Hydraulic extrusion type activated carbon granulator

An extruded, activated carbon technology, applied in the direction of extrusion granulation of raw materials, mixers, dryers, etc., can solve the problems of affecting scraping, not easy to fall and collect, affecting the operation of granulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

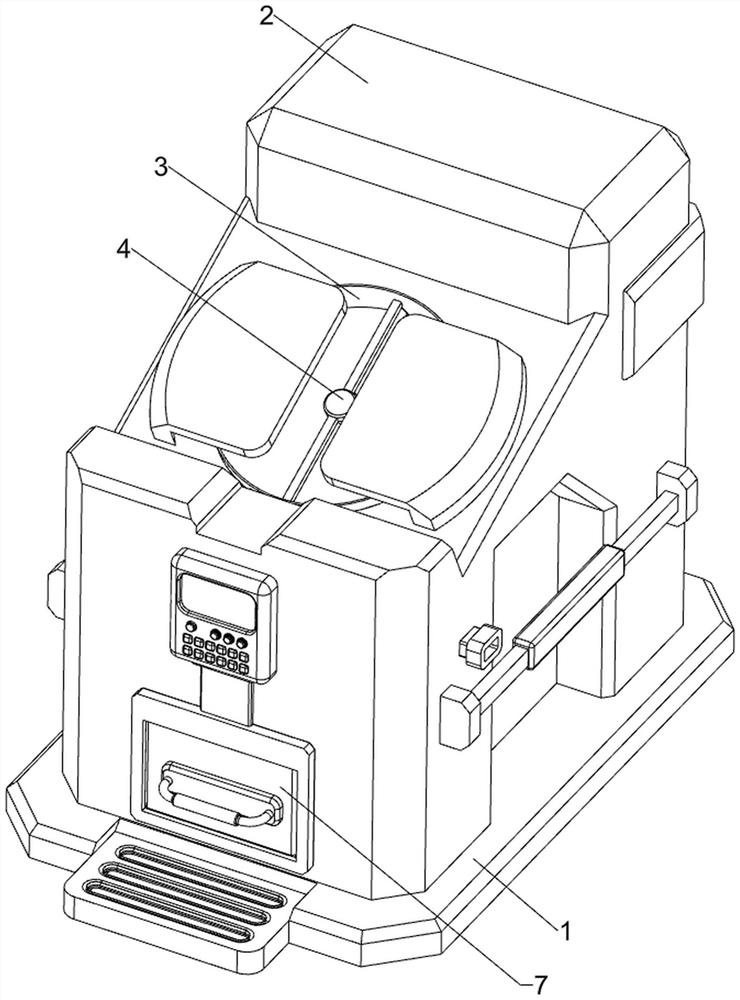

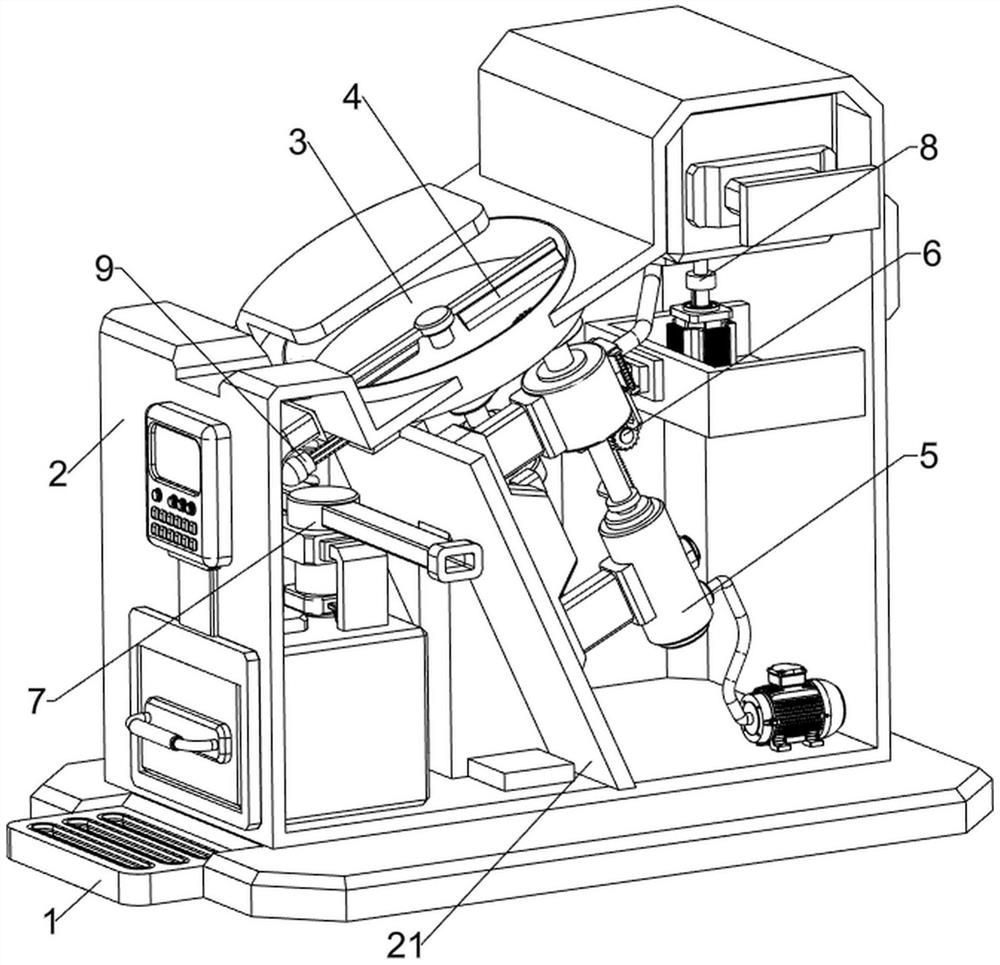

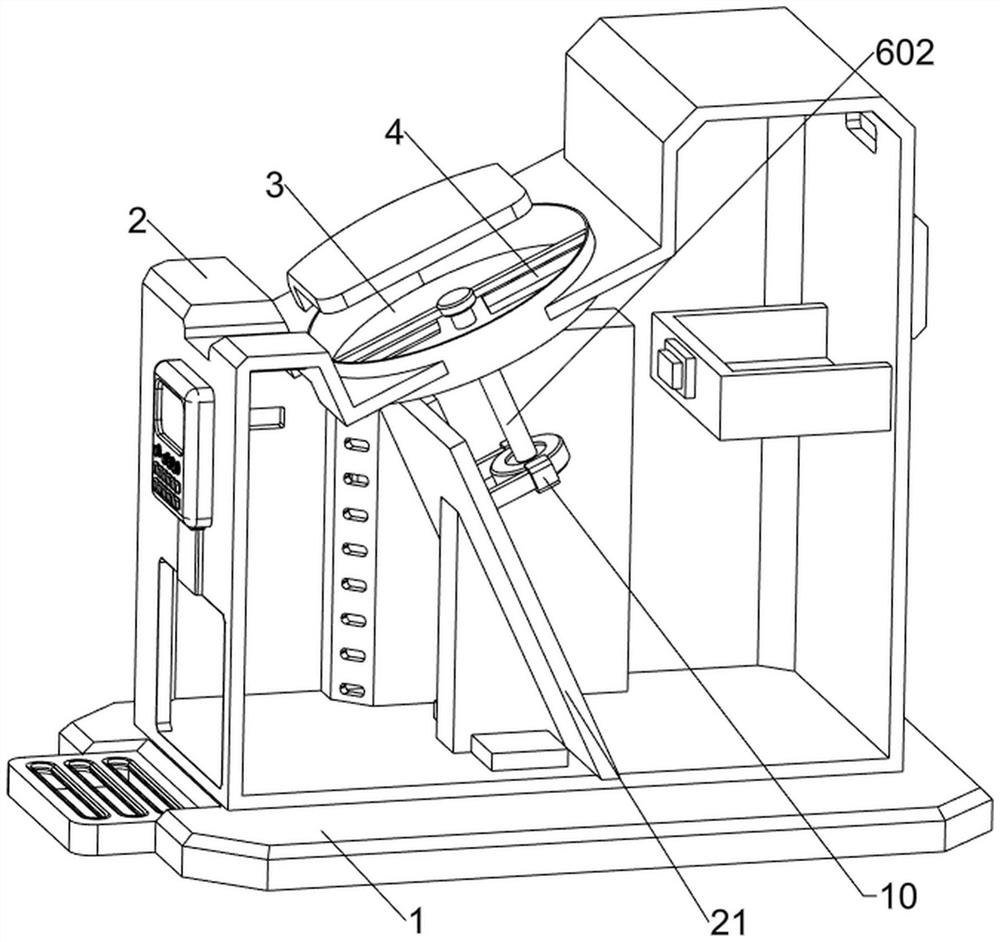

[0034] like Figure 1 to Figure 9 As shown, this embodiment discloses a hydraulic extrusion type activated carbon granulator, including a base 1, a shell 2, a support plate 21, a granulation disc 3, a scraper 4, a discharge assembly 5 and a rotating assembly 6, and the upper part of the base 1 The shell 2 is connected, and the inner lower side of the shell 2 is connected with the support plate 21 in the middle, and the upper part of the shell 2 is connected with the granulation disc 3 in the middle. There is an opening, and a discharge assembly 5 is provided between the inner lower rear side of the shell 2, the support plate 21 and the granulation disk 3, and a rotating assembly is provided between the middle part of the granulation disk 3, the inner rear side of the casing 2, and the discharge assembly 5. 6. The rotating assembly 6 is provided with a scraper 4 .

[0035]The discharge assembly 5 includes a first support frame 501, a water pump 502, a hydraulic press 503, a wa...

Embodiment 2

[0039] Such as Figure 1 ~ Figure 3 , Figure 10 ~ Figure 15 As shown, in some embodiments, a drying assembly 7 is also included, and the drying assembly 7 includes a drop pipe 701, a drying box 702, a charging box 703, a fourth support frame 704, an air inlet pipe 705, a heating pipe 706 and A fan 707, a drying box 702 is connected to the front side of the lower part of the casing 2, a blanking pipe 701 is connected between the rear side of the upper part of the drying box 702 and the granulation tray 3, a charging box 703 is placed inside the drying box 702, and the top of the drying box 702 The rear side is connected with a fourth support frame 704, and the left and right sides of the upper part of the fourth support frame 704 are connected with an air inlet pipe 705, and the outside of the air inlet pipe 705 is connected with the shell 2, and the upper part of the fourth support frame 704 is connected with a heating tube in the middle. The pipe 706 is connected to the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com