Mixed lap joint type ingate system of aluminum alloy die-casting gearbox shell

A technology of inner sprue and gearbox to avoid the generation of eddy current and turbulent flow area, slow down the frontal impact, reduce the local drag coefficient and pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

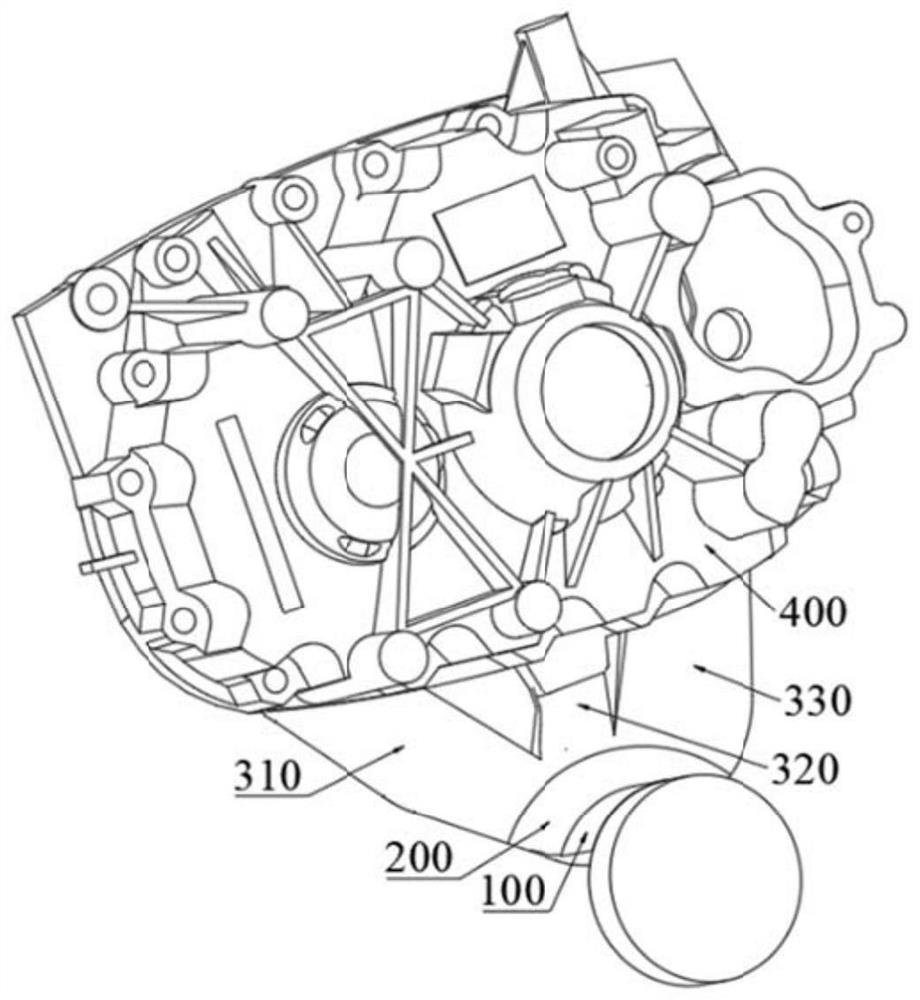

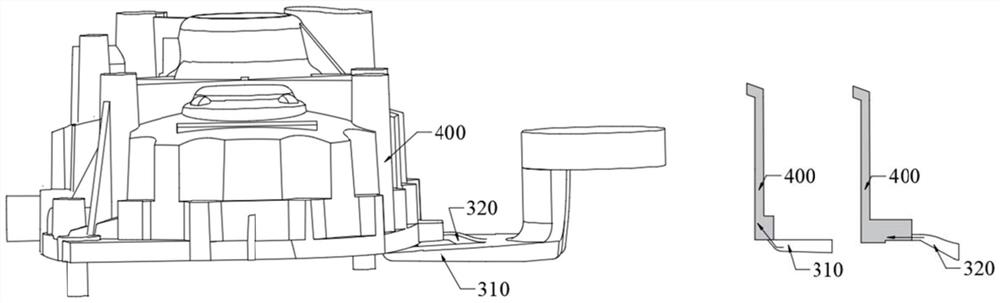

[0020] A hybrid lap-type inrunner system for an aluminum alloy die-casting gearbox housing, the inrunner system consists of a housing cavity 400, an inrunner 310, an inrunner 320, an inrunner 330, a runner 200 and The four parts of the sprue 100 are sequentially connected, such as figure 1 shown. In order to make the molten aluminum advance smoothly in the runner system and enhance its filling capacity, the housing cavity 400, the runner 310, the runner 320, the runner 330, the runner 200 and The successive connections of the four parts of the sprue 100 are transitioned through rounded corners, and the radius of the rounded corners is in the range of 2 to 10 mm. Preferably, combined with the size of the runner in this embodiment, when the sprue 100 and the runner 200 are rounded at the junction Radius 10 mm, runner 200 and ingate 310, ingate 320, ingate 330 junction fillet radius 5 mm and ingate 310, ingate 320, ingate 330 and shell cavity 400 When the fillet radius of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com