Pipeline plugging device

A technology for sealing devices and pipelines, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problems of decreased sealing effect of pipelines, decreased sealing performance of rubber rings and pipelines, weakened elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

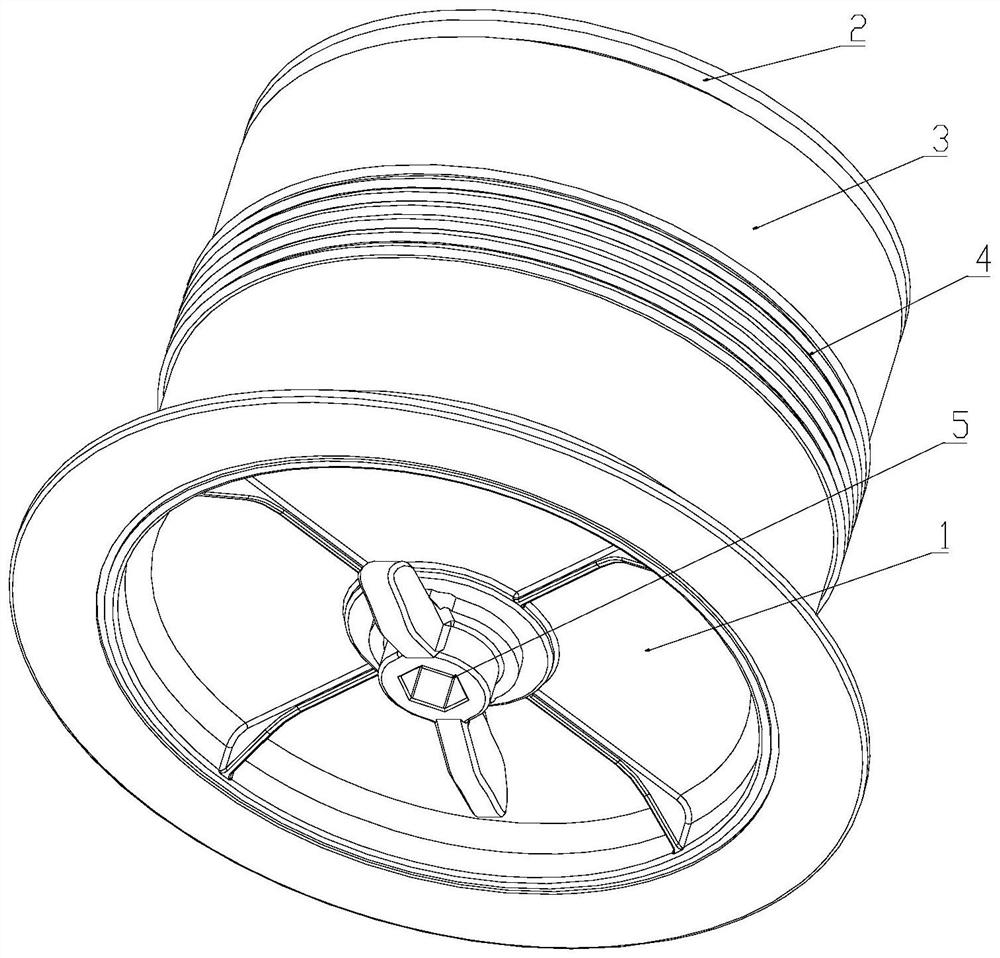

[0018] like figure 1 , figure 2 , image 3 As shown, the present invention discloses a pipe blocking device including an upper platen 1, a lower pressure plate 2, and a sealed rubber sleeve 3, and both ends of the sealing rubber sleeve 3 are connected between the upper press plate 1, the lower pressure plate 2, respectively. Four guiding columns 14 are provided between the upper platen 1 and the lower pressure plate 2, and there is a circular slider 10 on the guide column 14, and one through hole 6 is provided at the center of the upper platen 1, in the through hole 6. A rotating shaft 5 is provided in which a jam 7 is provided on the upper press plate 1 at the through hole 6, and a ring card slot 8 is provided on the rotating shaft 5 at correspond to the ree spring 7, the jam 7 card Inside the annular card groove 8, an external thread 9 is provided on the rotating shaft 5 below the annular card groove 8, and a threaded hole is provided on the circular slider 10 corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com