Conveying object distribution device, pneumatic sending system, and sample container sending method

A distribution device and object technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problem that the structure cannot complete the corresponding transportation, etc., and achieve the effect of fast data acquisition efficiency, high accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

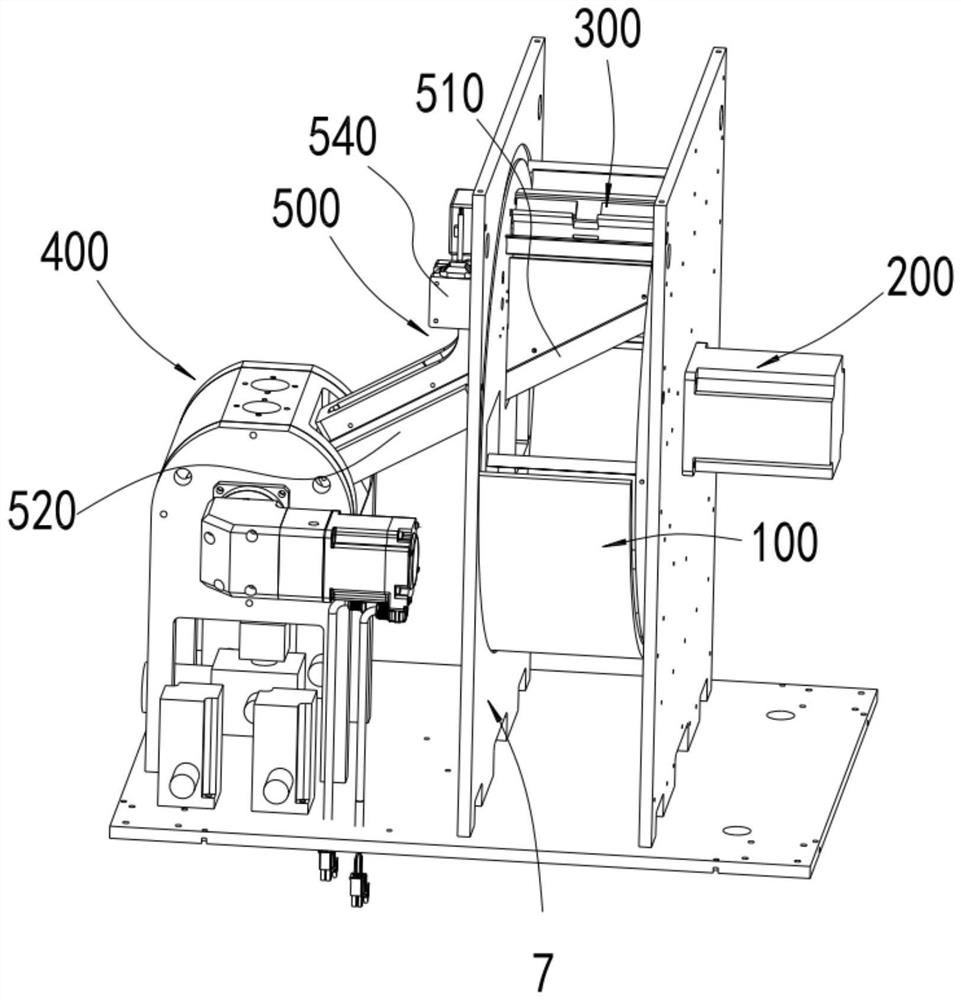

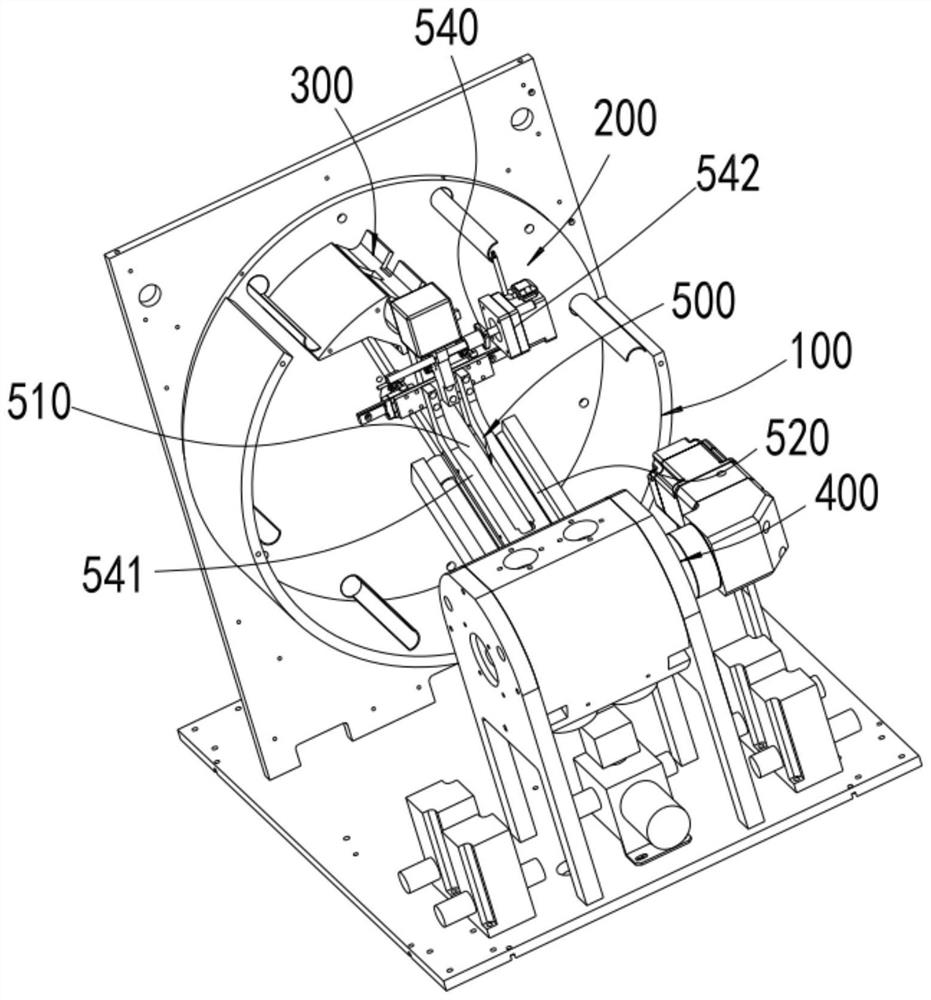

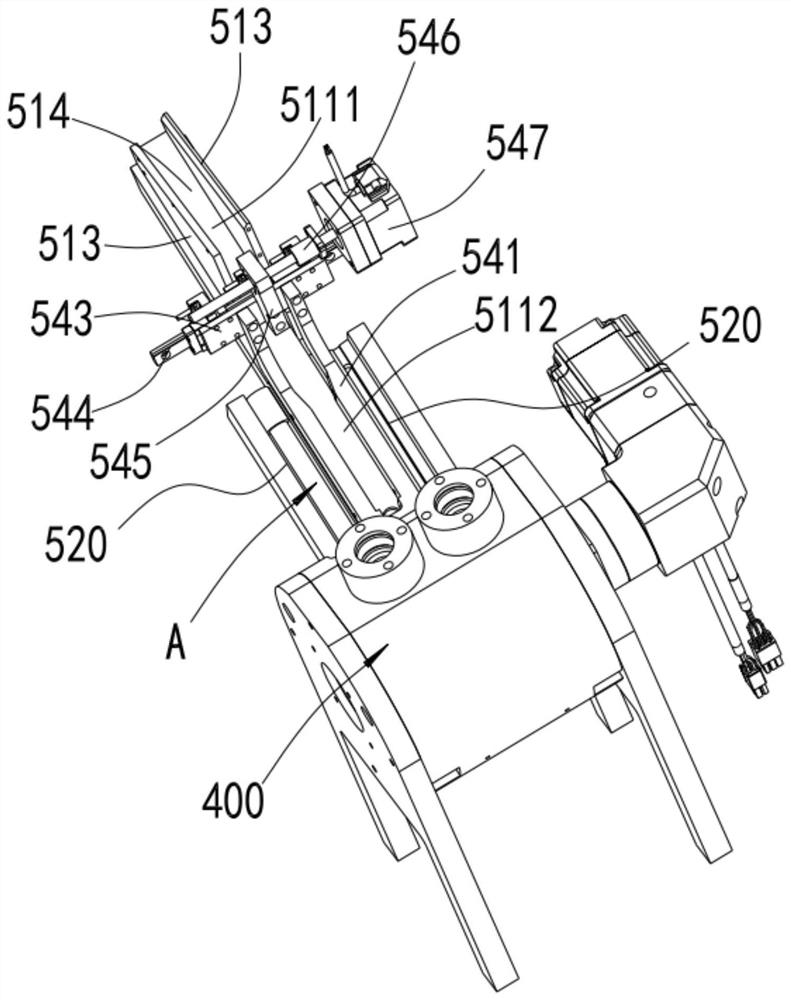

[0088] The difference between this embodiment and embodiment 1 is: as attached image 3 As shown, in this embodiment, the silo 100, the feeding part 200, the buffer storage part 300, etc. in the above-mentioned embodiment 1 are all omitted, and only at least two sending components and the distribution mechanism 500 are provided. At this time, The conveying objects can be directly placed on the unloading chute. At the same time, only one sensor can be set at the unloading chute in the distribution mechanism 500 to determine whether there is a conveying object in the lower section of the unloading chute. During work, no distinction can be made. The length of the object to be conveyed, but by forming two conveying channels to speed up the sending beat of the entire device, so as to improve the sending efficiency.

[0089] Of course, a more optimal structure is a structure that combines the length recognition and direction recognition in the first embodiment above.

Embodiment 3

[0091] This embodiment further discloses a pneumatic sending system, which is used to send various tubular or columnar or bottle-shaped items, preferably for delivery of blood collection tubes, as attached Figure 9 As shown, it includes the delivery object allocation device of the above embodiment or the structure disclosed by the application number 202021337054.4 with only one sending component 400 .

[0092] Here, one sending assembly 400 is taken as an example for illustration. One connection port of the sending assembly 400 is connected to the output pipeline 600, and the other connecting port is connected to the air supply pipeline 700, and the air supply pipeline 700 is used to supply the air to the sending assembly. The sending channel 411 of the sending rotary block 410 of 400 transports gas, so that the delivery object in the sending channel 411 enters the output pipe 600 under the action of air flow and is transported to the corresponding position.

[0093] Among th...

Embodiment 4

[0112] This embodiment further discloses a method for sending blood collection tubes using the above-mentioned pneumatic sending system, which includes the following steps:

[0113] S1, make the blood collection tubes of different lengths enter the feeding chute, determine the length of the blood collection tubes in the feeding chute through the sensor and send it to the control system; when there are only distribution mechanisms and sending components, directly put the blood collection tubes into the On the unloading chute. When there is a silo 100, a feeding part 200 and a buffer storage part 300, the blood collection tube is put into the inlet of the shell, and after the blood collection tube enters the feed bin 100, it is transported by the feeding part 200 and the buffer storage part 300. In the unloading chute.

[0114] S2, the blood collection tube that enters the unloading chute slides to its lower section along the slope and is restricted on the slope by the limit pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com