Normal fault physical simulation test device and method for coal and gas outburst simulation test

A gas outburst, simulated test technology, applied in measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of unsatisfactory production methods and processes, inability to use sealed boxes, large size, etc. To achieve the effect of simple structure, easy implementation and high degree of similarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

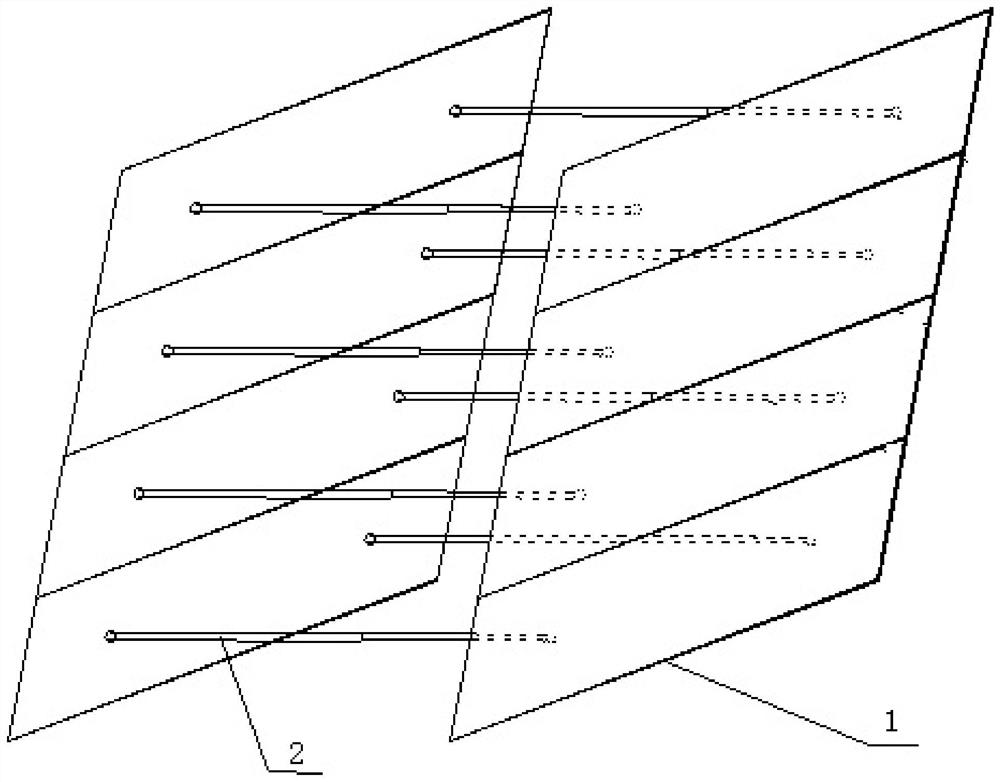

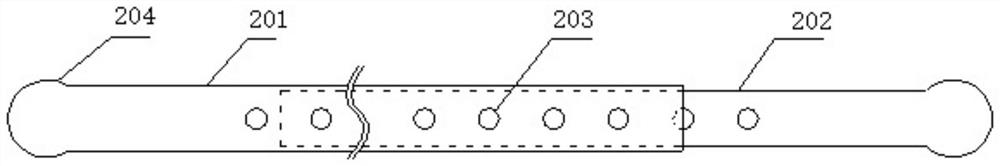

[0023] Such as Figure 1-6 As shown, a normal fault physical simulation test device for coal and gas outburst simulation test is composed of a telescopic baffle 1 and an adjustable cross brace 2 spliced together.

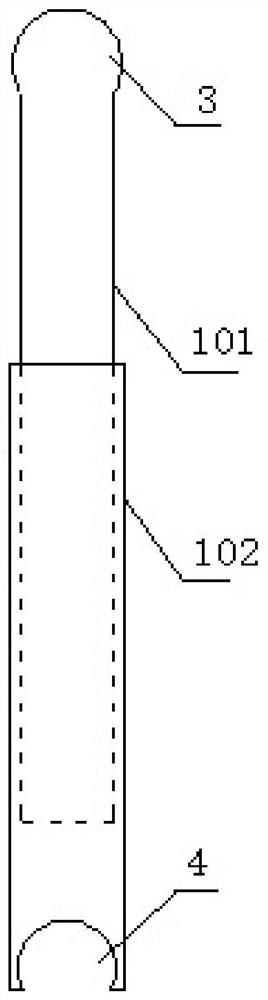

[0024] At least two telescopic baffles 1 are connected up and down to form a baffle, and the two baffles are symmetrically arranged opposite to each other, and the space between the two baffles forms a normal fault distance and drop.

[0025] The retractable baffle 1 includes an upper half baffle 101 and a lower half baffle 102, the upper half baffle 101 is plugged into the corresponding vertical slot on the lower half baffle 102, the upper and lower adjacent The two telescopic baffles 1 are connected by a foldable connection structure, and the foldable connection structure includes a spherical flange 3 and a ball-socket groove 4 respectively arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com