Vehicle door lock fastening bolt and vehicle

A technology for fastening bolts and bolts, which is applied in the direction of locking fasteners, bolts, threaded fasteners, etc., and can solve the problem of small, theoretically safe distance between the bolt head and the lock pin bottom plate 61, and large gap between actual vehicles and other issues to achieve the effect of increasing the safety gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The application will be described in detail below in conjunction with the accompanying drawings.

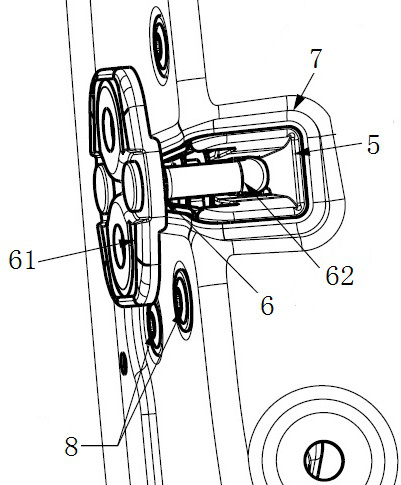

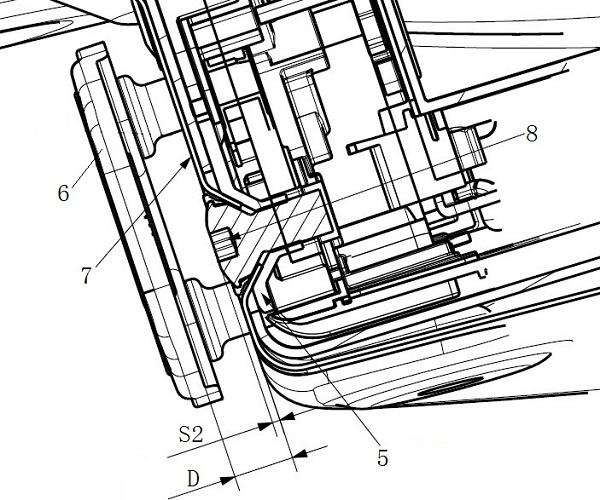

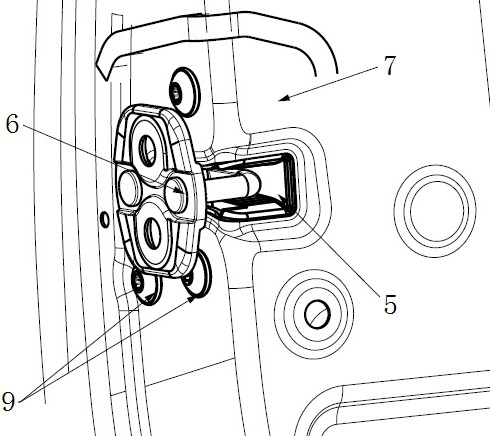

[0028] see Figure 5 to Figure 7 , the car door lock fastening bolt shown includes an integrally formed bolt head 1 and a screw rod 2, the screw rod 2 is provided with a threaded section 3, the bolt head 1 is provided with a through hole 11 penetrating in the axial direction, the A groove 21 is provided at the position corresponding to the end of the screw 2 and the through hole 11, and the opening of the groove 21 communicates with the through hole 11, and the through hole 11 and the groove 21 together form a fastening groove that is compatible with the fastening tool . Furthermore, the height dimension of the bolt head 1 can be significantly reduced without reducing the tightening torque value that the bolt can bear, that is, the bolt head 1 is thinned, so that the height S1 of the bolt head 1 protruding from the surface of the door sheet metal 7 is equivalent to Compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com