Patents

Literature

34results about How to "Reduce frontal impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deep sea aquaculture net cage HDPE pipe material and preparation method thereof

InactiveCN105015041AStable mechanical propertiesEfficient waterproof waveClimate change adaptationSynthetic resin layered productsUv absorbanceCage aquaculture

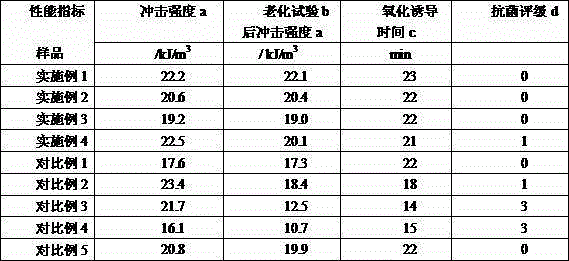

The present invention discloses a deep sea cage aquaculture net cage HDPE pipe material and a preparation method thereof. The HDPE pipe material is divided into inner and outer layers, the inner layer consists of the following raw materials in parts by mass: 100 parts of PE100 pipe resin, and 3-5 parts of a toughening agent; the outer layer is composed of the following parts of the raw materials by mass: 100 parts of ultrahigh molecular weight polyethylene, 10-20 parts of POE, 1-10 parts of polyethylene wax, 5-8 parts of carbon black, 2-10 parts of an ultraviolet absorber, 2-10 parts of a light stabilizer and 1-10 parts of an antioxidant. The thickness ratio of the inner and outer layers is 5-10: 1. The HDPE double-layer pipe material is used in a deep sea cage aquaculture net cage system, the frame impact resistance is improved, the wall thickness of the pipe material can be reduced, cost can be effectively reduced, net cage buoyancy is increased, mechanical properties of the pipe material can be maintained, and are not reduced, under the long sea water soaking and sun exposure, and the breeding of marine organisms in the pipe surface can be prevented.

Owner:GUANGDONG LIANSU TECH INDAL

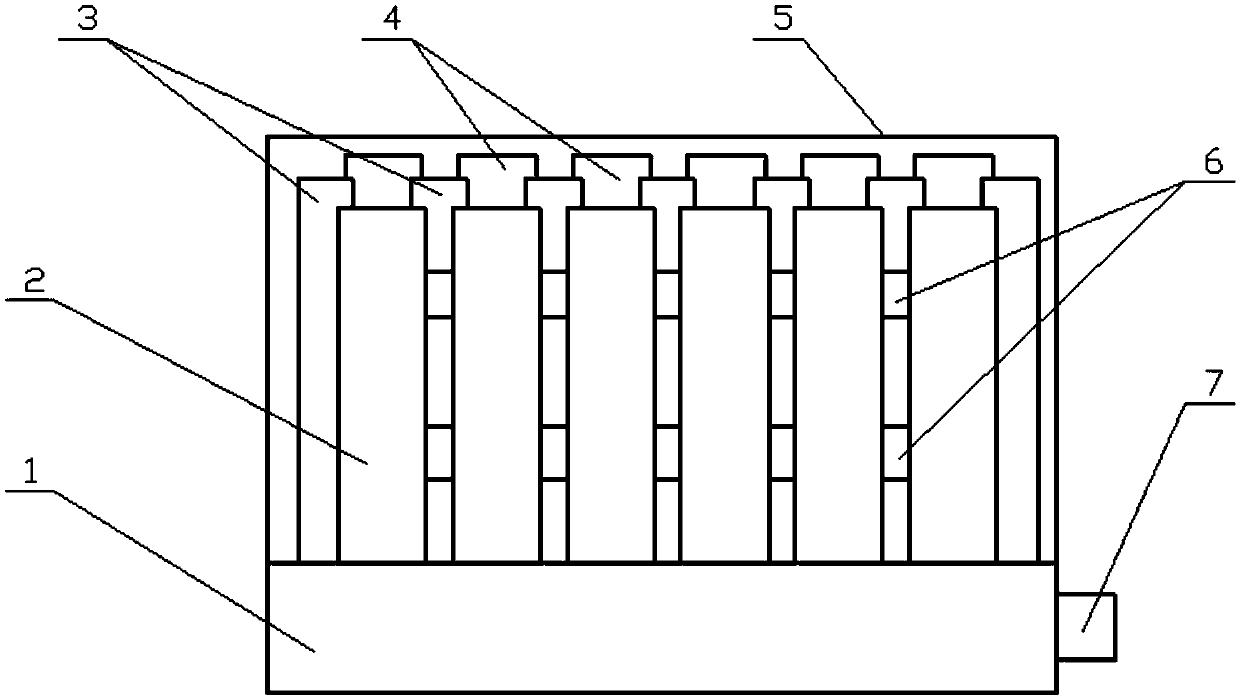

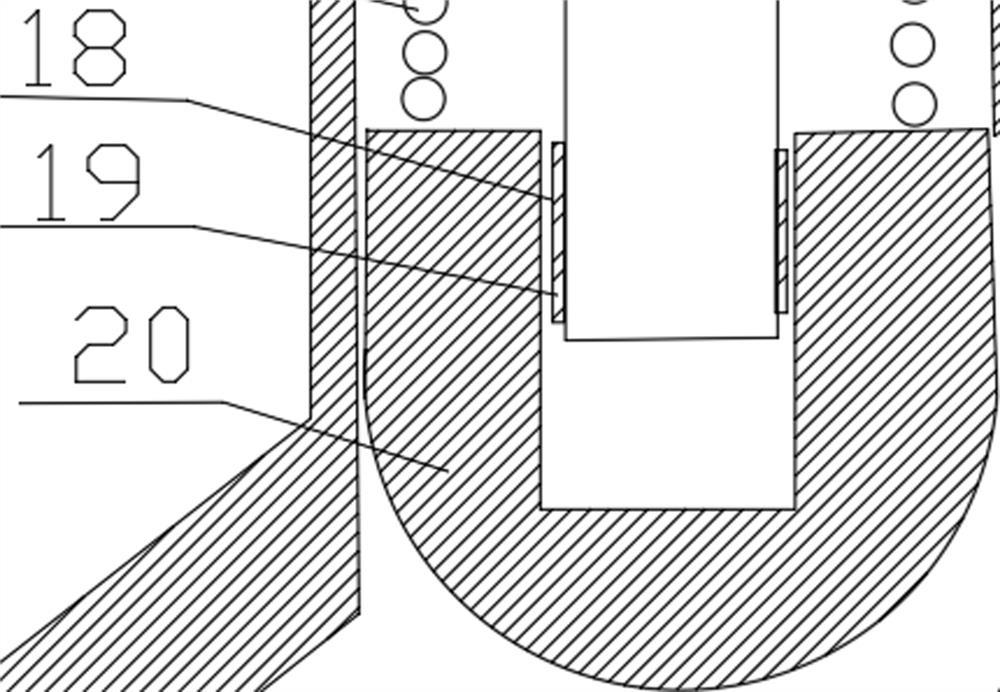

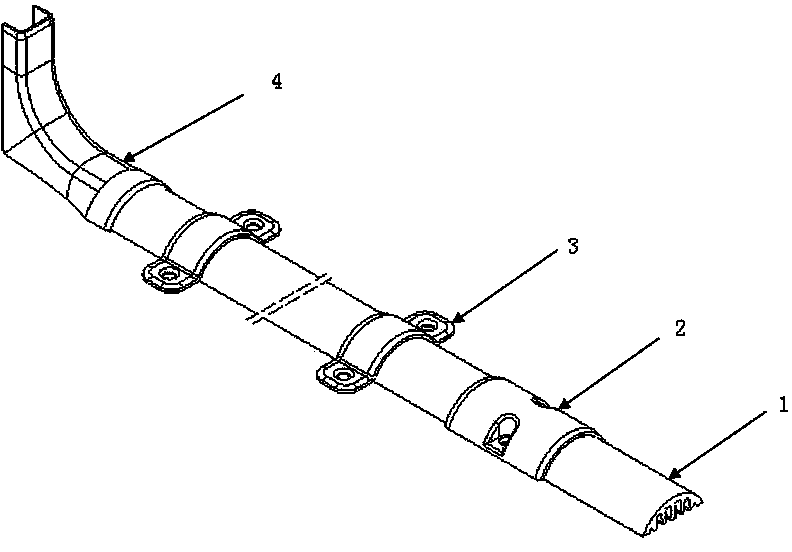

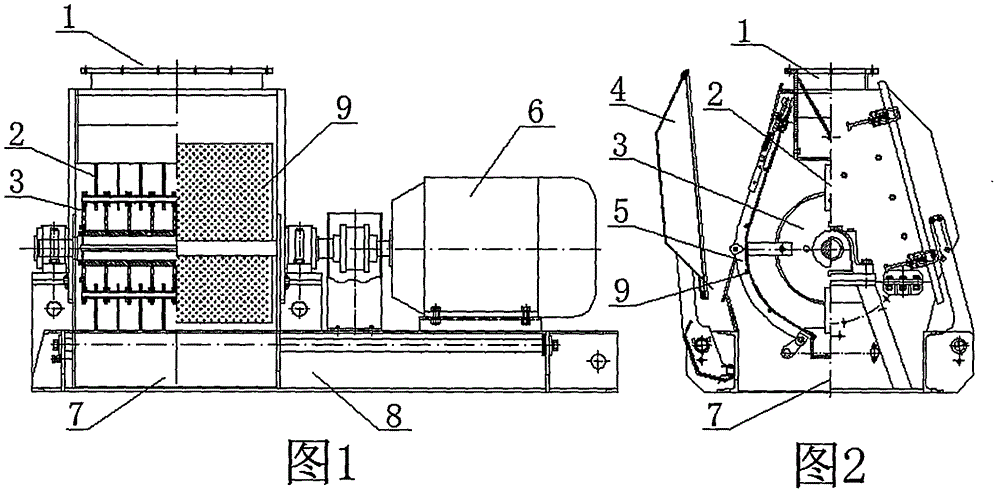

Mineral particle swirling flow pneumatic conveying system

InactiveCN106494891ASmooth and uniform speed and uniform entryLower energy requirementsBulk conveyorsMineral particlesMechanical engineering

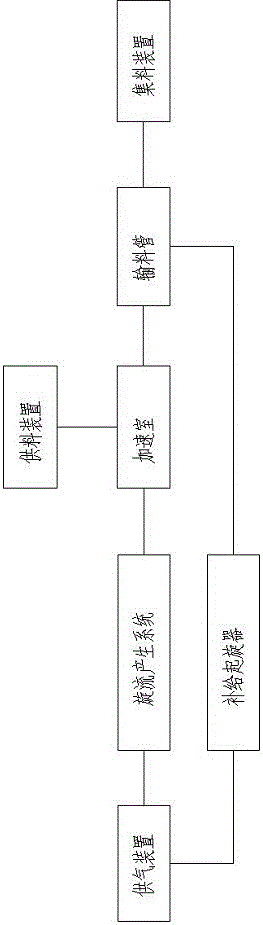

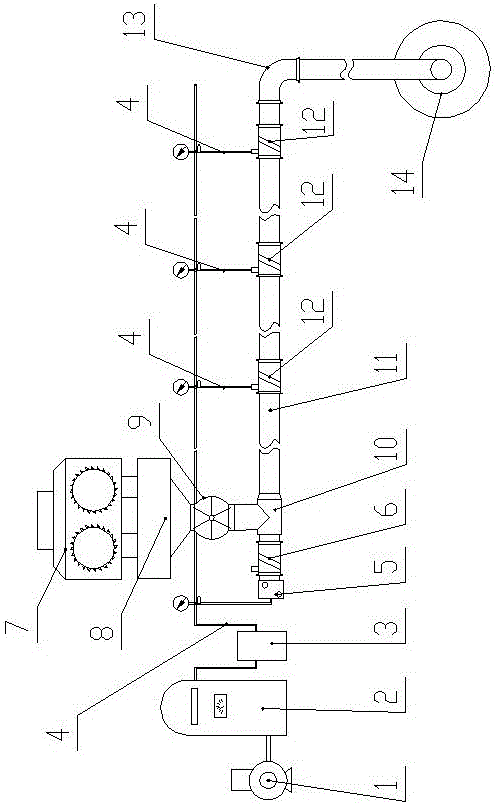

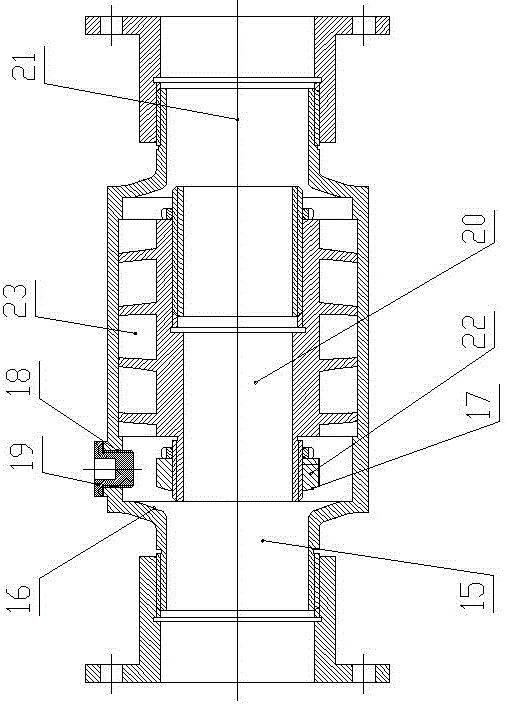

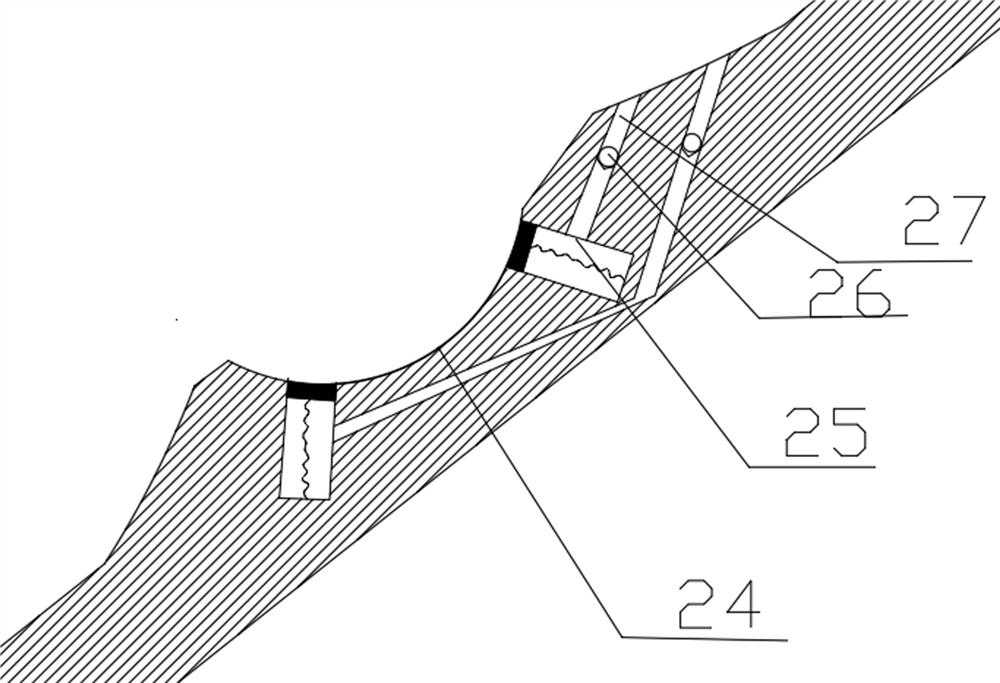

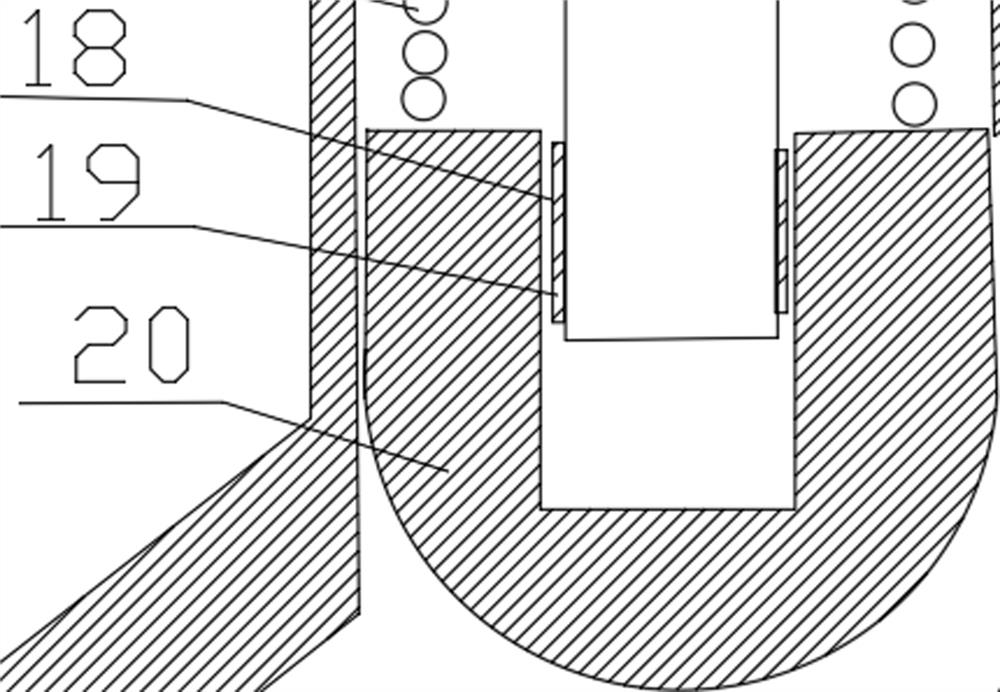

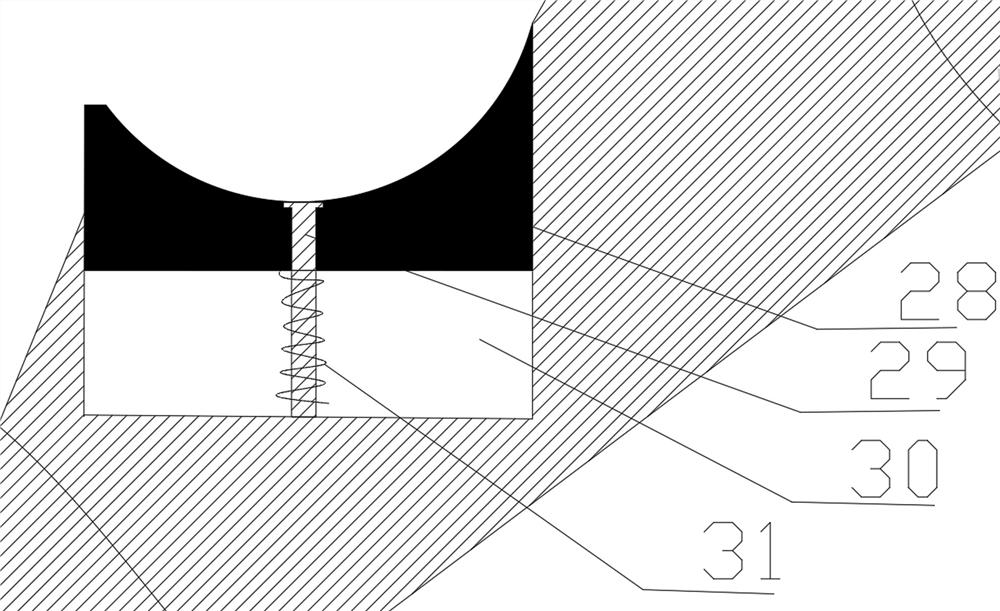

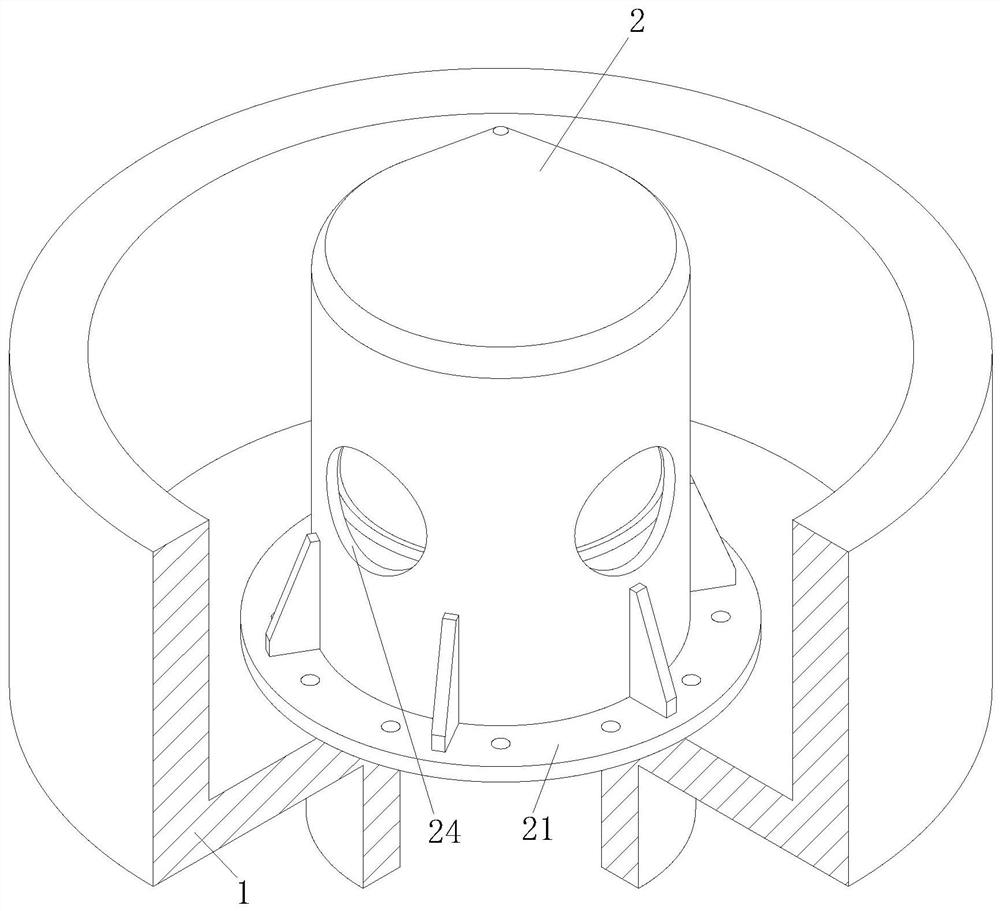

A mineral particle swirling flow pneumatic conveying system comprises an air supply device, a feeding device, air conveying pipes, a swirling flow generating system, replenishment swirlers, an accelerating chamber, a conveying pipe and a collecting device. An air outlet of the air supply device is connected with an air inlet of the swirling flow generating system and replenishment air inlets of the replenishment swirlers separately. An air outlet of the swirling flow generating system is connected with an air inlet of the accelerating chamber. A discharging outlet of the feeding device is connected with a feeding inlet of the accelerating chamber. An air and material outlet of the accelerating chamber is connected with an air and material inlet of the conveying pipe. A plurality of replenishment swirlers are evenly arranged at intervals on the conveying pipe in the direction of conveying. Each replenishment swirler is arranged in front of a corresponding section of bent pipe of the conveying pipe. An air and material outlet of the conveying pipe is connected with a feeding inlet of the collecting device. According to the mineral particle swirling flow pneumatic conveying system, the critical conveying speed of mineral particles is reduced, particle deposition and pipeline clogging are relieved, bent pipe abrasion and particle damaging are mitigated, the service life of conveying pipelines is prolonged, and the safe and efficient long-distance delivery of the mineral particles in the pipelines is achieved.

Owner:HENAN POLYTECHNIC UNIV

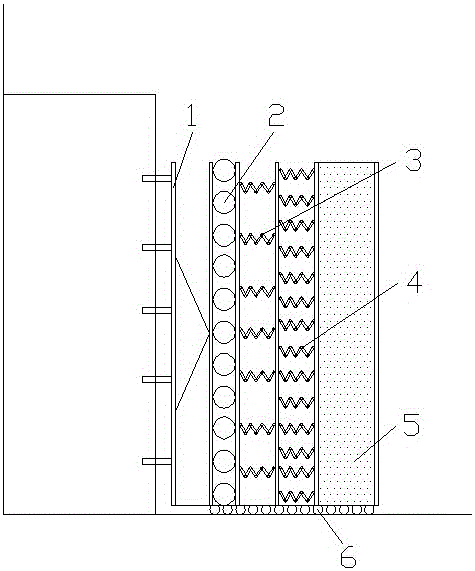

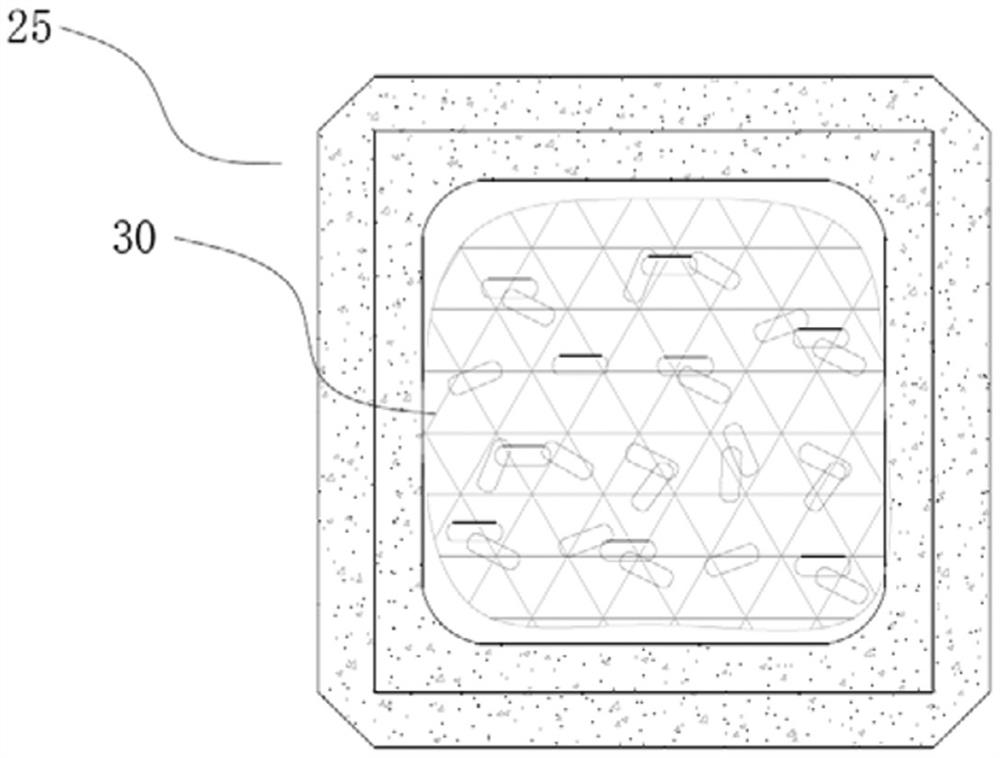

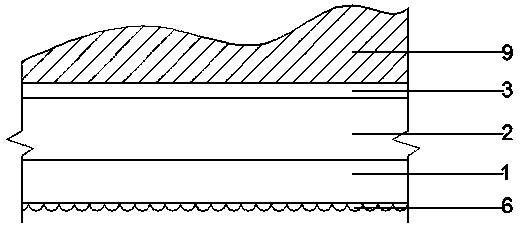

Pier anti-collision module

PendingCN106192820AReduce casualtiesReduce lossesRoadway safety arrangementsEngineeringVehicle safety

The invention belongs to pier protective devices and particularly relates to a pier anti-collision module. The purposes of pier protection and guarantee of vehicle safety are achieved. The pier anti-collision module comprises a fixed plate, a flow bead layer, a thick spring layer, a dense spring layer and a flexible glue pier layer. The inner side of the fixed plate is flexibly connected with a pier, the flow bead layer is arranged on the outer side of the fixed plate, the thick spring layer is arranged on the outer side of the flow bead layer, the dense spring layer is arranged on the outer side of the thick spring layer, the flexible glue pier layer is arranged on the outer side of the dense spring layer, a module body is formed by the fixed plate, the flow bead layer, the thick spring layer, the dense spring layer and the flexible glue pier layer jointly, and sliding balls are arranged at the bottom of the module body. Casualty accidents caused by pier impact can be effectively reduced, and losses, caused by impact accidents, of bridges and vehicles in accident can be relieved.

Owner:冯仓武

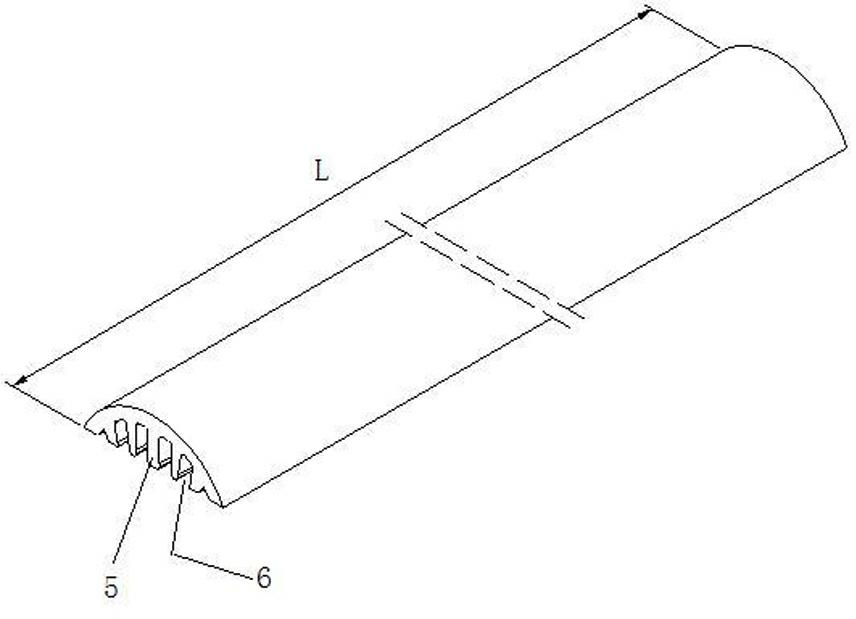

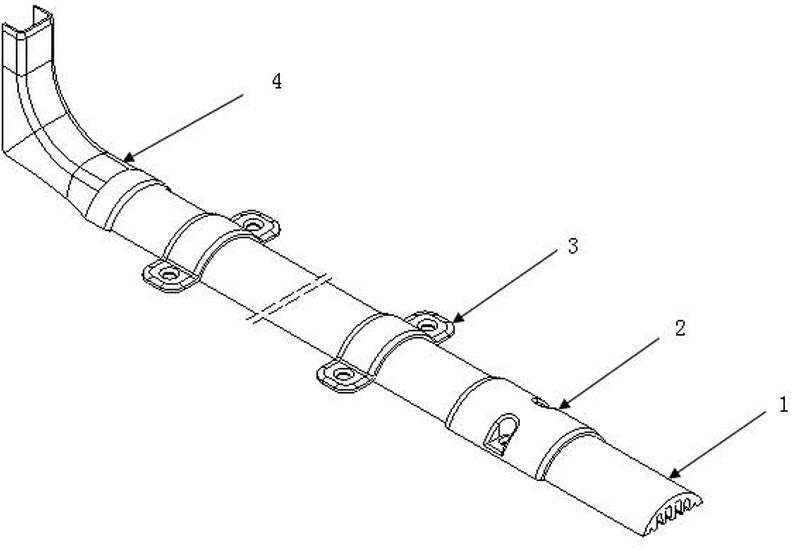

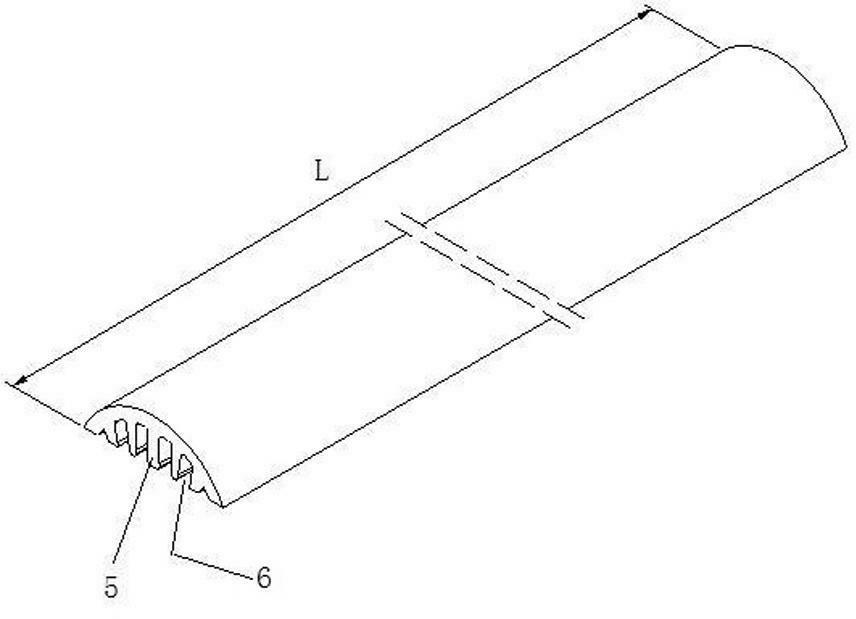

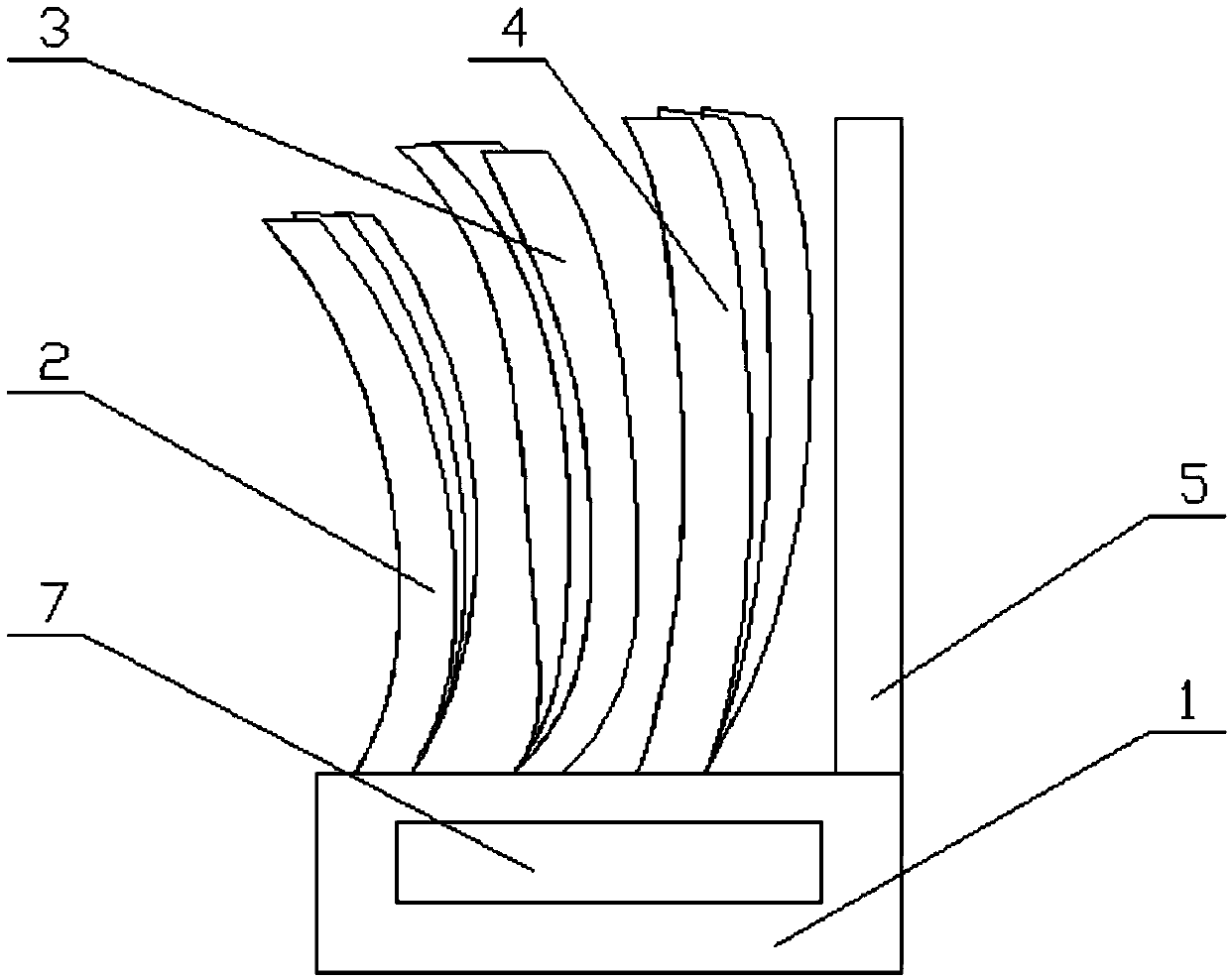

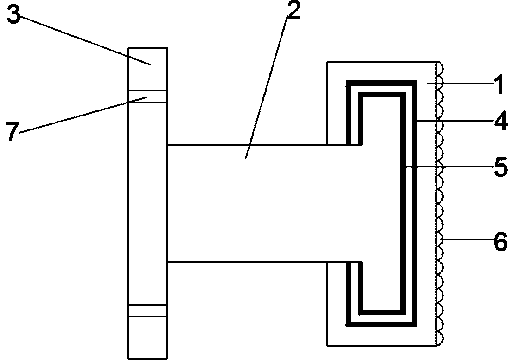

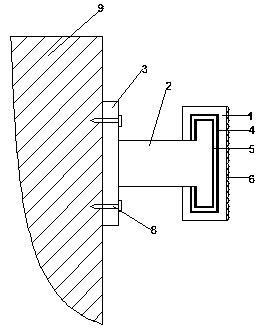

Ground cabling trough for bow-type optical cables

ActiveCN102565978AReduce kicking, bumpingReduce stepping, pressing and other damageOptical fibre/cable installationFiberEngineering

The invention belongs to optical cable cabling trough devices for communication network Fiber To The Home (FTTH) optical fiber comprehensive wiring. A ground cabling trough for bow-type optical cables comprises a trough body. Bow-type optical cable troughs are arranged in the trough body, the upper surface of the trough body is in a shape of a circular arc, protruding portions which are in a direction of the center of the circular arc are disposed in the trough body, and the height of the protruding portions are parallel and level to lower bottom surface of the cabling trough. The ground cabling trough coordinates with an inside corner of the cabling trough, the bow-type optical cables are led from a wall surface to a ground surface, the surface is designed in the arc structure, four bow-type optical cable troughs are arranged, the protruding portions are used for improving the strength and rigidity of the cabling trough, a cambered surface is combined with the ground surface, kicking and bumping of the ground cabling trough are avoided when users pass through, and the cabling trough can not be damaged and deformed when treaded, therefore the bow-type optical cables are effectively protected to smoothly pass through the ground surface under the condition of open wire distributing, a plurality of cabling troughs can be connected to the cabling trough through cabling trough joints, and the distance is not limited.

Owner:NANJING HUAMAI TECH

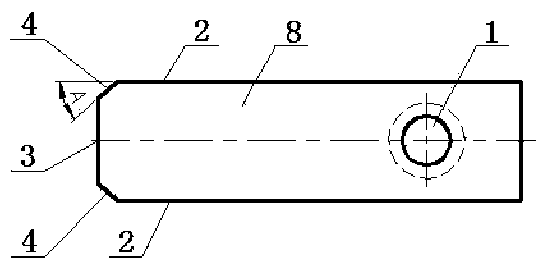

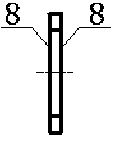

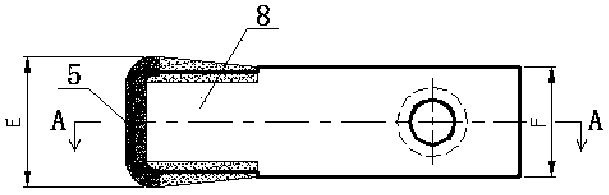

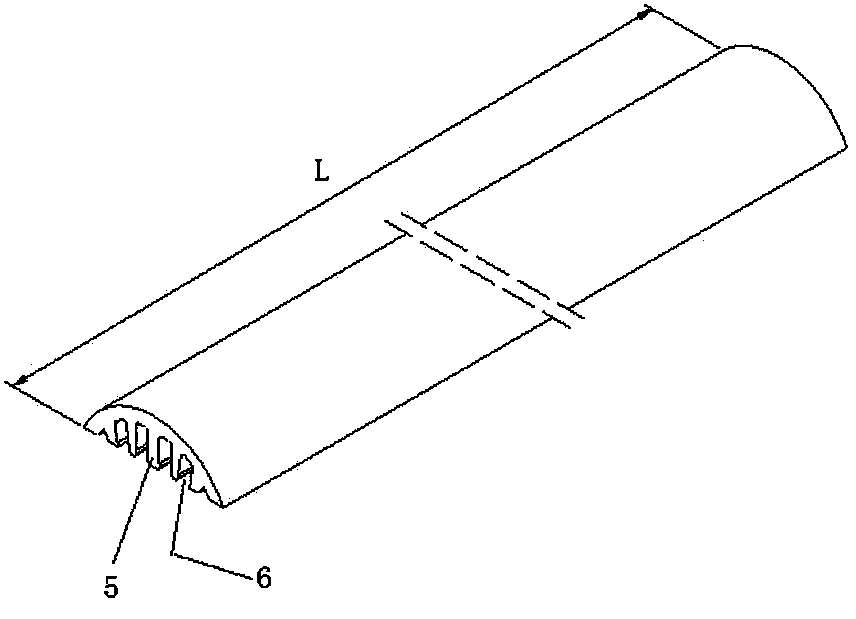

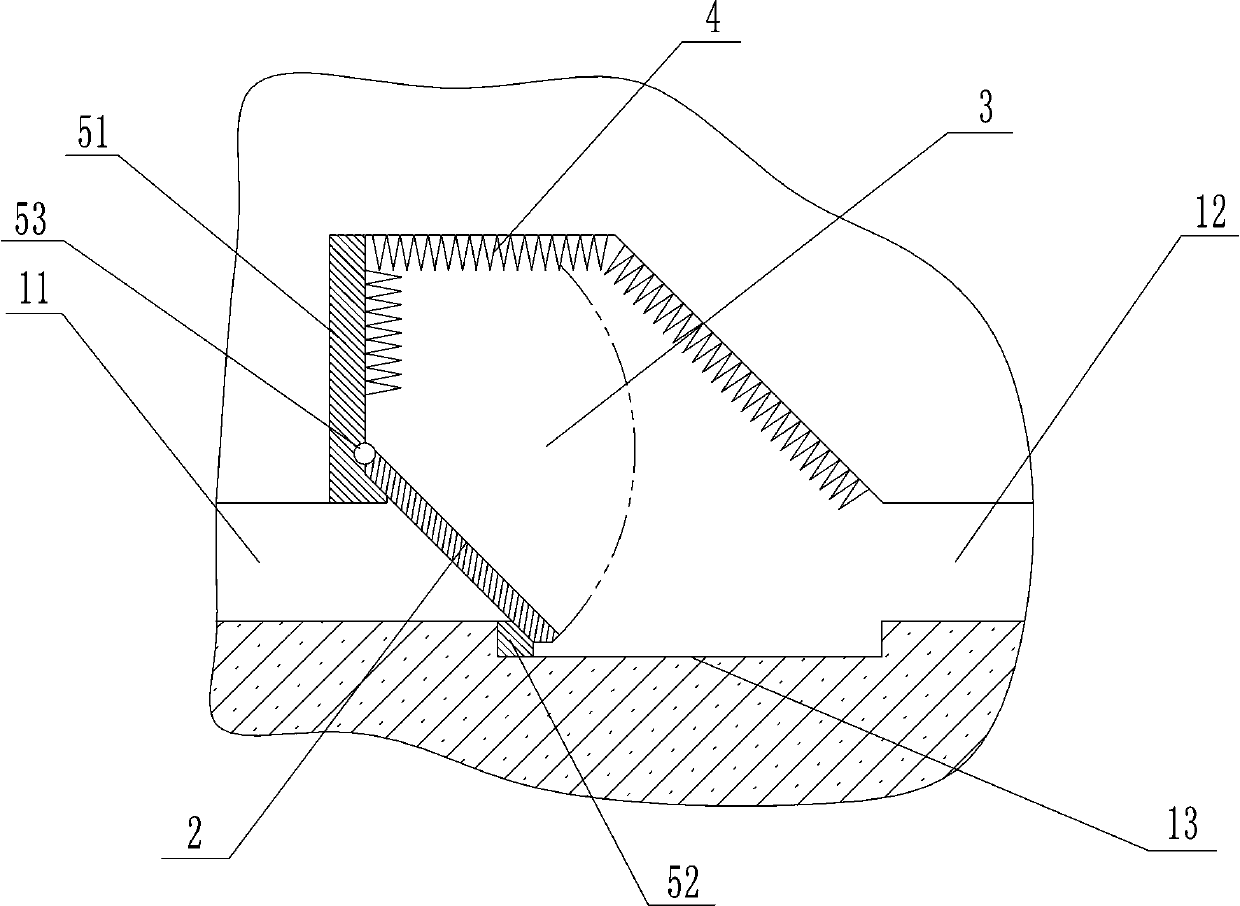

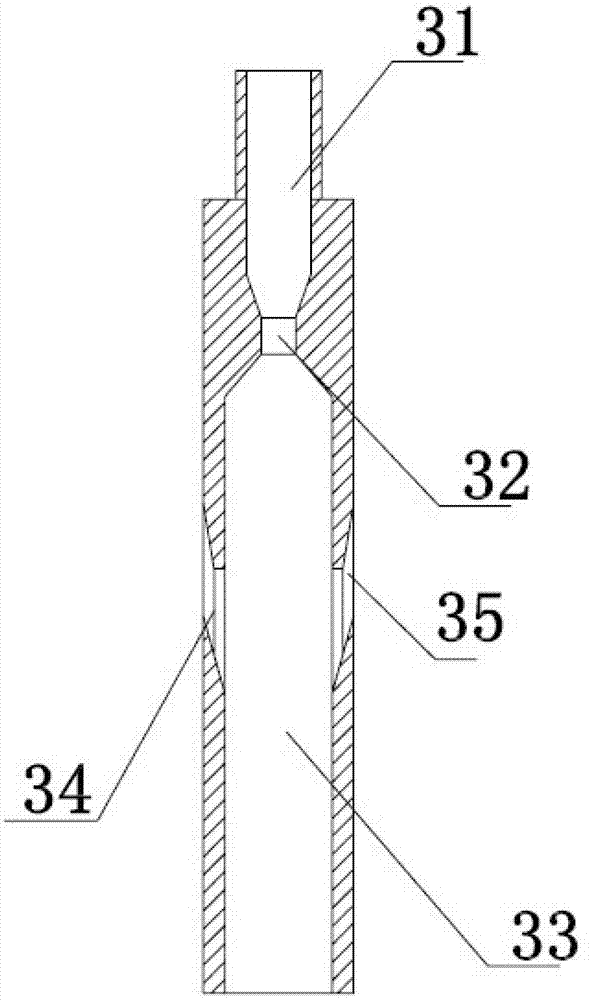

Hammer for pulverizer

PendingCN110314738AIncrease the surfacing contact areaIncrease thump speed differenceGrain treatmentsWear resistantAlloy

The invention aims to provide a hammer for a pulverizer. The hammer for the pulverizer can improve the crushing efficiency and prolong the service life. The hammer for the pulverizer is structurally characterized by comprising a sheet-shaped hammer parent body, one end of the hammer parent body is provided with a pin hole (1), wear-resistant materials are resurfacing welded on the two right-angledparts of the other working end of the hammer parent body, namely, a side end surface (2) and a front end surface (3), and the wear-resistant materials are made of tungsten carbide alloy. The hammer for the pulverizer is characterized in that at two right-angled positions of the other working end of the hammer body parent body, straight angles are symmetrically removed, so that an inclined pushingend surface (4) is machined, the inclined pushing end surface (4) is connected with the front end surface (3) and the side end surface (2), the wear-resistant materials are resurfacing welded to forma fan-shaped end surface (5), and the fan-shaped end surface (5) is connected and resurfacing welded to an upper and lower plane (8) adjacent to the fan-shaped end surface (8) to form a ball head (6), so that the cutaway view of the side surface of the hammer is provided with a matchstick with the ball head.

Owner:上海春谷机械制造有限公司

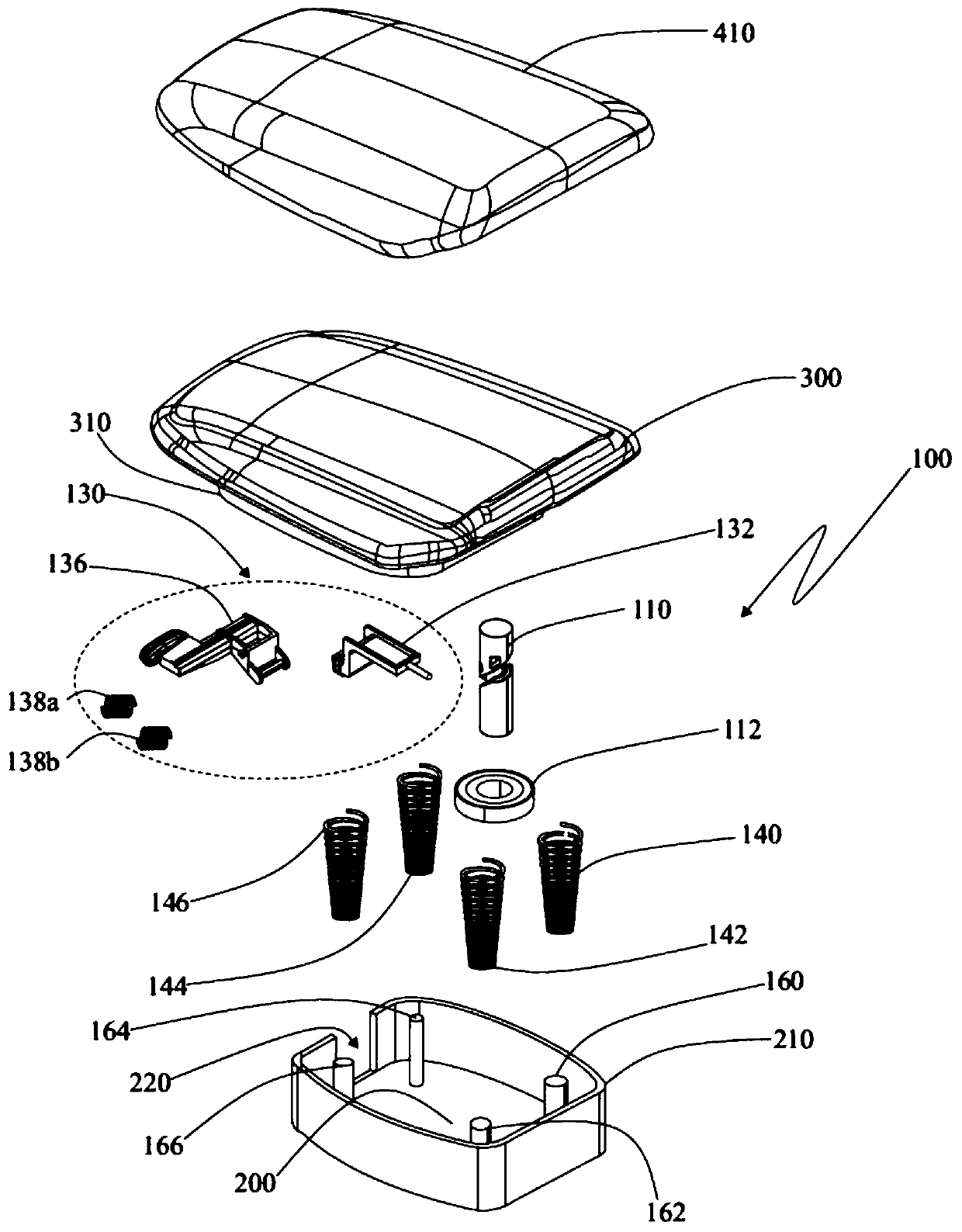

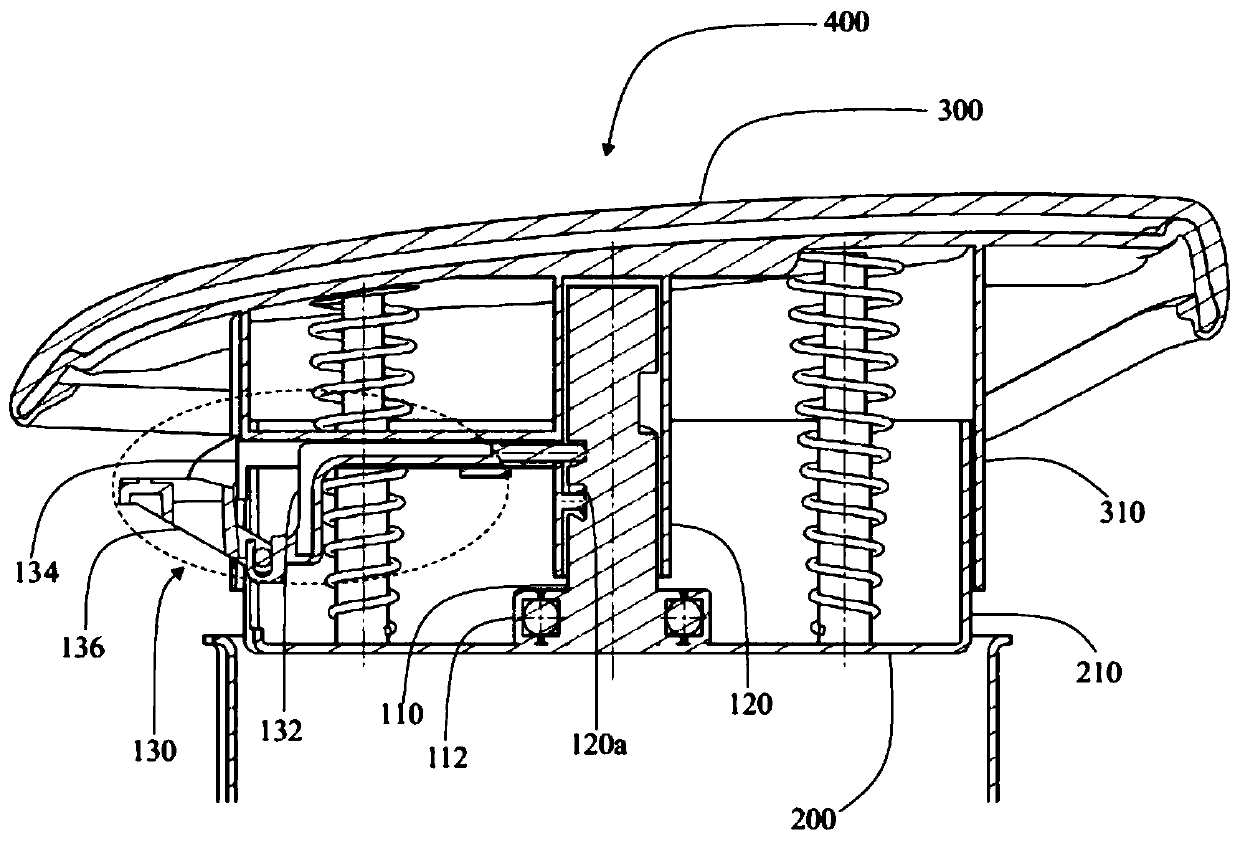

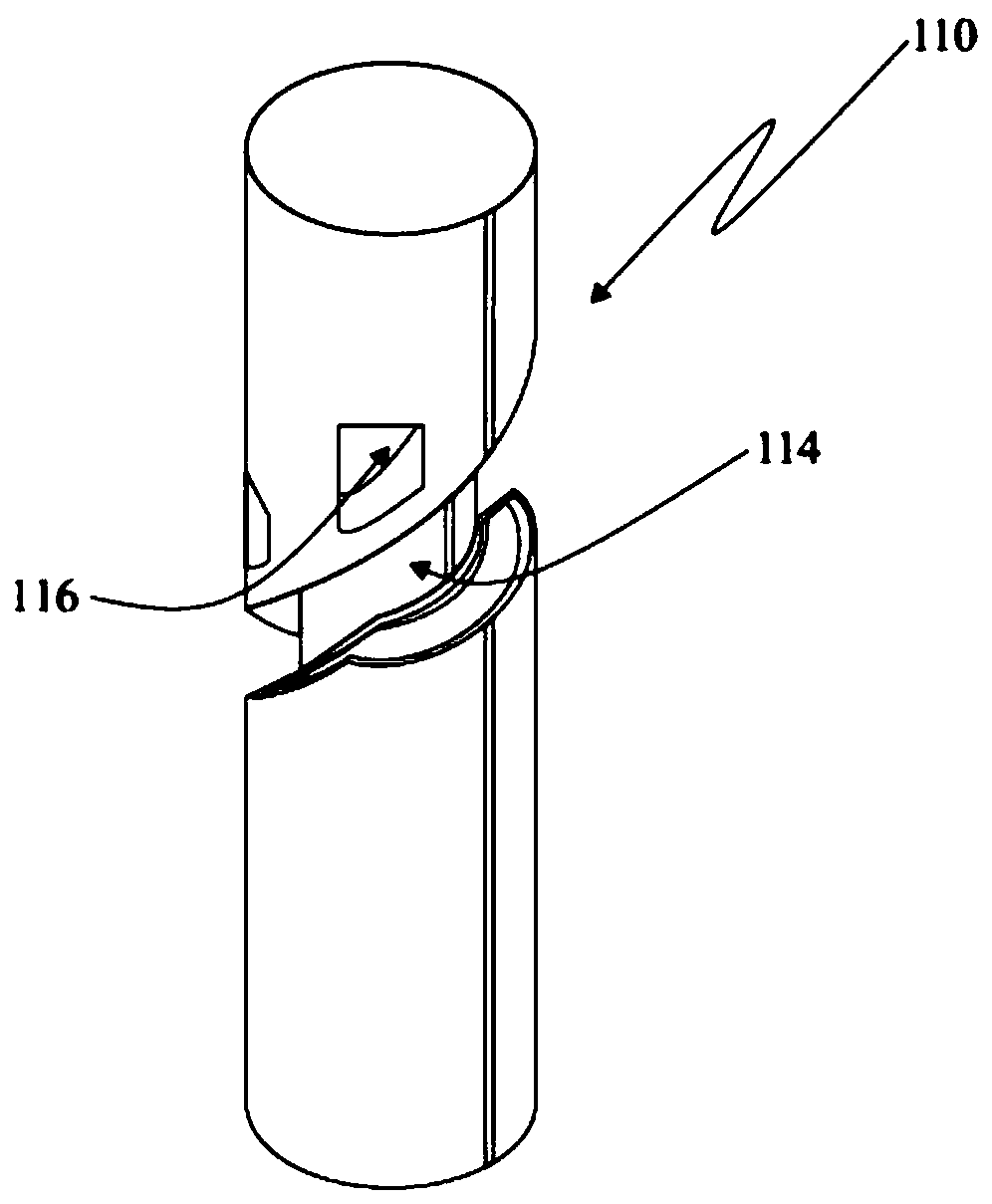

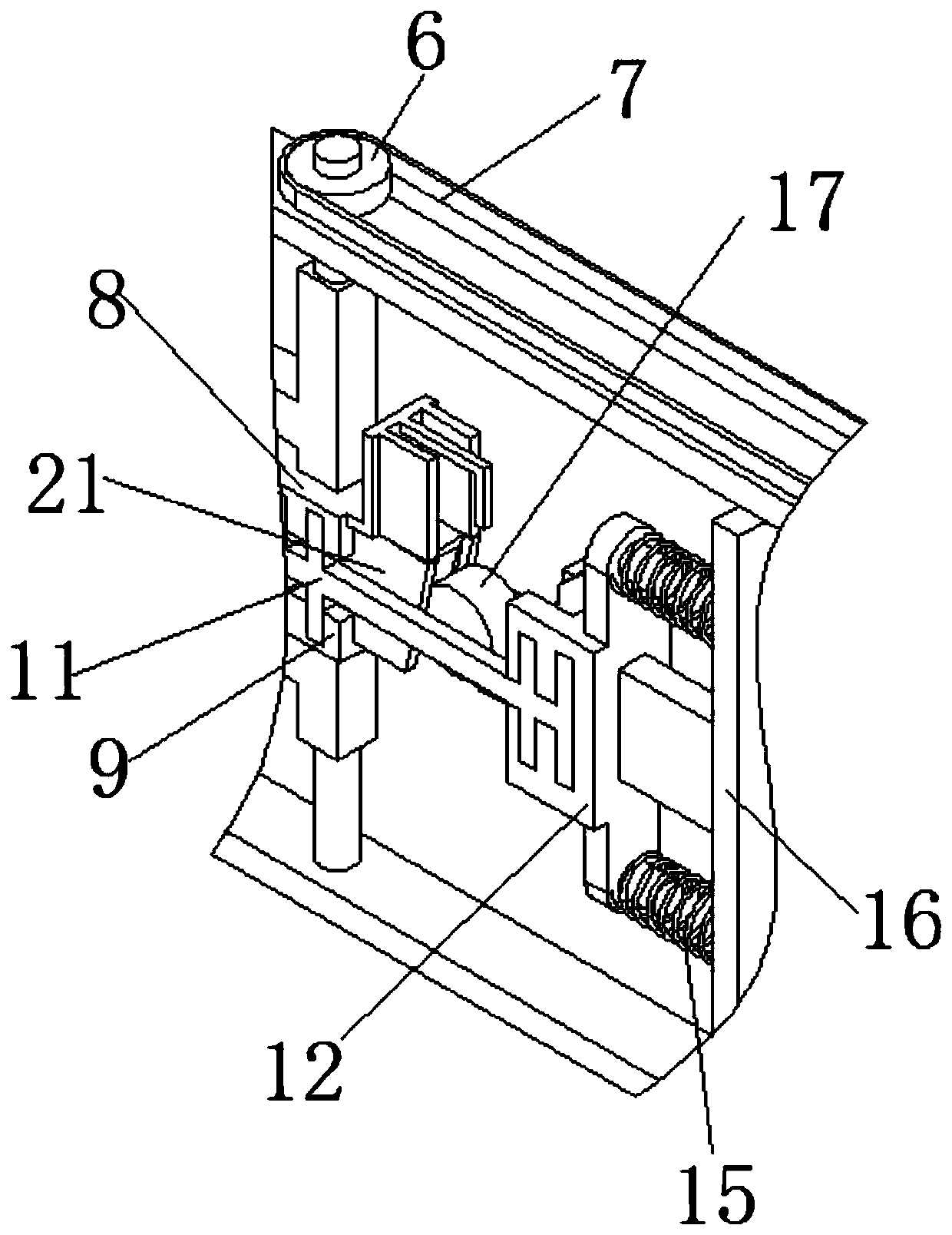

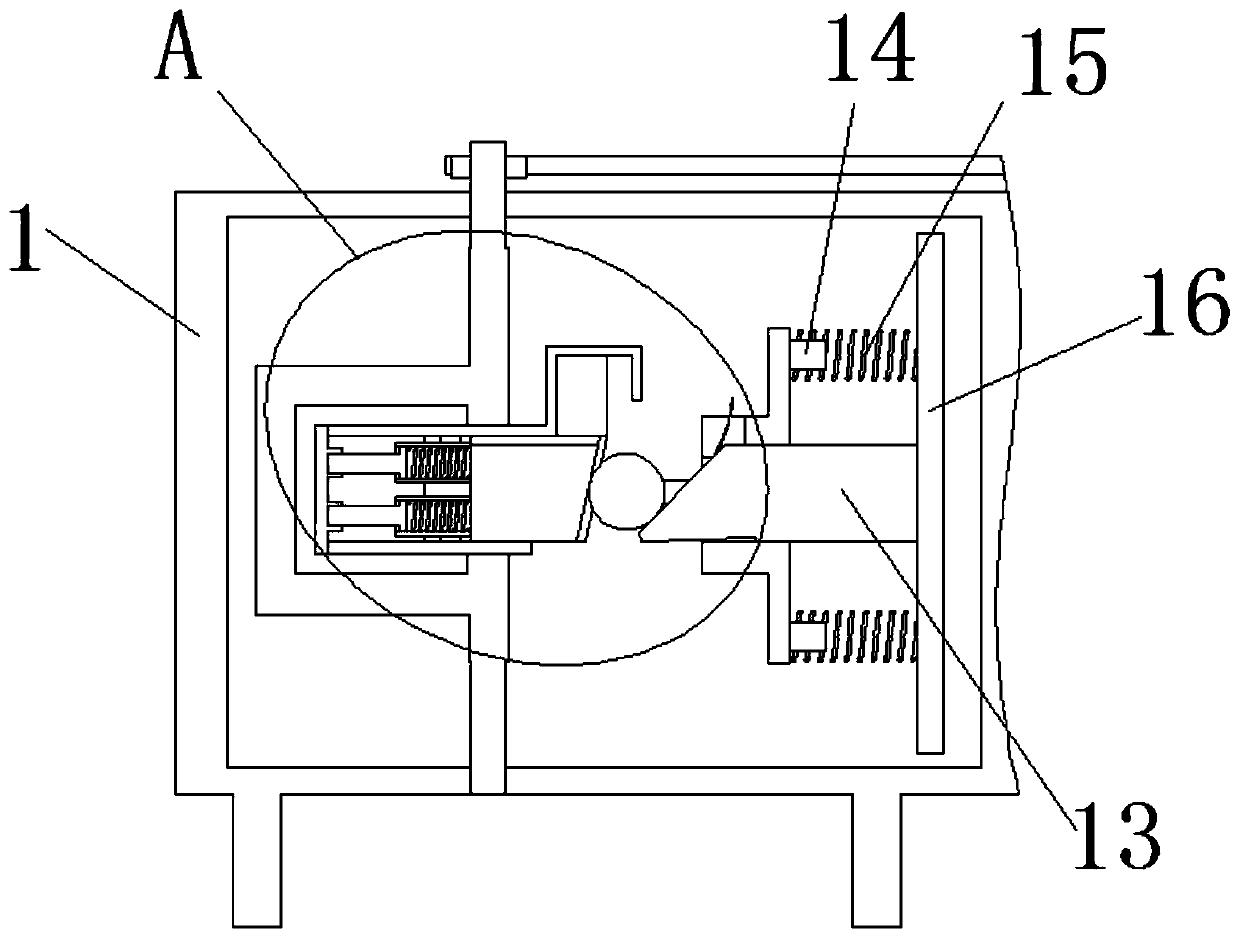

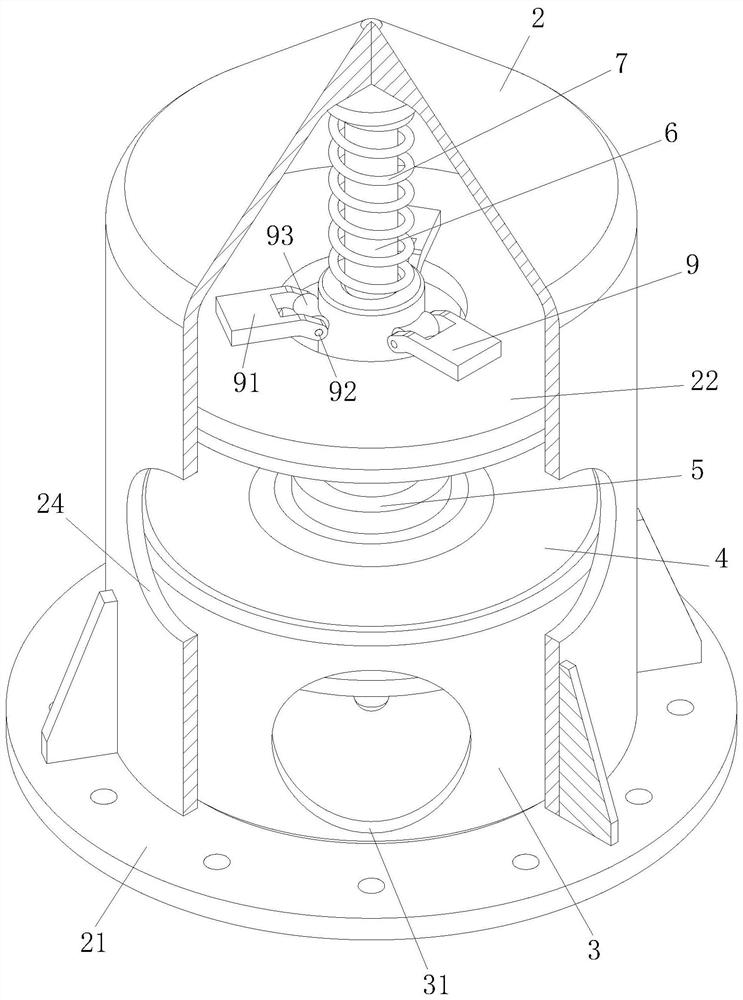

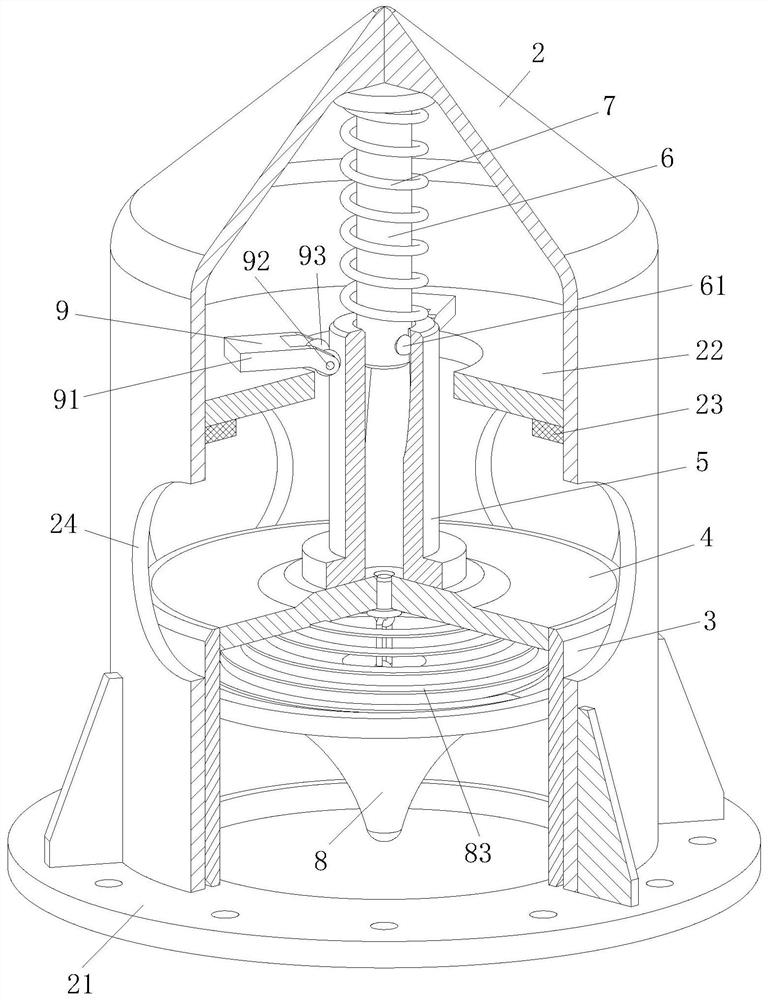

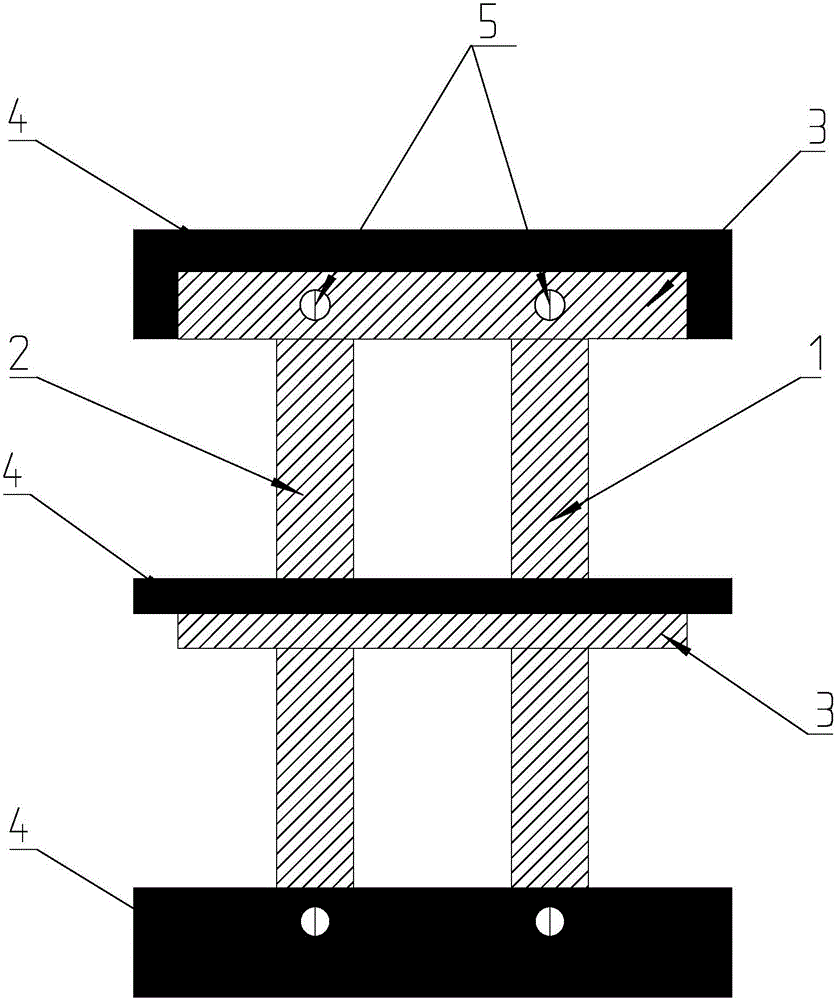

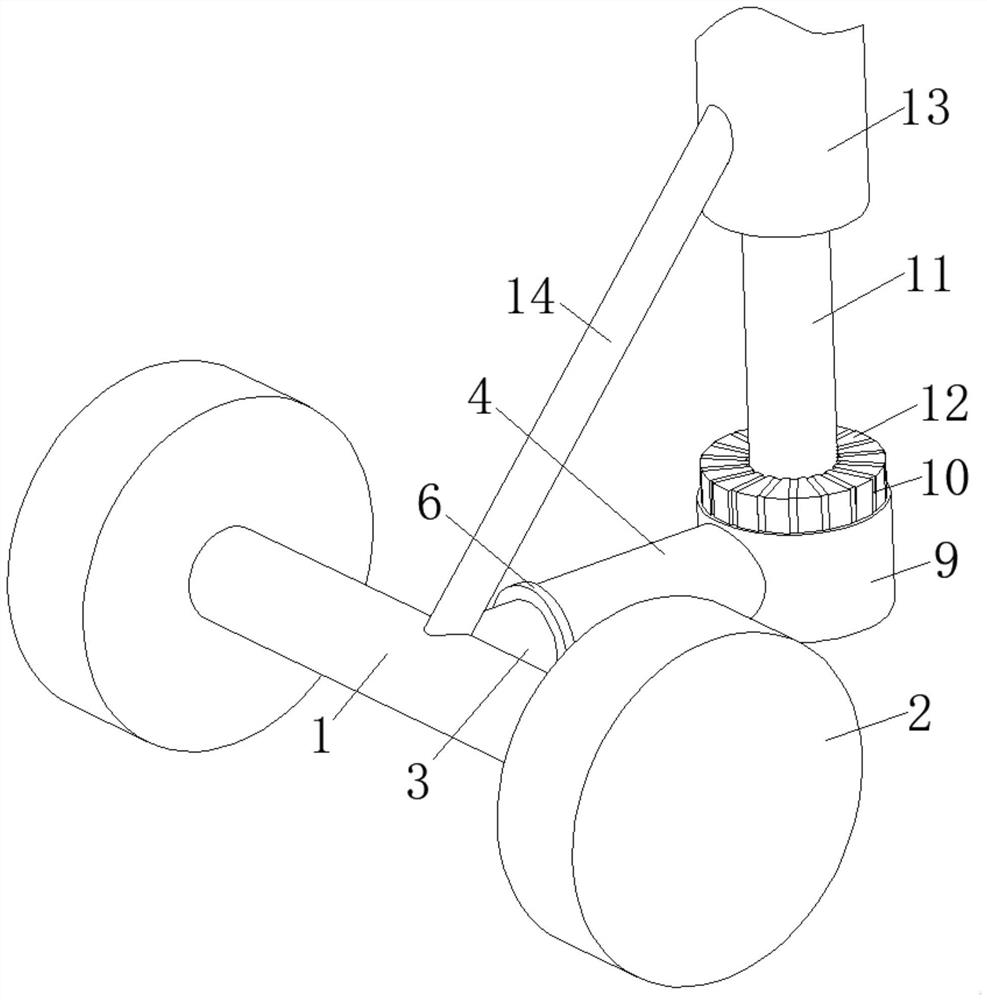

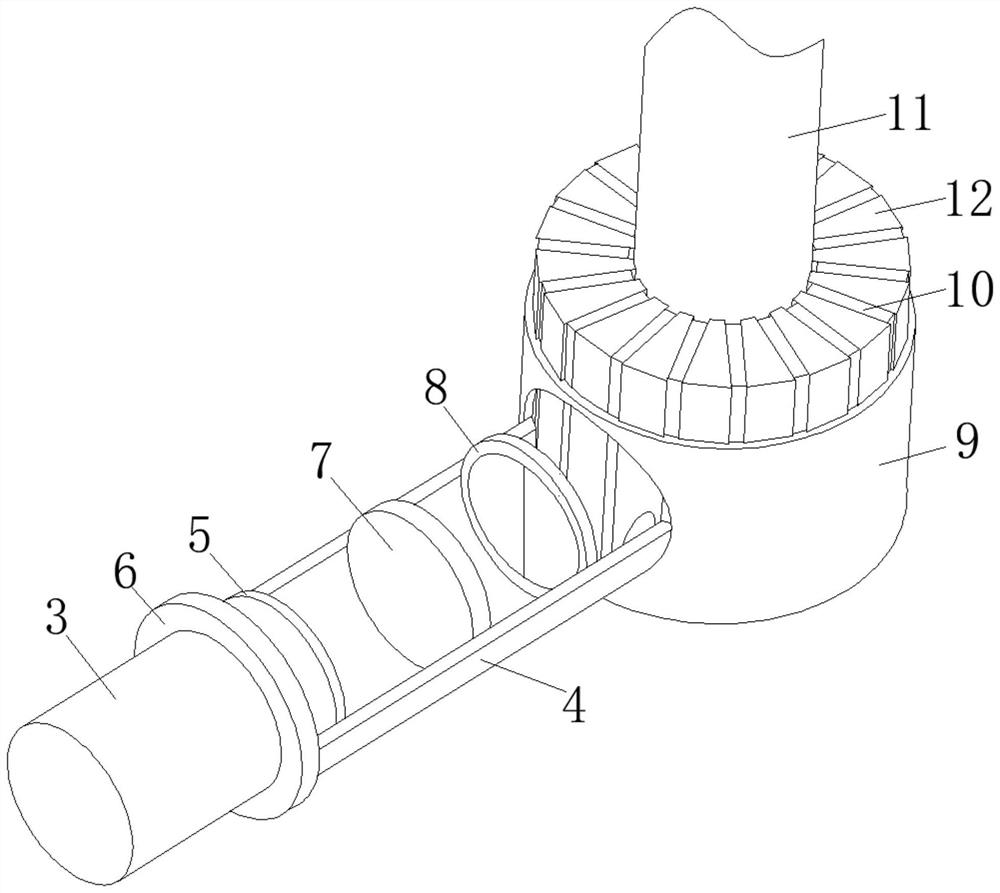

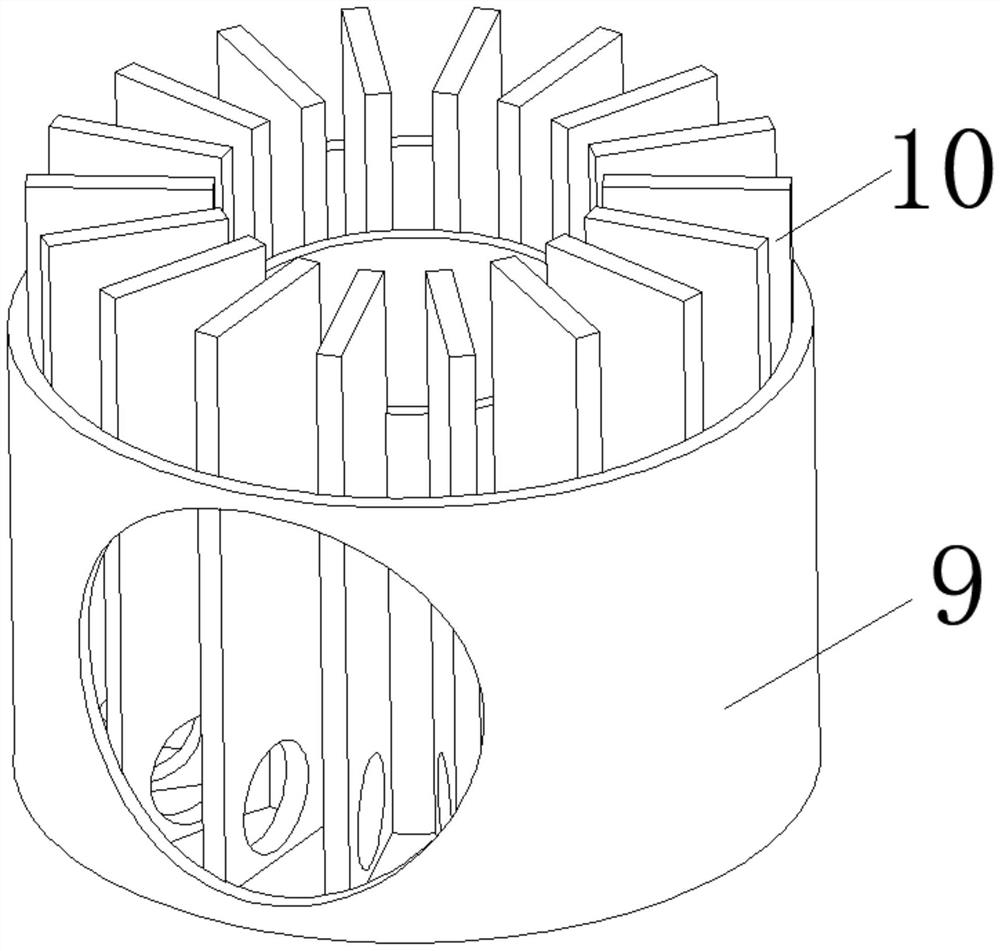

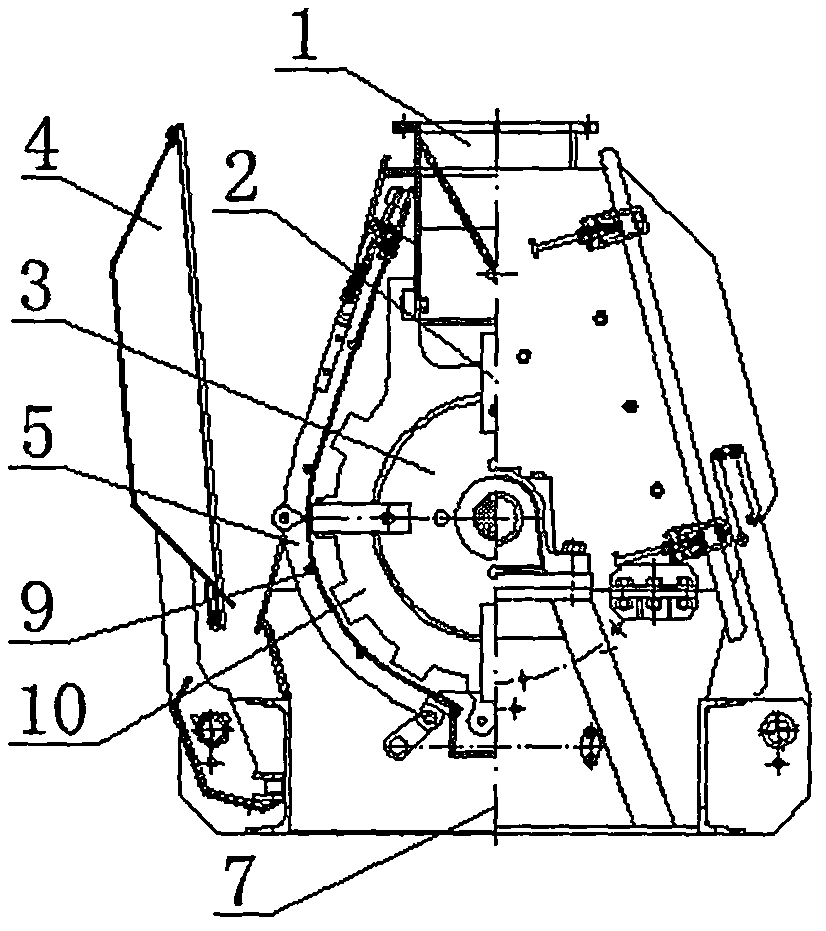

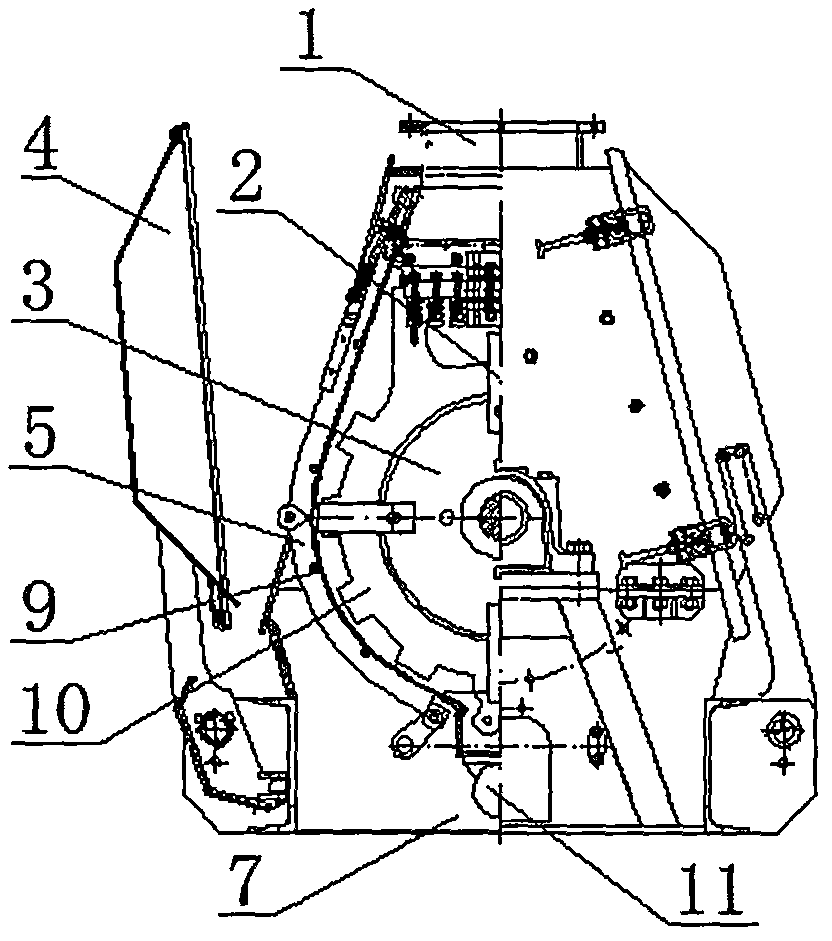

A mechanical device for adjusting distance between two elements

ActiveCN110290974AReduce frontal impactHeight adjustableArm restsMovable seatsMechanical engineering

A mechanical device for adjusting a distance between two elements. The present invention provides a mechanical device for adjusting a distance between a first element and a second element. The first element is a support and the second element is an arm support of an armrest. The mechanical device comprises a rotating member, an engaging member, a locking arrangement and an operating member. The rotating member with a helical guide with plurality of locking slots is rotatably arranged on the first element. Further, the engaging member engages with the helical guide and moves upon rotating the rotating member along the helical guide for moving the second element. The locking arrangement engages with a slot for latching with the rotating member for restricting movement of the second element. The at least one biasing member is arranged between the first element and the second element. The at least one biasing member moves the second element upon unlatching the locking arrangement from the slot.

Owner:FAURECIA INDIA PTE LTD

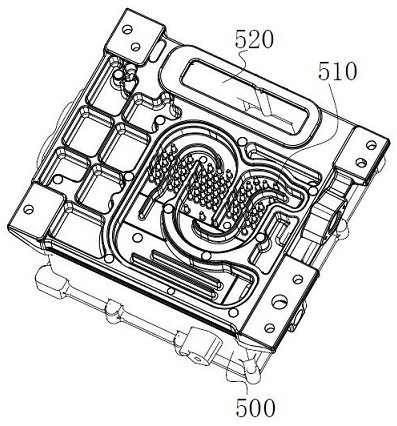

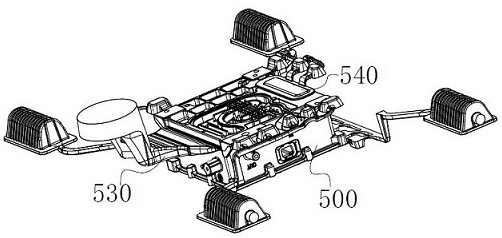

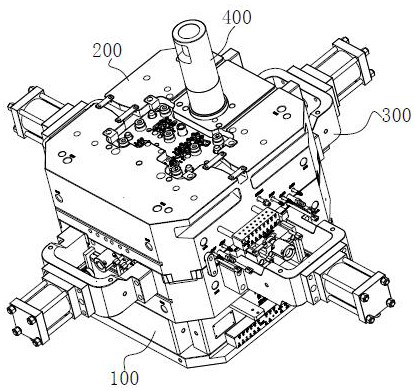

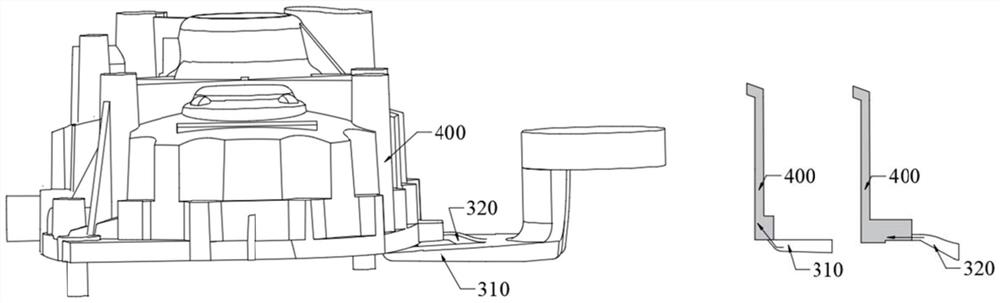

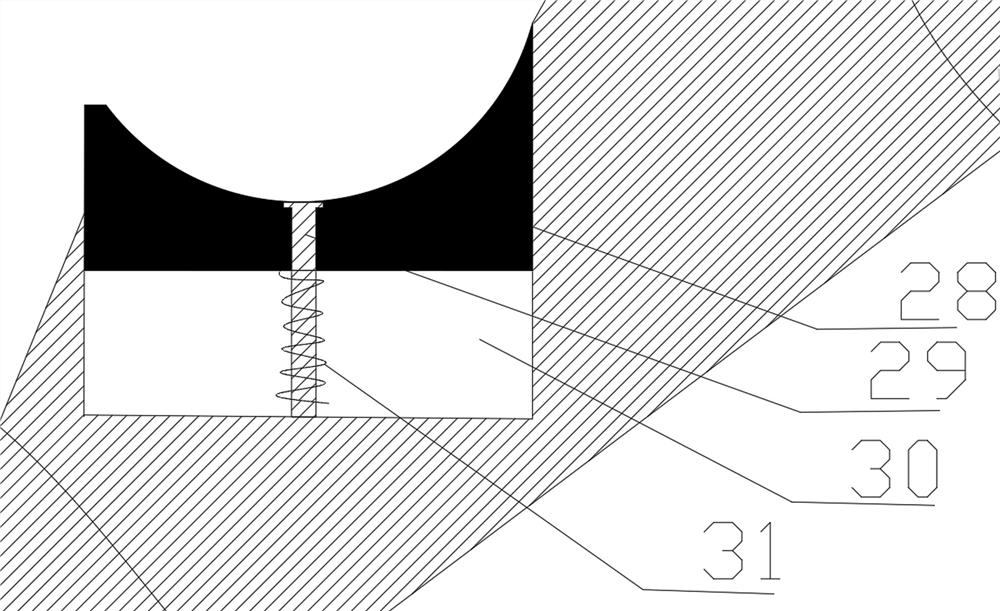

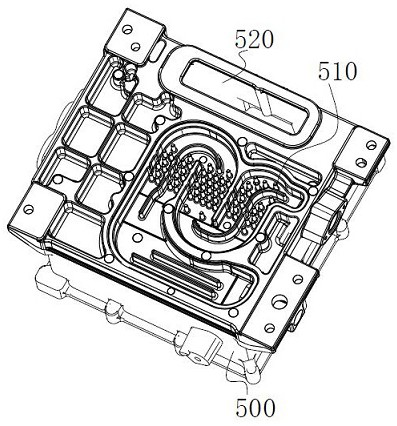

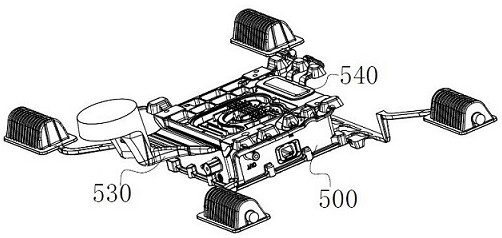

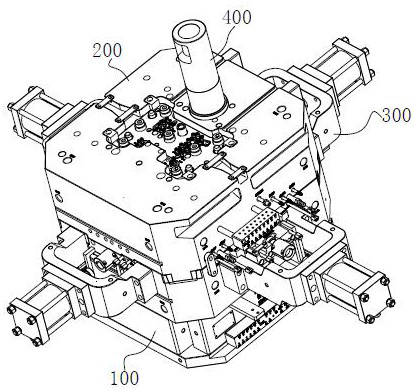

Die-casting die for producing shell and production method of shell

The invention relates to the technical field of die-casting dies, and provides a die-casting die for producing a shell and a shell production method.The die-casting die comprises a movable die assembly, a fixed die assembly and a sliding block mechanism, and a product cavity is formed among the movable die assembly, the fixed die assembly and the sliding block mechanism; the runner assembly is provided with a feeding sleeve and a sprue spreader arranged on the movable mold assembly, a feeding runner communicated with the product cavity is formed between the upper surface of the sprue spreader and the lower surface of the fixed mold assembly, the feeding sleeve is communicated with the feeding runner, and the thickness of the feeding runner in the direction from the sprue spreader to the product cavity is gradually reduced. And the joint of the feeding runner and the product cavity is linear. Compared with the prior art, the die-casting mold has the advantages that the joint of the feeding runner and the product cavity is arranged to be linear, so that the feeding speed of the shell and the speed of discharging gas out of the product cavity are increased, and the die-casting defects of material shortage, air holes, fluffy structure and the like of a plurality of positioning columns arranged on the shell are prevented.

Owner:NINGBO HUASHUO MOLDING & MACHINE

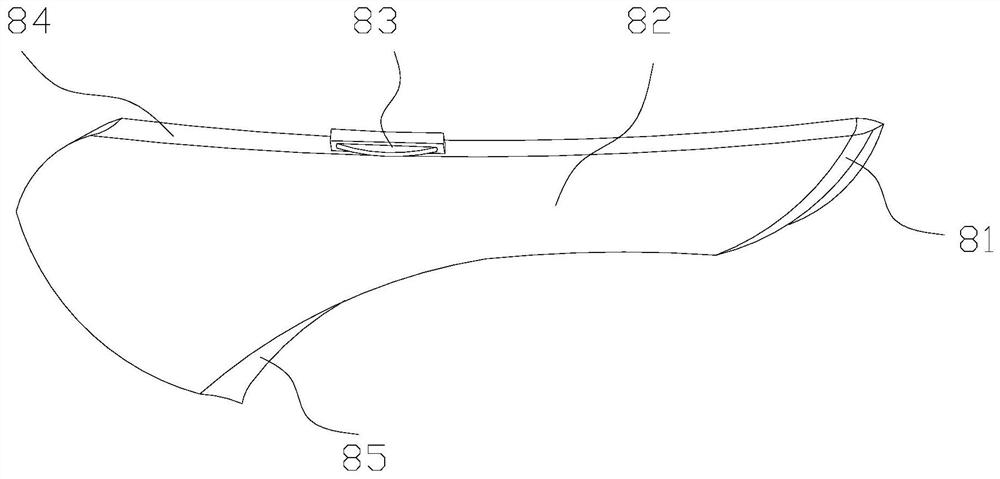

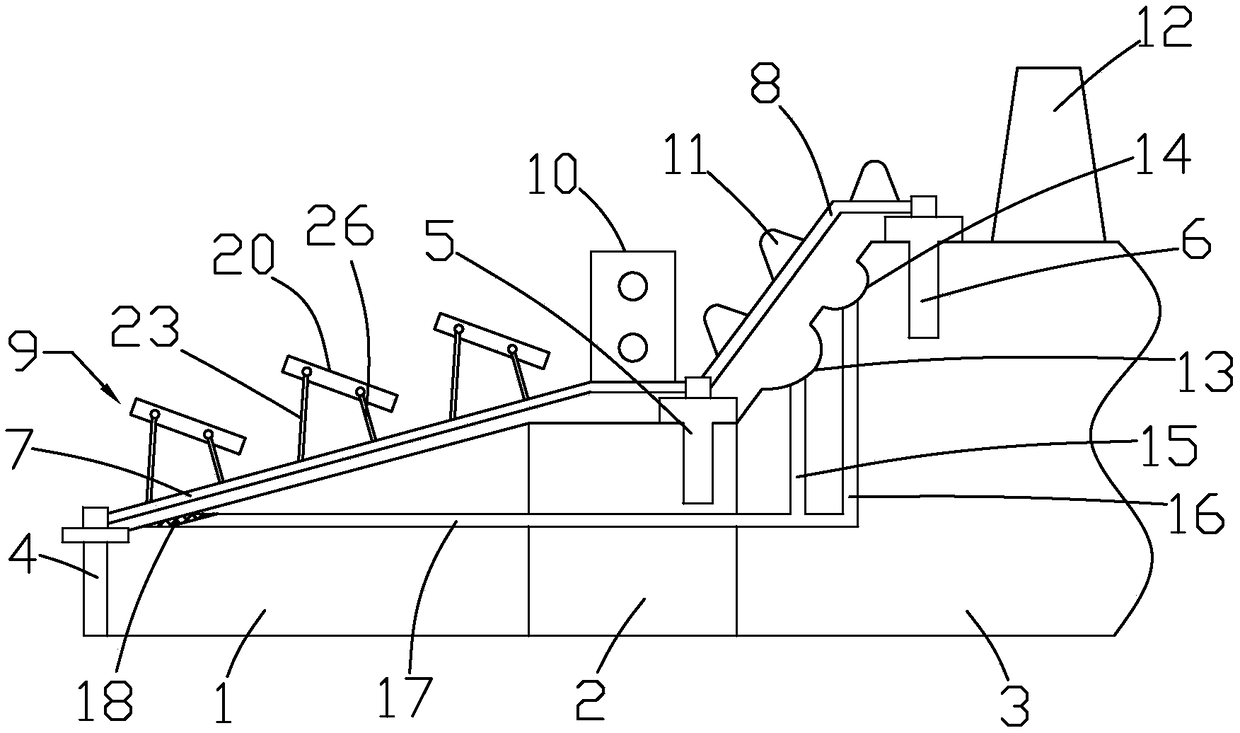

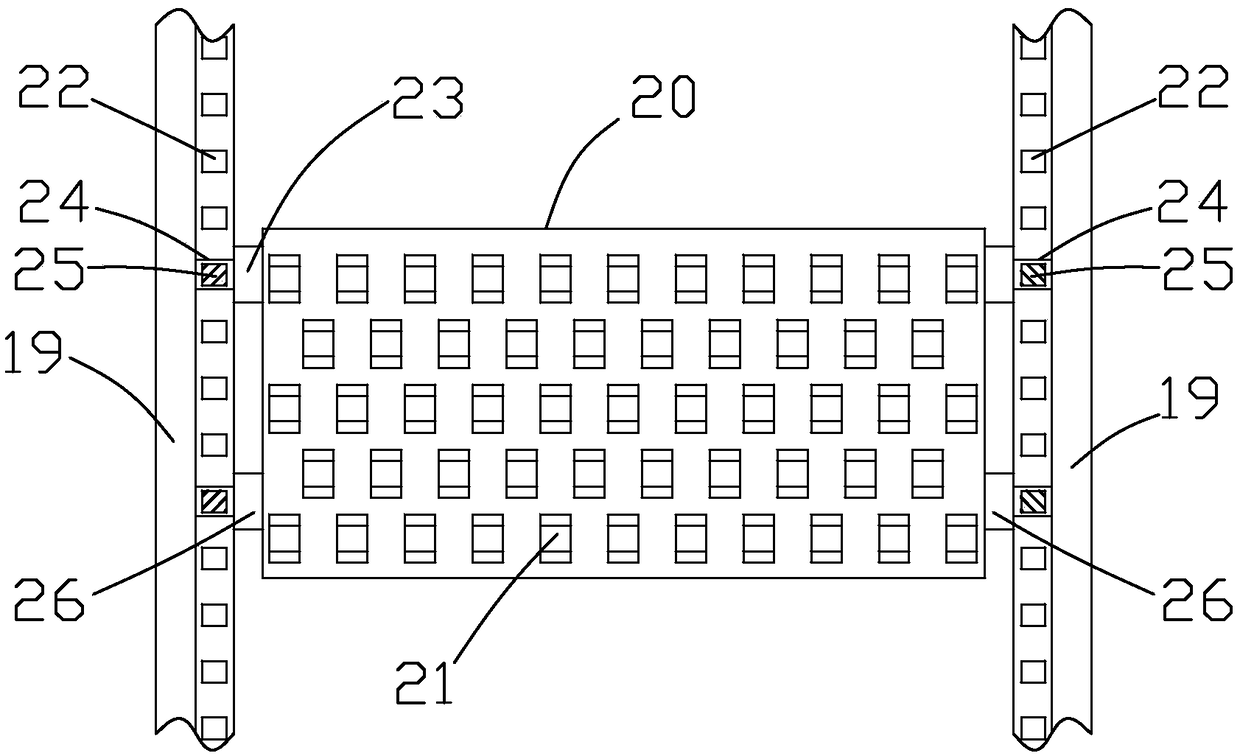

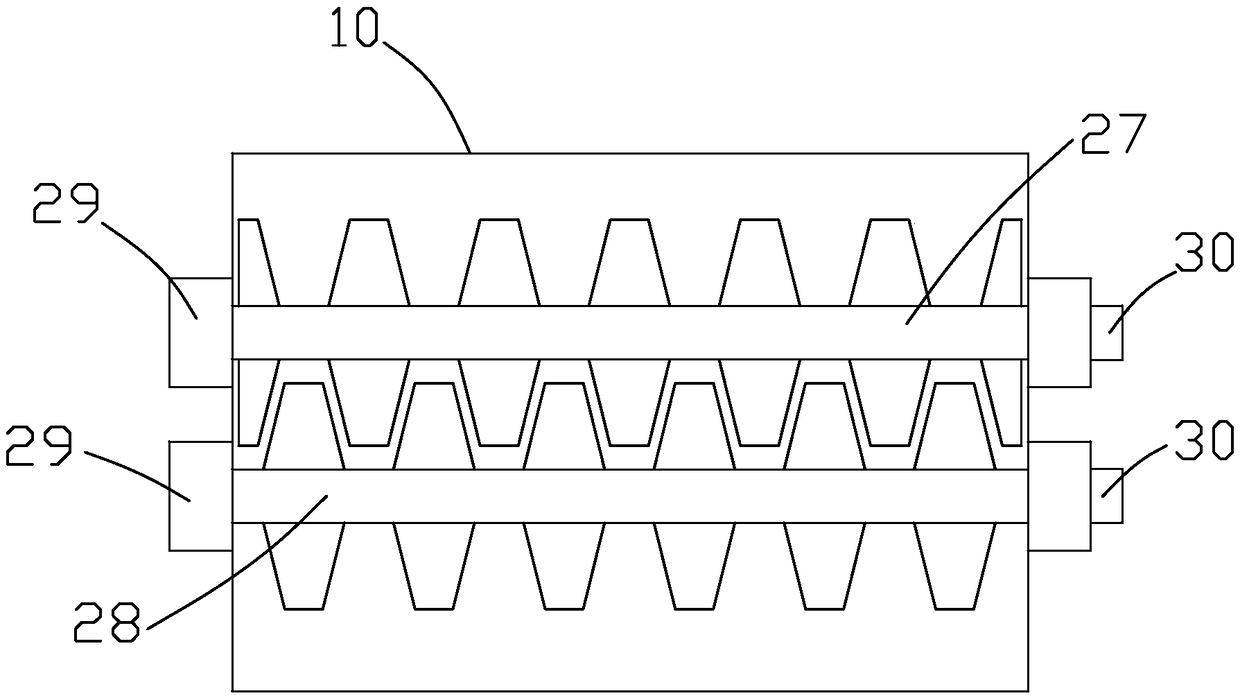

Ship cab with anti-shock front window

InactiveCN108100164ANo influx problemsReduce frontal impactVessel superstructuresVessel mastsRubber ringEngineering

The invention discloses a ship cab with an anti-shock front window. The ship cab comprises a shell, front side glass, rear side glass and a rectangular frame. The front side of the shell is provided with a rectangular window and installation screws. A rectangular installation frame is arranged on the periphery of the rear side glass and fixed to the front side of the rectangular window. A rectangular glass frame is installed on the periphery of the front side glass. An elastic rubber frame is arranged on the periphery of the rectangular glass frame. A rubber ring clamping base is arranged on the front side of the rectangular glass frame. A sealing rubber strip is installed on the rubber ring clamping base. Guide holes are formed in the rear side face of the rectangular glass frame at intervals. The ends of the installation screws are inserted in the guide holes in a sliding mode respectively. A pressure spring, an annular gasket and an adjusting nut are arranged on each installation screw. By means of the ship cab with the anti-shock front window, when strong wind and rain impact on the front side glass, the front side glass can elastically retreat under the effect of the pressuresprings, and front side impact force is weakened.

Owner:扬州凯勒机械有限公司

Collision railing for reducing casualty rate of out-of-control vehicles beside road

PendingCN111519565AGood protectionReduce damageRoadway safety arrangementsAutomotive engineeringImpact

The invention discloses a collision railing for reducing the casualty rate of out-of-control vehicles beside a road and relates to the technical field of guardrails. The collision railing comprises arailing frame; a rotating frame is rotationally mounted on the railing frame; a first roller set, a second roller set and a third roller set are rotationally mounted on the railing frame; two throughholes are formed in the top side of the railing frame; and the top side of the rotating frame and the top side of the first roller set penetrate through the two through holes correspondingly and are fixedly provided with synchronous wheels correspondingly. According to the collision railing of the invention, when a vehicle collides with a collision plate, a first wedge block and a second wedge block move leftwards; in this process, the collision plate is subjected to the elastic action of a first spring and a second spring, and therefore, the impact force of an automobile can be effectively reduced; at the moment when column wheels enter temporary grooves, the two wedge blocks rebound under an elastic effect due to the fact that the first wedge block and the second wedge block are not provided with middle force transmission elements, and therefore, the impact damage degree of the vehicle is reduced, and the safety of a person in the vehicle can be effectively protected.

Owner:长沙开湖设备有限公司

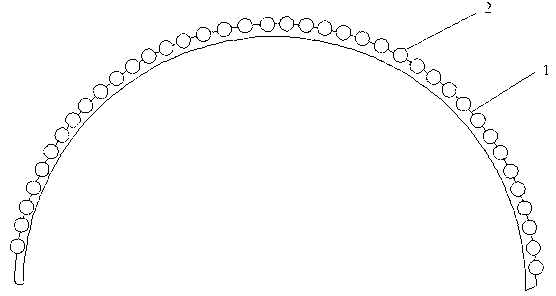

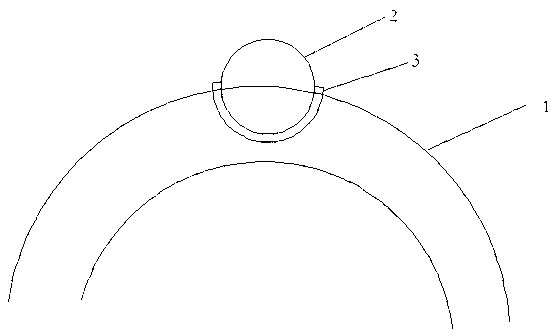

Ball safety helmet

The invention discloses a ball safety helmet. The ball safety helmet comprises a helmet shell, wherein a plurality of ball grooves are embedded in the outer side of the helmet shell, and balls are installed in the grooves. When an object falling from a high altitude hits the ball safety helmet, due to the rotation of the balls, the object is difficult to hit the front surface of the safety helmet, so that the impact force of the falling object on the safety helmet is significantly reduced, the possibility of cracking of the safety helmet due to stress is reduced, and the safety coefficient is increased.

Owner:SUZHOU ORIGIN IND DESIGN

A water conservancy dam wave-resisting wall

Owner:防城港市泽农工程设计活动有限公司

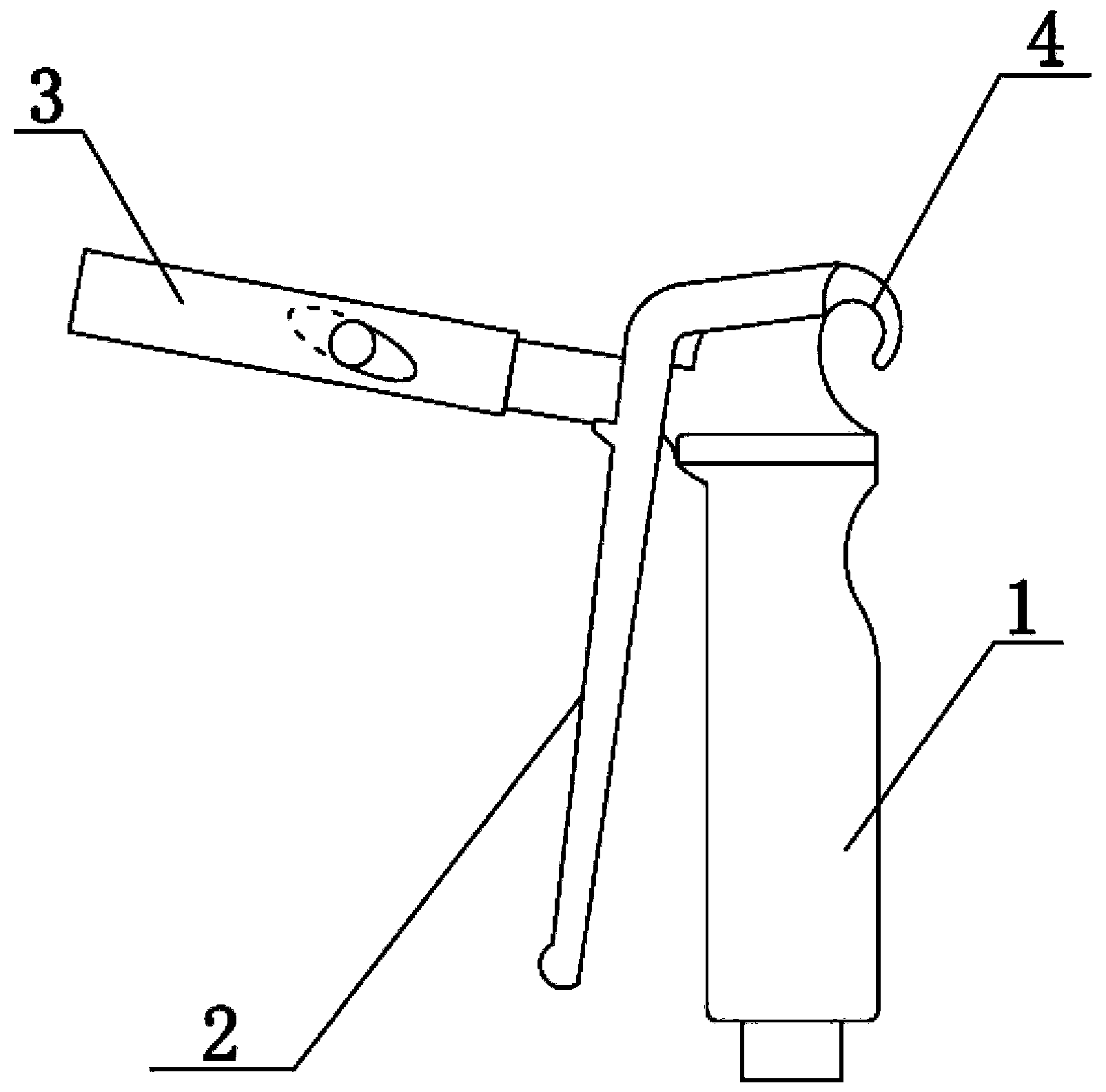

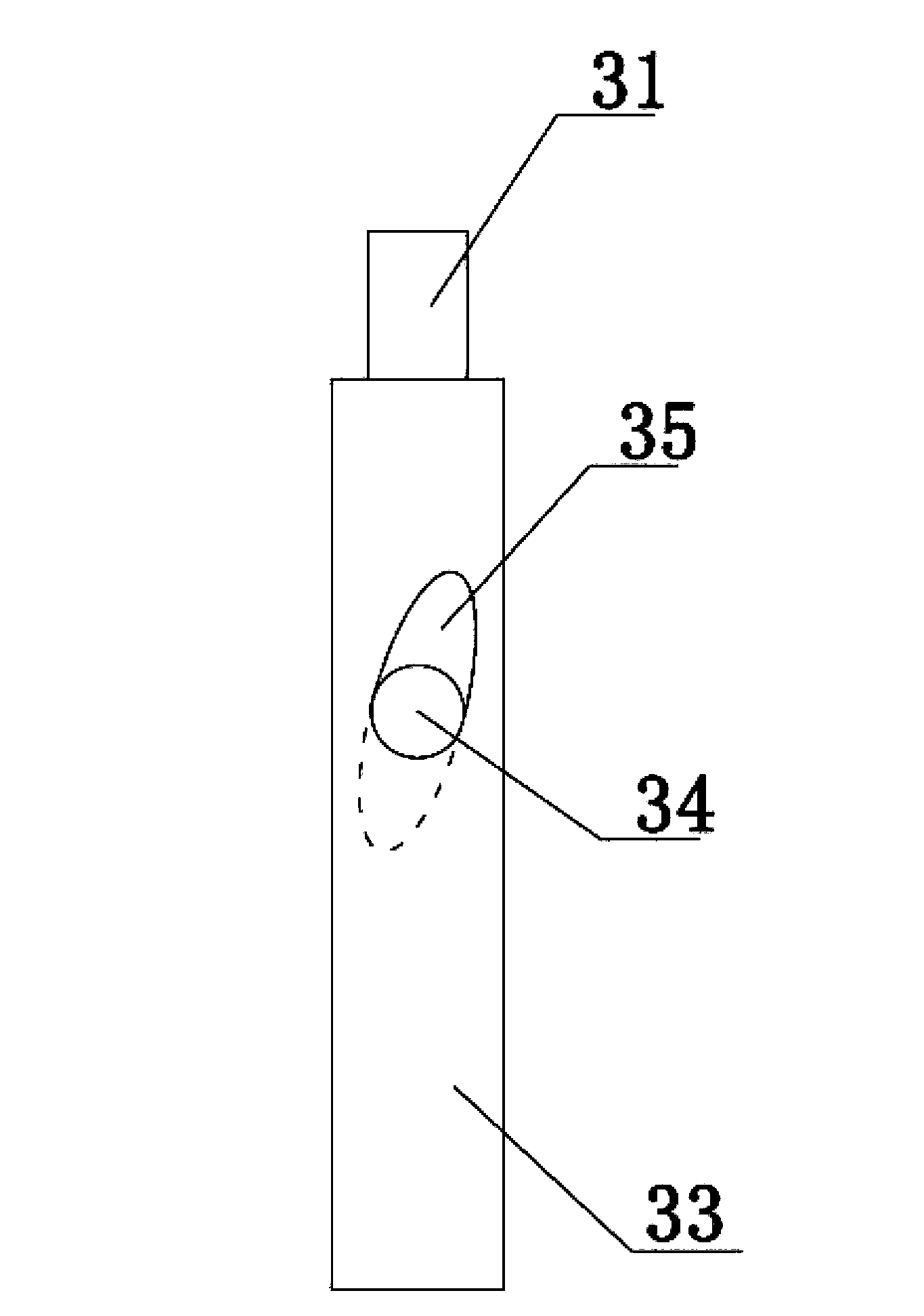

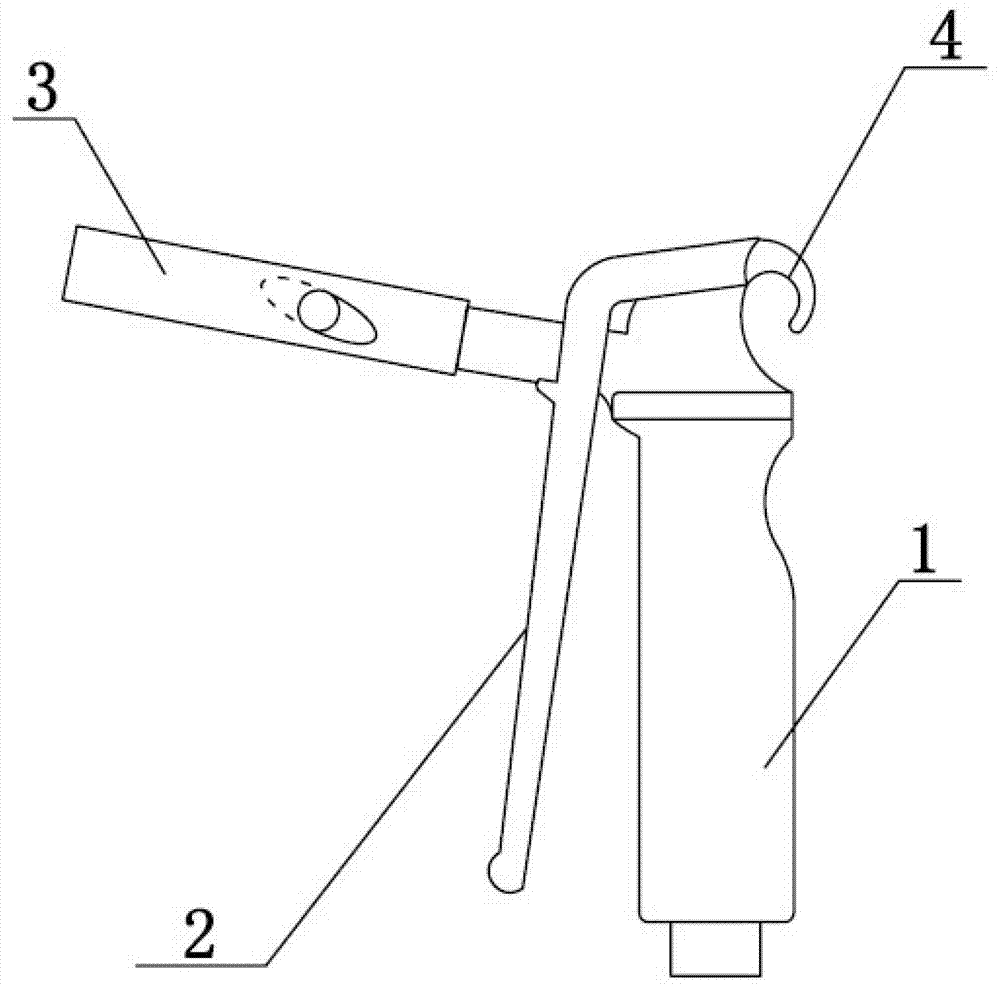

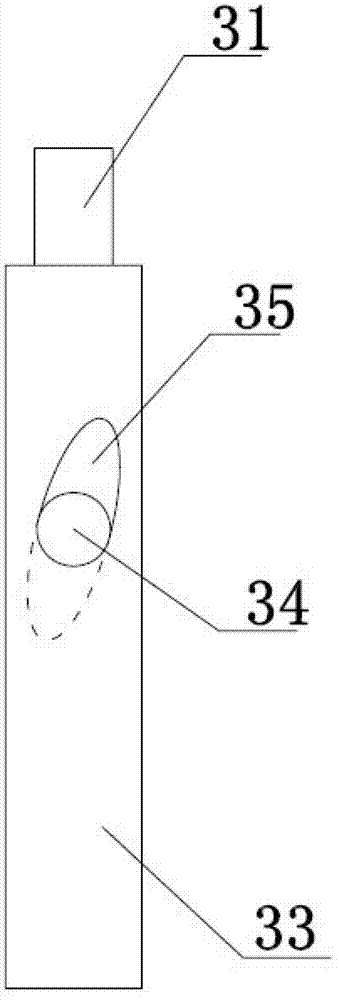

Siphonic energy-saving blowing gun

The invention relates to a siphonic energy-saving blowing gun which comprises a handle, a wrench and a spray nozzle, wherein the upper end of the wrench is connected with the upper end of the handle, and rotates around the upper end of the handle, the spray nozzle is connected with the upper end of the handle on one side where the wrench is position, an air inlet joint is arranged at one end of the spray nozzle, an air outlet pipe is arranged at the other end of the spray nozzle, the internal diameter of the air inlet joint is smaller than that of the air outlet pipe, one end of the air inlet joint is communicated with the air outlet pipe through a central hole, transverse through holes are symmetrically formed in the center positions of the two sides of one side wall of the air outlet pipe, elliptical inclined holes are formed in the positions of the transverse through holes, the transverse through holes are formed in the centers of the elliptical inclined holes, the inclined angle between the long axis of each elliptical inclined hole and the central axis of the air outlet pipe is 15 degrees, and the bottoms of the elliptical inclined holes are communicated with the transverse through holes through inclined planes. The siphonic energy-saving blowing gun has a simple structure, pressurizes the compressed air by the siphon principle, is remarkable in effect, and is low in production cost.

Owner:NINGBO SINPPA TOOLS CO LTD

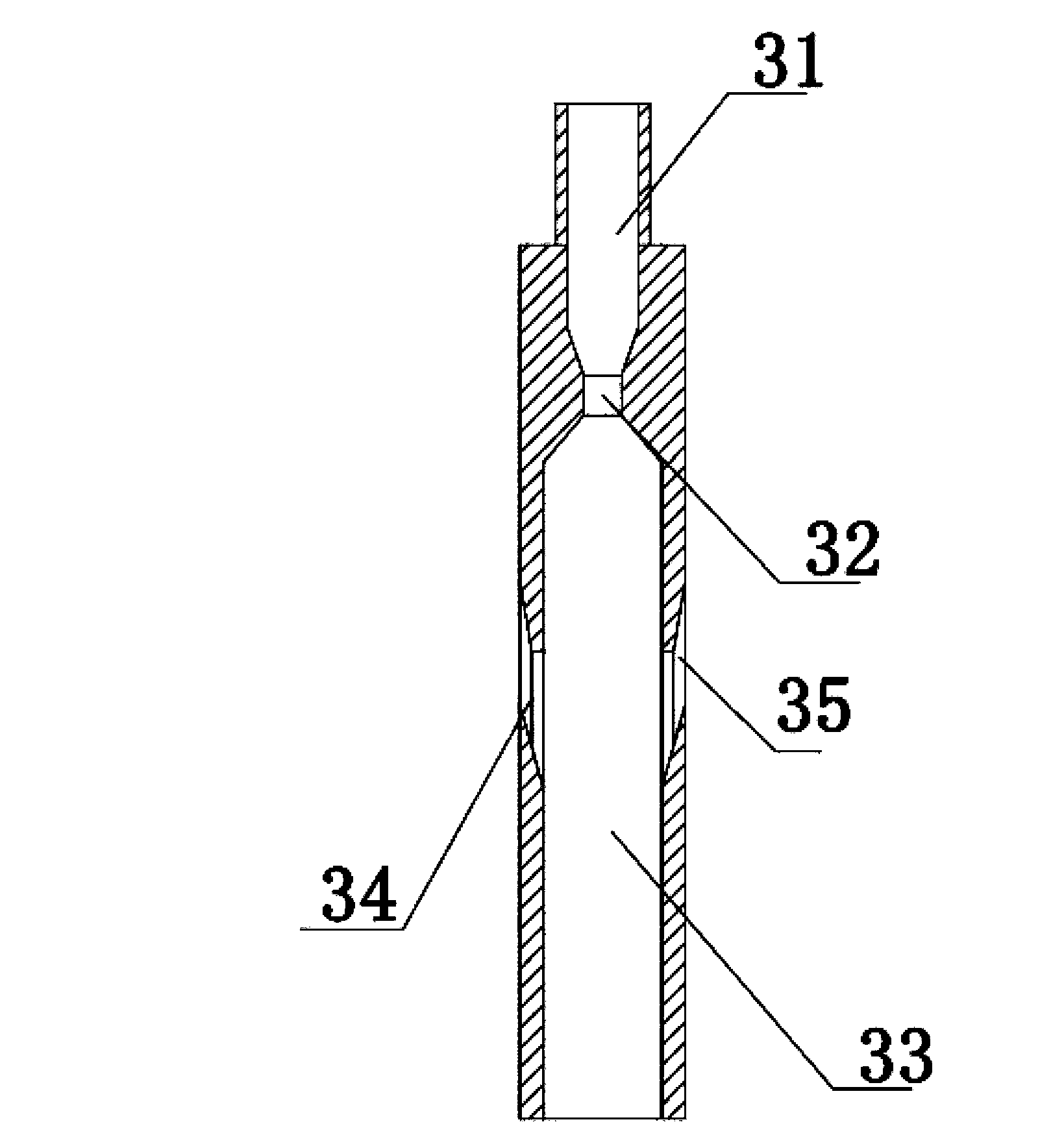

A stable anti-drifting sundries floating tube hydroelectric power generation device

ActiveCN109653932BIncrease reaction forceIncrease contact areaWaterborne vesselsHydro energy generationWater wheelWater flow

The invention discloses a stable floating-debris-preventing floating tube type hydraulic electrogenerating device which structurally comprises an anti-blocking cover, a sealing floating tube, a connecting frame, a fixing ring, a support, a barrel body, a horizontal water diversion plate and a bottom water diversion plate. The left side of the anti-blocking cover is nested to the outer surface of the right side of the barrel body, and the sealing floating tube is fixed above the barrel body. Compared with the prior art, the contact area between the device and water is enlarged on the horizontalface and the vertical face through the horizontal water diversion plate and the bottom water diversion plate, impact force of water flow on the front face of the device is reduced, the counter-actingforce of the device on water is improved, device is higher in stability, the problem that the device direction is changed, water flow cannot impact a water wheel, and power generation efficiency is affected is avoided, a rotating body has rotating force by means of accelerated water flow inside the barrel body through a water blocking plate, a water blocking block is impacted by water to enable an impurity grabbing net to be shrunk to grab small impurities and fish which penetrate through the anti-blocking cover in water flow, the small impurities and fish are thrown out through movable exhaust holes, and the rotating water wheel is prevented from being entangled or damaged.

Owner:临沂联泰新型建材合伙企业(有限合伙)

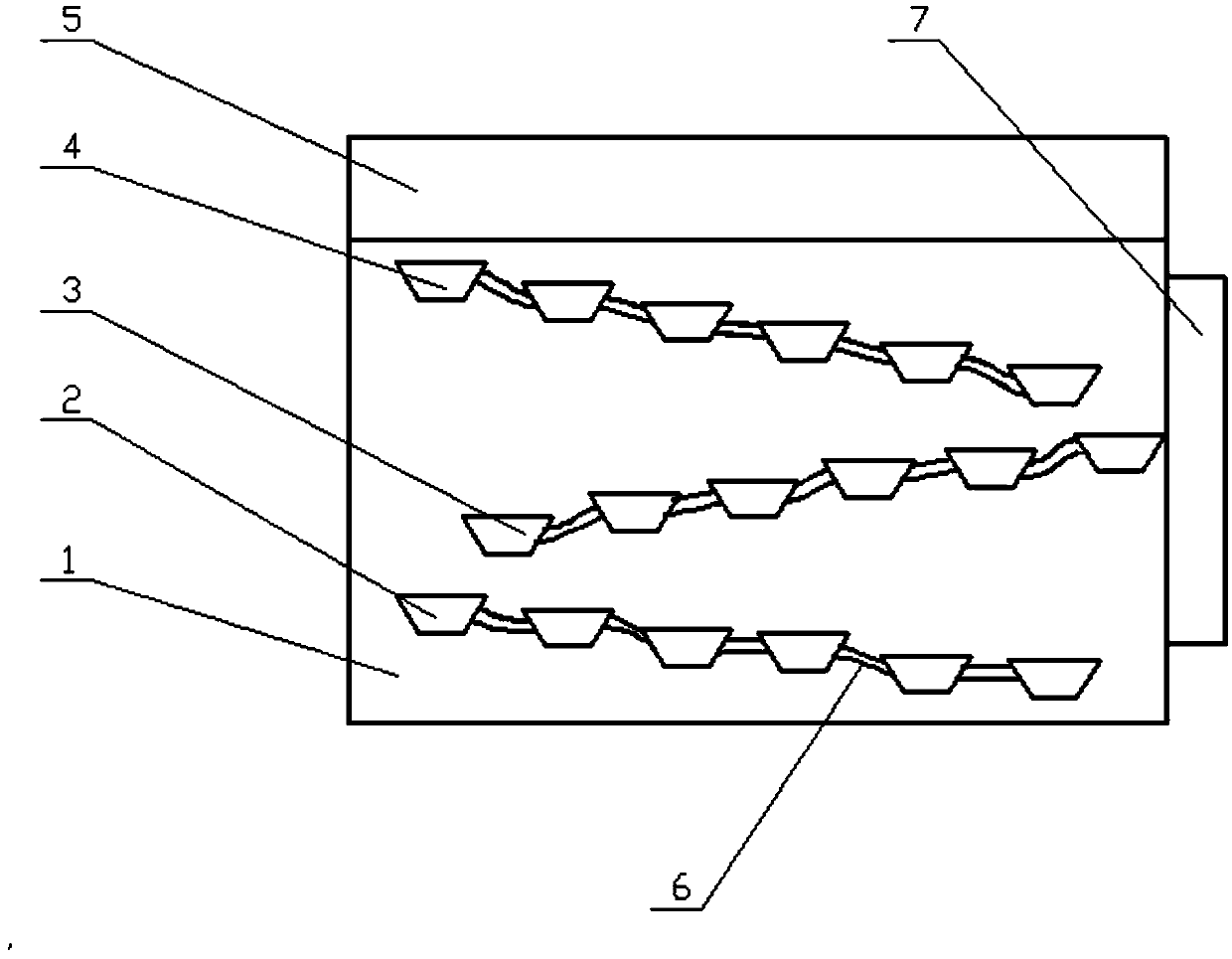

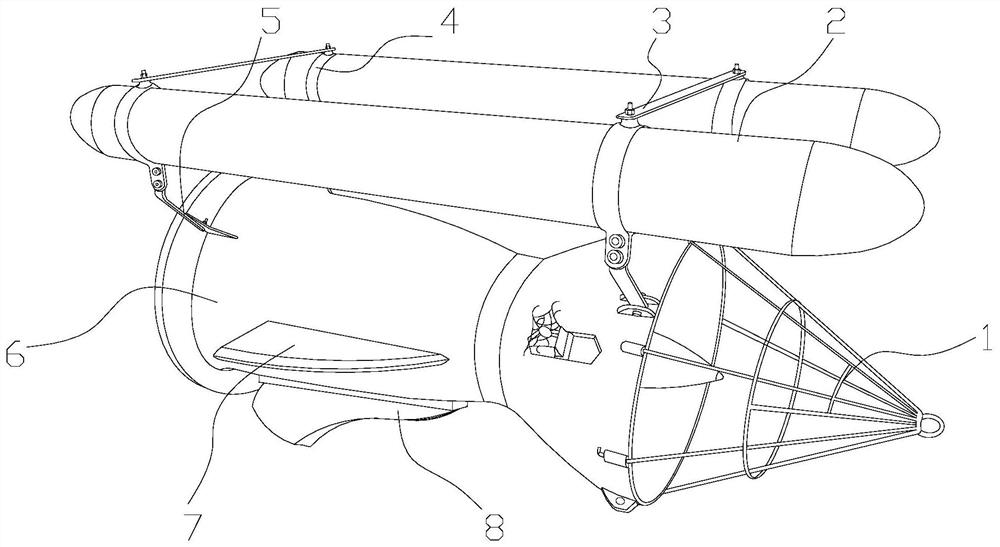

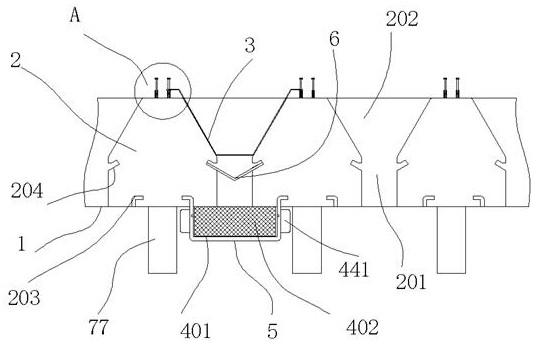

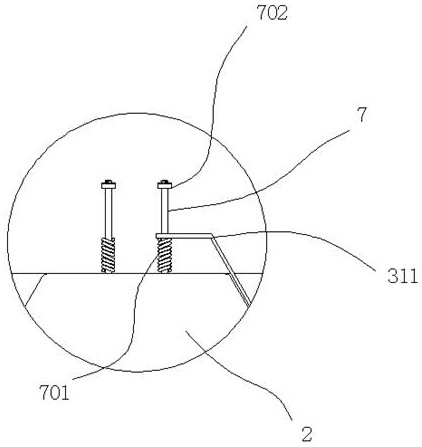

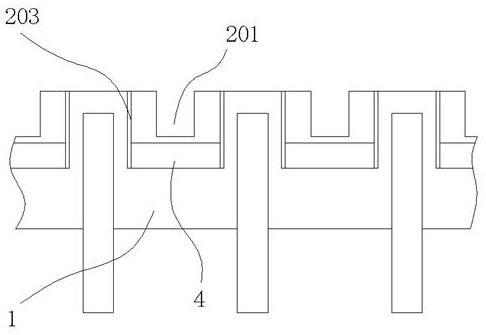

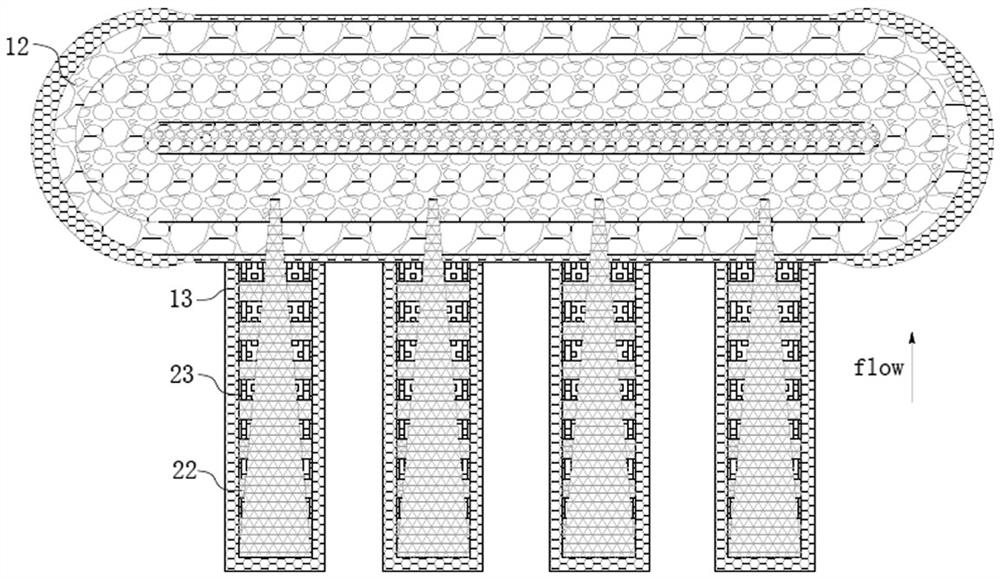

An environmental protection water treatment intercepting device and its operating method

ActiveCN112144487BReduce frontal impactIncrease water intakeBarrages/weirsClimate change adaptationFiltrationMechanical engineering

The invention discloses an environmental protection water treatment intercepting device, comprising an intercepting dam, the intercepting dam being a concrete pouring dam; the upper end of the intercepting dam is formed with a plurality of upwardly protruding diverting blocks, and the diverting blocks and the intercepting dam are a pouring integrated structure , the diverter blocks set at intervals can pass pedestrians without affecting the flow of water. A shunt channel is formed between the adjacent shunt blocks, a V-shaped drainage port is formed at the rear of the shunt channel, and the width of the drainage port gradually increases backward; a filter plate is assembled in the drainage port, and the The front end of the filter plate is provided with a flat plate part, and filter holes are evenly distributed on the flat plate part; in this device, the positive installation of the filter plate can realize water filtration, and the reverse installation of the filter plate can also realize water filtration, but it will be A channel is formed between the bottom of the filter plate and the intercepting dam for aquatic organisms to pass; while satisfying water filtration, it can also ensure the return of organisms.

Owner:嵊州市万睿科技有限公司

Anti-explosion angle seat valve

ActiveCN114215959ASolve the technical problem of vibrationTechnical Issues in Reducing VibrationValve members for absorbing fluid energySlide valveElastic componentWater flow

The anti-explosion angle seat valve comprises a valve body, a silencer, a front cover, a piston rod, a piston, an exhaust pressure regulating connector, a rear cover, a cylinder barrel, a reset spring, a guide groove, a limiting plate, a first spring, a damping shaft sleeve, an elastic component and a plug. A water drainage damping mechanism is further arranged in the valve body. Compared with the prior art, the hemispherical plug is matched with the staggered arc-shaped groove, and the technical problem that in the prior art, when a piston closing pressing plate and a water flow opening are closed, water pressure fluctuates violently, and consequently a valve body vibrates violently is solved. Meanwhile, due to the fact that the drainage damping mechanism is arranged in the groove, the problem that the water pressure is too large when the groove is closed by the plug is further solved; and the damping shaft sleeve is arranged between the piston rod and the plug, so that the impact of water flow on the plug can be greatly reduced.

Owner:NINGBO SONO MFG

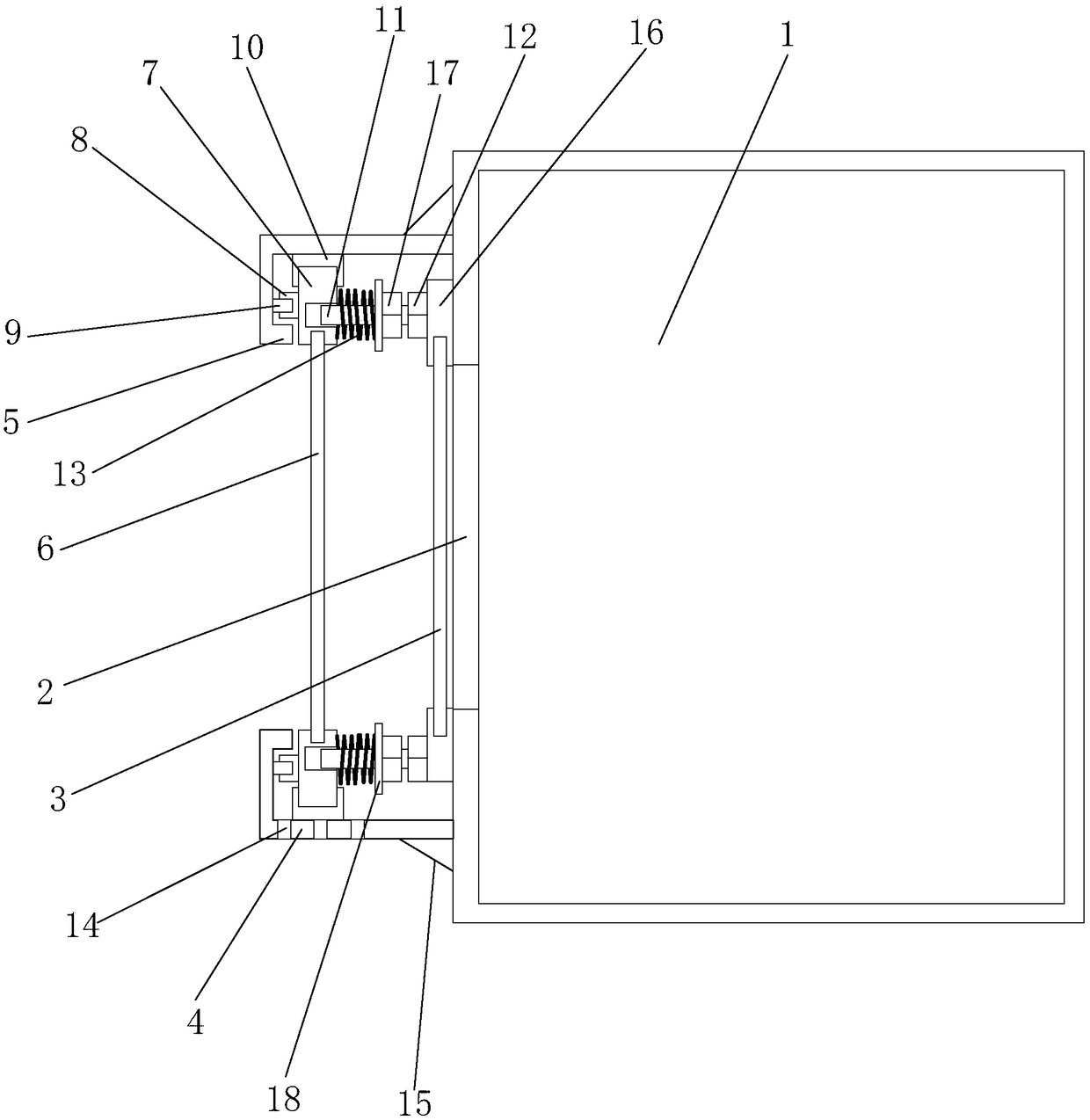

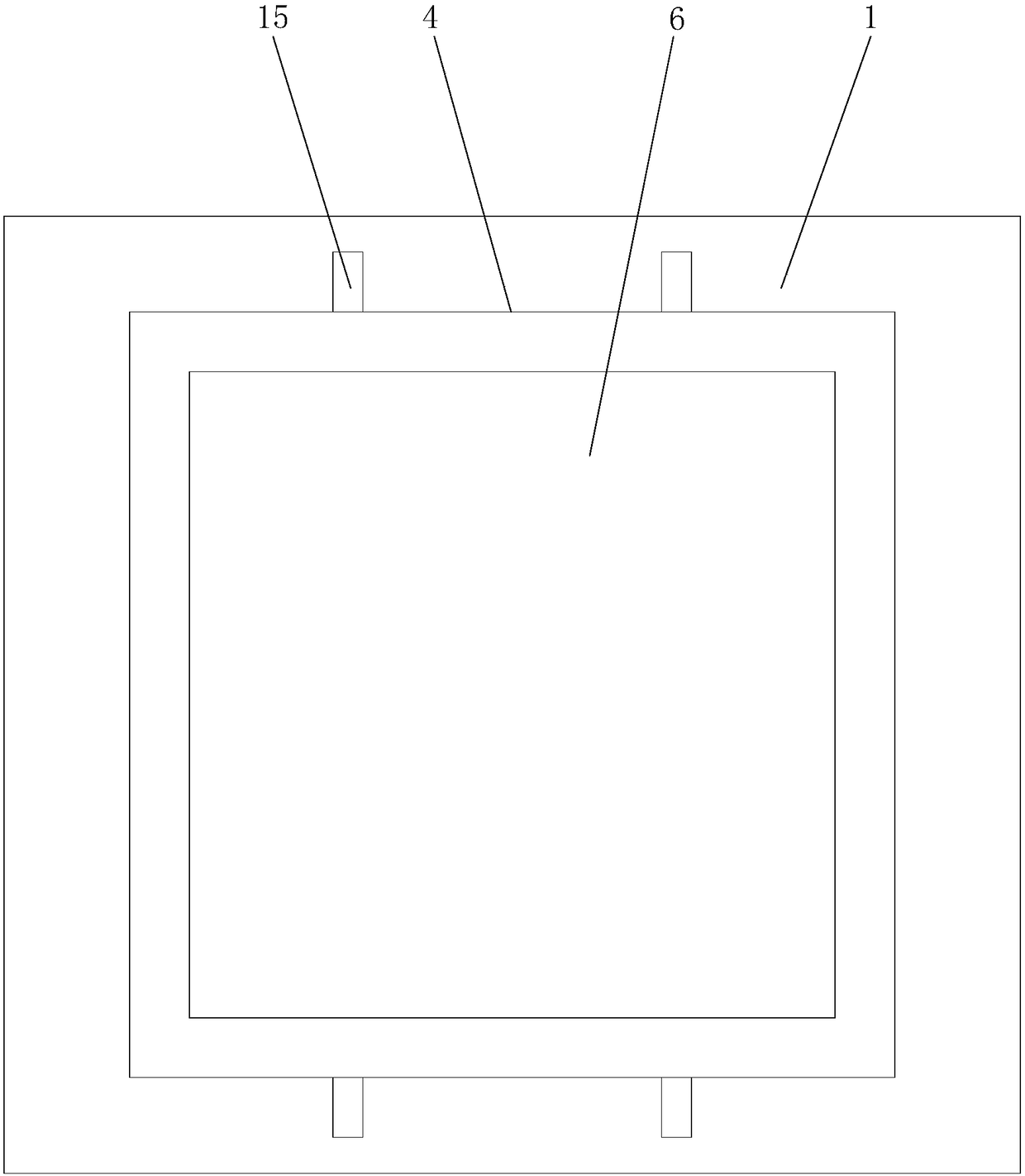

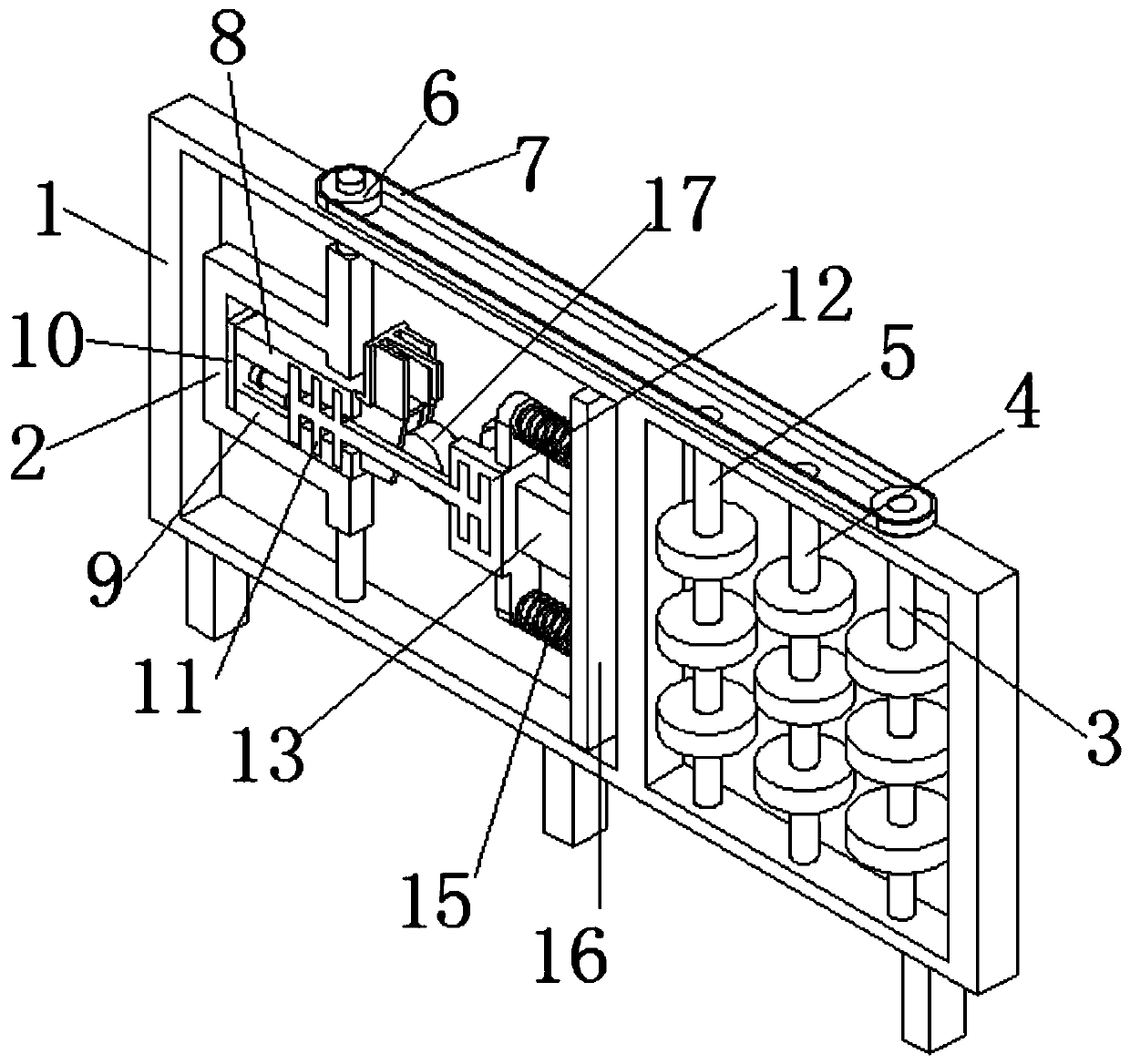

A kind of self-returning explosion-proof door for vertical air shaft in mining area

ActiveCN111561349BDissipate automatically and quicklyEnsure safetyMining devicesFireproof doorsToxic gasEngineering

The invention belongs to the technical field of explosion-proof doors, and specifically relates to a self-recovering explosion-proof door for vertical air shafts in mining areas, including a base, an explosion-proof barrel, a mounting plate, a limit plate, an anti-collision block, a sliding cylinder, an impact-resistant plate, Rotating cylinder, support shaft, No. 1 spring and counterweight; in the present invention, the shock wave generated by the explosion is used to cooperate with the large-pitch spiral groove to realize the automatic rotation of the rotating cylinder, and then automatically realize the alignment of the No. 1 through hole and the No. 2 through hole, and then Realize the automatic and rapid dissipation of the shock wave after the explosion; and the shock wave generated in the shaft needs to overcome the elasticity of the No. 1 spring and the gravity of the counterweight during the process, so as to weaken the shock wave generated by the explosion to a certain extent, and will not damage the surrounding area. The environment produces a large shock; at the same time, the rebound force of the No. 1 spring and the self-gravity of the counterweight are used to stagger the No. 2 through hole and the No. 1 through hole, thereby realizing the automatic sealing of the explosion-proof door, thereby reducing the poisonous gas in the well. Diffusion of dust.

Owner:SHANXI CHANGZHI BEIKE ELECTRIC CO LTD

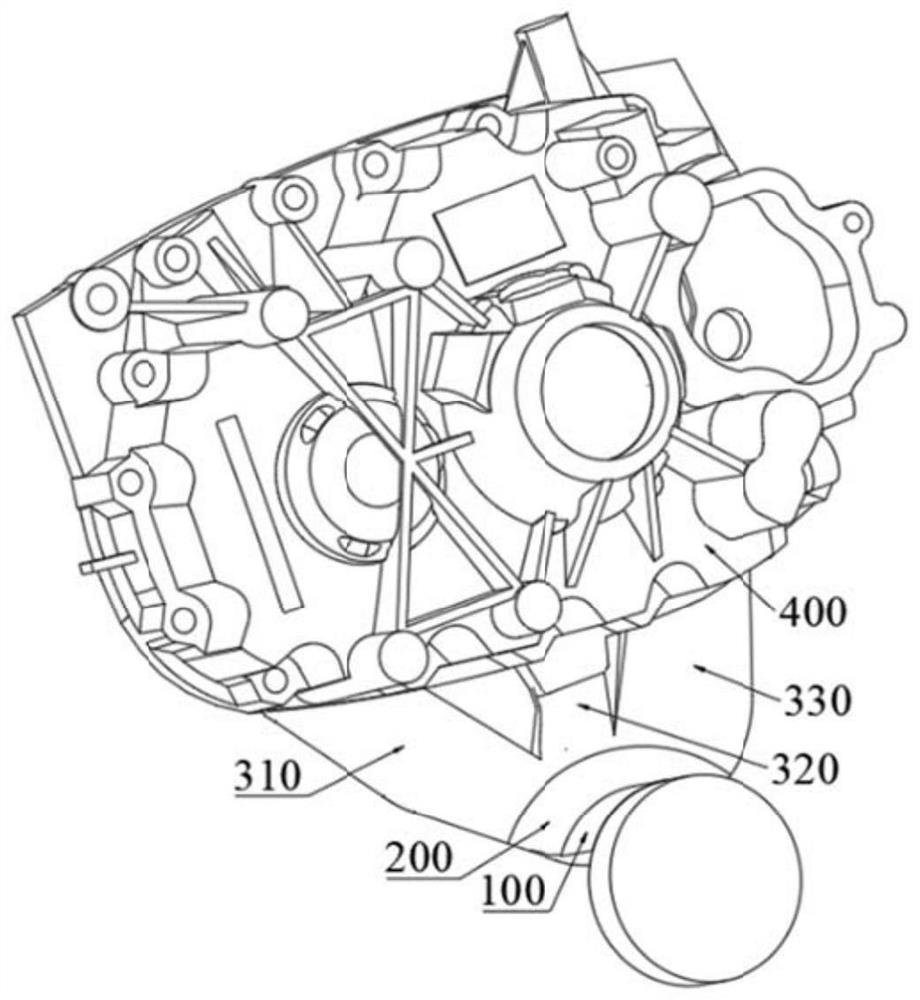

Mixed lap joint type ingate system of aluminum alloy die-casting gearbox shell

ActiveCN114603109AReduce resistanceReduce total pressure lossProcess efficiency improvementThermodynamicsLap joint

A mixed lap joint type ingate system of an aluminum alloy die-casting gearbox shell is characterized in that the mixed lap joint type ingate system is formed by sequentially connecting a shell cavity, an ingate, a transverse pouring gate and a straight pouring gate, and the outflow end of the ingate is arranged on the lower left portion, the lower middle portion and the lower right portion of the shell cavity in sequence; molten aluminum liquid enters a shell cavity at different jet flow angles through the ingate outflow end, and the cross section area of the cross gate outflow end is larger than the total cross section area of the ingate outflow end and tends to be gradually reduced. According to the invention, molten aluminum can stably and sequentially pass through the sprue, the cross gate and the ingate, enters the shell cavity and then is stably filled, so that the local resistance coefficient and pressure loss of the molten aluminum in the runner and the shell cavity are reduced, and the front impact of the molten aluminum on the inner side of the shell cavity is greatly relieved; the generation of eddy current and turbulent flow areas and the generation of defects such as air holes and loose structures are avoided, and the compactness and the yield of the shell structure are effectively improved.

Owner:NANJING TECH UNIV

A seawall flood protection structure and its construction method

ActiveCN106939578BReduce frontal impactReduce impactBarrages/weirsBreakwatersWave power generationEngineering

The invention discloses a seawall flood season protection structure and a construction method thereof. The seawall flood season protection structure comprises a wave dissipating device, a wave power generation device, a dam and a buffer system. The wave dissipating device is movably connected to a first supporting structure. The first supporting structure comprises two parallel first supports. The two ends of the first supporting structure are fixedly connected to a speed reducing slope and a current stabilization slope through a foundation pile and a first positioning pile correspondingly. The wave power generation device is arranged at the tail end of the first supporting structure. A second supporting structure is arranged at the other end of the first positioning pile. The buffer system penetrates through the speed reducing slope, the current stabilization slope and the dam. The method includes the steps of surveying and setting out, construction of the foundation pile and the positioning pile, construction of the buffer system, construction of the wave dissipating device and the wave power generation device, construction of the second supporting structure and construction of the dam. By means of the seawall flood season protection structure and the construction method thereof, flood season installation protection of seawalls with different lengths and widths can be met, sediment loss is reduced, a good seawall protection effect is achieved, seawater power generation can be achieved, and economical benefits are remarkable.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Wear-resistant gear

InactiveCN106763643AIncreased load-bearing capacityReduce frontal impactPortable liftingGearing elementsWear resistantMechanical engineering

The invention discloses a wear-resistant gear. The wear-resistant gear is characterized by comprising a gear frame; the gear frame is composed of a first gear stand and a second gear stand, the first gear stand and the second gear stand are both of cake-shaped structures, and the two gear stands are arranged to be in parallel; outer edges of the two gear stands are provided with a plurality of gear plates; each gear plate is furthermore externally provided with a buffering plate, and the buffering plates and the gear plates are all provided with bolts. The two gear stands are arranged, so that bearing capacity of the gear is further improved; and in addition, the gear frames are additionally provided with wear-resistant layers so as to lower front impact borne by the gear in work, and thus the wear degree of the gear is lowered.

Owner:吴肖颜

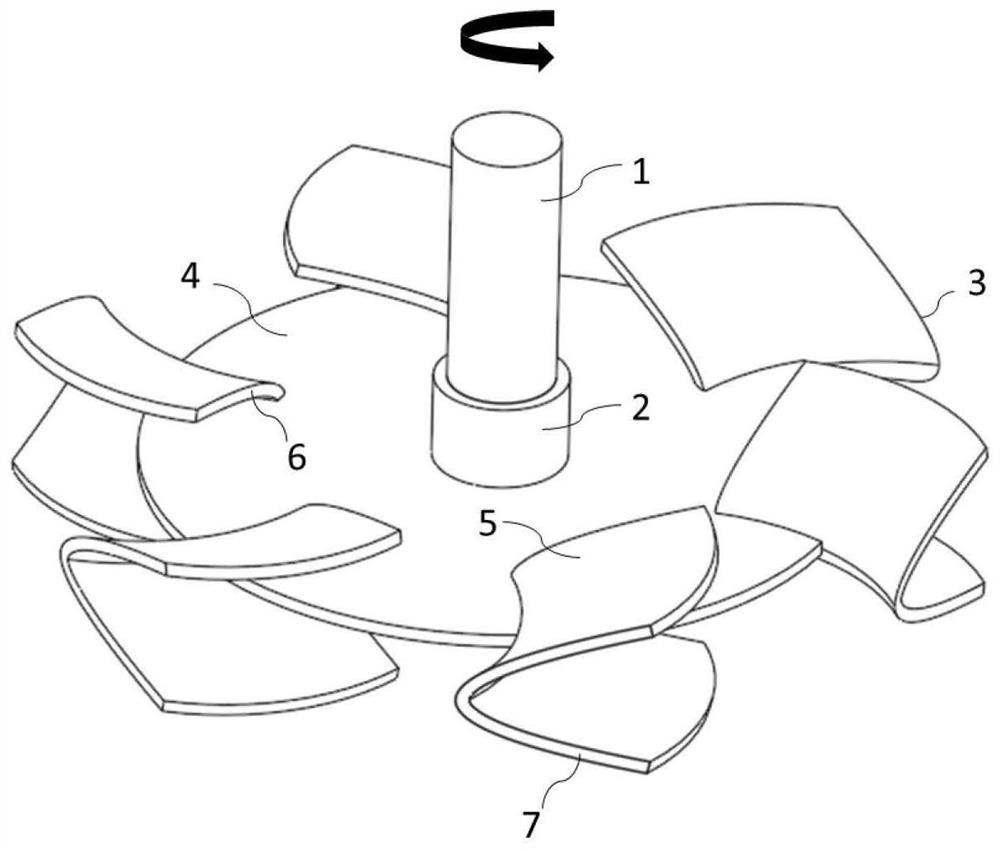

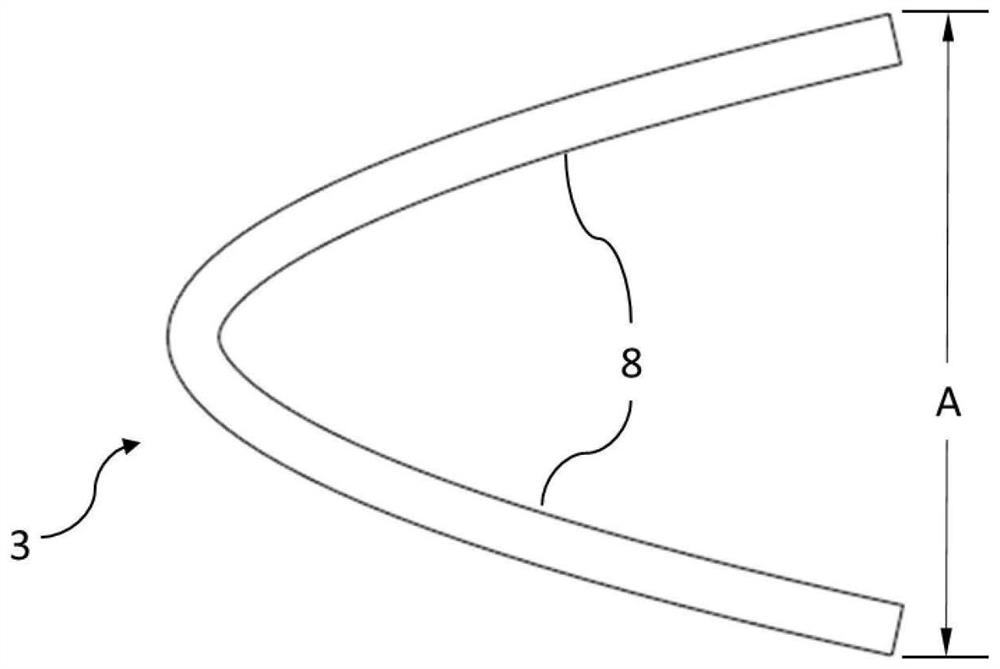

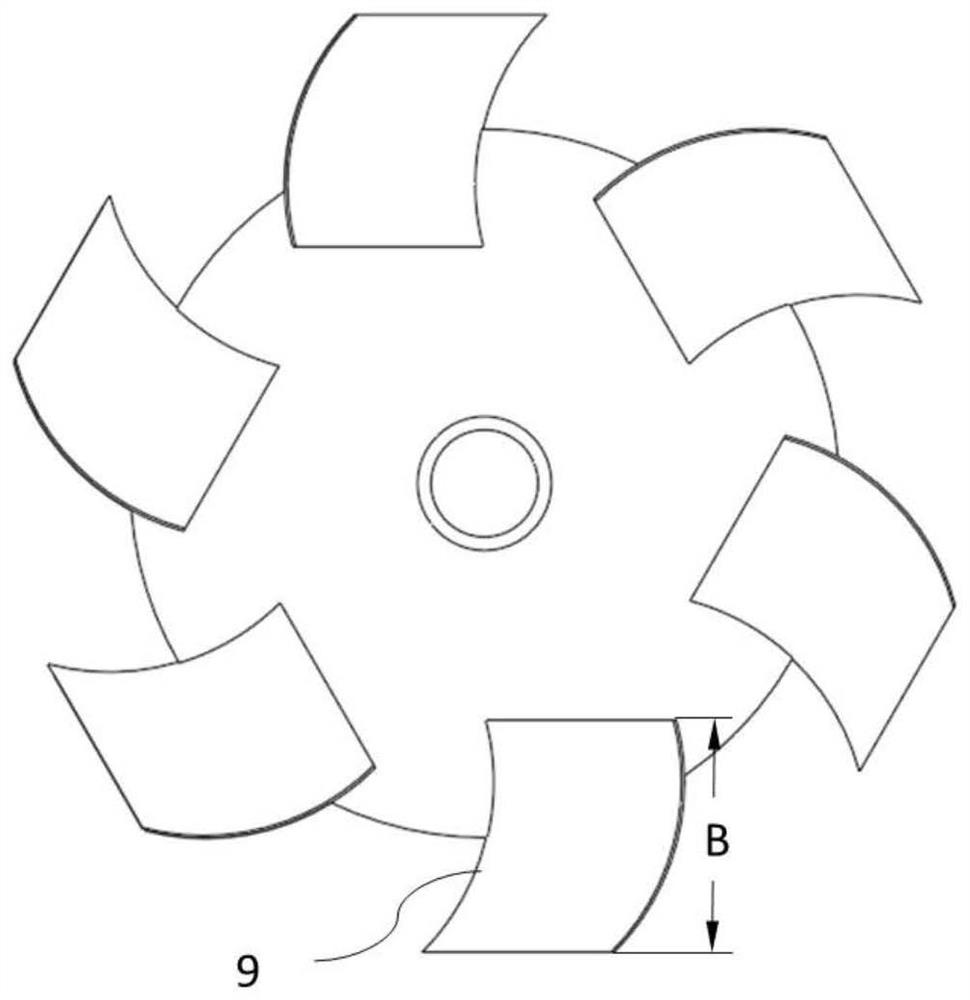

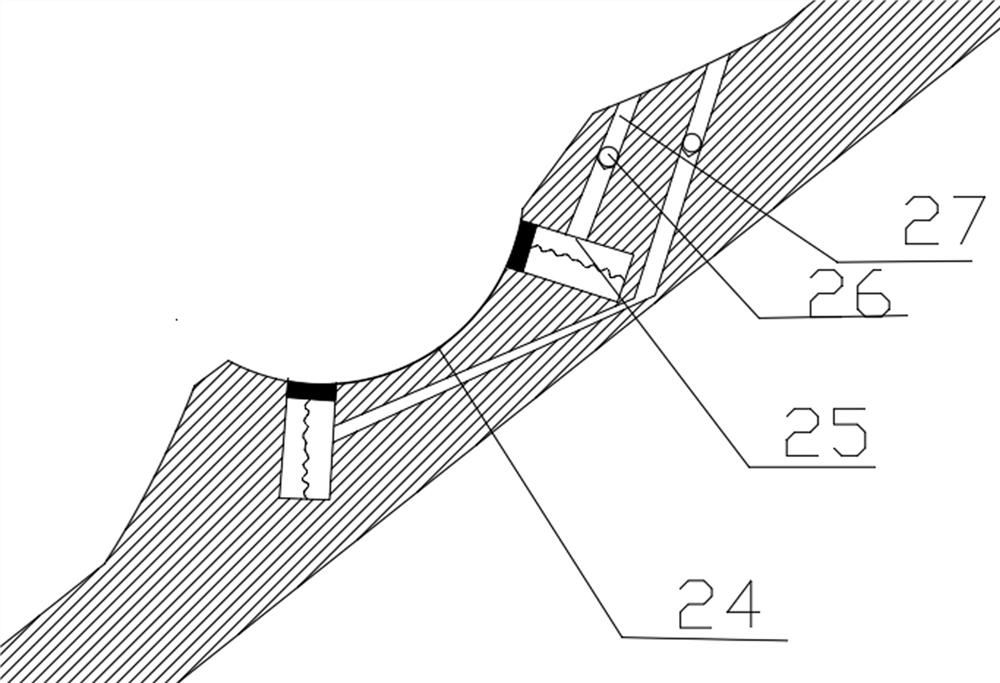

A backswept disc turbine impeller

ActiveCN113731219BReduce frontal impactReduce stirring power consumptionRotary stirring mixersTransportation and packagingChemical industryCircular disc

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

An explosion-proof angle seat valve

ActiveCN114215959BSolve the technical problem of vibrationTechnical Issues in Reducing VibrationValve members for absorbing fluid energySlide valveWater dischargeWater flow

The invention is an explosion-proof angle seat valve, comprising: a valve body, a muffler, a front cover, a piston rod, a piston, an exhaust pressure regulating joint, a rear cover, a cylinder barrel, a return spring, a guide groove, a limit plate, a spring one, A damping shaft sleeve, an elastic part and a plug; the valve body is also provided with a water discharge damping mechanism. Compared with the prior art, the present invention adopts the hemispherical plug and the dislocation arc-shaped groove to cooperate, and solves the technical problem that the water pressure fluctuates violently when the piston is used to close the pressure plate and the water flow opening is closed in the prior art, causing the valve body to vibrate violently. . At the same time, the water discharge damping mechanism is arranged in the groove, which further prevents the problem of excessive water pressure when the plug closes the groove; and the damping bushing is set between the piston rod and the plug, which can greatly reduce the blocking of water flow. head shock.

Owner:NINGBO SONO MFG

A kind of die-casting mold for producing shell and the production method of shell

Owner:NINGBO HUASHUO MOLDING & MACHINE

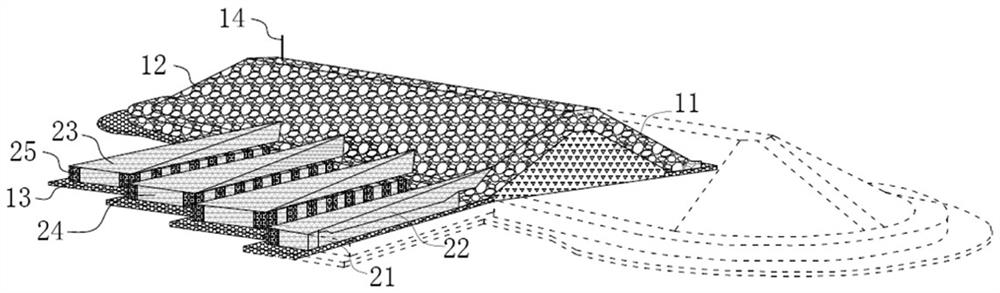

Ecological breakwater structure suitable for constructing oyster reef habitat

The invention relates to an ecological breakwater structure suitable for constructing an oyster reef habitat. The invention is suitable for the technical field of ocean engineering. According to the technical scheme, the ecological breakwater structure suitable for constructing the oyster reef habitat is characterized in that the ecological breakwater structure is provided with a breakwater main body and a plurality of slope type reef body structures arranged on the head wave side of the breakwater main body, wherein the breakwater main body is provided with an internal main body structure constructed by small-particle-size core stones and a surface layer structure constructed by large-particle-size surface stones; and each slope type reef body structure is provided with a rectangular stone laying structure and a slope body located above the rectangular stone laying structure, a plurality of ecological concrete oyster frames for providing survival places for oyster shell attaching larvae are embedded in the edge of the rectangular stone laying structures, and the top faces of the slope bodies are slope faces inclining downwards from the ends close to the breakwater main body to the ends away from the breakwater main body.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Airplane front damping undercarriage device

ActiveCN113443130AAlleviate frontal impactMitigation reduces frontal impact forceWeight reductionWheel arrangementsAviationReciprocating motion

The invention relates to the technical field of aeronautical manufacturing, and discloses an aircraft front damping undercarriage device which comprises a supporting rod, aircraft wheels are movably installed at the two ends of the supporting rod, a moving shaft is fixedly installed in the middle of one side of the supporting rod, and one end of the moving shaft is movably connected with a damping cavity in a sleeved mode. Through forward and reverse reciprocating motion of two sections of gas in the inner cavity of the damping cavity, the front impact force borne by the aircraft wheels is effectively reduced, the problem that the aircraft landing balance is unstable due to the fact that the aircraft wheels are collided in the front direction is solved, fixed teeth and clamping teeth are crossed and clamped, the problem that the piston rod and the shock absorber rotate and fall off due to the torque of a piston rod is solved, gas is divided into two gas flows through the fixed teeth, the gas flows collide with the clamping teeth in a split-flow mode, the clamping teeth generate relative extrusion force, the effect that the clamping teeth prevent the fixed teeth from rotating is effectively enhanced, and the problem that the piston rod rotates and is separated from a shock absorber due to torque generated by the piston rod is avoided.

Owner:上海捷翔航空技术有限公司

Ground cabling trough for bow-type optical cables

ActiveCN102565978BReduce frontal impactGuaranteed StrengthOptical fibre/cable installationFiberEngineering

The invention belongs to optical cable cabling trough devices for communication network Fiber To The Home (FTTH) optical fiber comprehensive wiring. A ground cabling trough for bow-type optical cables comprises a trough body. Bow-type optical cable troughs are arranged in the trough body, the upper surface of the trough body is in a shape of a circular arc, protruding portions which are in a direction of the center of the circular arc are disposed in the trough body, and the height of the protruding portions are parallel and level to lower bottom surface of the cabling trough. The ground cabling trough coordinates with an inside corner of the cabling trough, the bow-type optical cables are led from a wall surface to a ground surface, the surface is designed in the arc structure, four bow-type optical cable troughs are arranged, the protruding portions are used for improving the strength and rigidity of the cabling trough, a cambered surface is combined with the ground surface, kicking and bumping of the ground cabling trough are avoided when users pass through, and the cabling trough can not be damaged and deformed when treaded, therefore the bow-type optical cables are effectively protected to smoothly pass through the ground surface under the condition of open wire distributing, a plurality of cabling troughs can be connected to the cabling trough through cabling trough joints, and the distance is not limited.

Owner:NANJING HUAMAI TECH

Inclined protection structure and using method

PendingCN110805383AReduce frontal impactSolve the poor wave suppression effectProtective buildings/sheltersWing arrangementsTunnel wallMechanical engineering

The invention discloses an inclined protection structure and a using method. The inclined protection structure comprises an inner tunnel, an outer tunnel and a tunnel wall, one side of the tunnel wallis connected with a door frame, and a door body is connected between the inner tunnel and the outer tunnel; the end, close to the door body, of the outer tunnel is provided with a wave-absorbing chamber; and a wave-absorbing wall is connected to the inner surface of the tunnel wall. According to the device, a protective door plate with a certain inclination angle is arranged, the impact of shockwaves on the front face of the door plate is reduced, the wave-absorbing chamber is built in the tunnel at the front end of the door plate, the shock waves are scattered into the wave-absorbing chamber through the door plate, and the shock waves are dispersed and absorbed by through the wave-absorbing wall in the wave-absorbing chamber. The inclined protection structure solves the problems of poorwave-absorbing effect and poor use convenience of the existing underground civil air defense work wave-absorbing technology and has the advantages of no need of frequent maintenance, good wave-absorbing effect, capability of being put into use at any time and no need of preparation work before use.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

Anti-collision device for wharf

InactiveCN108677874AReduce frontal impactAvoid damageClimate change adaptationShipping equipmentCollision preventionMagnet

The invention relates to an anti-collision device for a wharf, and belongs to the field of wharf collision prevention. The device comprises a buffering sliding block, an anti-collision column and a mounting base plate, wherein the longitudinal section of the buffering sliding block is C-shaped; a buffering layer is arranged on an anti-collision contact surface of the buffering sliding bock; a first magnet strip is arranged on the inner side surface of the buffering sliding block; the buffering column is provided with a T-shaped section, and a second magnet strip is arranged on the outer surface of the end with big section of the buffering column; the buffering sliding block sleeves the side with big section of the buffering column, and the end with small section of the buffering column isfixedly connected to the mounting base plate and is arranged on the sidewall of the wharf. With the adoption of the anti-collision device for the wharf, the front impacting force of a ship body to thewharf can be effectively reduced, and moreover, the sliding block is arranged, so that the anti-collision device can move together with the ship body, thus the lateral force produced by relative moving of the ship body and the anti-collision device can be reduced, and as a result, the anti-collision device is prevented from damage caused by bearing lateral stress for a long term, and the servicelife of the anti-collision device is prolonged, and the anti-collision effect is improved.

Owner:SHENYANG JIANZHU UNIVERSITY

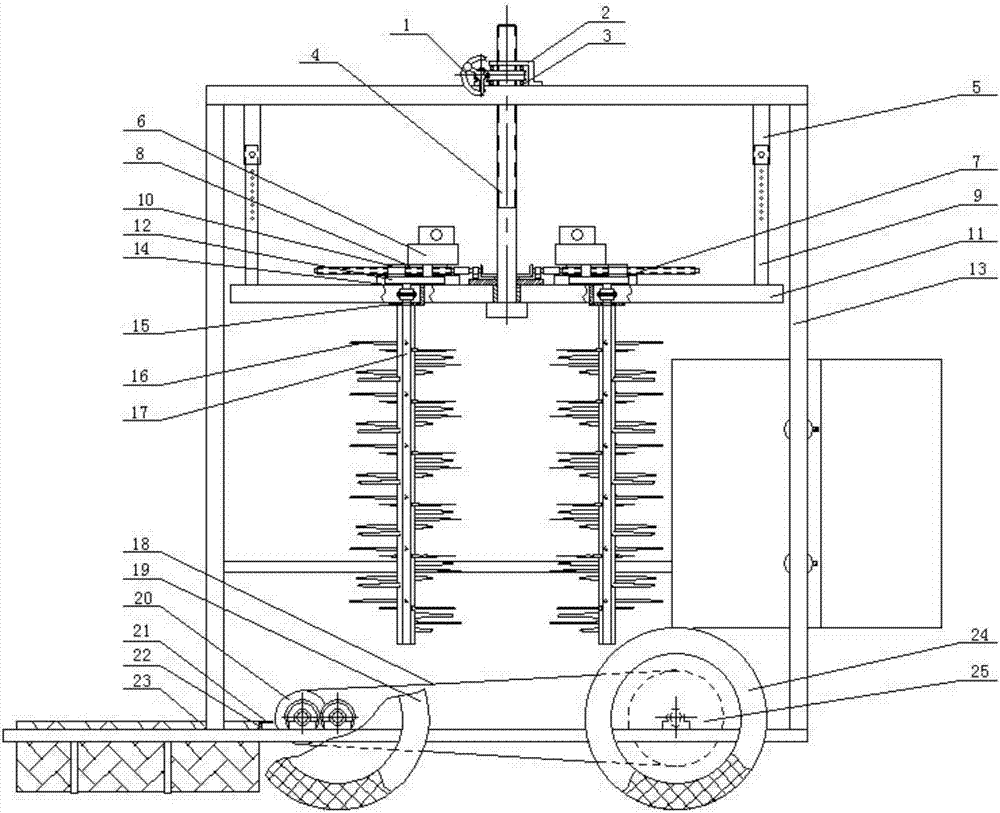

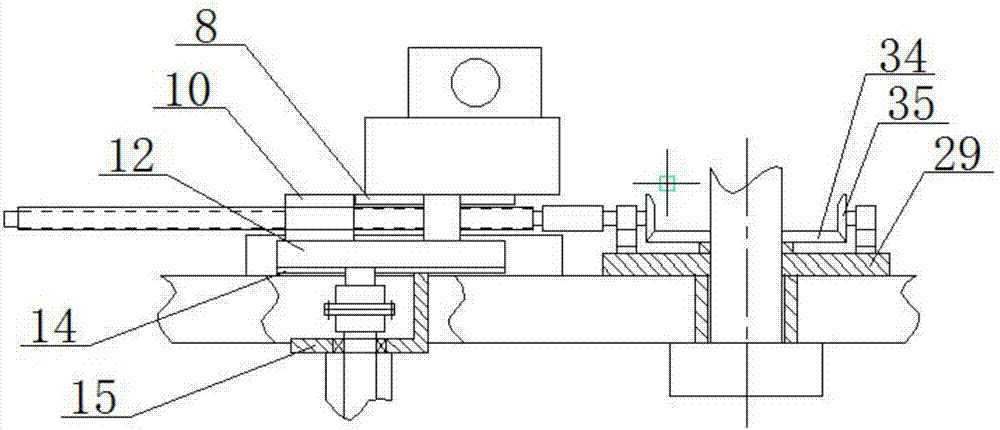

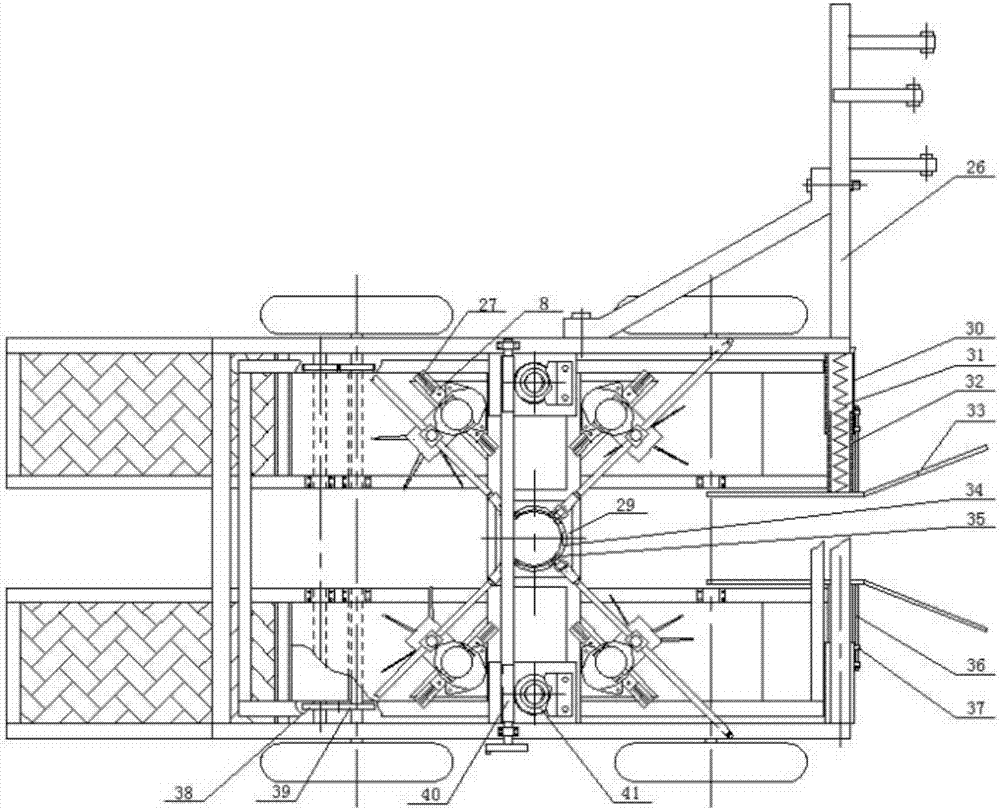

Rotary Brush Blueberry Harvester

InactiveCN105684645BImprove harvesting efficiencyEasy to separatePicking devicesBrush toothHydraulic motor

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A siphon energy-saving hair gun

The invention relates to a siphonic energy-saving blowing gun which comprises a handle, a wrench and a spray nozzle, wherein the upper end of the wrench is connected with the upper end of the handle, and rotates around the upper end of the handle, the spray nozzle is connected with the upper end of the handle on one side where the wrench is position, an air inlet joint is arranged at one end of the spray nozzle, an air outlet pipe is arranged at the other end of the spray nozzle, the internal diameter of the air inlet joint is smaller than that of the air outlet pipe, one end of the air inlet joint is communicated with the air outlet pipe through a central hole, transverse through holes are symmetrically formed in the center positions of the two sides of one side wall of the air outlet pipe, elliptical inclined holes are formed in the positions of the transverse through holes, the transverse through holes are formed in the centers of the elliptical inclined holes, the inclined angle between the long axis of each elliptical inclined hole and the central axis of the air outlet pipe is 15 degrees, and the bottoms of the elliptical inclined holes are communicated with the transverse through holes through inclined planes. The siphonic energy-saving blowing gun has a simple structure, pressurizes the compressed air by the siphon principle, is remarkable in effect, and is low in production cost.

Owner:NINGBO SINPPA TOOLS CO LTD

Hammer mill

The invention provides a hammer mill. The hammer mill is characterized in that a hammer is such designed that two sides of the front end of the hammer are both in a single-sided edged state and the angle a of each edged slope is in a range of 30 to 60 DEG; so after the hammer hammers a material, the material does not rotate around the hammer, the edged slopes allow the material to carry out transverse movement, and a large velocity difference is obtained when a subsequent group of hammer hammers the material. Under the action of the slopes at cutting edges, the surface of a screen mesh located between hammers allows a great number of the material to maintain transverse movement, so crushing efficiency is improved and uniformity of the crushed material is improved; meanwhile, under the action of the slopes at the cutting edges, impact force on the front of the hammer weakens and the service life of the hammer is prolonged.

Owner:上海春谷机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com