Heat-not-burn smoking set adopting thin film for heating

A heat-not-burn, thin-film technology, used in applications, tobacco, smokers' supplies, etc., can solve the problems of surrounding people's health hazards, uneven smoke, radiation equipment, etc., to achieve stable smoking concentration, easy to miniaturize production, The effect of uniform smoke composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

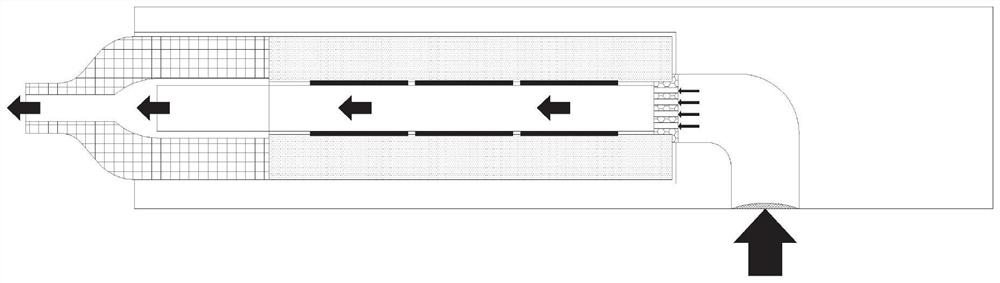

[0021] Below in conjunction with accompanying drawing, the present invention will be further described.

[0022] The smokable material in the present invention includes any material containing tobacco and smoke oil, such as one or more of tobacco, tobacco derivatives, reconstituted tobacco, and tobacco substitutes, which can be in the form of solid, liquid, or gel. After being heated, it releases volatile components and is sucked by people.

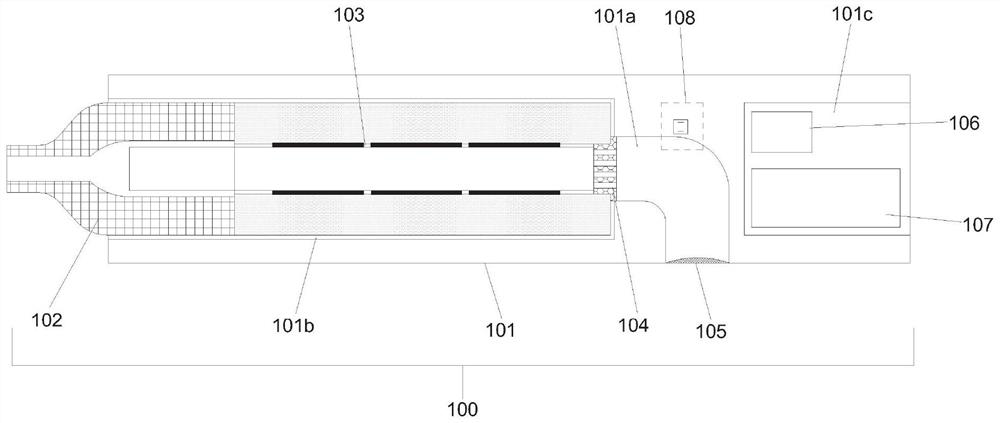

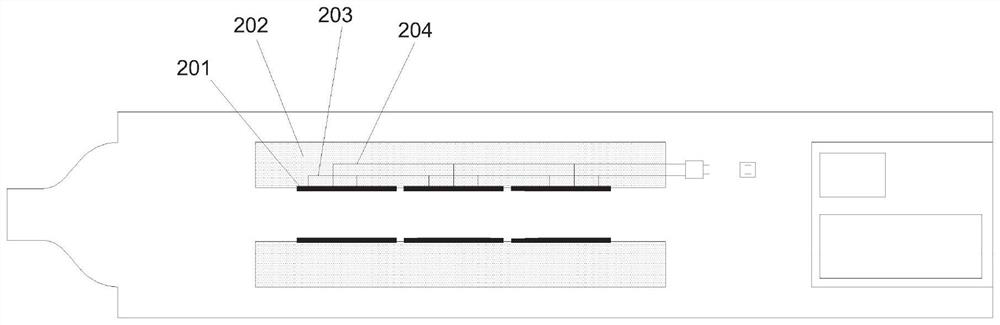

[0023] refer to figure 1 , a heat-not-burn smoking article using film heating, including a smoking article assembly 100, which is used to volatilize one or more components in the inhalable material without causing it to burn. The smoking article assembly 100 includes an elongated shell 101, The mouthpiece 102 connected to the housing 101 and extending outward, the heating part 103 built in the housing 101, the heating part 103 is used to heat the inhalable material, and the user smokes through the mouthpiece 102 and is heated and volatil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com