Cloth sanding machine with airflow softening mechanism

A sanding machine and cloth technology, applied to the cleaning method using air flow, fabric kneading/softening, textiles and papermaking, etc., can solve the problems of easy wrinkling of cloth and inability to process debris synchronously, and achieve the degree of freedom of adjustment high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

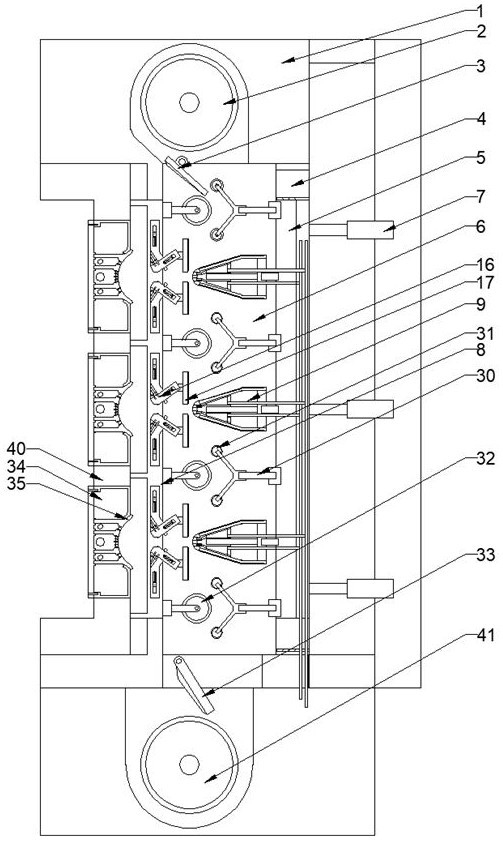

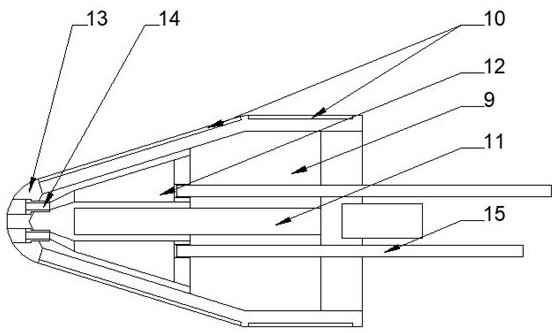

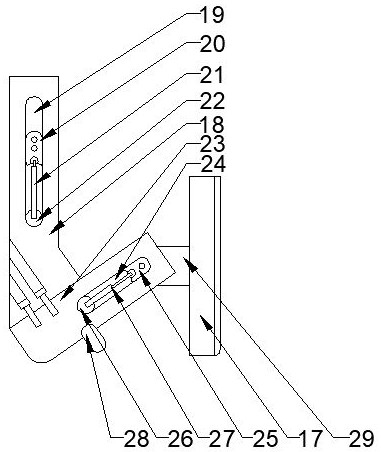

[0026] The present invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

[0027] A fabric grinding machine with airflow soft mechanism, including:

[0028] Such as figure 1 The support frame, including the longitudinal floating frame, and a transverse push frame parallel to the longitudinal floating frame longitudinal axis, and a fabric transmission zone is provided between the longitudinal floating frame and the transverse push frame, wherein in the top of the support frame corresponding to the top of the fabric transmission area. The cloth roller is provided, and the lower cloth roller is provided with a cloth pre-tightening plate that is arranged along the binding roller cut the axis, and the end portion of the pre-tightening plate is rotated to the support frame by the swing motor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap