Highly translucent pure amino acid self-thickening cleansing soft gel and preparation method thereof

An amino acid and soft gel technology, applied in the field of skin care products, can solve the problems of easy delamination, poor water solubility and reduced consistency, and achieve the effects of strong anti-drying ability, good stability and stable consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Feeding ratio:

[0065] Cosmetic grade potassium cocoyl glycinate powder - 100 kg;

[0066] Cosmetic grade potassium lauroyl glycinate powder - 80 kg;

[0067] 30% cosmetic grade sodium lauroyl sarcosinate - 250 kg;

[0068] 50% cosmetic grade potassium lauroyl taurate - 15 kg;

[0069] 30% Cosmetic Grade Sodium Cocoyl Apple Amino Acid——18kg;

[0070] 30% Cosmetic Grade Sodium Lauroyl Oat Amino Acid——18kg;

[0071] 30% Cosmetic Grade Palmitoyl Hydrolyzed Wheat Protein - 5kg;

[0072] Pharmaceutical-grade high-purity potassium glycyrrhizinate——1.2 kg;

[0073] Pharmaceutical grade trimethylglycine - 10 kg;

[0074] Cosmetic grade glycerin - 6 kg;

[0075] Pharmaceutical grade sodium citrate - 28 kg;

[0076] Pharmaceutical grade sodium chloride - 35 kg;

[0077] The plant essential oil adopts natural geranium essential oil --- 1.5 kg;

[0078] Purified water uses deionized water --- 412.3 kg.

[0079] Concrete preparation steps:

[0080] 1) Put 334.29 kg of d...

Embodiment 2

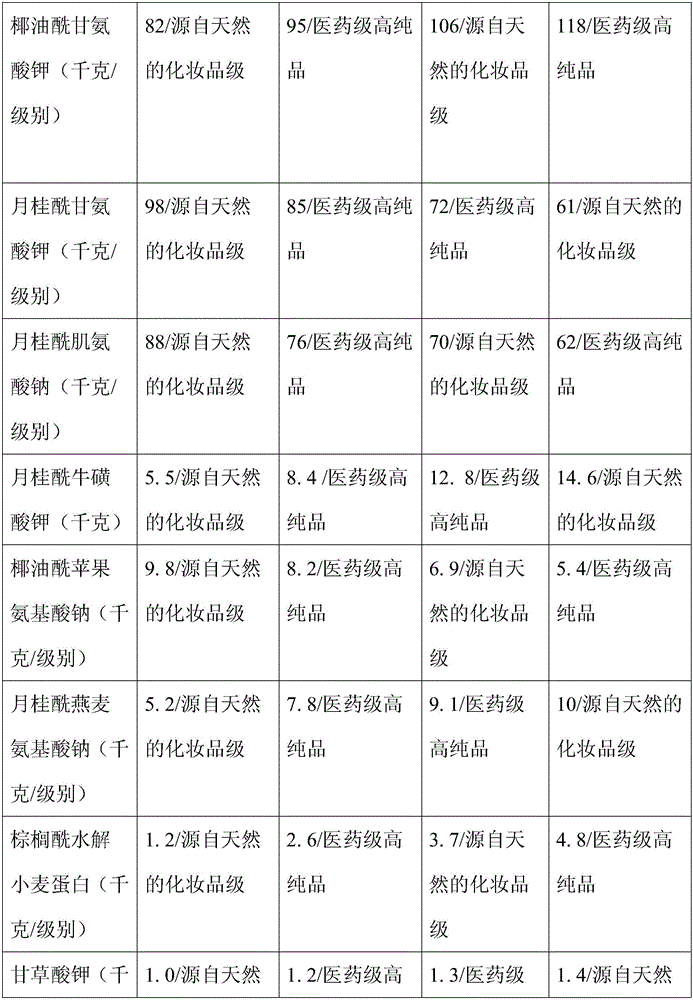

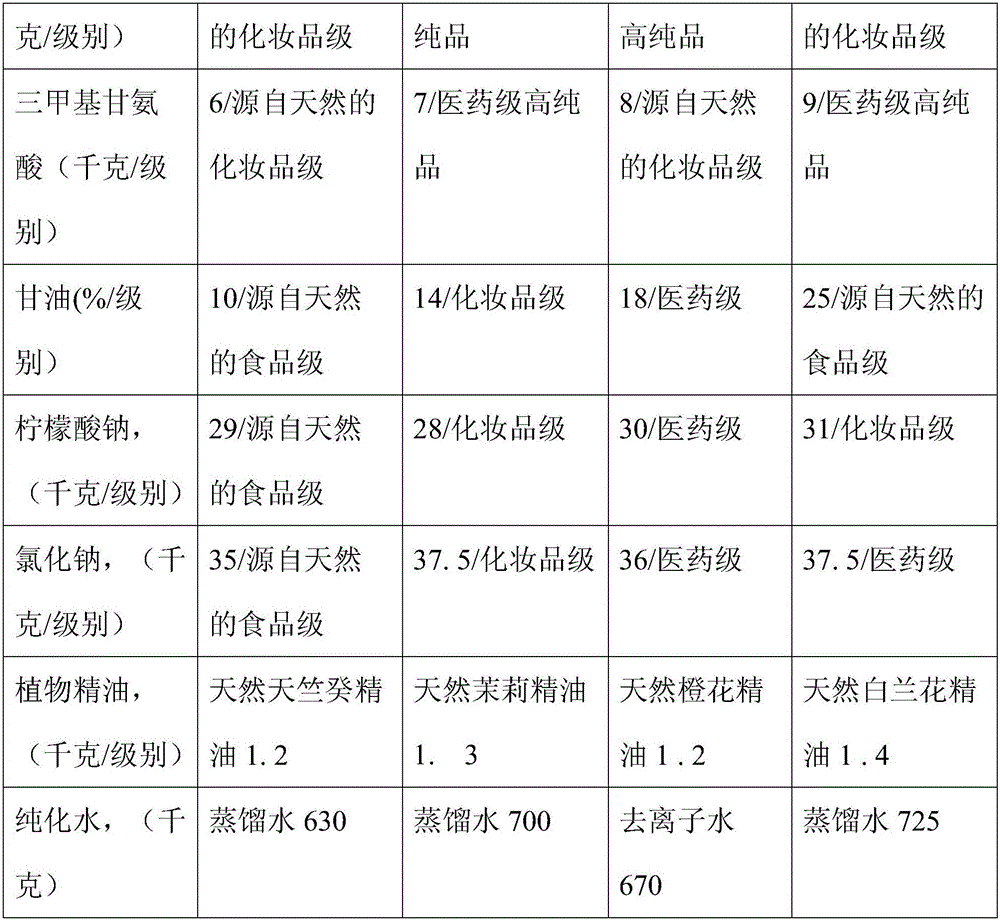

[0086] The feeding ratio is shown in Table 1.

[0087] Concrete preparation steps:

[0088] 1) Put 334.29 kilograms of distilled water into a 1000-liter enamel reaction pot, and mix 82 kilograms of commercially available natural cosmetic grade potassium cocoyl glycinate powder and natural cosmetic grade laurel within half an hour under stirring at 90 rpm Add 98 kg of potassium acylglycinate powder in 6 batches, stir for at least 1 hour, and make a 35% aqueous solution, and spray 15.42 kg of 0.1% edible-grade xanthan gum aqueous solution into the system within 10 minutes with a sprayer to make the edible-grade yellow gum in the system The concentration of raw gum reaches 30ppm. After stirring evenly, spray 5.14 kg of 0.5% soluble chitin aqueous solution into the system within 10 minutes to make the concentration of soluble chitin in the system reach 50ppm. Control the temperature at 40°C and mix and stir for at least 8 hours. Add 0.5% of the total material weight to the system...

Embodiment 3

[0094] The feeding ratio is shown in Table 1.

[0095] Concrete preparation steps:

[0096] 1) Put 334.29 kilograms of distilled water into a 1000-liter enamel reaction pot, and stir 95 kilograms of commercially available pharmaceutical-grade high-purity potassium cocoyl glycinate powder and 85 kilograms of pharmaceutical-grade high-purity potassium lauroyl glycinate powder within half an hour under stirring at 90 rpm Add in 6 batches, stir for at least 1 hour, and make a 35% aqueous solution. Spray 15.42 kg of 0.1% edible-grade xanthan gum aqueous solution into the system within 10 minutes with a sprayer, so that the concentration of edible-grade xanthan gum in the system reaches 30ppm. After stirring evenly, use a sprayer to spray 5.14 kg of 0.5% soluble chitin aqueous solution within 10 minutes, so that the concentration of soluble chitin in the system reaches 50ppm, control the temperature at 40°C and mix and stir for at least 8 hours, then add a total material weight of 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com