Deep sea aquaculture net cage HDPE pipe material and preparation method thereof

A cage and deep-sea technology, applied in chemical instruments and methods, applications, fish farming, etc., can solve problems such as cage damage, mechanical performance decline, cracking, etc., and achieve high-efficiency wave resistance and long-term stable mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

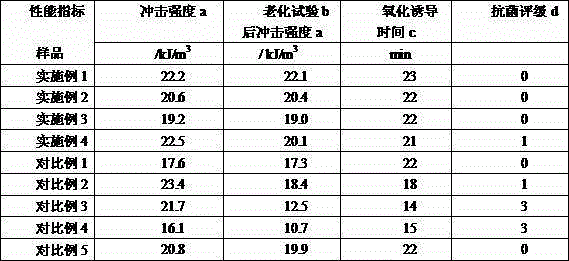

Examples

specific Embodiment approach

[0020] The present invention will be further described below in conjunction with specific examples, but the examples do not limit the present invention in any form. Unless otherwise specified, the reagents, methods and equipment used in the present invention are conventional reagents, methods and equipment in the technical field.

[0021] The selected raw material model of following embodiment:

[0022] PE100: Borealis HE3490-LS

[0023] POE: Mitsubishi Chemical DF110

[0024] UHMWPE: Yanshan Petrochemical 9100 CG

[0025] Polyethylene wax: Shandong Dongfeng Synthetic Chemical CH-4

[0026] Carbon black: Shanghai Cabot Chemical N550

[0027] UV absorber: Jiangsu Baosheng Chemical UV-531

[0028] Light stabilizer: Germany BASF 770

[0029] Antioxidant: Germany BASF 1010

[0030] Through the test, it is found that with the increase of the amount of POE added, the impact strength of the pipe increases from small to large, and then decreases after a peak. Preferably, the a...

Embodiment 1

[0038] Prepare HDPE pipe according to the following formula:

[0039] Inner layer: HE3490-LS 100 parts, DF110 8 parts;

[0040] Outer layer: 9100CG 100 parts, DF110 15 parts, CH-4 10 parts, N550 8 parts, UV-531 10 parts, 770 10 parts, 1010 10 parts.

Embodiment 2

[0042] Prepare HDPE pipe according to the following formula:

[0043] Inner layer: HE3490-LS 100 parts, DF110 5 parts;

[0044] Outer layer: 9100CG 100 parts, DF110 10 parts, CH-4 10 parts, N550 8 parts, UV-531 10 parts, 770 10 parts, 1010 10 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com