Hammer mill

A hammer mill and pulverizer technology, used in solid separation, sieves, grilles, etc., can solve the problems of high pulverization efficiency, short service life, and large relative speed of hammering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

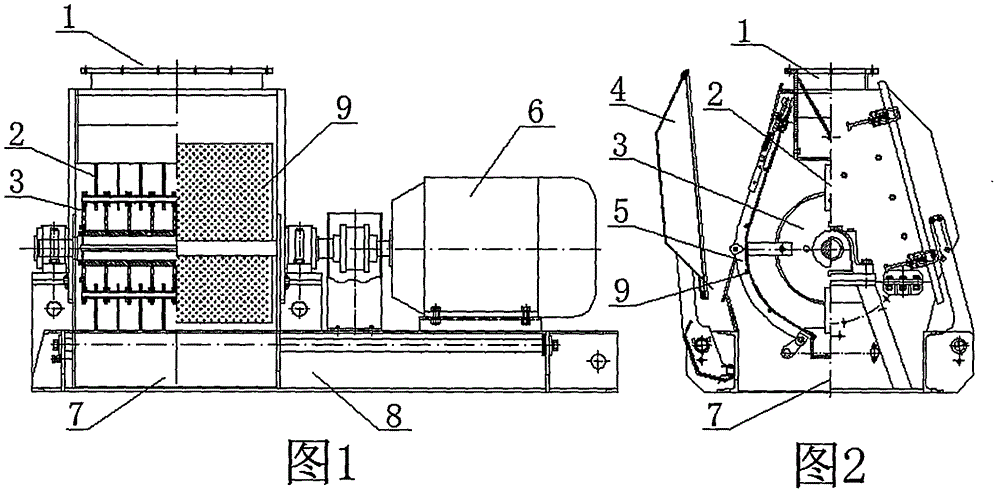

[0019] Embodiment 1: Fig. 1, Fig. 2, a kind of horizontal pulverizer, pulverizer inlet (1), hammer (2), rotor (3), door (4), press screen frame (5), motor (6), pulverizer outlet (7), machine body (8), sieve sheet (9), etc. composition. Hammers are mounted on the rotor. The front end of the hammer is treated with wear-resisting treatment such as tungsten carbide surfacing, and has a beveled edge surface, and the included angle a of the hammer edge angle is 45°. Considering the smooth rotation of the rotor, the Figure 7 When the hammer is used, it can be installed symmetrically and evenly on the front and back. Figure 5 , Image 6 When using two kinds of hammers, install them symmetrically and evenly. No matter which kind of hammer is used, each group of coaxial hammers maintains the same cutting direction, and the other group of hammers can use the opposite direction.

Embodiment 2

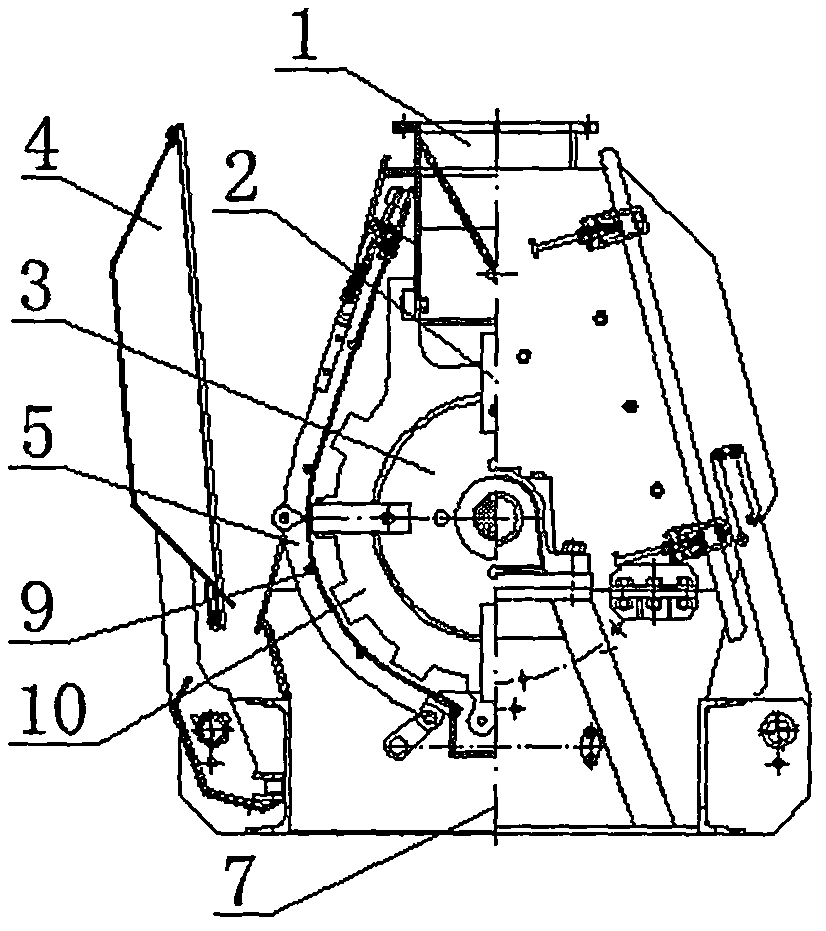

[0020] Example 2: image 3 Among them, a hammer mill with a fixed hammer, the pulverizer feed port (1), hammer (2), rotor (3), door (4), screen press frame (5), motor (6), The pulverizer discharge port (7), body (8), sieve sheet (9), fixed hammer (10) etc. are composed. The installation of the fixed hammer is required to be misaligned with the hammer and keep a certain distance. The installation method of the hammer is the same as that in Example 1.

Embodiment 3

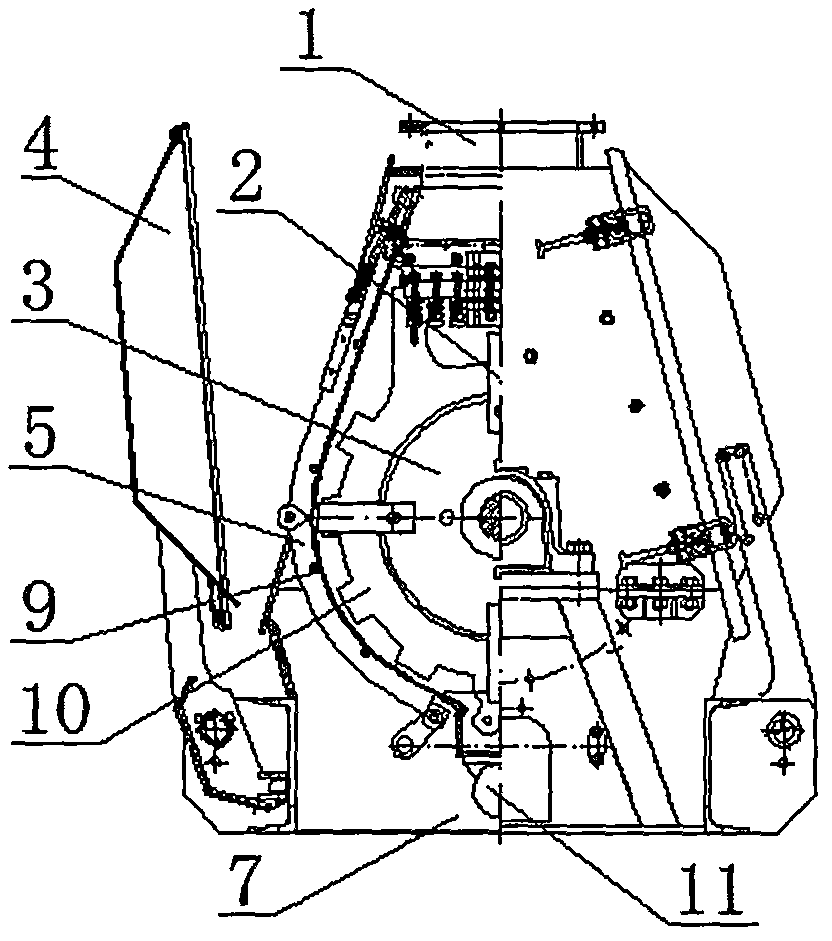

[0021] Example 3: Figure 4 , a hammer mill with vibrating screen, pulverizer inlet (1), hammer (2), rotor (3), door (4), screen press frame (5), motor (6), pulverizer Machine discharge port (7), body (8), sieve sheet (9), fixed hammer (10), vibrating motor (11) and other components. It is characterized in that there is a vibrating motor under the sieve pressing frame (5), the vibrating motor (11) is connected with the sieve pressing frame, and the sieve pressing frame and the sieve (9) can vibrate independently through vibration isolation devices such as springs, and the hammer is installed Method is with embodiment 1.

[0022] Beneficial effect:

[0023] For the pulverizer equipped with sharpened hammers, after the hammers hammer the material, the material no longer rotates with the hammers. In the hammering of another set of hammers, it is still required to maintain a large relative speed difference between the hammers and the materials. . At the same time, in addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com