A kind of whisker fiber material and its preparation and application

A fiber material and whisker technology, which is applied in the field of novel whisker fiber material and its preparation, achieves the effects of simple preparation method, low equipment requirements and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Directly select pure magnesium rolling materials with magnesium content ≥ 99.9%, and process them into several rods with a diameter of 10mm*20mm by wire cutting. After polishing with sandpaper, remove the oxide layer during cutting, put them into glass bottles, and then Put a certain amount of absolute ethanol to submerge it. Then carry out ultrasonic cleaning, the time is about 15 minutes each time, until it is cleaned. After taking it out and drying it, put it in a clean bottle for later use.

[0030] The chemical composition of the prepared solution: 2 grams of Na 3 PO 4 , 0.3g KCl, 0.25KH 2 PO 4 , 10 grams of NaCl, add 500 mL of distilled water to prepare 500 mL of corrosion degradation solution, and put it into a clean bottle for later use.

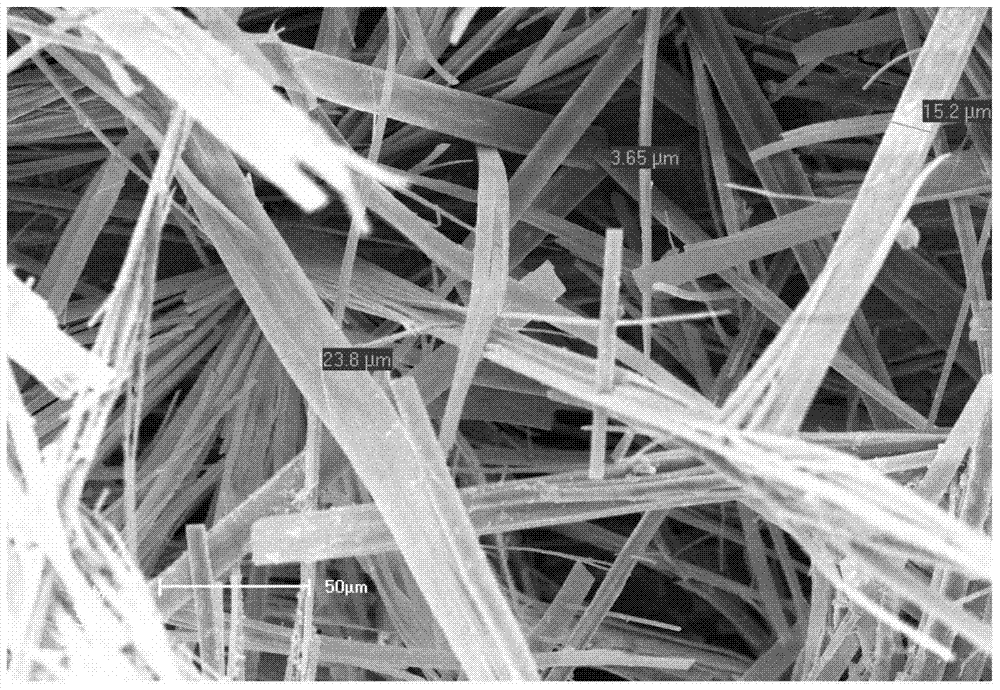

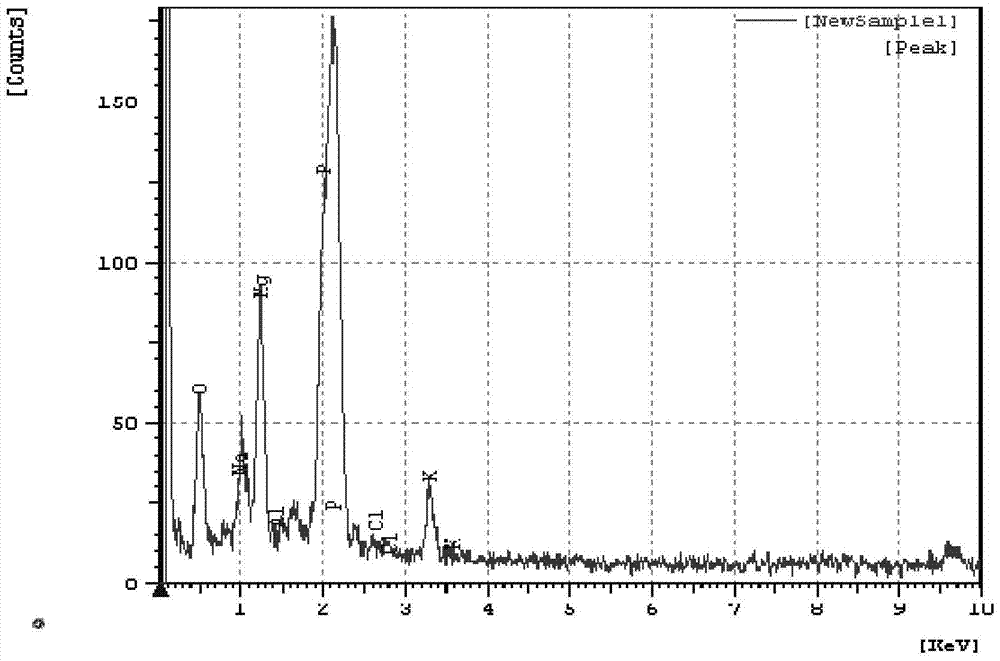

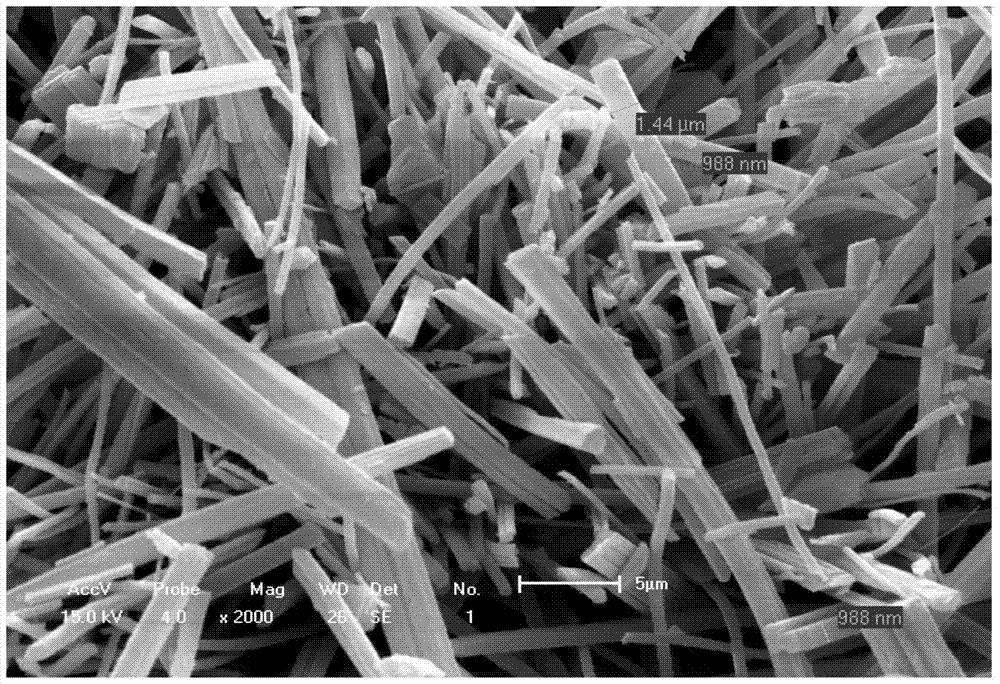

[0031] Put 5 prepared pure magnesium rods into 5 clean test tubes with a volume of 50mL, and then use a pipette to draw 35mL of the prepared solution, and drop them into the test tubes with magnesium rods respectively. P...

Embodiment 2

[0034] Directly select pure magnesium extruded materials with a magnesium content ≥ 99.9%, process them into several rods with a diameter of 10mm*20mm by wire cutting, polish them with sandpaper, remove the oxide layer during cutting, put them into glass bottles, and then Put a certain amount of absolute ethanol to submerge it. Then carry out ultrasonic cleaning, the time is about 15 minutes each time, until it is cleaned. After taking it out and drying it, put it in a clean bottle for later use.

[0035] The chemical composition of the prepared solution: 3 grams of Na 3 PO 4 , 0.6 g KH 2 PO 4 , 9 grams of NaCl, add 500 mL of distilled water to prepare 500 mL of corrosion degradation solution, and put it into a clean bottle for subsequent use.

[0036] Put 5 prepared pure magnesium rods into 5 clean test tubes with a volume of 50mL, and then use a pipette to draw 35mL of the prepared solution, and drop them into the test tubes with magnesium rods respectively. Put it in a ...

Embodiment 3

[0039] Directly select pure magnesium drawing wire materials with a magnesium content ≥ 99.9%, process them into several wires with a diameter of 1mm*10mm, polish them with sandpaper, remove the oxide layer during cutting, put them into a glass bottle, and then put them into a certain Immerse it with a certain amount of absolute ethanol. Then carry out ultrasonic cleaning, the time is about 15 minutes each time, until it is cleaned. After taking it out and drying it, put it in a clean bottle for later use.

[0040] The chemical composition of the prepared solution: 5 grams of Na 3 PO 4 , 8 grams of KCl, 0.15 grams of KH 2 PO 4 , add 200mL of distilled water to prepare 200mL of corrosion degradation solution, put it into a clean bottle for later use.

[0041] Put 5 prepared pure magnesium wires into 5 clean test tubes with a volume of 20mL respectively, then use a pipette to absorb 10mL of the prepared solution, drop them into the test tubes containing magnesium wires resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com