Fan cleaning system, range hood and control method of fan cleaning system

A technology of cleaning system and control method, which is applied in the control of fan cleaning system, range hood, and fan cleaning system, and can solve problems such as poor cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

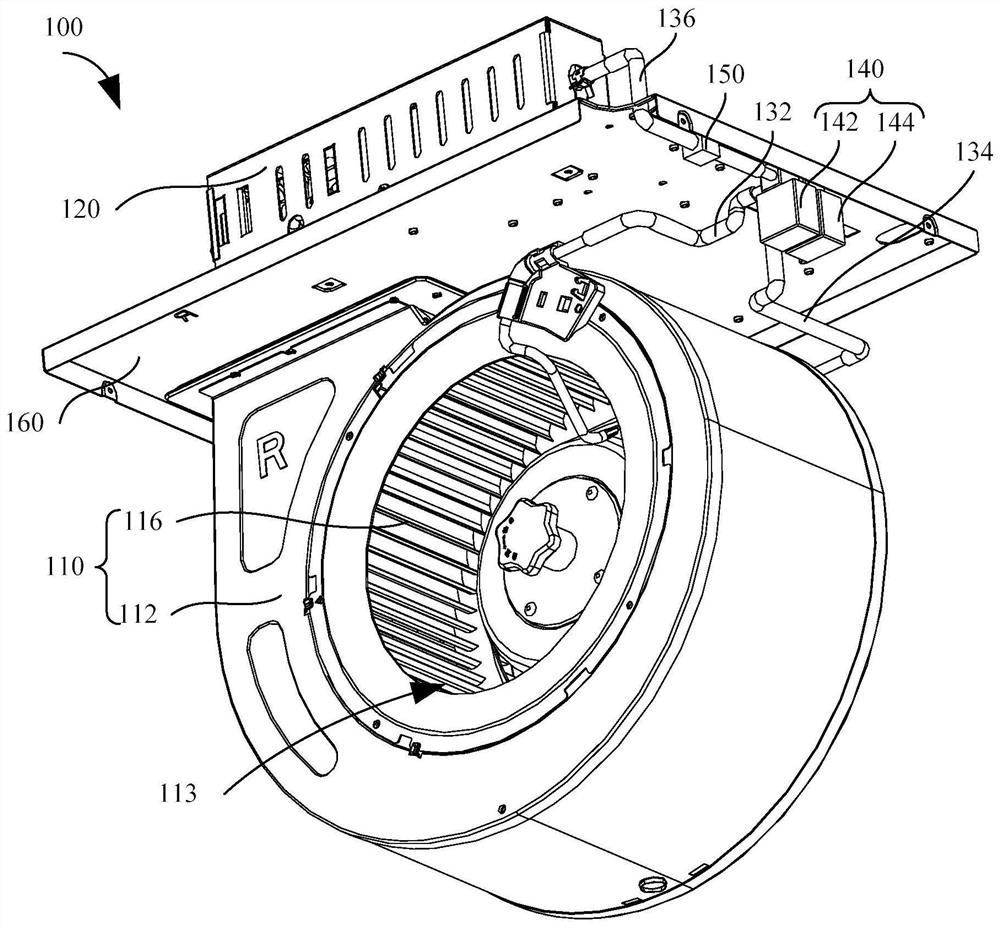

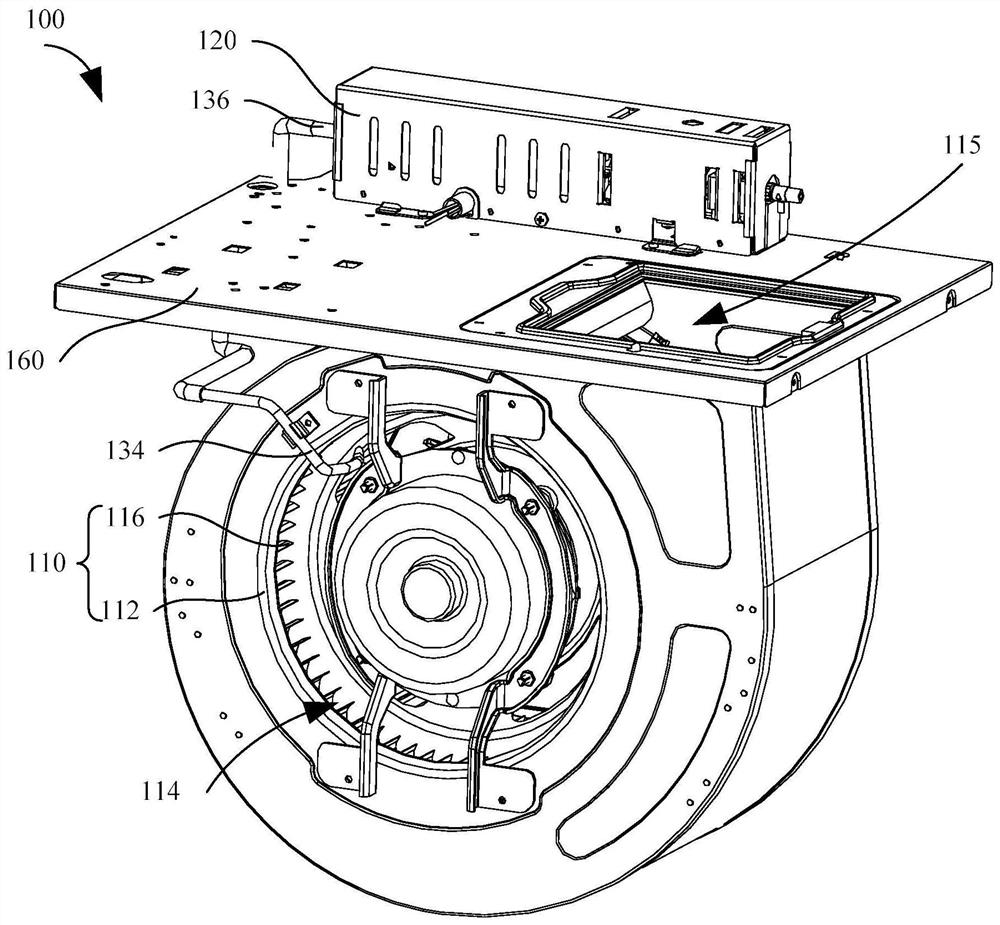

[0059] Such as Figure 1 to Figure 3As shown, according to the first aspect of the present invention, the present invention provides a fan cleaning system 100 for range hoods. The fan cleaning system 100 includes: a fan assembly 110, a steam generating device 120 and a nozzle assembly, and the fan assembly 110 Including a first air inlet 113 and a second air inlet 114; the nozzle assembly communicates with the steam generating device 120, the nozzle assembly includes a plurality of nozzles, and the nozzle of at least one nozzle in the plurality of nozzles faces the first air inlet 113 , the nozzle of at least one nozzle among the plurality of nozzles faces the second air inlet 114 .

[0060] The fan cleaning system 100 provided by the present invention includes a fan assembly 110, a steam generating device 120, and a nozzle assembly. The fan assembly 110 includes a first air inlet 113 and a second air inlet 114. The steam generating device 120 can heat the cleaning medium and ...

Embodiment 2

[0064] Such as figure 1 As shown, on the basis of the first embodiment above, further, a valve assembly 140 is provided on the nozzle assembly, and the valve assembly 140 can open or close the nozzle of the nozzle assembly, thereby better controlling the operation of the blower cleaning system 100 .

[0065] Further, as figure 1 As shown, a plurality of nozzles include a first nozzle 132 and a second nozzle 134, wherein the first nozzle 132 and the second nozzle 134 are connected to the steam generating device 120, and the nozzle of the first nozzle 132 faces The first air inlet 113 cleans the impeller 116 on the side opposite to the first air inlet 113 in the fan assembly 110, and the nozzle of the second spray pipe 134 faces the second air inlet 114 to clean the fan assembly 110 and the second air inlet. The impeller 116 on the side opposite to the tuyere 114 is cleaned, thereby realizing simultaneous cleaning of the front side and the rear side of the impeller 116, thereb...

Embodiment 3

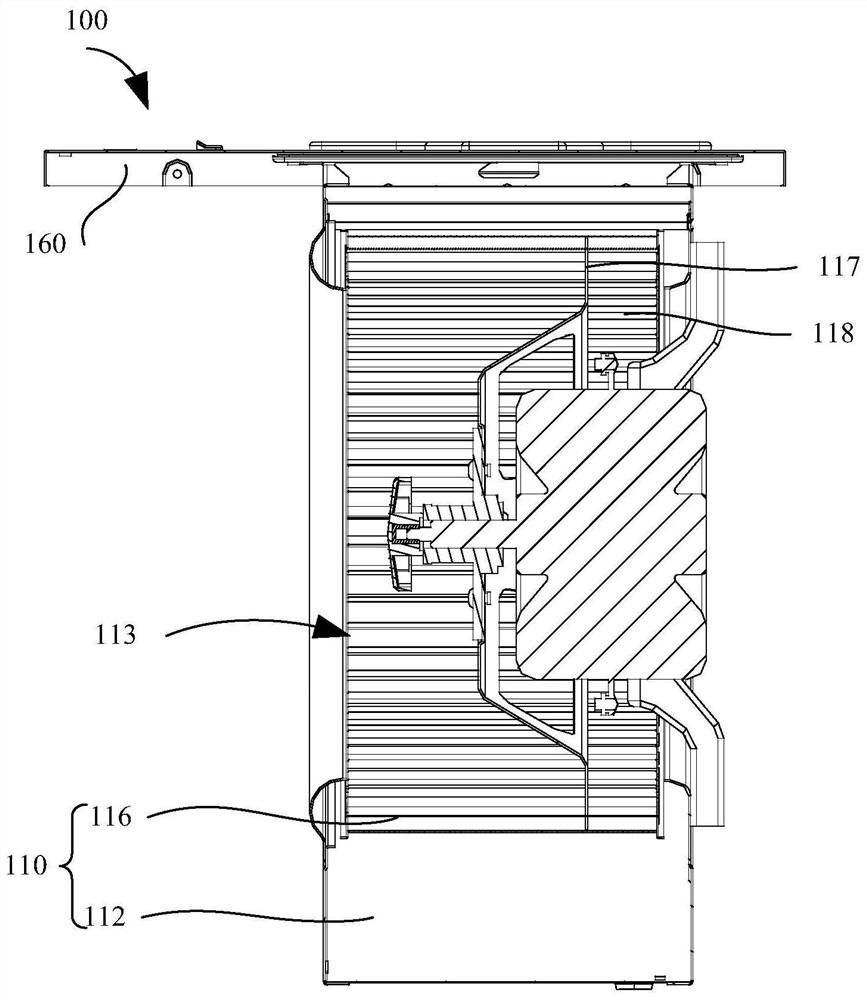

[0070] On the basis of the above-mentioned embodiment 1 or embodiment 2, further, as image 3 As shown, the fan assembly 110 includes a volute 112, an impeller 116 and a partition 117, the impeller 116 is arranged in the volute 112, the impeller 116 includes a plurality of blades 118, and the partition 117 is arranged in the middle of the height direction of the plurality of blades 118, Thus, the impeller 116 is divided into a first area and a second area, the first area corresponds to the first air inlet 113 provided on the volute 112, and the second area corresponds to the second air inlet 114 provided on the volute 112 Correspondingly, by arranging a plurality of nozzles, the structure of the impeller 116 and the volute 112 in the first area and the structure of the impeller 116 and the volute 112 in the second area can be cleaned separately, thereby realizing cleaning without dead ends.

[0071] Specifically, such as figure 1 with figure 2 As shown, the first nozzle 132...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap