Bidirectional impeller pressurizing structure of compressor, centrifugal compressor and air conditioner

A technology of supercharging structure and compressor, applied in the field of compressors, can solve the problems of difficulty in the assembly process and complex structure, and achieve the effect of good axial force and balance of axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

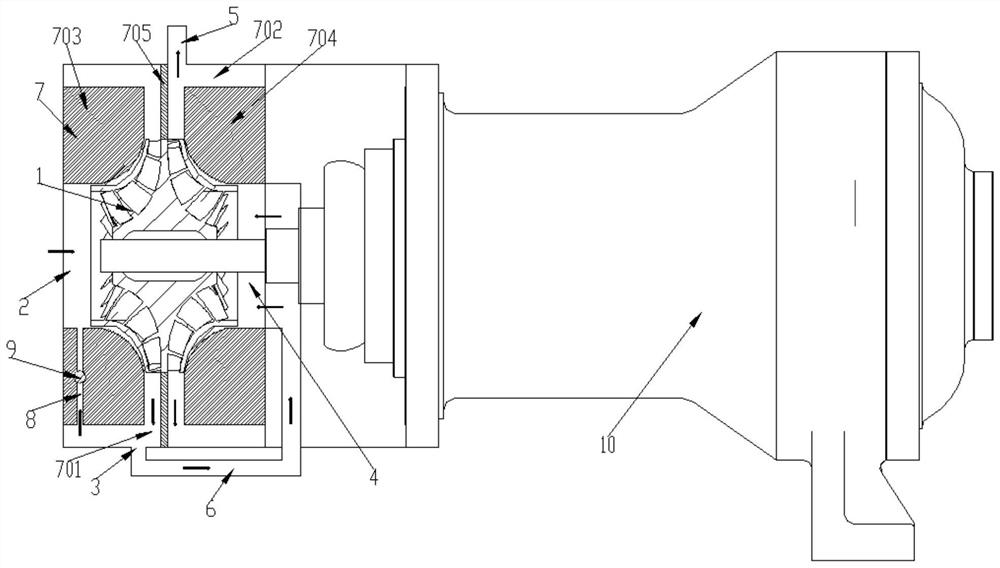

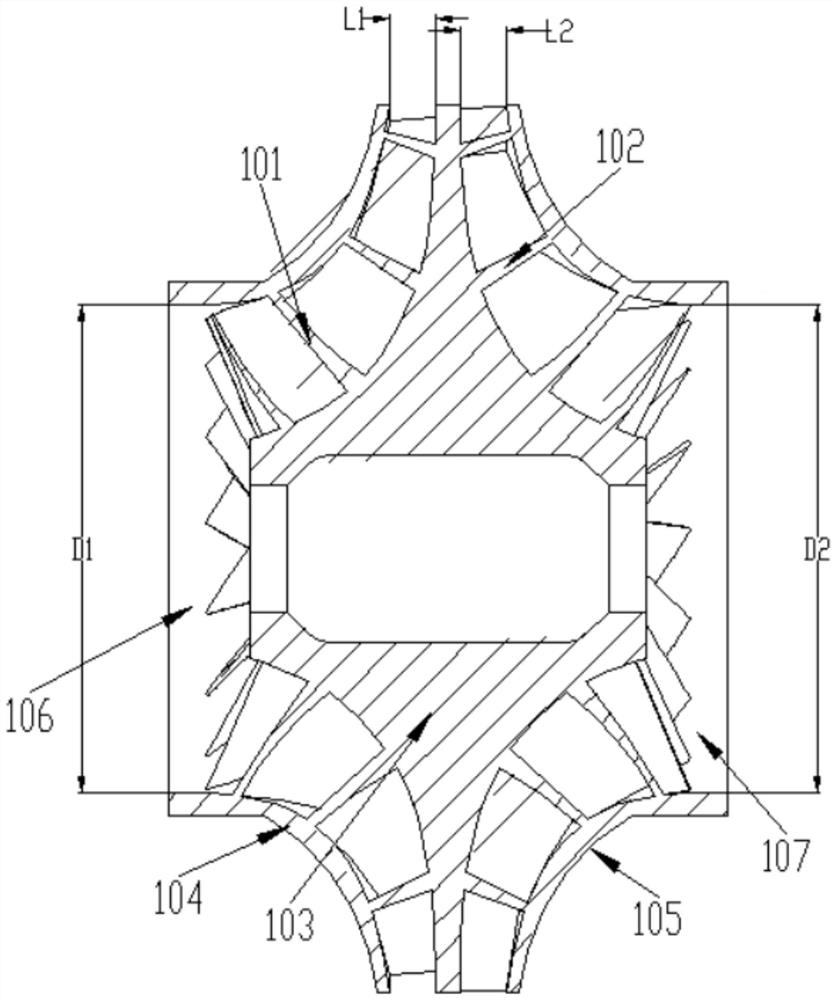

[0033] see Figure 2-Figure 3 , the present invention provides a two-way impeller supercharging structure of a compressor, including a two-way impeller 1 and a connecting channel 6 with blades arranged on both sides of the left and right sides. The two-way impeller 1 is preferably integrally formed, wherein the left blade of the two-way impeller 1 101 corresponds to the primary air inlet 2 and the primary exhaust port 3 of the compressor, the right blade 102 of the two-way impeller 1 corresponds to the secondary air intake 4 and the secondary exhaust port 5 of the compressor, and the connecting channel 6 connects a Stage exhaust port 3 and secondary air intake port 4.

[0034] Specifically, the bidirectional impeller supercharging structure also includes a shell structure 7 with a central through hole formed inside, the bidirectional impeller 1 is located in the central through hole and the two ends of the central through hole form the primary air inlet 2 and the secondary air...

Embodiment 2

[0041] Different from Example 1: see figure 2 , a bypass channel 8 is formed in the shell structure 7, and the bypass channel 8 communicates with the first-level air inlet 2 and the first-level air outlet cavity 701; The size of the flow area. When the overall axial force on the bidirectional impeller 1 is to the left, the flow area of the bypass passage 8 is adjusted through the adjustment structure, and the high-pressure gas in the primary air outlet chamber 701 flows to the primary air inlet 2 through the bypass passage 8, so that a The pressure of the first-stage air inlet 2 is increased, the pressure difference between the first-stage exhaust port 3 and the first-stage air inlet 2 is reduced, and the axial force on the two-way impeller 1 as a whole is reduced to the left. By adjusting the structure, adjust The size of the flow area of the bypass channel 8 changes the flow of gas from the primary exhaust port 3 to the primary air inlet 2. Of course, the bypass channe...

Embodiment 3

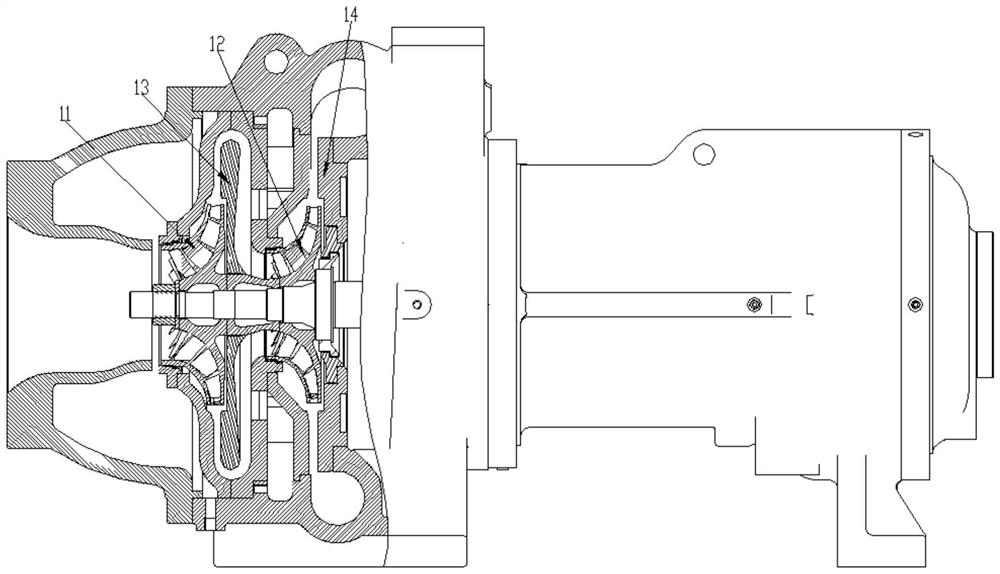

[0044] see figure 2, a centrifugal compressor, comprising a motor 10 and a bidirectional impeller supercharging structure of the compressor provided in embodiment 1 or embodiment 2, the rotating shaft of the motor 10 is connected to the bidirectional impeller 1 of the bidirectional impeller supercharging structure. When the two-way impeller supercharging structure is installed on the centrifugal compressor, the centrifugal compressor is started, the two-way impeller 1 rotates, the gas enters through the primary air inlet 2, and after being pressurized by the left blade 101 of the two-way impeller 1, it passes through The primary exhaust port 3 is discharged, the pressurized gas discharged from the primary exhaust port 3 flows through the connecting channel 6 to the secondary air inlet 4, and the high-pressure gas discharged from the secondary air inlet 4 passes through the right blade of the two-way impeller 1 After 102 is pressurized again, it is discharged from the secondar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com