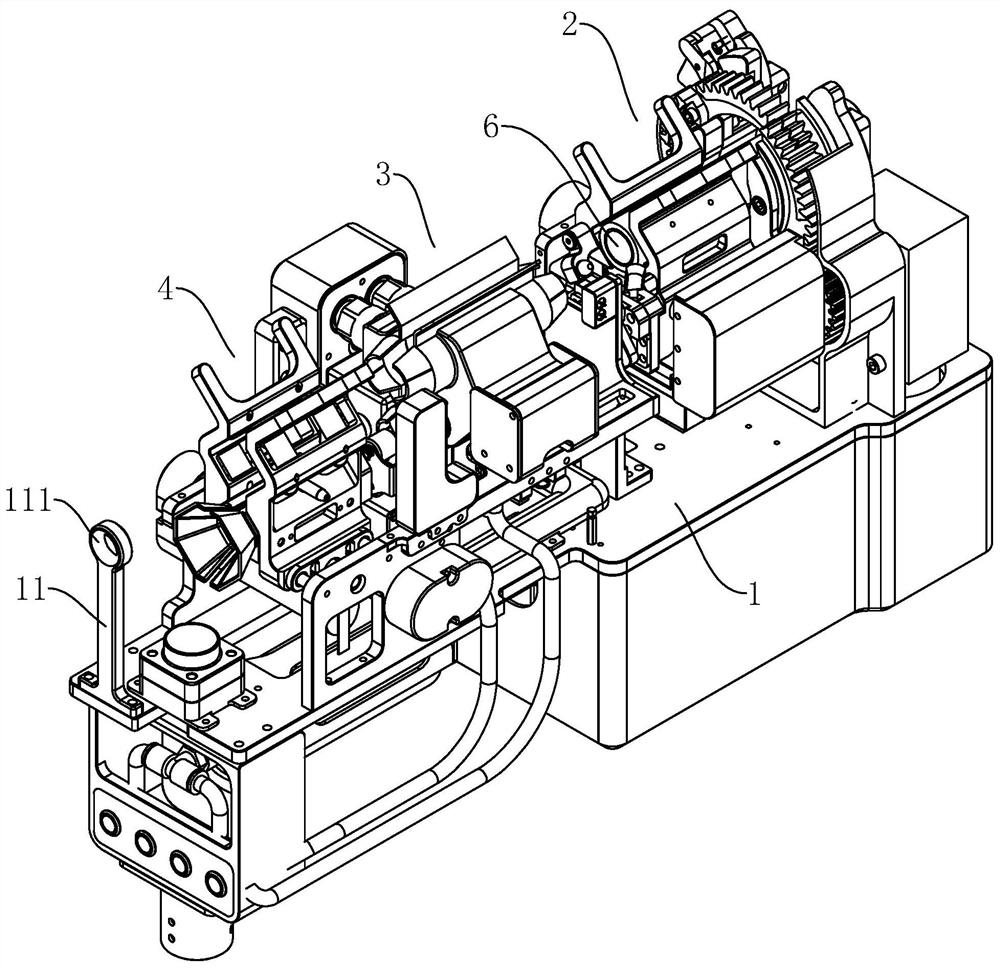

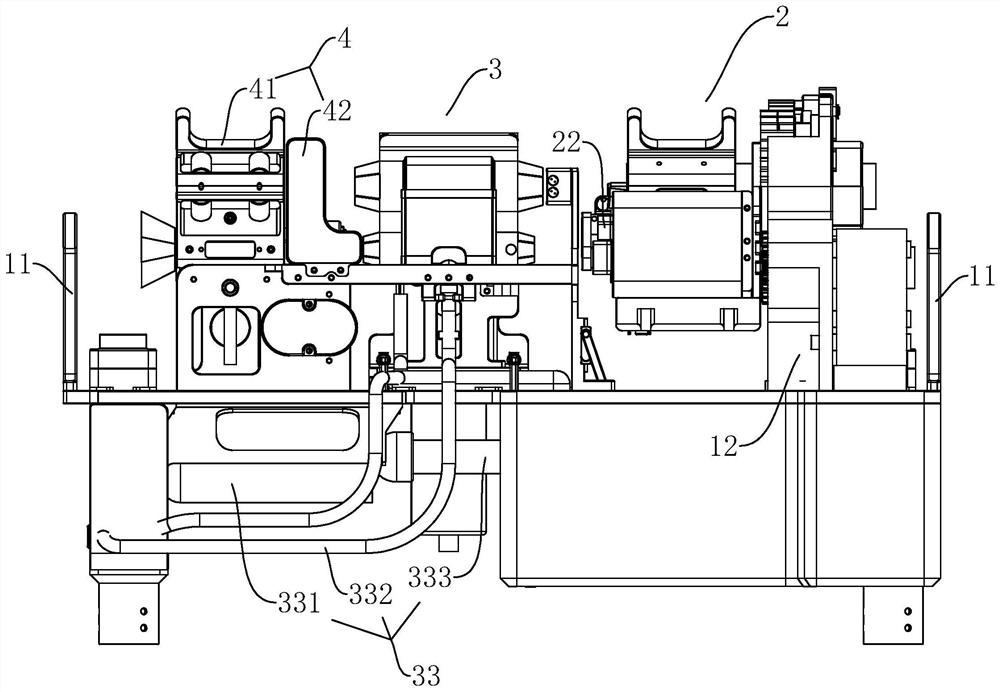

[0052] combine Figure 1 to Figure 11 A further description will be made on the whole-process operation robot for live distribution network of the present invention.

[0053] A live distribution network full-process operation robot is characterized in that it includes a base plate 1, a wire stripping walking device 2 installed on the base plate 1, a wire positioning and clamping device 4, and a wire clamp installation device 3.

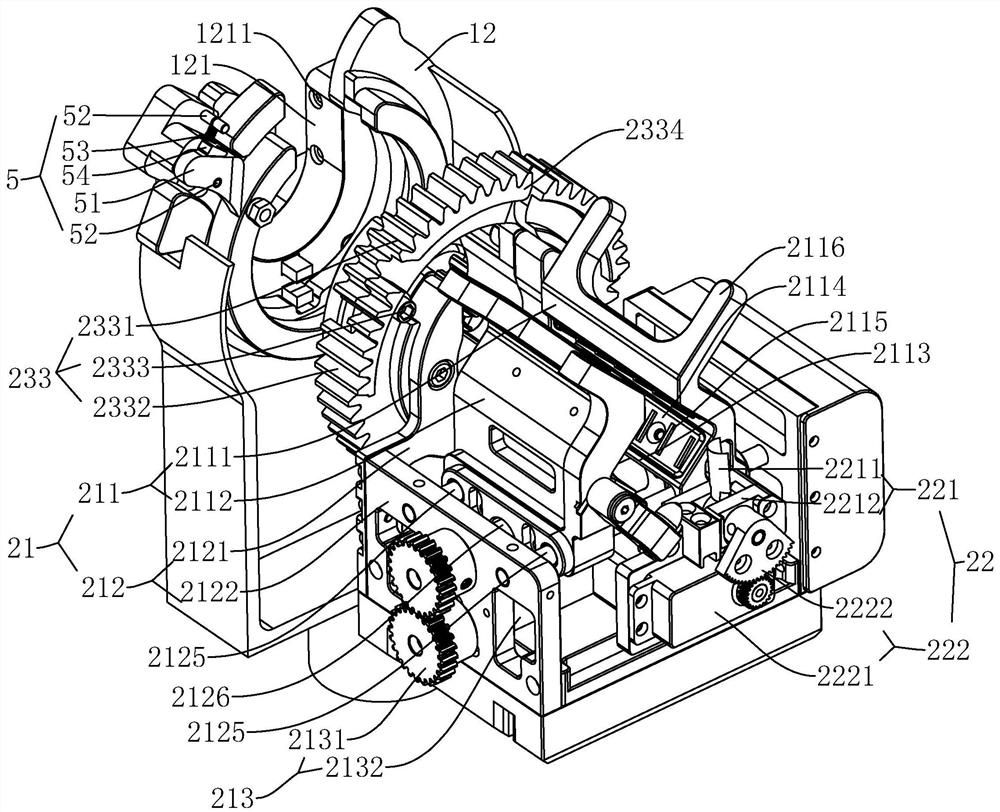

[0054] Such as Figure 3-5As shown, the wire stripping traveling device 2 includes a driving mechanism 23 , a wire stripping mechanism 22 and a wire holding traveling mechanism 21 . The wire-holding walking mechanism 21 has a wire-holding channel 2113 for cables to enter and a guide piece 2114 arranged on the inner wall of the wire-holding channel 2113 . The stripping mechanism 22 has a stripping cutter 221 and a cutter adjustment assembly 222, the stripping cutter 221 is arranged on the line along the wire holding channel 2113, and the cutter adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com