Non-frame spacing fully-mechanized hydraulic support and method for preventing roof leakage of inclined loose thick coal seam

A technology of hydraulic support and thick coal seam, which is applied to pillars/supports, earthwork drilling, mining equipment, etc., can solve problems such as gangue leakage, slippage, roof beam caving, etc., to save expenses, reduce equipment damage, increase The effect of high frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

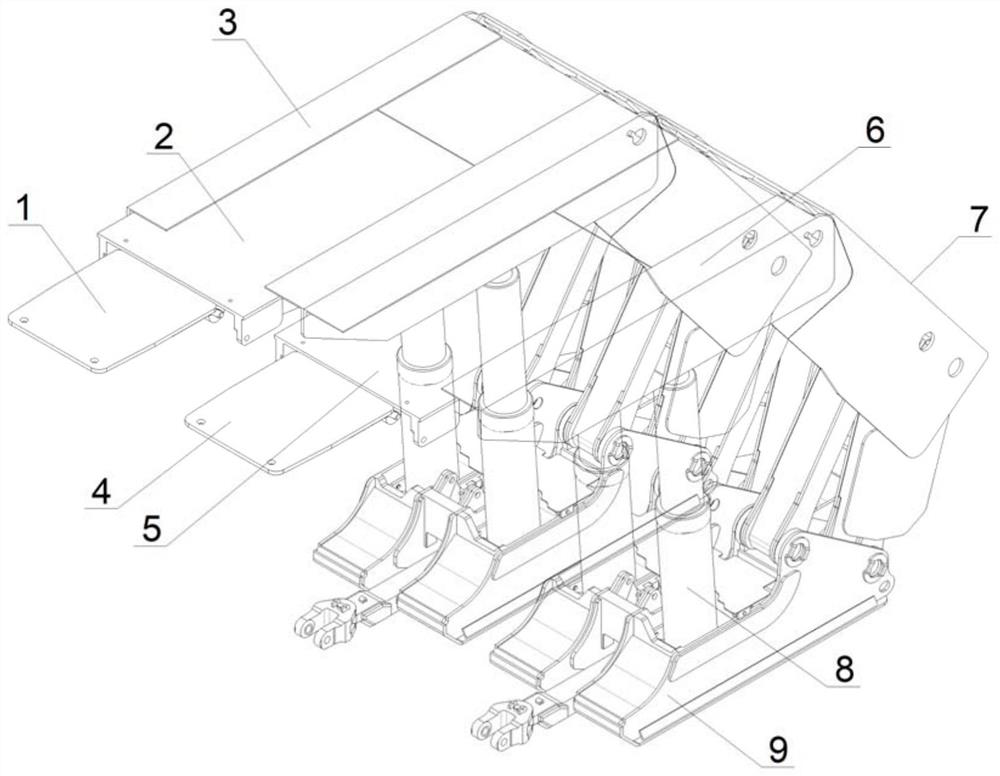

[0037] See attached figure 1, in the inclined loose thick coal seam working face, due to the inclination angle of the coal seam, the top beams 2, 5 and base 9 of the traditional hydraulic support cannot tightly support the coal seam roof and floor, so that the coal and gangue falling from the loose and broken coal seam roof can only be moved along the hydraulic pressure. The top beam of the support rolls down to the scraper conveyor at the rear, and often breaks and leaks in the gap between the front beam side panels 1 and 4 of two adjacent hydraulic supports and at the side of the top beam;

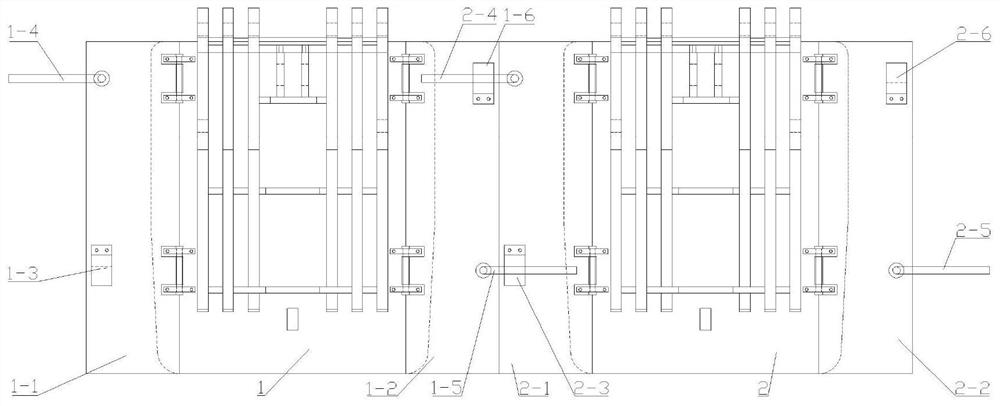

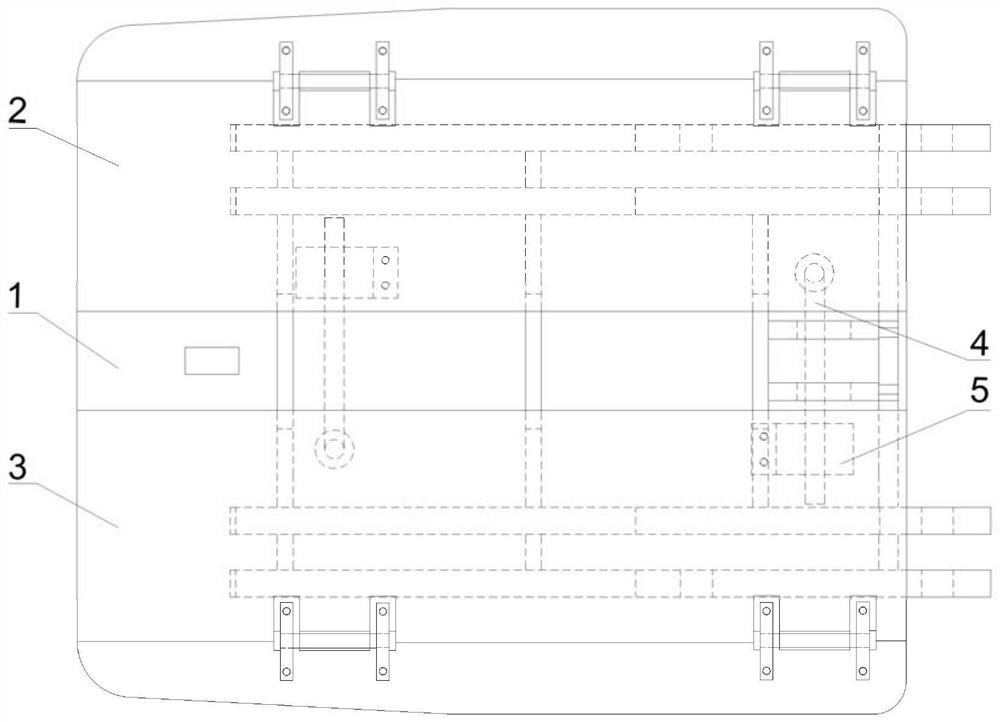

[0038] To solve the above problems, see the attached figure 1 And attached figure 2 , a pair of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com