Multifunctional clamp with pressure sensor, control method and workpiece clamping device

A technology of a pressure sensor and a control method, which is applied in the direction of workpiece clamping devices, measuring devices, force/torque/power measuring instruments, etc., and can solve problems such as inability to measure the clamping force, failure to find the fixture device for the workpiece, and inability to use it flexibly. Achieve the effects of strong overall structural stability, simple maintenance methods, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

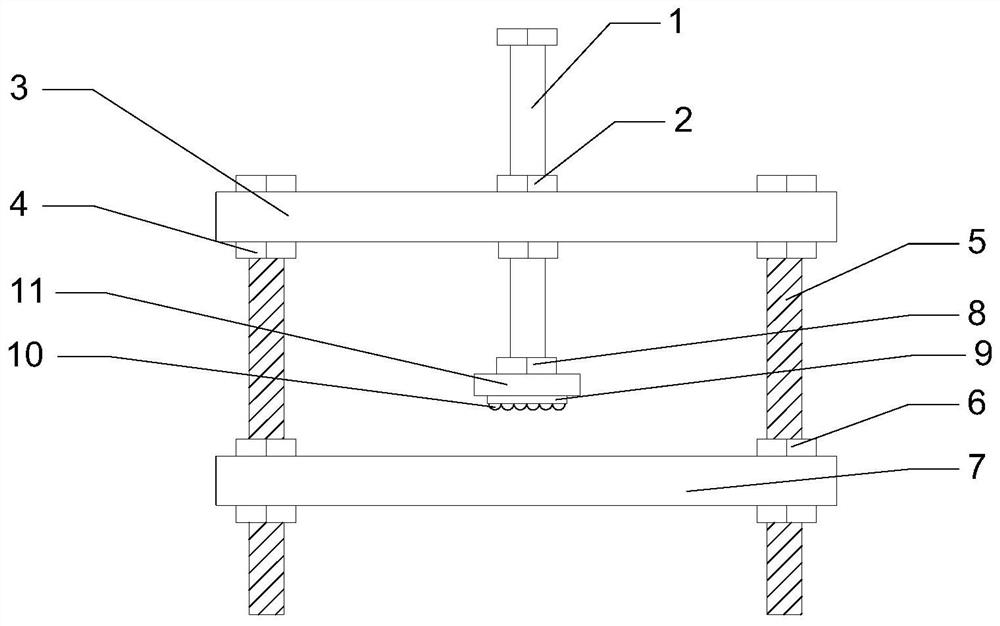

[0045] Such as figure 1 As shown, the multifunctional clamp with pressure sensor provided by the embodiment of the present invention is a multifunctional clamp in the form of a gantry clamp, including: a force applying bolt 1, a force applying screw fixing nut 2, an upper splint 3, and a fixing nut 4 on the support bolt , support bolt 5, support bolt lower fixing nut 6, lower splint (arc plate) 7, pressure sensor fixing nut 8, plane bearing slotted square 9, bearing ball 10 and pressure sensor 11. The force applying bolt 1 is fixed on the upper middle position of the upper splint 3 through the force applying screw fixing nut 2, and the lower end of the force applying bolt 1 is fixed with a pressure sensor fixing nut 8 through threads, and the pressure sensor fixing nut 8 is connected with the pressure sensor 11 and the flat bearing slotted square 9 are connected, and the plane bearing grooved block 9 is provided with bearing balls 10. The two ends of the upper splint 3 are pr...

Embodiment 2

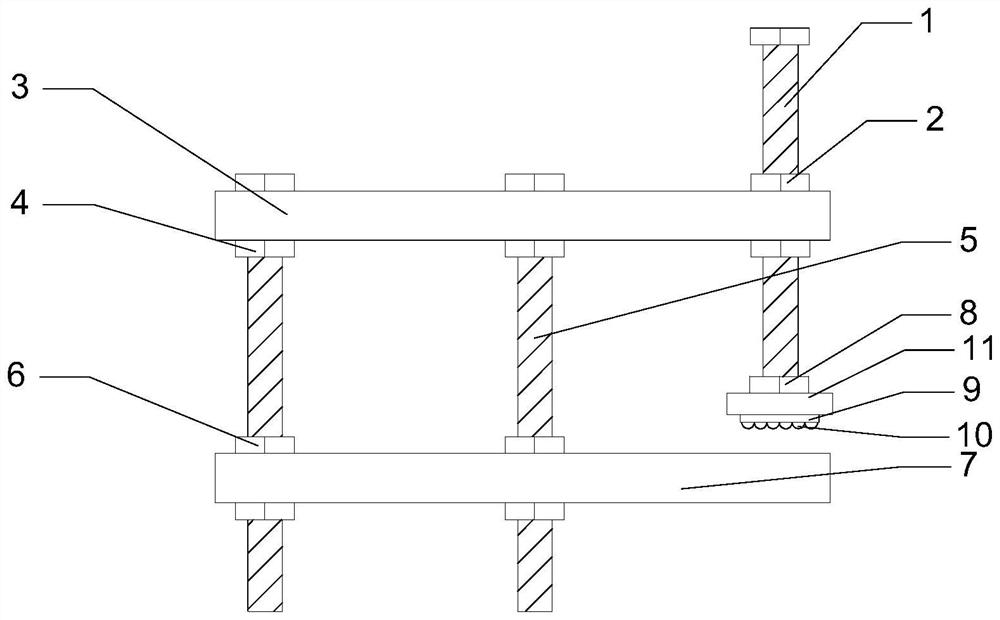

[0048] Such as figure 2 As shown, the embodiment of the present invention provides a multifunctional clamp with a pressure sensor in the form of an I-shaped clamp with a multifunctional clamp. The force applying bolt 1 is fixed on both ends of the upper splint 3 through the force applying screw fixing nut 2, the middle position of the upper splint 3 is screwed with a supporting bolt 5 through a threaded hole, and is fixed by the fixing nut 4 on the supporting bolt 5, and the lower end of the supporting bolt 5 passes through The fixing nut 6 under the support bolt is fixed with the lower splint 7 .

[0049] First, assemble the upper and lower splints with the middle support bolts, and fix the support bolts with the upper and lower nuts. The distance between the two splints is the maximum depth that the clamp can hold; then assemble and connect two force-applying bolts in the holes on both sides; Finally, the plane bearing and the pressure sensor are installed on the end of th...

Embodiment 3

[0051] Such as image 3 As shown, the multifunctional clamp with pressure sensor provided by the embodiment of the present invention is a C-shaped clamp form of a multifunctional clamp, and the force applying bolt 1 is screwed to one end of the upper splint 3 through a threaded hole, and the nut is fixed by the force applying screw 2 for fastening. One end of the upper splint 3 is screwed with two support bolts 5 through threaded holes, and is fastened by the fixing nut 4 on the support bolts. The lower ends of the two supporting bolts 5 are respectively screwed on the lower splint 7 through threaded holes, and fixed by the lower fixing nuts 6 of the supporting bolts.

[0052] First, assemble the upper and lower bolts with the two supporting bolts. The fixed positions of the two supporting bolts are in the two adjacent turning holes on one side of the splint. The distance between the two splints is the maximum depth that the clamp can hold. The support bolts are fixed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com