Platemaking method of octagonal cap

An octagonal and cap-top technology, which is applied in the field of clothing and hats, can solve the problems of unsightly finished products, inconsistent head shapes, and insufficient combination of hat walls and hat mouth strips, etc., to achieve the effect of comfortable wearing, beautiful appearance and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

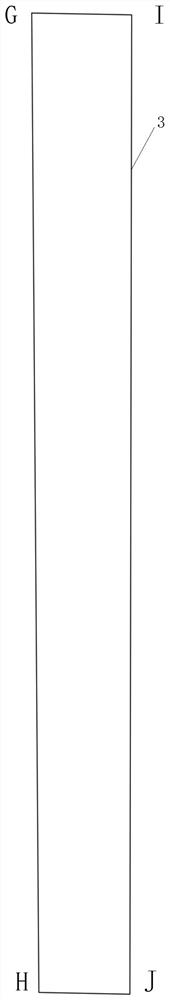

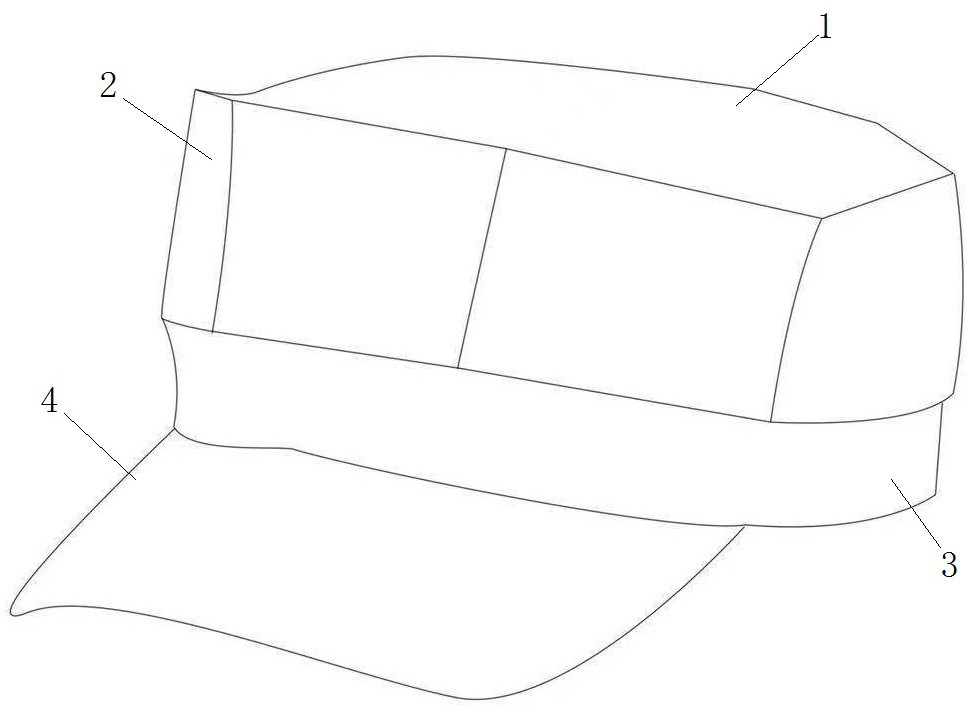

[0025] as attached Figure 1-3 Shown, the plate-making method of octagonal cap of the present invention, described octagonal cap comprises cap top 1, the hat wall 2 that is arranged on cap top 1 bottom and the hat mouth strip 3 that is arranged on hat wall 2 bottoms, in described hat mouth strip 3 The bottom is provided with a hat brim 4; the hat top 1, the hat wall 2 and the hat mouth strip 3 adopt the following steps for plate making:

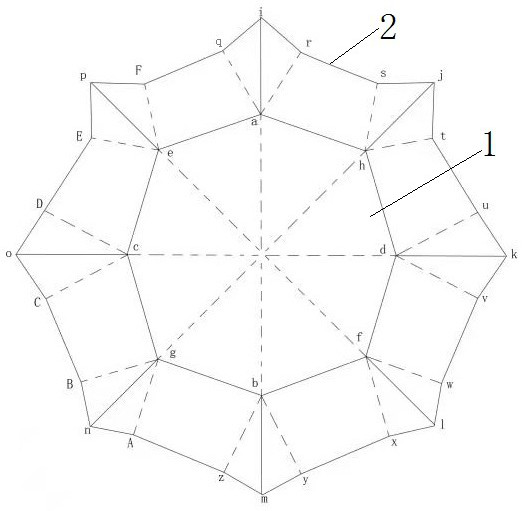

[0026] Step 1, plate making of cap top 1: make a horizontal line segment cd, and make a vertical line ab through the midpoint of cd, cd and ab are bisected each other, the length of the ab line is 22.5 to 23.5, and the length of the cd line is 22.5 to 23.5 ;

[0027] Make the angle bisectors ef and gh of the ab and cd lines, the lengths of the ef line and the gh line are both 23.5 to 24.5; the straight lines connect ah, hd, df, fb, bg, gc, ce and ea in sequence , Then ahdfbgce is the top of the hat;

[0028] Step 2. Plate making of hat wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com