Anti-explosion angle seat valve

An angle seat valve, valve body technology, applied in valve device, valve details, sliding valve and other directions, can solve the problems of violent vibration of the valve body, violent fluctuation of water pressure, etc., to reduce the frontal impact and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

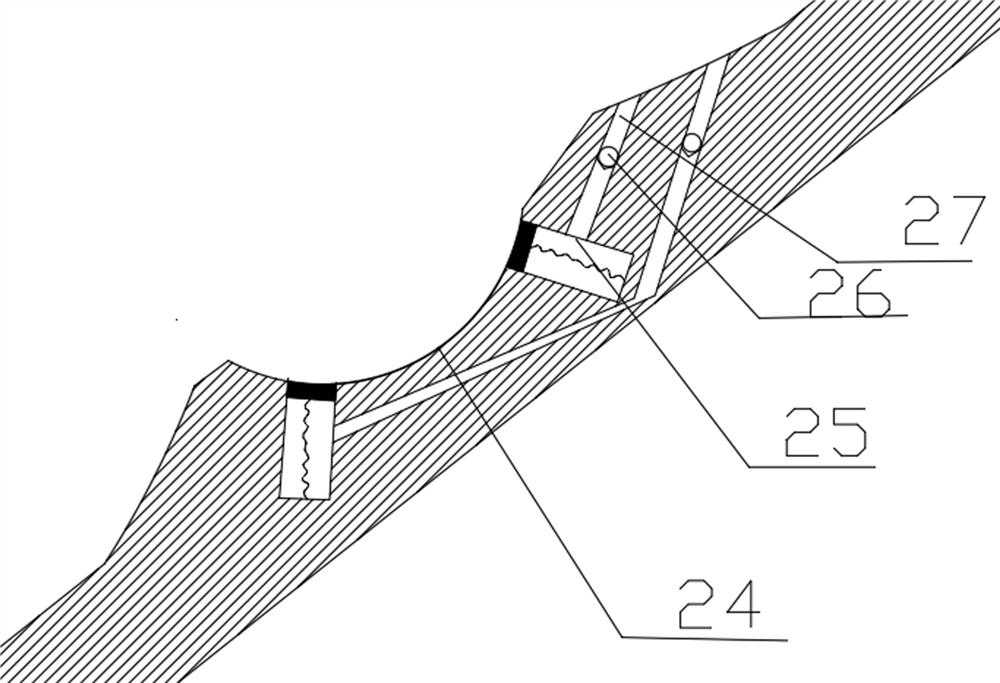

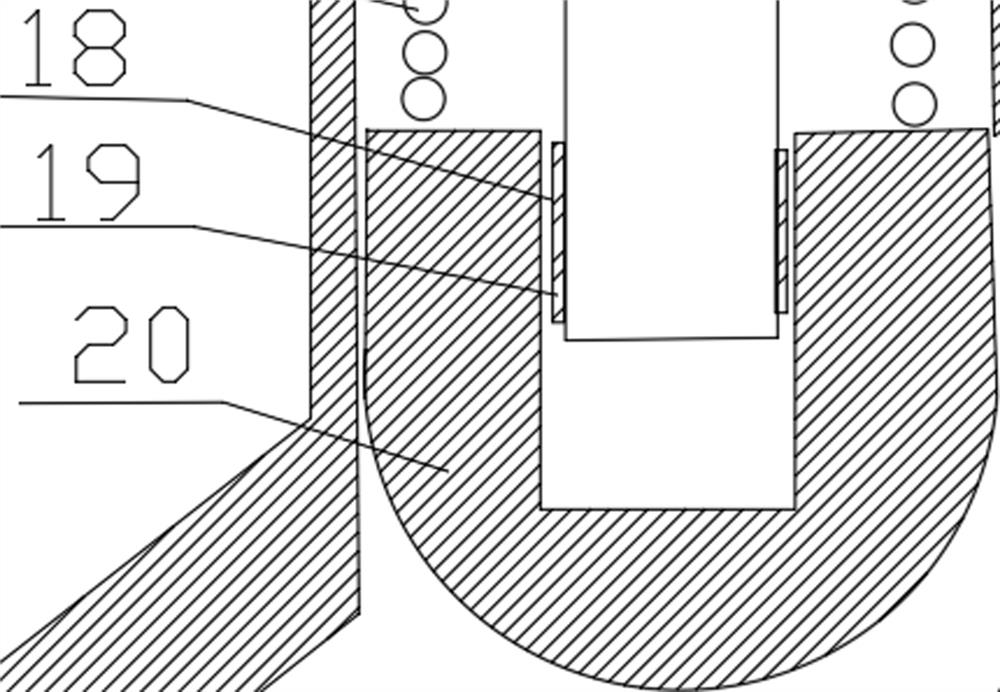

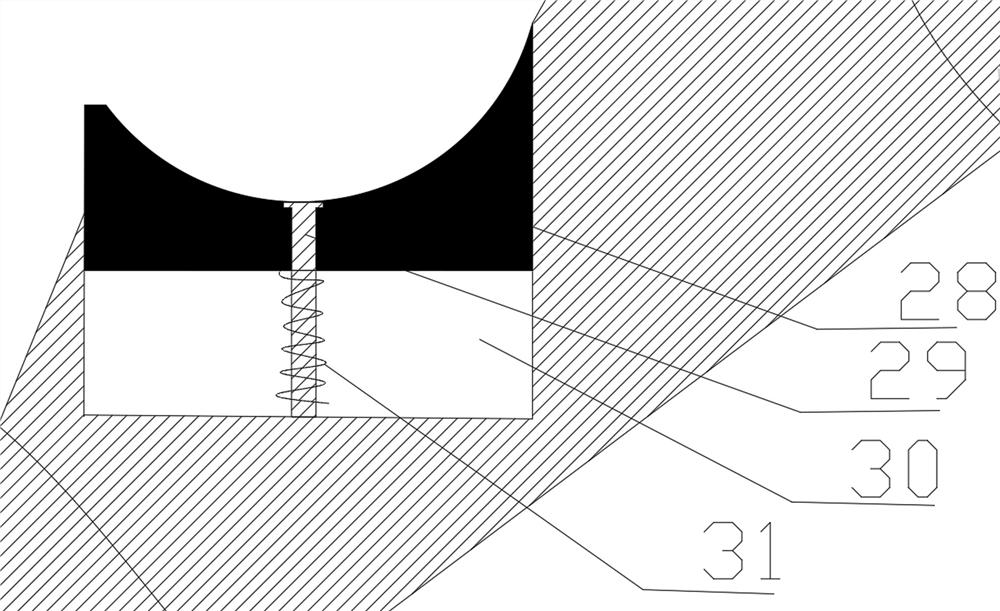

[0026] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

[0027] see Figure 1-3 , the present invention provides a technical solution: an explosion-proof angle seat valve, including: valve body 1, muffler 3, front cover 4, dust-proof combination ring 5, elastic pad 12, hexagon socket screw 13, piston rod 6, piston 7 , Exhaust pressure regulating joint 9, rear cover 10, cylinder 11, return spring 14, guide groove 15, limit plate 16, spring one 17, shock absorbing bushing 18, elastic component 19, plug 20.

[0028] The upper opening of the valve body 1 is connected to the front cover 4, the piston 7 is connected to the upper part of the piston rod 6 through the hexagon socket head screw 13, the right side of the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com