A kind of tunnel water inrush mud inrush model test device and method

A model test device and tunnel model technology, which is applied in the direction of measuring device, fluid dynamics test, machine/structural component test, etc., to achieve the effect of high universality, simple and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

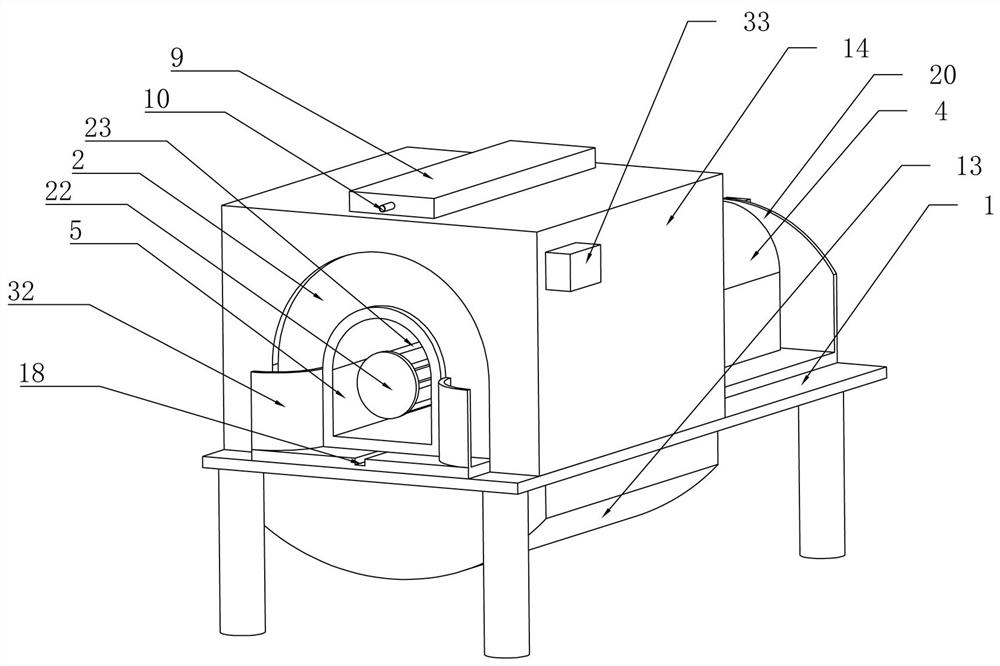

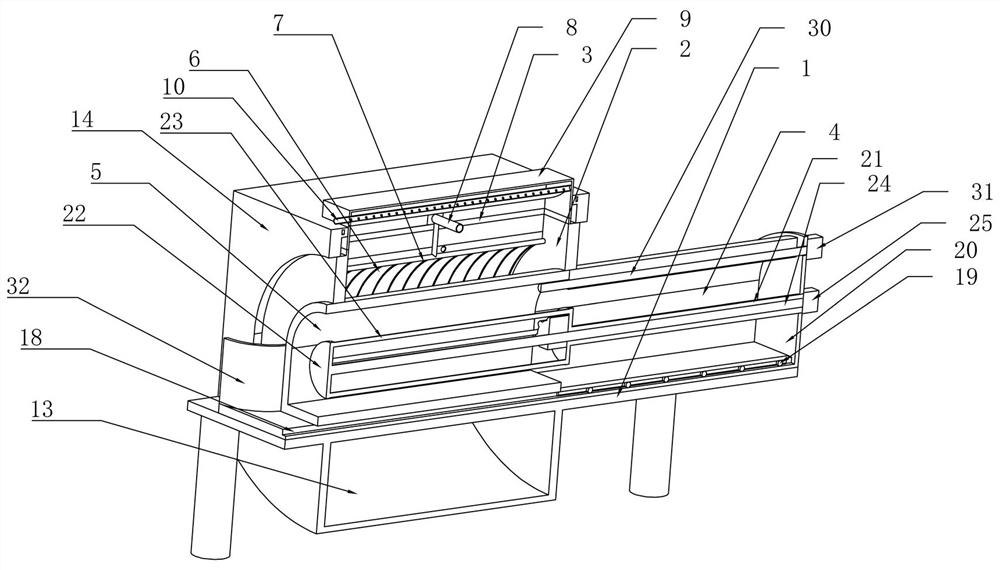

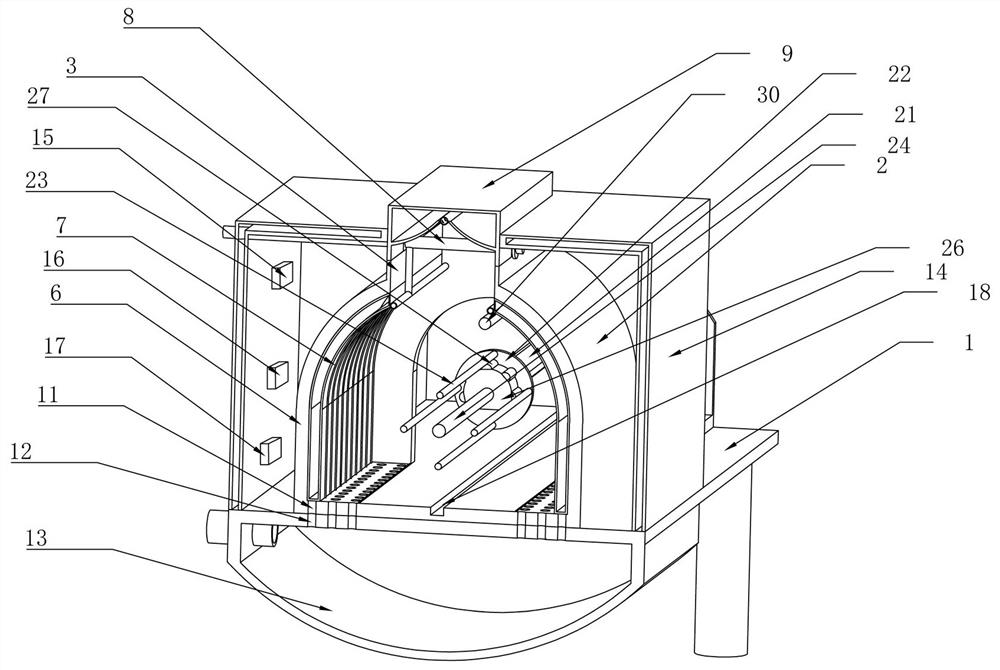

Embodiment 1

[0039] Embodiment 1, the present invention is a tunnel water and mud inrush model test device and method, including a support base 1, the support base 1 is placed on the ground to provide a fixed support foundation for subsequent structures, the support base 1 The upper end is fixedly connected with a feeding bin 2, and the upper end of the feeding bin 2 is fixedly connected with a feeding frame 3. Through the feeding frame 3, soil can be injected into the feeding bin 2. The feeding bin 2 There is a built-in support mold 4, the support mold 4 and the feeding bin 2 are gap-fitted, and the front end of the support mold 4 is detachably connected with a tunnel model 5. When the support mold 4 is placed in the feeding When inside the silo 2, inject soil into the gap portion of the supporting mould 4 and the feeding bin 2 through the feeding frame 3, and cover the supporting mould 4 with soil;

[0040] The inner wall of the feeding bin 2 is fixedly connected with a ram air bag 6, an...

Embodiment 2

[0043] Embodiment 2, on the basis of Embodiment 1, in the process of spraying water on the soil, water will remain in the soil, causing the water body to flow sluggishly, and the problem of not being able to shoot to the outside smoothly, so this embodiment Provide a structure for diverting the water in the soil to ensure the smooth flow of the water body in the soil. The lower end of the support base 1 is provided with a lower permeable hole 12 which is matched with the said permeable hole. In order to ensure that the water body in the said feeding bin 2 will not be scattered everywhere, the said upper permeable hole 11 is close to the said tunnel model. 5. A water retaining strip is fixedly connected on one side, and the water retaining strip prevents the water flow from flowing around. The lower end of the support base 1 is fixedly connected with a liquid return silo 13, and the liquid return silo 13 is pre-stored with water. The liquid return bin 13 is provided with a wate...

Embodiment 3

[0044] Embodiment 3, on the basis of Embodiment 1, due to the difference in temperature environment, the phenomenon of water and mud inrush in the tunnel will be affected. In order to create a different temperature environment, the temperature environment where the tunnel model 5 is located is changed. The embodiment provides a structure for adjusting and controlling the temperature environment. Specifically, the upper end of the support base 1 is fixedly connected with a thermal insulation shield 14 sleeved on the outside of the feeding bin 2. The thermal insulation shield 14 It is a double-layer thermal insulation structure, the described feeding bin 2 is covered by the described thermal insulation protective cover 14, the described feeding bin 2 is protected, and the temperature environment near the described feeding bin 2 is controlled at the same time, Reduce the exchange of the temperature near the feeding bin 2 and the external environment to ensure that the feeding bin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com