Process for realizing automatic assembly of vehicle-mounted automobile parts

A technology for auto parts and processes, which is applied in the process of realizing automatic assembly of vehicle auto parts, can solve the problems of small operating space and difficulty in meeting market demands, and achieves high production efficiency, reliable and stable assembly and manufacturing system, and improved product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

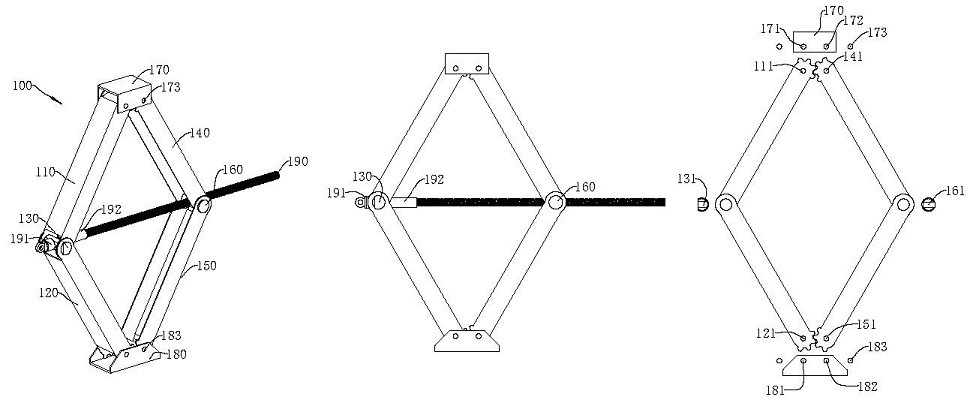

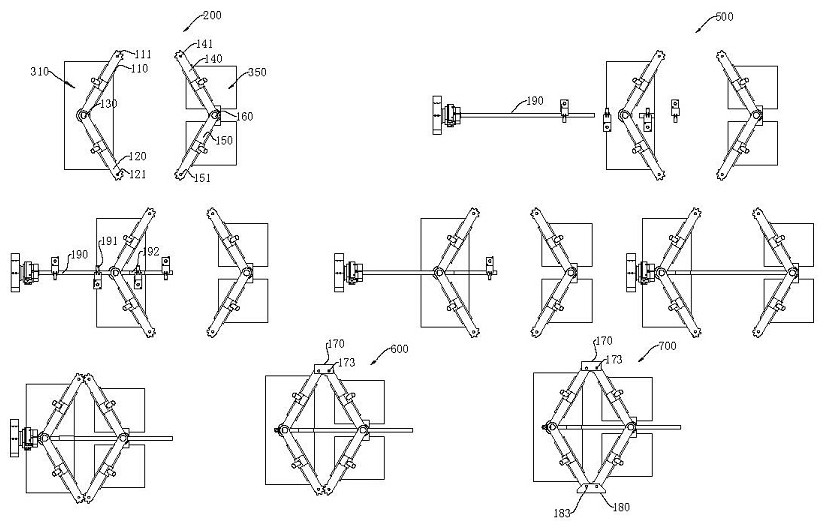

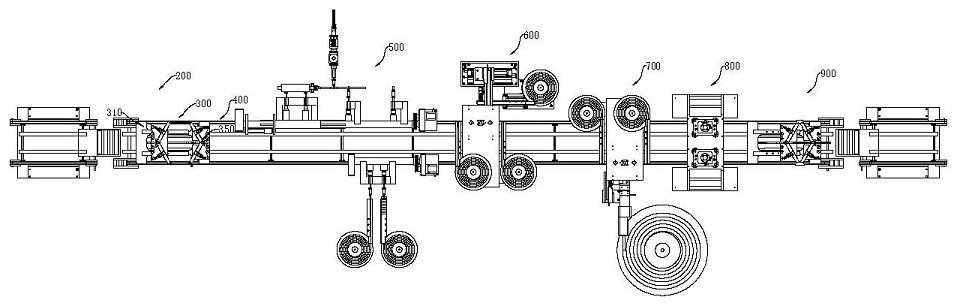

[0037] In order to make the objects and advantages of the present invention, the present invention will be specifically described below with reference to the embodiments. It should be understood that the following text is only used to describe one or more of the specific embodiments of the present invention, and the scope of the specifically requested protection of the present invention is not strictly limited.

[0038] The jack 100 is an important venture tool. At present, the product is mainly manually operated or semi-automated assembly operation. As the car's production is steadily improved, traditional production methods are difficult to meet the needs of the market. Currently, there are also some ways to automate assembly, but this mode is mainly to assemble structural parts into a complete support rack, and then assemble the screw that adjusts the jack 100 for top rolling. This assembly method, when there is an assembly screw, operation Space small defects, therefore it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com