Double-color injection mold and injection molding method

A two-color injection molding and mold technology, applied in the direction of coating, etc., can solve the problems of unqualified products, difficult ring mesh without wrinkling, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

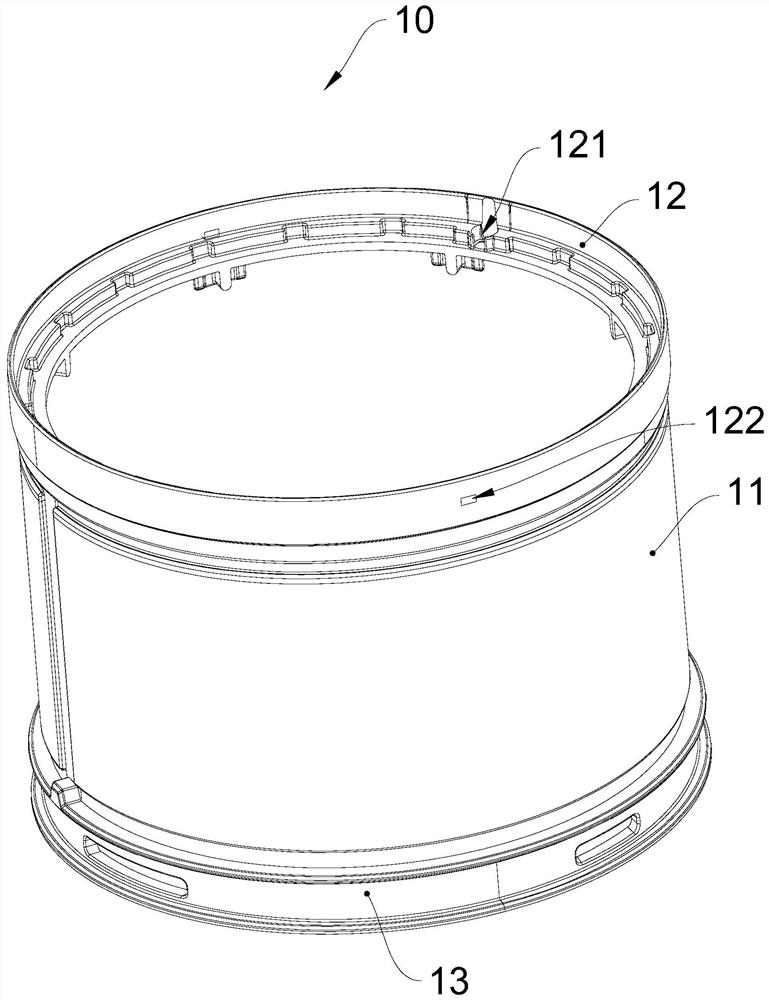

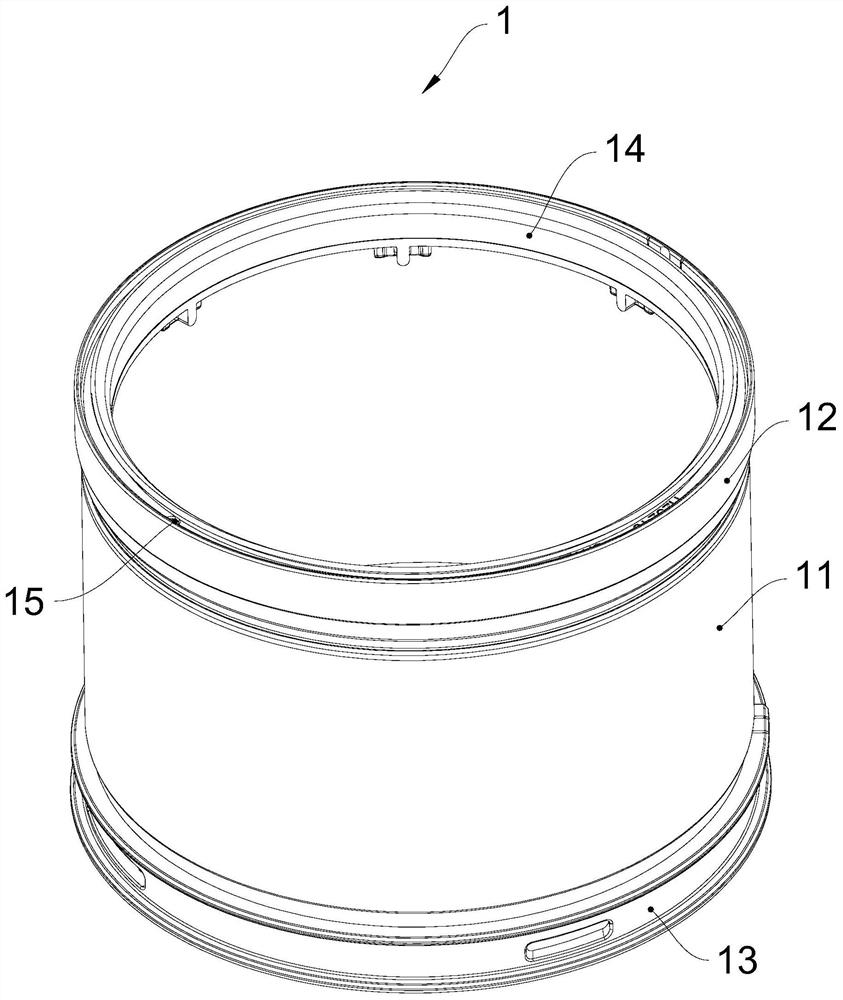

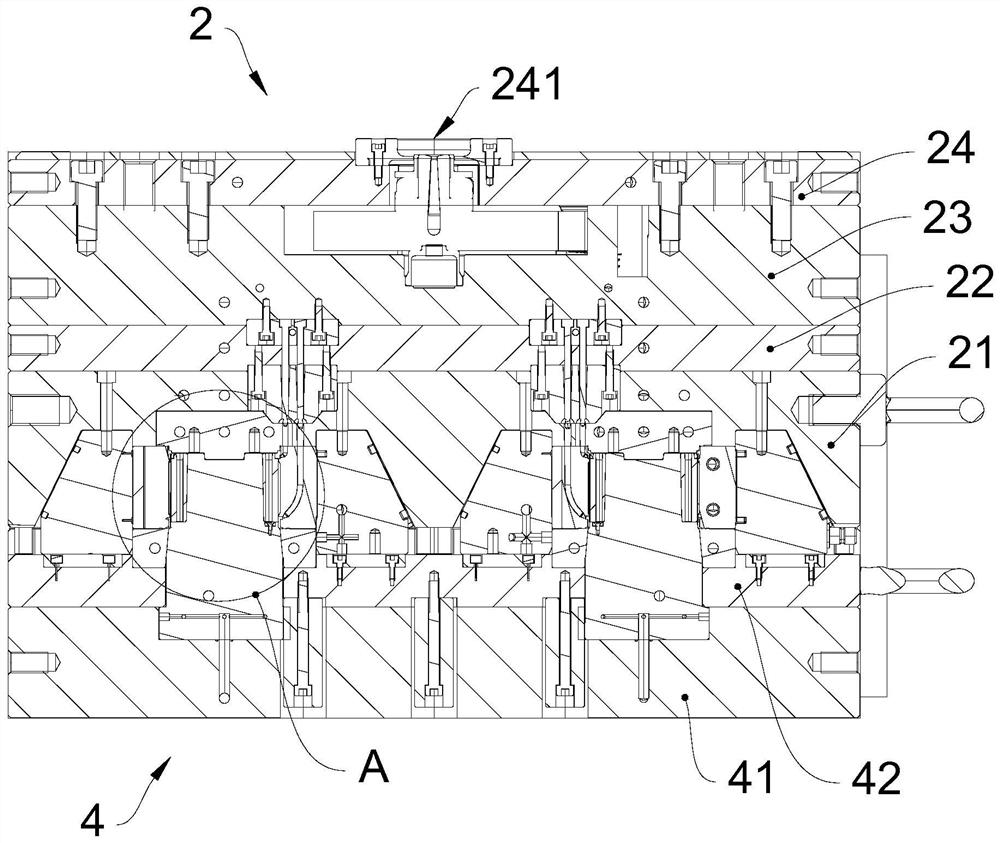

[0047] see figure 1 and figure 2 , the product to be produced in this embodiment is the mesh filter assembly 1 of the vacuum cleaner. The mesh filter assembly 1 includes an annular mesh 11, a first plastic ring 12, a second plastic ring 13, a third plastic ring 14 and two magnet pieces 15. Wherein, the annular mesh cloth 11 is the cotton cloth with filter hole, and its texture is soft, and the first plastic ring 12 and the second plastic ring 13 are arranged on the upper and lower ends of the annular mesh cloth 11 axial direction respectively, and the first plastic ring 12 and the second plastic ring The materials and colors of the two plastic rings 13 are the same. The third plastic ring 14 is arranged inside the first plastic ring 12 and is fixedly connected with the first plastic ring 12 . The color of the third plastic ring 14 is different from that of the first plastic ring 12 . The inner side of the first plastic ring 12 is provided with two installation holes 121 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com