Particle filter with ultrasound device

A filter and ultrasonic technology, applied in the direction of dispersed particle filtration, instrumentation, dispersed particle separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0505] preamble

[0506] For clarity, the following Figure 1 to Figure 35 Only the essential components of the invention are shown. Peripherals necessary for carrying out the invention include conventional and known electronic, electrical, mechanical, pneumatic and hydraulic devices such as computers, computer chips, power supplies, power cords, motors, lights, cameras, network Cameras, lasers, exciters and receivers, power packs, batteries, accumulators, measuring and control devices, actuators, sensors, powder dosing or metering devices, manometers, spectrometers, gas chromatographs, mass spectrometers, microscopes, particles Counters, feed pumps, vacuum pumps, mechanical grippers and actuators for remote monitoring.

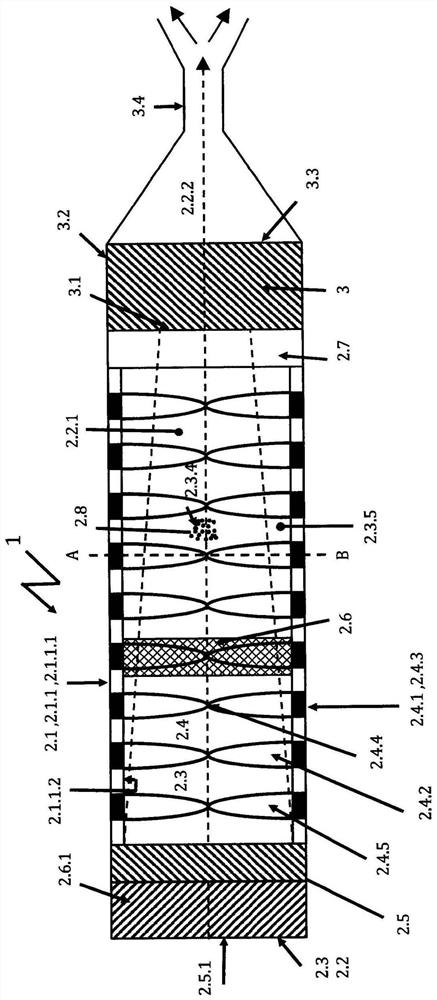

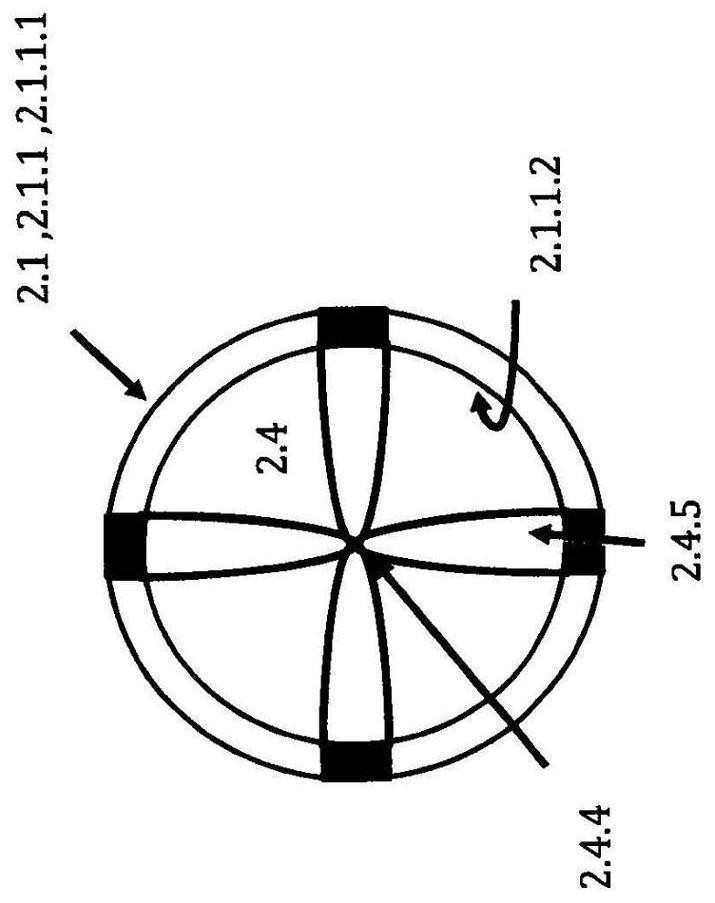

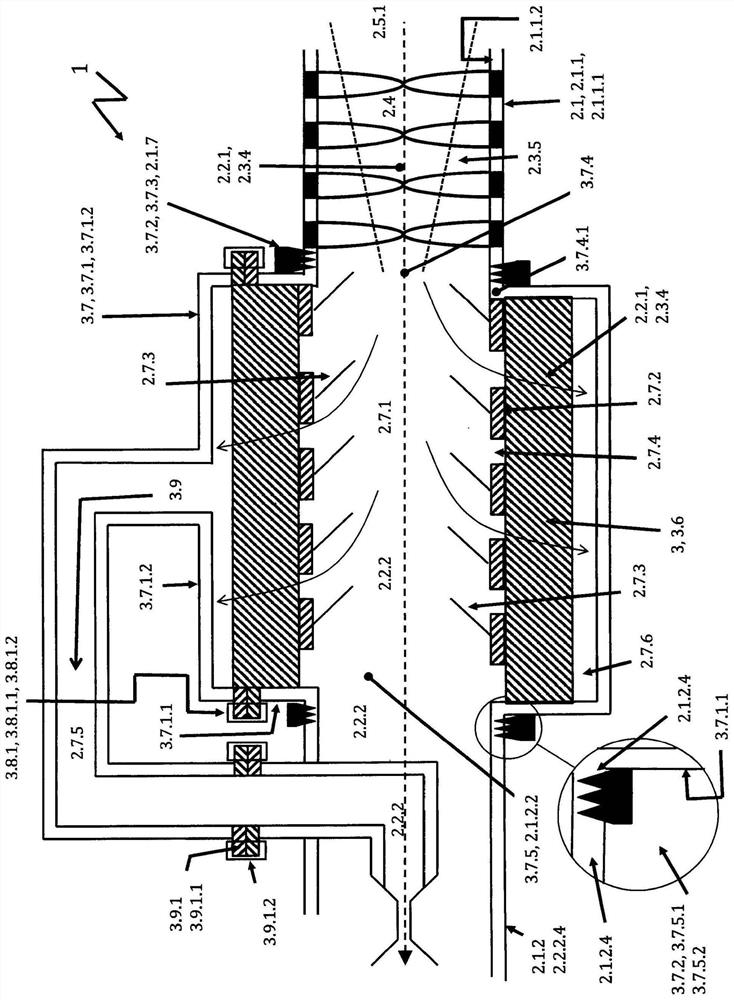

[0507] figure 1

[0508] concept test

[0509] Here and hereinafter, N represents the number of particles, V represents the volume in cubic meters, and t represents the time in hours, expressed as the specific particle number N / Vt.

[0510] The percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com