Leakage early warning type cooling system for injection mold

A cooling system and injection mold technology, applied in the field of injection molds, can solve the problems of not being able to find the coolant in time, poor reminder effect, leakage, etc., and achieve the effect of improving the reminder effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. DETAILED DESCRIPTION OF THE INVENTION The present invention is not intended to limit the invention. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

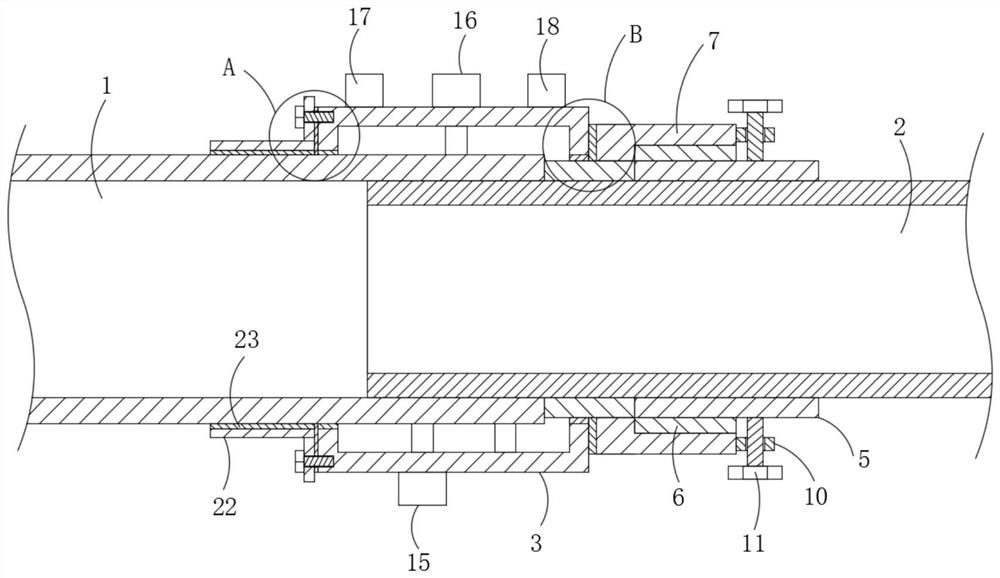

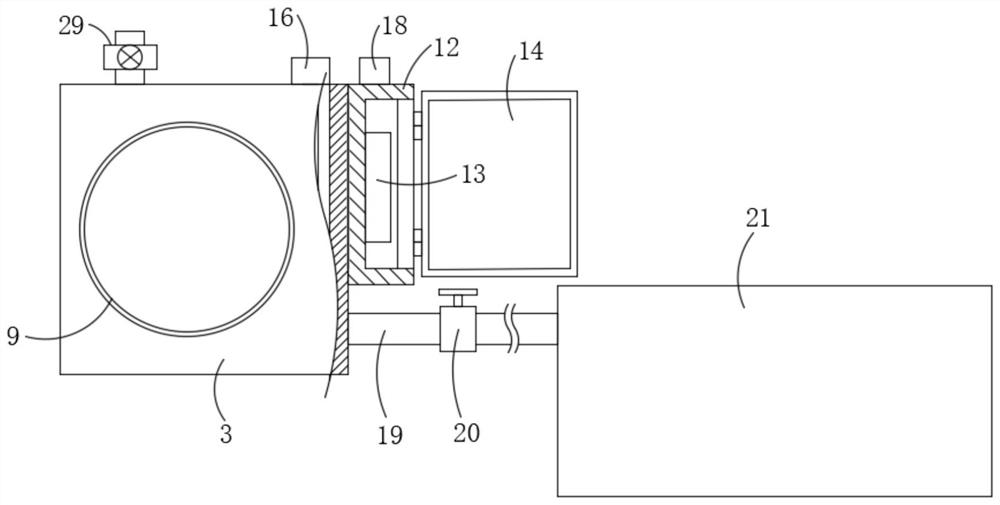

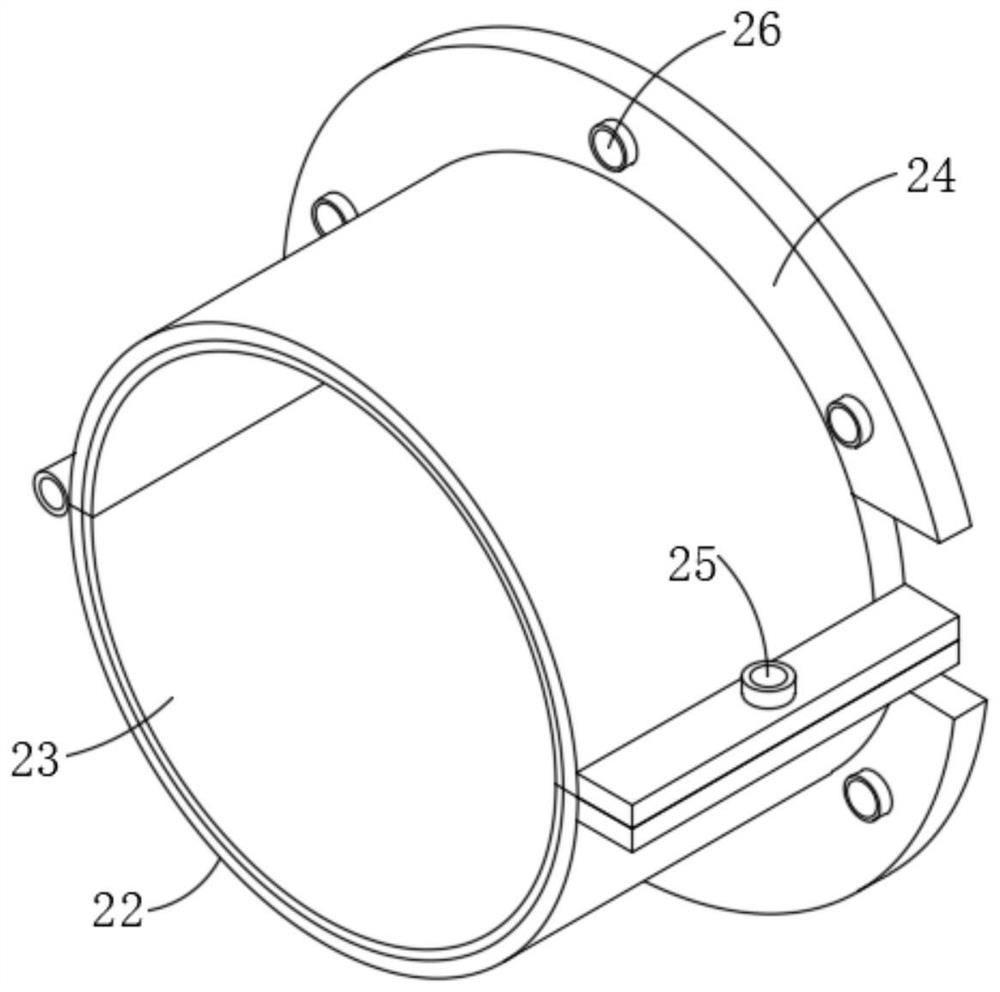

[0025] The present invention provides Figure 1-6 A leakage pre-warning type injection mold, including the water tube 1 and the water pipe 2, and the water pipe 2 are fixedly mounted in the water pipe 1, and a fixing frame 3 is provided on the water pipe 1, and one end welding is fixed by one end of the water pipe 1. The ring 4, the inside of the fixing ring 4 is fitted to the oute...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap