Structure and method for lowering steel cofferdam through drilling platform steel pipe piles

A drilling platform and steel cofferdam technology, applied in infrastructure engineering, construction, etc., can solve problems such as position deviation, long distance, and inability to use steel casings, and achieve the effect of preventing plane position deviation and ensuring the accuracy of lowering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

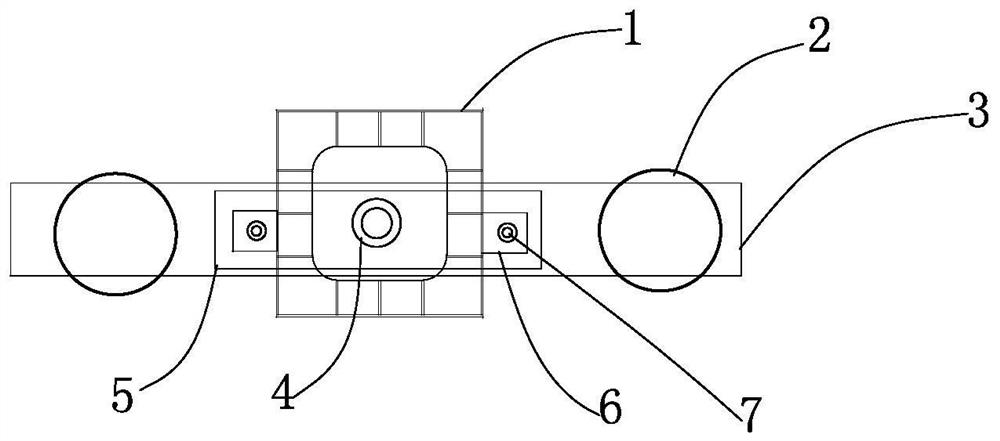

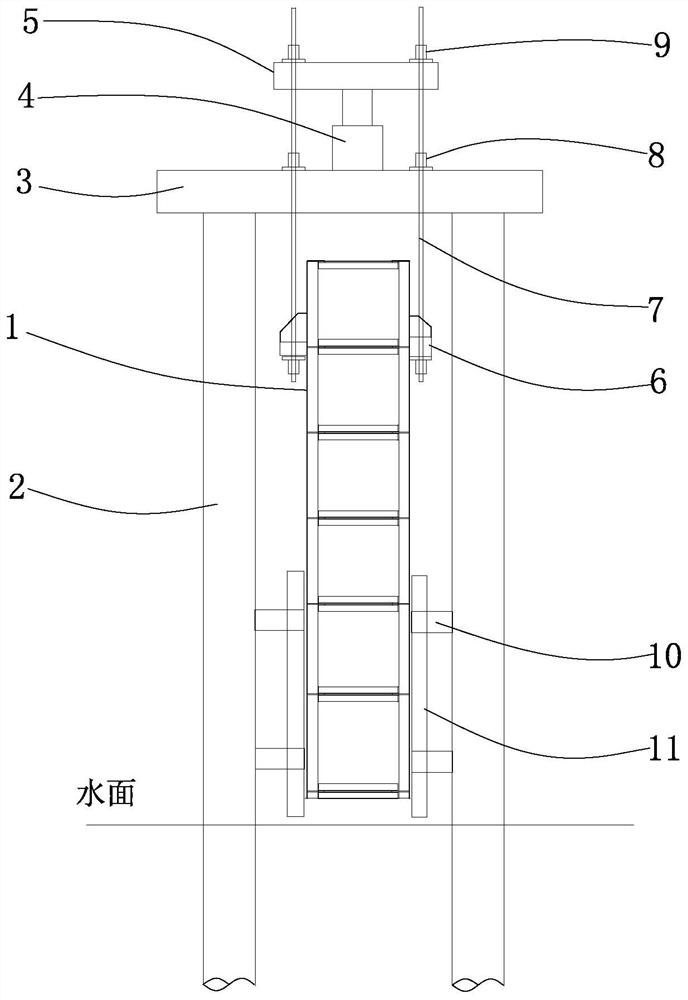

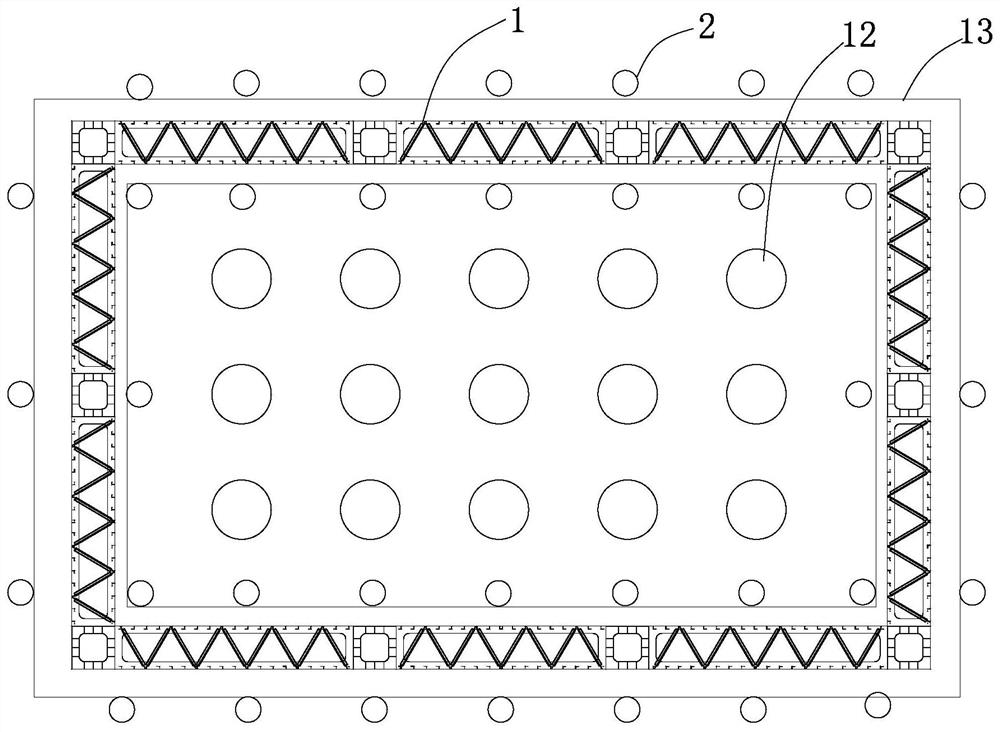

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a structure for lowering steel cofferdams by using steel pipe piles on drilling platforms. A load-bearing beam 3 is erected on the top of two opposite steel pipe piles 2 on both sides of the side plate, and a through-hole jack 4 is set on the load-bearing beam 3 facing the side plate of the steel cofferdam, and a pole beam 5 is set up on the jack. The positions of the load-bearing beams on the two side walls of the side slab of the weir are respectively welded with a lifting point 6, and the lifting point can adopt a corbel or ear plate structure, which is welded to the side wall of the steel cofferdam. The lower end of a suspension rod 7 passes through the suspension point 6 and is anchored at the bottom of the suspension point. The upper end of the suspension rod 7 passes through the load-bearing beam 3, the jack 4, and the pole beam 5 sequentially from bottom to top. A nut 8 is screwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com