Method for producing a cellulose paper material from used textiles

A technology of cellulose and textiles, applied in the field of paper materials, can solve problems such as fiber shortening and rejection, and achieve the effect of reducing false hits, efficient and robust methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

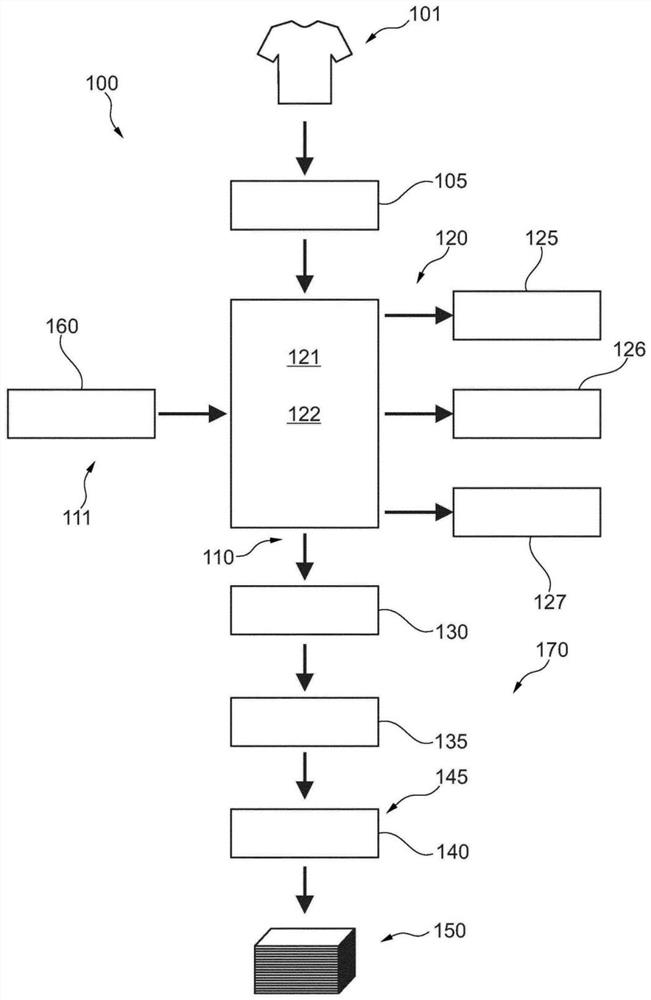

[0102] Before describing the exemplary embodiments with reference to the drawings, some basic considerations should be outlined upon which the exemplary embodiments of the present invention are derived.

[0103] According to an exemplary embodiment, suitable processing steps within the scope of the manufacturing process influence the properties of the prepared raw material and influence the properties of the paper made from such pulp: i) short cooking times in NaOH resulting in Chain lengths are largely maintained in the resulting pulp, ii) remove too short chain lengths from the manufacturing process, iii) reduce metal oxides from old textiles (bonding, filtration, etc.), iv) pass Choose old textiles (or recycle raw materials), reduce synthetic fibers (polymers), v) control cooking time, cooking temperature, etc. This achieves < 5% of each polymer fiber type in the resulting pulp, vi) reactive generation and conversion or removal of metal oxides and / or synthetic polymers by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap