A kind of die-casting mold for producing shell and the production method of shell

A technology for die-casting molds and shells, applied in the field of die-casting molds, can solve problems such as material shortage, and achieve the effect of increasing the feeding speed and reducing the frontal impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

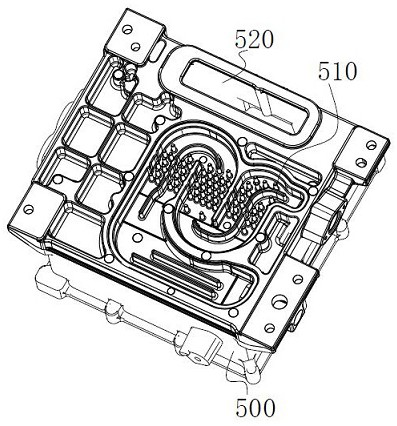

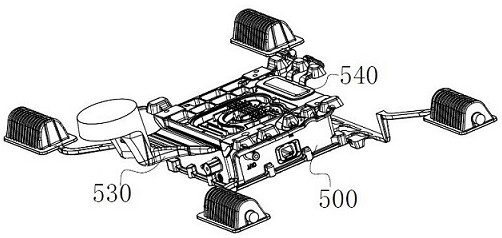

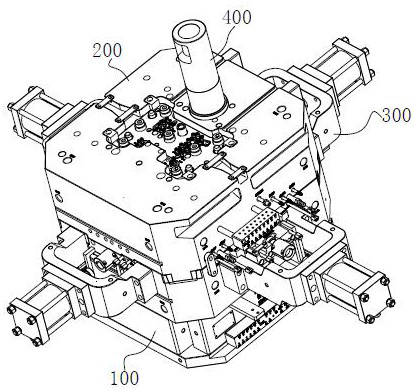

[0034] like Figure 2 to Figure 7 As shown, a die-casting mold for producing a casing of the present invention includes: a movable mold assembly 100 , a fixed mold assembly 200 and a slider mechanism 300 . Below, the slider mechanism 300 is slidably arranged on the movable mold assembly 100, and a product cavity is formed between the movable mold assembly 100, the fixed mold assembly 200 and the slider mechanism 300, and further includes: a runner assembly 400, a runner assembly 400 has a feed sleeve 410 and a diverter cone 420 arranged on the movable die assembly 100 , the feed sleeve 410 is inserted on the fixed die assembly 200 , and the upper surface of the diverter cone 420 is between the lower surface of the fixed die assembly 200 . A fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com