Hammer for pulverizer

A pulverizer and hammer technology, which is applied in the field of hammers, can solve the problems of low crushing efficiency, reduced crushing efficiency, and difficulty in making major breakthroughs in hammer crushing efficiency and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

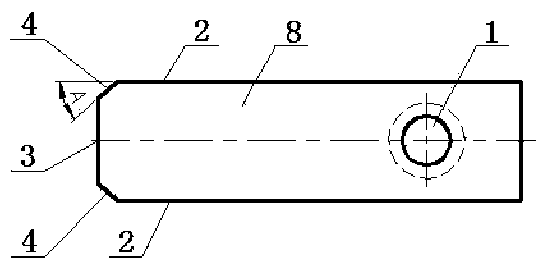

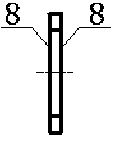

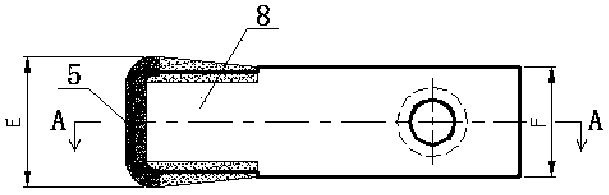

[0015] Embodiment 1, a hammer for a pulverizer, including a sheet-shaped hammer body, one end of the hammer body is provided with a pin hole (1), and two right angles at the other working end of the hammer body, namely The end faces (2) on both sides and the front working end face (3) are surfacing with wear-resistant materials. The wear-resistant materials are tungsten carbide alloys, etc., which are characterized in that they are at two right angles at the other working end of the hammer matrix ( figure 1 ), first cut off the right angle to make the inclined push end face (4), the angle A between the inclined push end face (4) and the side end face (2) is 45 degrees, as figure 1 , and then, the front-end step is filled with welded wear-resistant materials to form a fan-shaped end face (5), E>F, such as image 3 , and on both sides of the end face (2), and the upper and lower planes where the front working end face (3) intersects with it, the three sides are surfacing welded ...

Embodiment 2

[0016] Embodiment 2, a kind of hammer blade ( figure 1 ), including a flaky hammer body, one end of the hammer body is provided with a pin hole (1), the other end of the hammer body is the working end, and the two sides of the working end are side end faces (2), which are characterized in that The two right angles of the other working end of the hammer body ( figure 1 ), cut off the right angle, and process it into a stepped end face (9), such as Figure 7 , all the other are with embodiment 1.

Embodiment 3

[0017] Embodiment 3, a kind of hammer blade ( figure 1 ), including a sheet-shaped hammer body, one end of the hammer body is provided with a pin hole (1), and the other working end of the hammer body is characterized in that it is on the front surface of the other working end of the hammer body (3 ) have slot shapes such as Figure 8 , all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com