High-efficiency reduction and restoration agent for asphalt pavement, preparation method and application

A technology of asphalt pavement and repair agent, applied in the direction of asphalt coating and coating, which can solve the problems of loose aggregate on the surface of the pavement, slow driving speed and large water seepage coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 High-efficiency reduction and repair agent for asphalt pavement

[0022] S1. Preparation of 2-(1-cyclopentenyl) acetic acid side chain branched acrylic polymer: add 50 parts of ethylene glycol dimethyl ether into the reactor, under nitrogen flow, after heating to 110 ° C, stirring dropwise The mixed solution containing 52 parts of polypropylene glycol (meth)acrylate, 6.5 parts of polyethylene glycol mono (meth)acrylate and 1 part of tert-butyl peroxy-2-ethylhexanoate was added dropwise to React at 110°C for 0.5-3h to obtain an acrylic polymer with Mw of 8000, add 0.6 part of 2-(1-cyclopentenyl)acetic acid dropwise to the acrylic polymer, and react at 40-50°C for 0.5-2h to obtain 2- (1-cyclopentenyl) acetic acid side chain grafted acrylic polymer;

[0023] S2. Preparation of polymer emulsion: Dissolve 8-15 parts of methacryloyloxyethyltrimethyl ammonium chloride and 0.1-2 parts of benzenesulfonic acid in water, and add 5-12 parts of tetramethylammonium chlorid...

Embodiment 2

[0026] Example 2 High-efficiency reduction and repair agent for asphalt pavement

[0027] S1. Preparation of 2-(1-cyclopentenyl) acetic acid side chain branched acrylic polymer: add 50 parts of ethylene glycol dimethyl ether into the reactor, under nitrogen flow, after heating to 110 ° C, stirring dropwise The mixed solution containing 52 parts of polypropylene glycol (meth)acrylate, 6.5 parts of polyethylene glycol mono (meth)acrylate and 1 part of tert-butyl peroxy-2-ethylhexanoate was added dropwise to React at 110°C for 0.5-3h to obtain an acrylic polymer with Mw of 8000, add 0.6 part of 2-(1-cyclopentenyl)acetic acid dropwise to the acrylic polymer, and react at 40-50°C for 0.5-2h to obtain 2- (1-cyclopentenyl) acetic acid side chain grafted acrylic polymer;

[0028] S2. Preparation of polymer emulsion: dissolve 15 parts of sodium vinyl sulfonate and 2 parts of sulfuric acid in water, add 12 parts of vinyltrimethoxysilane and 35 parts of 2-(1-cyclopentenyl under stirring...

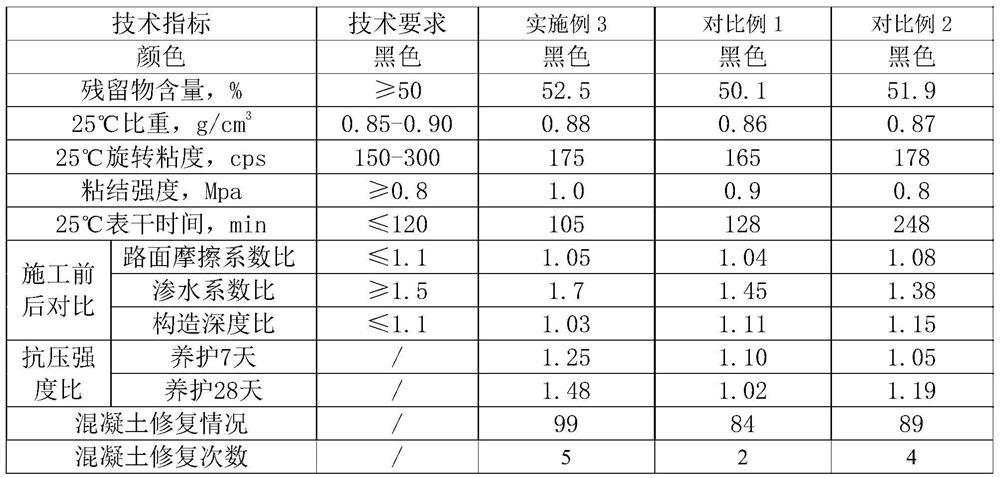

Embodiment 3

[0031] Example 3 High-efficiency reduction and repair agent for asphalt pavement

[0032] S1. Preparation of 2-(1-cyclopentenyl) acetic acid side chain branched acrylic polymer: add 50 parts of ethylene glycol dimethyl ether into the reactor, under nitrogen flow, after heating to 110 ° C, stirring dropwise The mixed solution containing 52 parts of polypropylene glycol (meth)acrylate, 6.5 parts of polyethylene glycol mono (meth)acrylate and 1 part of tert-butyl peroxy-2-ethylhexanoate was added dropwise to React at 110°C for 0.5-3h to obtain an acrylic polymer with Mw of 8000, add 0.6 part of 2-(1-cyclopentenyl)acetic acid dropwise to the acrylic polymer, and react at 40-50°C for 0.5-2h to obtain 2- (1-cyclopentenyl) acetic acid side chain grafted acrylic polymer;

[0033] S2. Preparation of polymer emulsion: dissolve 12 parts of methacryloyloxyethyltrimethylammonium chloride and 0.5 part of benzenesulfonic acid in water, add 8 parts of phenyltrimethoxysilane and 32 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com