Binocular vision different-plane round hole detection method based on cross laser

A binocular vision, cross laser technology, used in non-contact industrial inspection and vision-based precision inspection of circular holes, binocular vision different-sided circular hole detection field, to overcome the phenomenon of reflection and diffraction, the effect of great application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

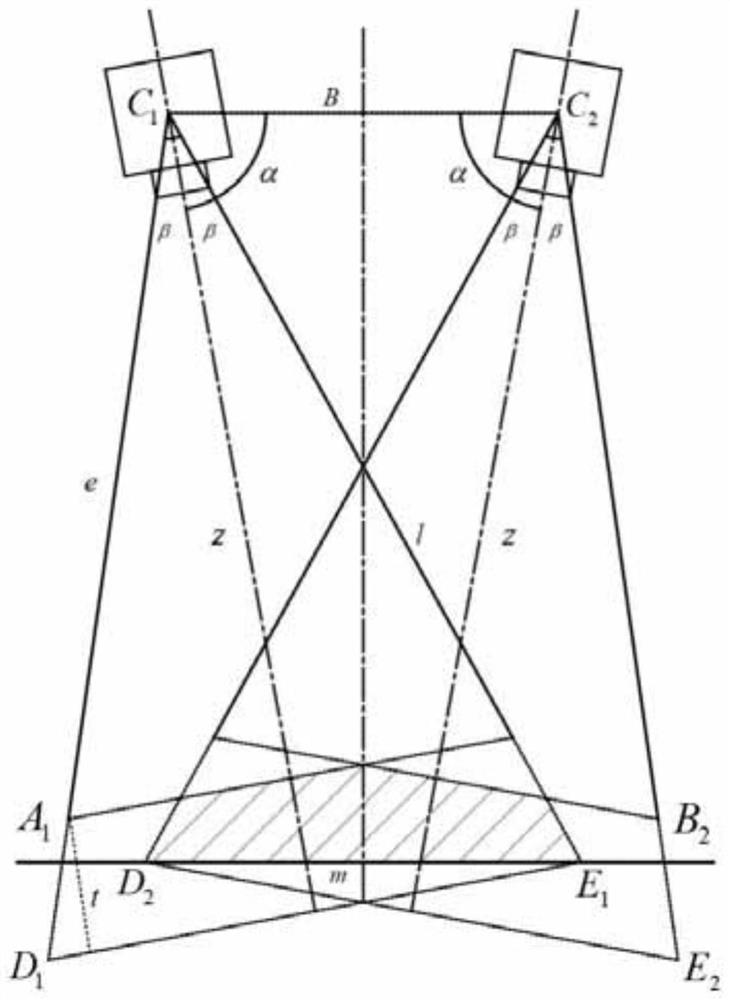

[0088] Include the following steps:

[0089] (1), connect with the industrial robot through the connection plate 7, the industrial robot drives the binocular camera to move to the top of the detection hole, and obtain the image of different faces of the workpiece through the binocular camera in the visual inspection system;

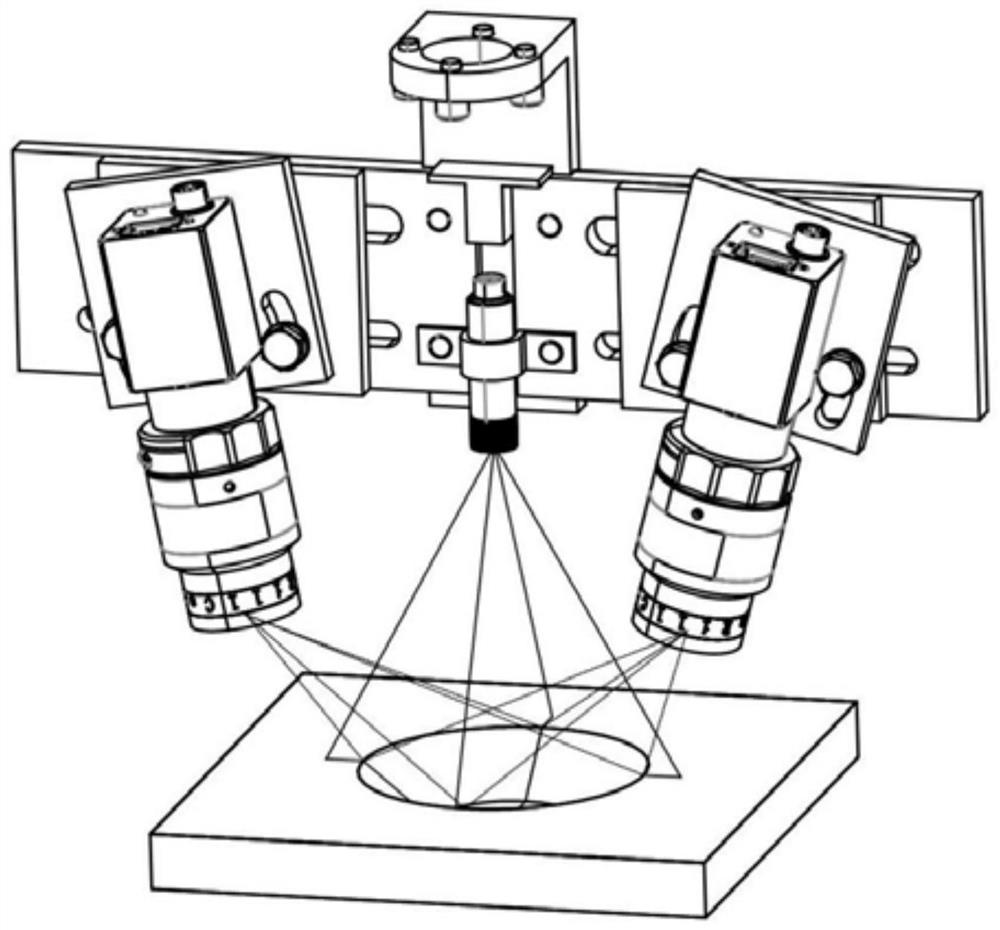

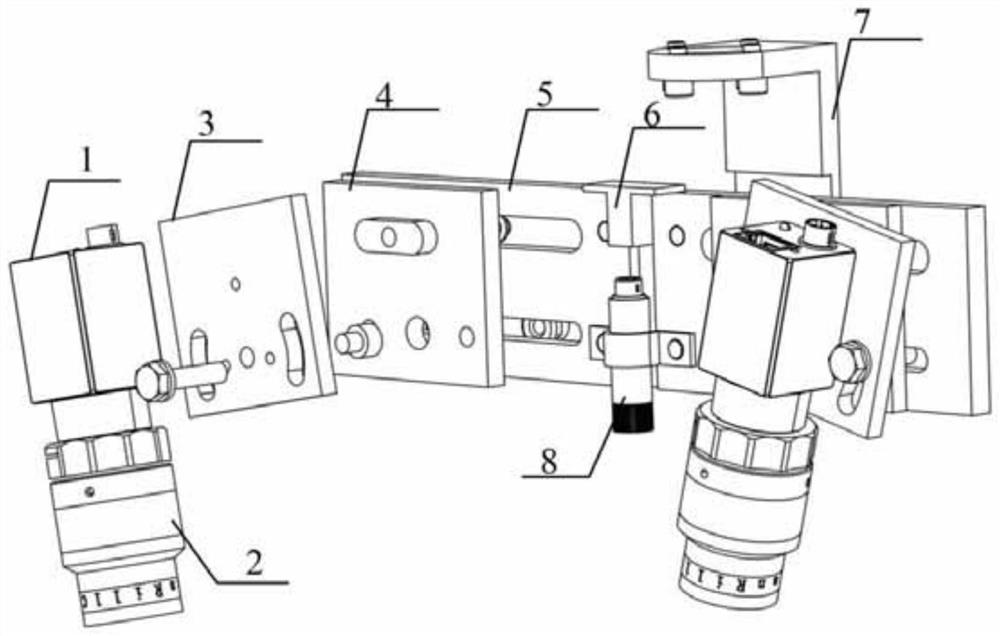

[0090] The visual inspection system includes an industrial camera 1, a high-definition macro lens 2, a turntable 3, a sliding block 4, a base plate 5, a positioning block 6, a connecting plate 7 and a laser emitter 8, wherein the sliding block 4 is in the long groove of the base plate 5 After adjusting the position, the bolts are connected. The turntable 3 is connected with the sliding block 4 through the arc groove and the angle is adjusted. Fixedly connected, the laser transmitter 8 is fixedly connected to the base plate 5 below the positioning block 6, and the base plate 5 is fixedly connected to the connecting plate 7 at the rear;

[0091] In the vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com