Sustainable ultrasonic anti-reflection equipment and process for low-permeability coal body

An ultrasonic and gas permeability technology, applied in mining equipment, mining fluid, gas discharge, etc., can solve the problems of reduced drainage effect and easy re-closing of coal cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

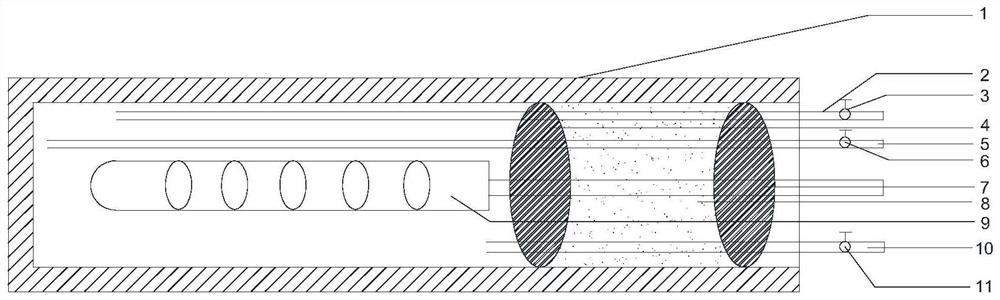

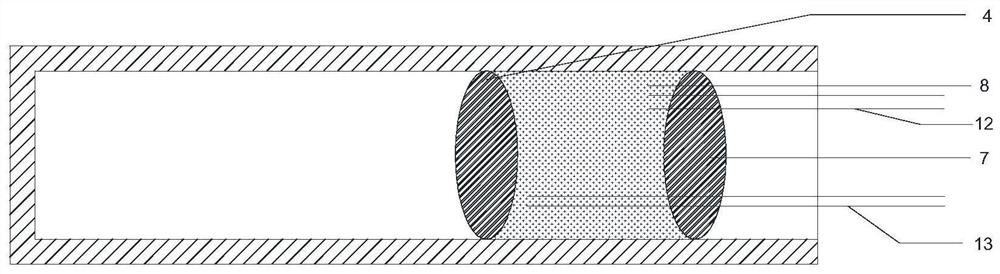

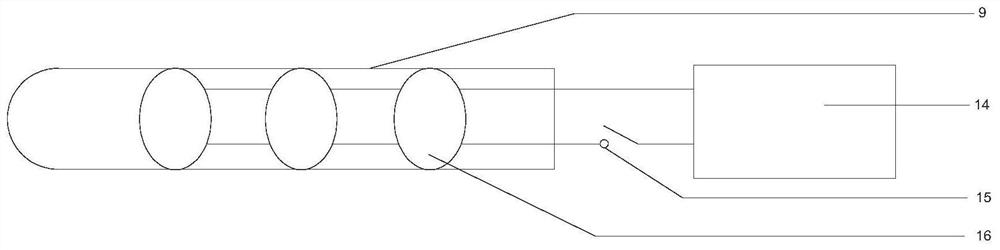

[0020] Embodiment 1, with reference to Figure 1-3 , a sustainable ultrasonic anti-reflection equipment for low-permeability coal, including an ultrasonic anti-reflection mechanism, the ultrasonic anti-reflection mechanism includes an ultrasonic generator 14, an ultrasonic transducer 16, an ultrasonic wave deriving rod 9 and a circuit switch 15, the The ultrasonic generator 14, the ultrasonic transducer 16, the ultrasonic wave deriving rod 9 and the circuit switch 15 are connected by wires to form a series circuit.

[0021] A process for sustainable ultrasonic anti-reflection equipment for low-permeability coal, comprising the following steps:

[0022] The first part is to be drilled to place the pipeline, drill hole 1 according to the requirements of the construction aperture, use the water injection pipe to flush the drill cuttings inside the drill hole 1, put in the drain pipe 10, ultrasonic wave export rod 9, water injection pipe 5 and gas drainage in sequence Pipe 2, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com