Adjustable blowing head for glass bottle production

An adjustable blowing head technology is applied in the field of adjustable blowing heads for glass bottle production. Adjust the effect of high precision and flexible adjustment function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

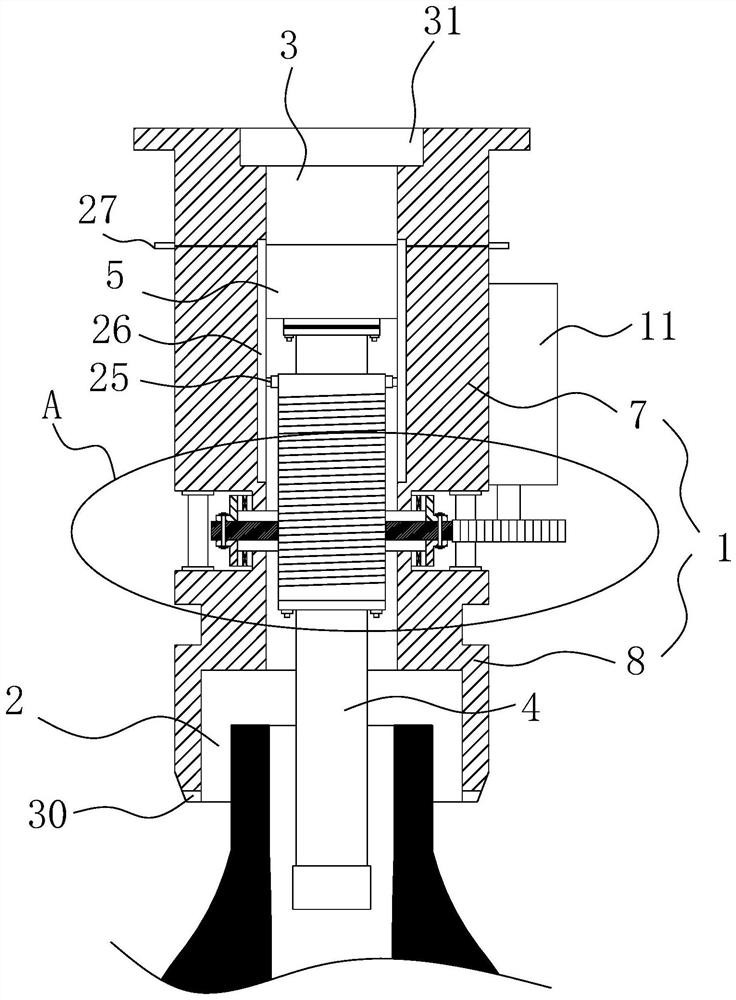

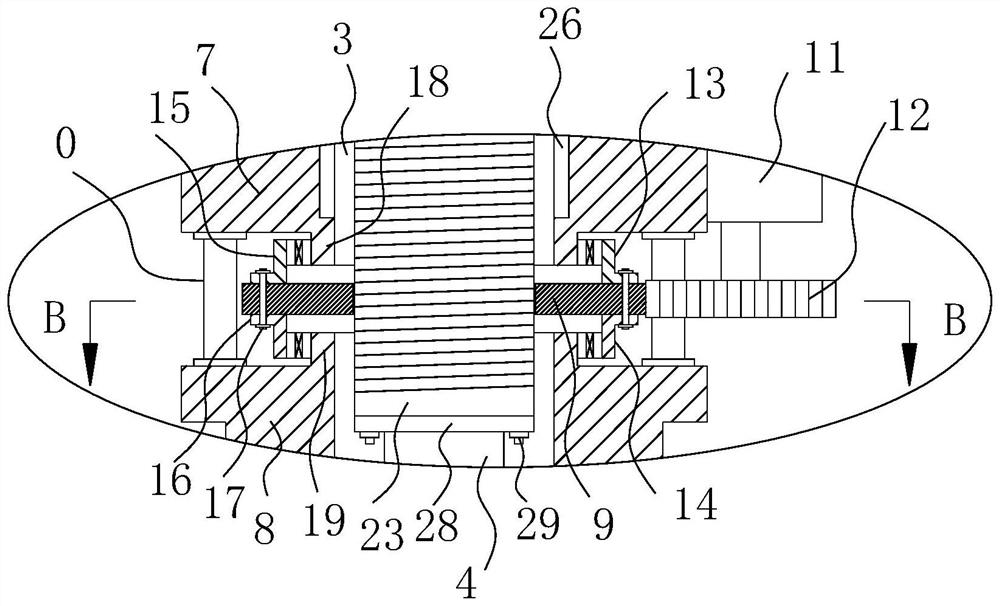

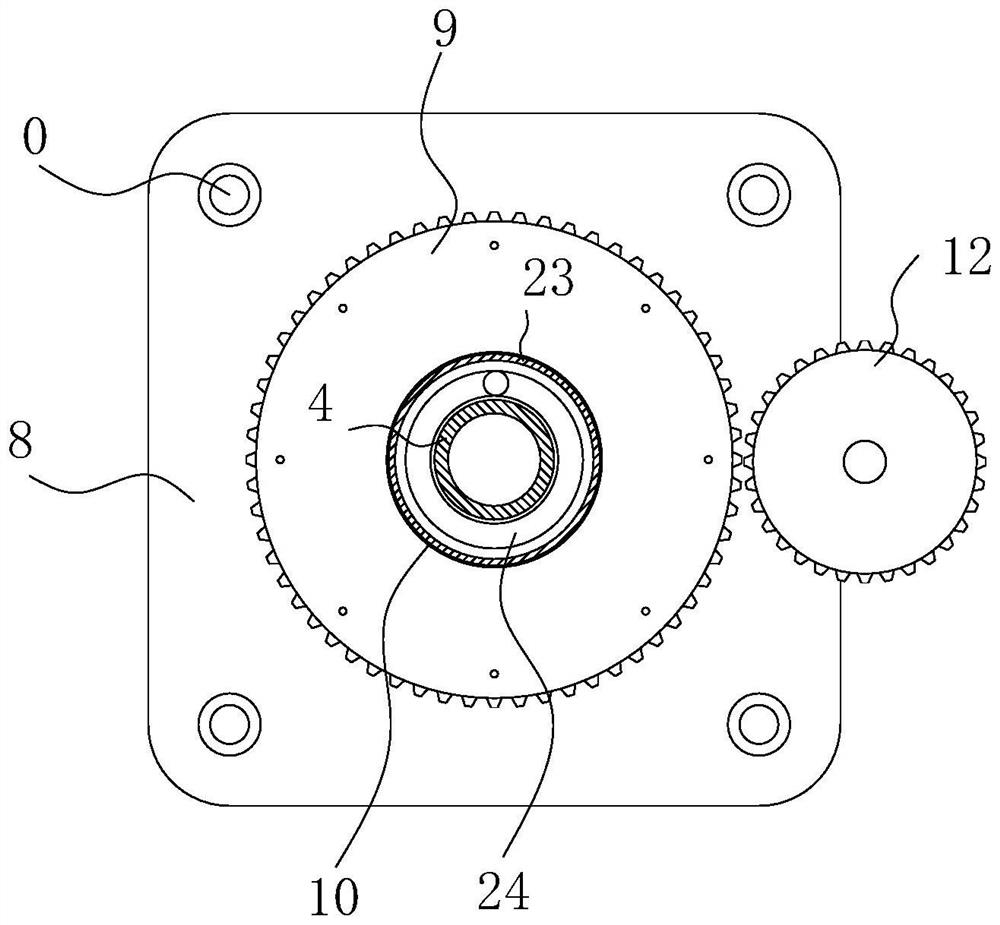

[0024] like Figure 1-5 As shown, an adjustable blowing head for glass bottle production, including a blowing head body 1, the bottom of the body 1 is provided with a groove 2 for being sleeved outside the bottle mouth, and the side wall of the groove 2 There is an exhaust horizontal groove 30 penetrating to the outer wall of the main body 1, which is similar to the traditional blowing head, and will not be described again. The main body 1 is provided with a vertical, square central hole 3. The central hole 3 is chosen to be square mainly for the purpose of limiting and guiding the sliding head 5. On the premise of playing the same role, the hexagonal shape is selected, and the five Other shapes such as polygons are also feasible.

[0025] The central hole 3 extends from the upper surface of the body 1 into the groove 2 , that is to say, the central hole 3 runs through the body 1 and has its upper surface to the surface of the groove 2 . The air blowing pipe 4 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com