Magnet fixing support, lens driving device, photographing device and electronic equipment

A technology for fixing brackets and magnets, applied in the field of motors, can solve problems such as glue leakage, material waste, and unstable connection of mosaic structures, and achieve the effect of maintaining cleanliness and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

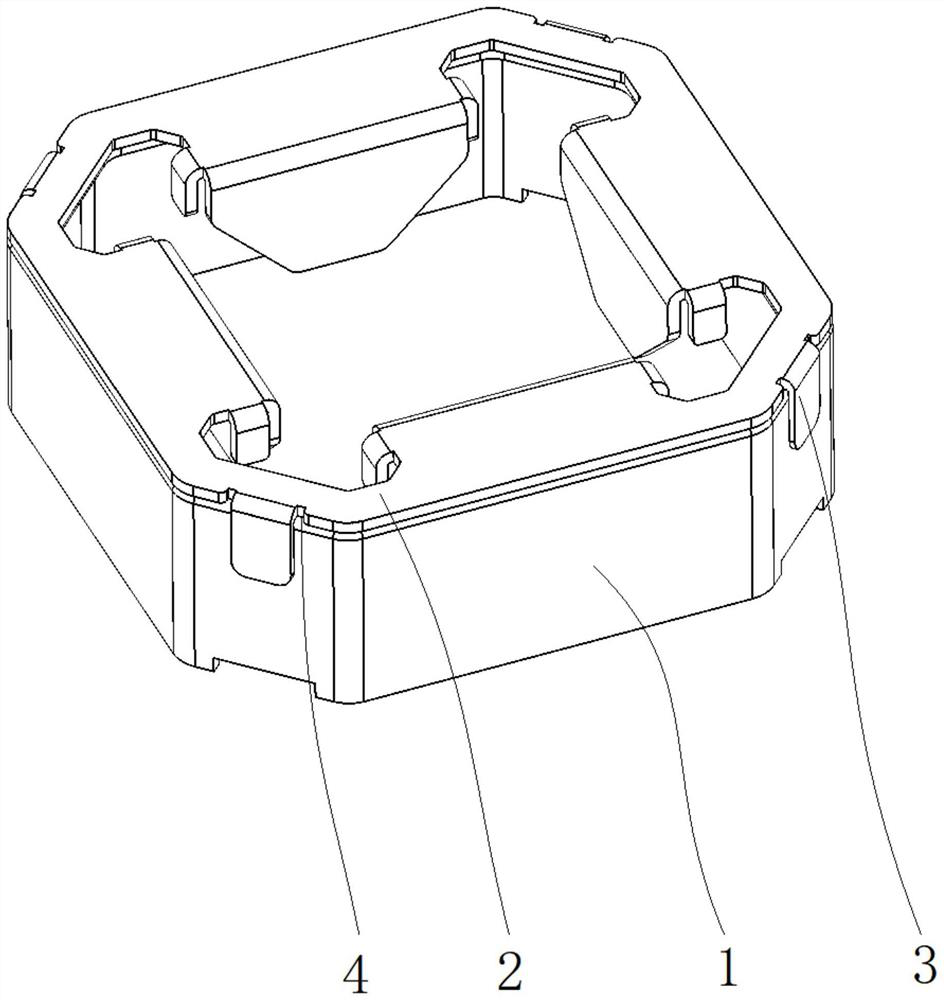

[0029] A magnet fixing bracket includes a yoke ring 1, a fixing bracket 2, connecting blades 3 and a glue dispensing groove 4.

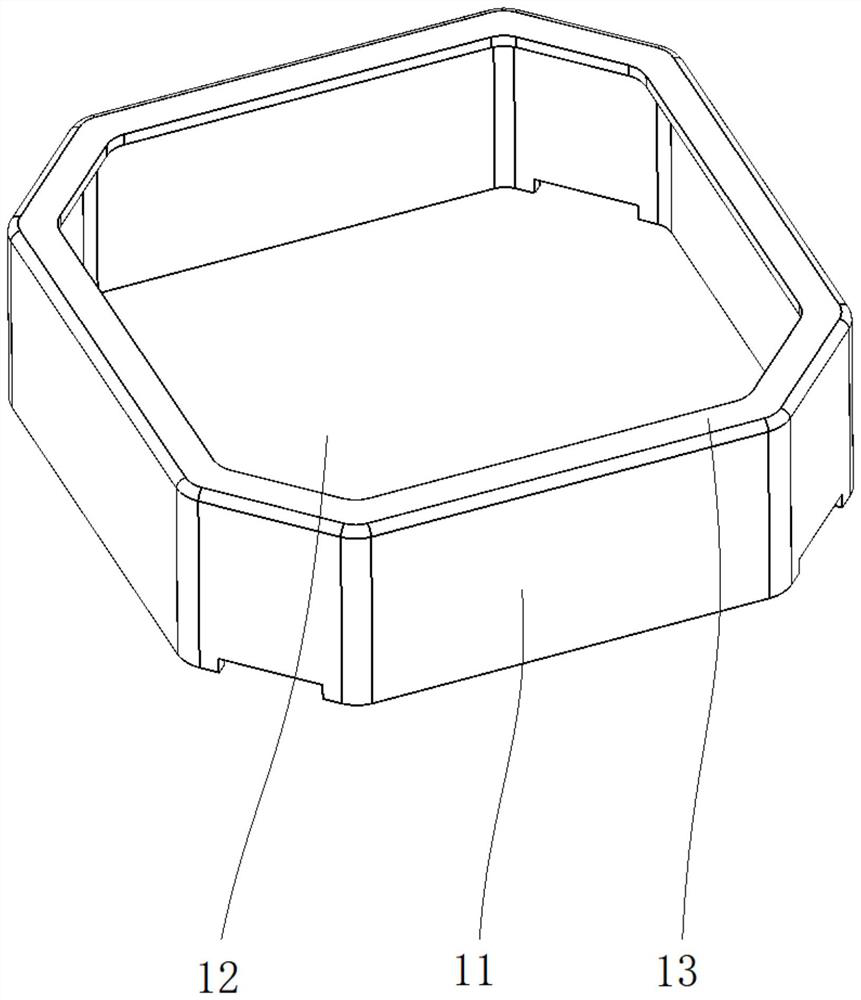

[0030] The yoke ring 1 includes a polygonal main body 11, a hollow structure 12 is provided inside the polygonal main body 11, and an inwardly extending limiting edge 13 is provided on the top of the polygonal main body 11, and the polygonal main body 11 and the limiting edge 13 constitute Outer magnet mounting slot.

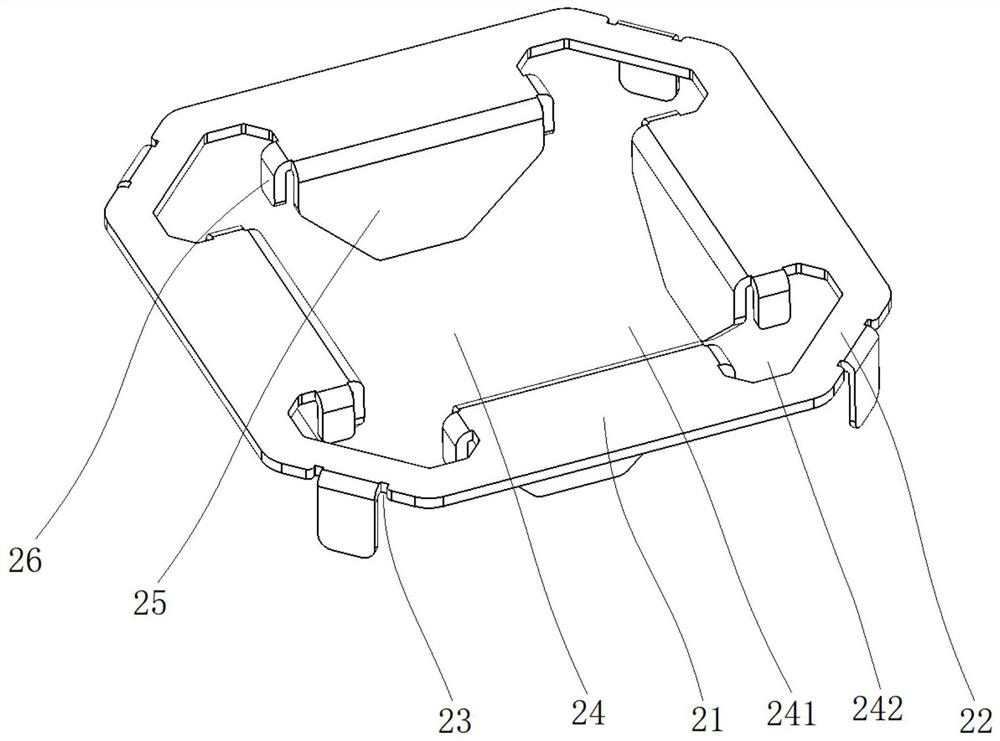

[0031] The main body of the fixed bracket 2 is a square plate 21, the four corners of the square plate 21 are provided with corner cutting structures 22, and the middle position of the fixed bracket 2 is provided with a through hole 24, and the through hole 24 includes a large hole in the middle. hole 241 , and the small through hole 242 arranged at the corner of the large through hole 241 . The edge of the large through hole 241 is provided with a limiting plate 25 extending downward, and a baffle plate 26 extending downward is provi...

Embodiment 2

[0036] A lens driving device has the magnet fixing bracket as described in Embodiment 1. In this implementation, other structures of the lens driving device are the same as those of the prior art, so no detailed description is given here.

Embodiment 3

[0038] A photographic device having the lens driving device as described in Embodiment 2. In this embodiment, other structures of the camera device are the same as those of the prior art, so no detailed description is given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com