Rotary Brush Blueberry Harvester

A technology of rotating brushes and harvesters, which is applied to harvesters, picking machines, agricultural machinery and tools, etc., can solve the problems of mechanical damage to blueberry fruit trees and fruits, difficult control of vibration parameters, decline in fruit quality and its economic value, etc., to achieve The effect of improving efficiency, reducing labor intensity of workers, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

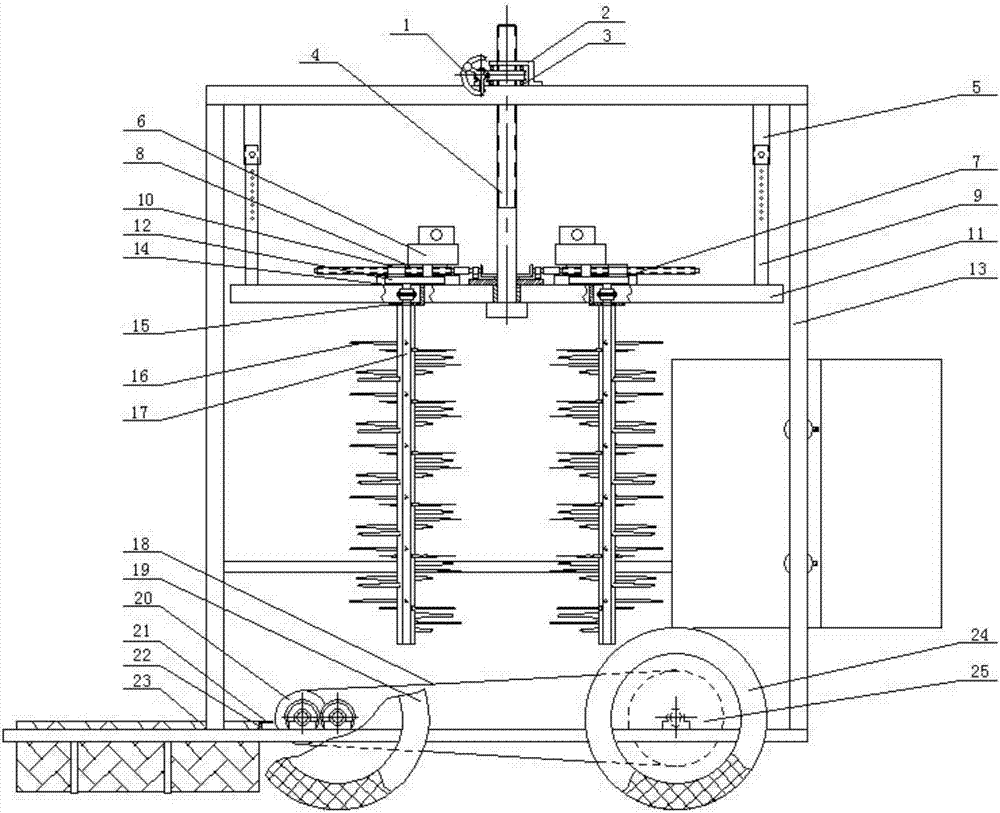

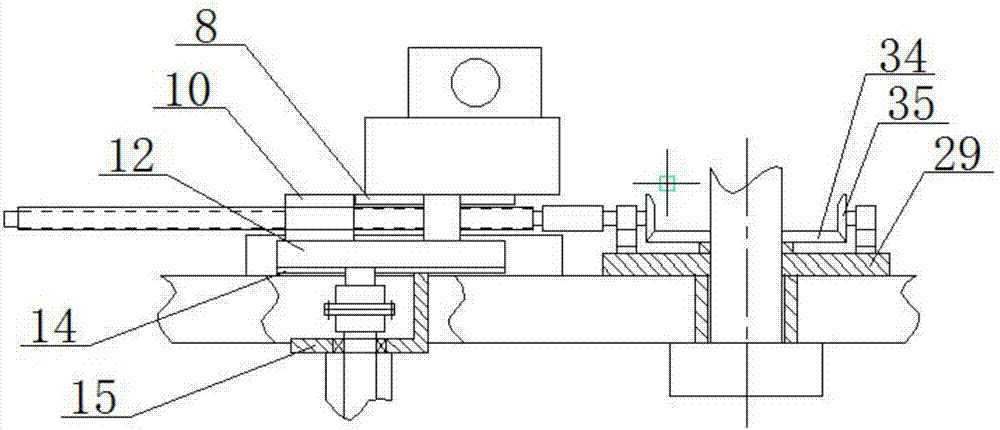

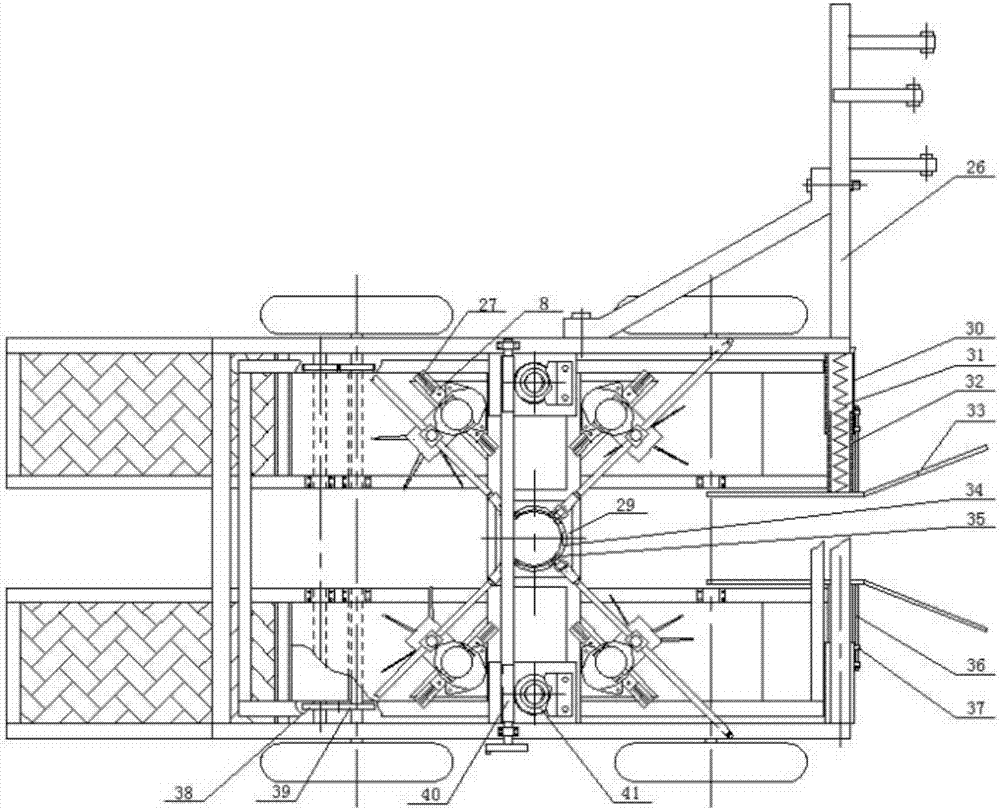

[0023]Rotary brush blueberry harvester, its main components include suspension frame 26, outer frame 13, inner frame 11, tree height follower adjuster, crown diameter follower adjuster, tree crown guide, hydraulic motor 6, T-shaped groove slideway 27. T-shaped sliding seat 8, reduction box 12, reduction box base 14, rotating brush mandrel support frame 15, rotating brush assembly, fruit conveying device, front traveling wheel 24, rear traveling wheel 19, collection box take-up plate 21, Collection box baffle plate 22, fruit collection box 23, according to the above-mentioned rotary brush type blueberry harvester, the described tree height following adjuster includes height adjustment guide cylinder 5, height adjustment lifting rod 9, height adjustment hand wheel 1, screw shaft Hole worm wheel support 2, axial thrust bearing 3, screw shaft hole worm wheel 41, worm shaft 40 at both ends, lifting screw shaft 4, according to the above-mentioned rotary brush blueberry harvester, the...

Embodiment 2

[0026] The tree height following adjuster mainly includes height adjustment guide cylinder 5, height adjustment lifting rod 9, height adjustment hand wheel 1, screw shaft hole worm wheel support 2, axial thrust bearing 3, screw shaft hole worm wheel 41, two ends The worm shaft 40, the lifting screw shaft 4, the height-adjusting guide tube 5 are fixed on the outer frame 13, the height-adjusting lifting rod 9 is fixed on the top of the inner frame 11, and the height-adjusting lifting rod 9 is drilled with a height adjustment hole. The guide cylinder 5 and the height-adjusting lifting rod 9 are fixed by bolts, the screw shaft hole worm wheel support 2 is fixed on the top of the outer frame 13, and the lifting screw shaft 4 passes through the screw shaft hole. The worm wheel support 2 is matched with the inner frame 11 through a sleeve. The center of the spiral shaft hole worm gear 41 is an internal thread hole structure, which is assembled with the lifting screw shaft 4 to form a ...

Embodiment 3

[0028] The crown diameter following adjuster includes a supporting plate 29, a large bevel gear 34, a small bevel gear 35, a crown diameter adjusting screw 7, and a spiral slide seat 10. The supporting plate 29 is fixed in the center of the top of the inner frame 11 At the position, the large bevel gear 34 is fitted on the supporting plate 29 and meshes with the four small bevel gears 35. The axes of the four small bevel gears 35 are spaced 90° apart from each other in the same plane. One end of the shaft device and the crown diameter adjusting screw 7 is fixed, and the other end of the crown diameter adjusting screw 7 is a square joint, and 4 crown diameter adjusting screw 7 are assembled on the inner frame 11 through the bearing seat, for different For blueberry plants with a crown diameter, any crown diameter adjustment lead screw 7 can be rotated, and the other three crown diameter adjustment lead screws 7 are driven to rotate through the meshing of the large bevel gear 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com