Paper pulp softening device for household paper processing

A technology for household paper and pulp, applied in the process of adding pulp raw materials, papermaking, textiles and papermaking, etc., can solve the problems of insufficient contact, large softener, and inability of pulp to flow out under natural conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

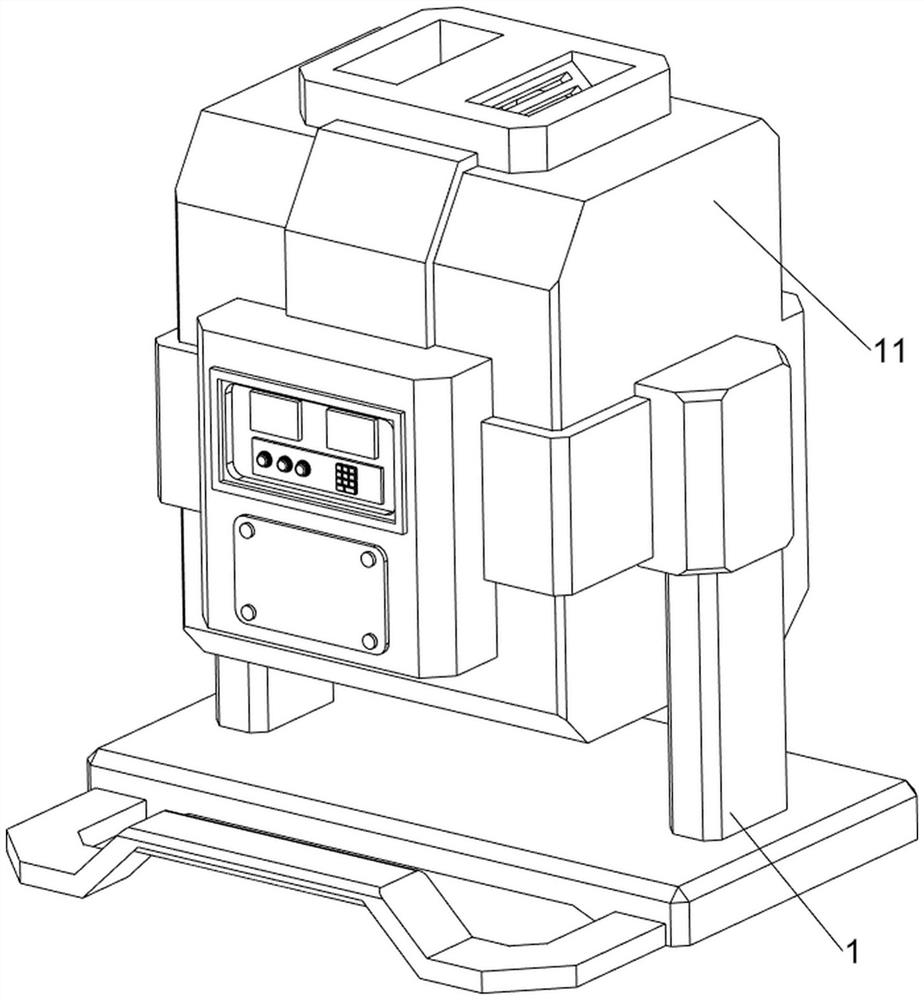

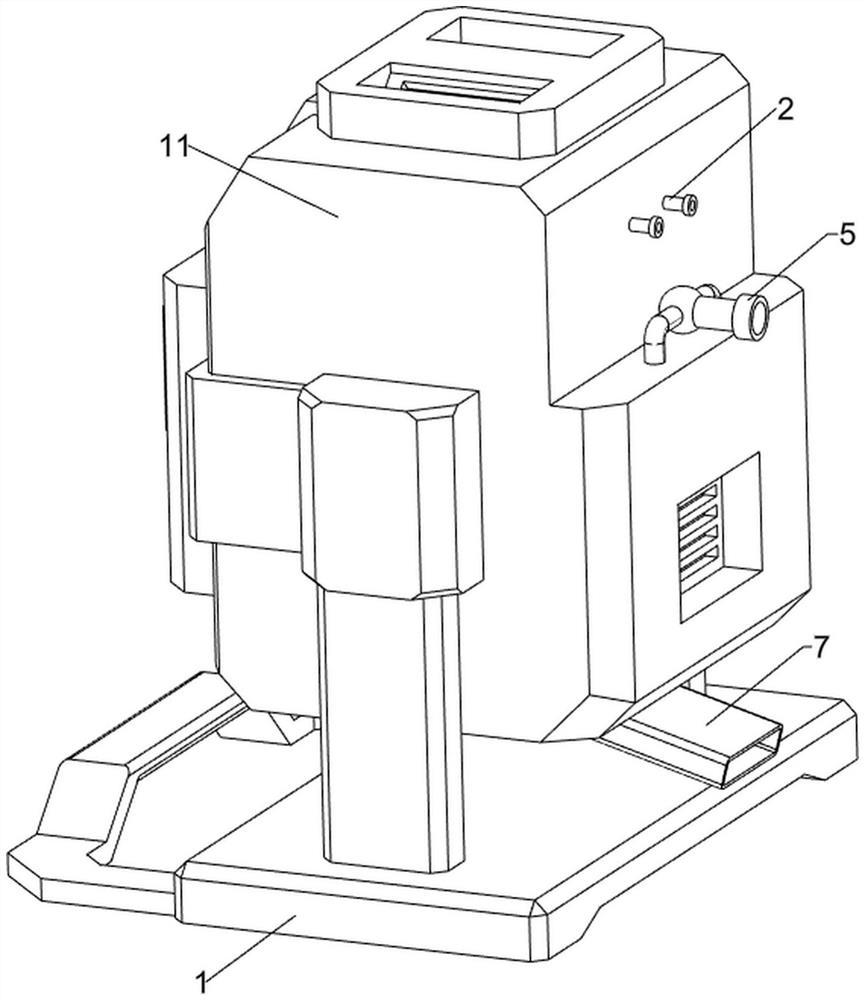

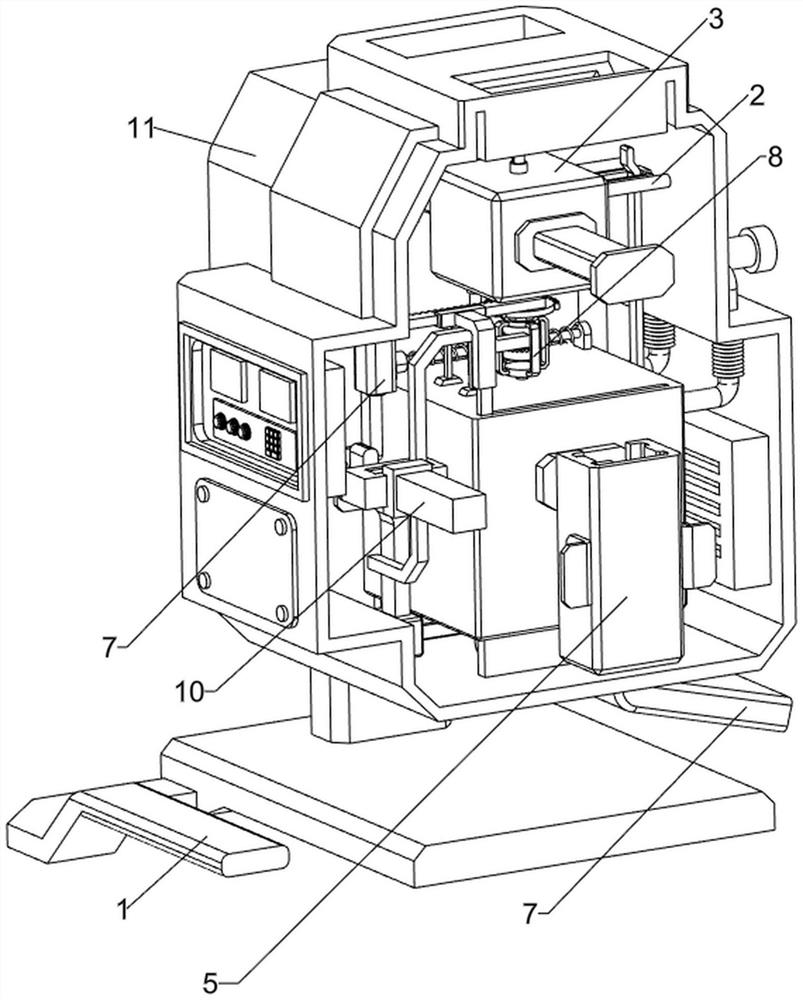

[0036] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a pulp softening device for tissue paper processing, including a support frame 1, a housing 11, a first feeding pipe 2, a mixing box 3, a mixing assembly 4, a charging assembly 5 and Feeding assembly 6, the inner side of the upper part of the support frame 1 is connected with a shell 11, the upper rear side of the upper part of the shell 11 is symmetrically connected with the first feeding pipe 2, the upper side of the inner shell 11 is connected with the mixing box 3, and the upper rear side of the mixing box 3 Connected with the first feed pipe 2, a mixing assembly 4 is provided between the inner upper side of the casing 11 and the mixing box 3, and a charging assembly 5 is provided on the casing 11, and the bottom of the mixing box 3 and the charging assembly 5 A feed assembly 6 is provided between them.

[0037] The mixing assembly 4 includes a motor 401, a fixed sleeve 402, a first stirring rod 403 ...

Embodiment 2

[0042] Such as figure 2 , image 3 , Figure 8 ~ Figure 17 As shown, in some embodiments, a discharge assembly 7 is also included, and the discharge assembly 7 includes an electric push rod 701, a first guide rod 702, a first baffle 703, a second spring 704, and a discharge square tube 705 , the first contact rod 706 and the push rod 707, the upper front side of the housing 11 is equipped with an electric push rod 701, the lower side of the electric push rod 701 telescopic rod is connected with the push rod 707, and the left and right sides of the bottom front side of the pulp material box 504 are symmetrically connected with the first A guide rod 702, a first baffle plate 703 is slidably connected between the first guide rod 702, a second spring 704 is connected symmetrically between the first baffle plate 703 and the pulp material box 504, and the second spring 704 covers the second spring 704. On a guide rod 702, the discharge square pipe 705 is connected to the lower re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com