Supplementing mechanism of rear supplementing type refrigerator

A technology for refrigerators and cabinets, applied in the direction of coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, which can solve the problems affecting vending machine sales, labor Regularly observe and affect the buyer's perception, etc., to achieve the effect of good service life, large size, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

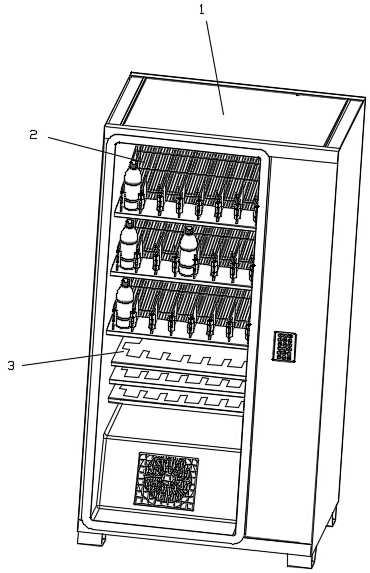

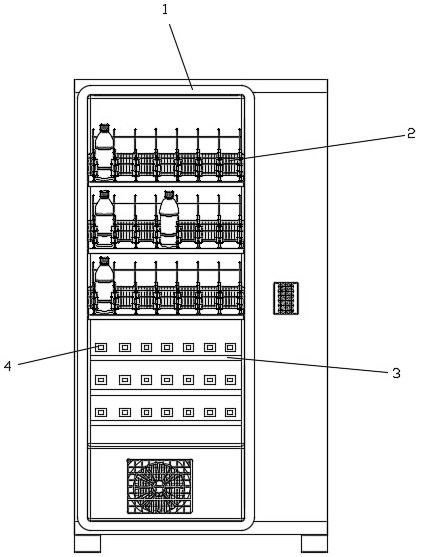

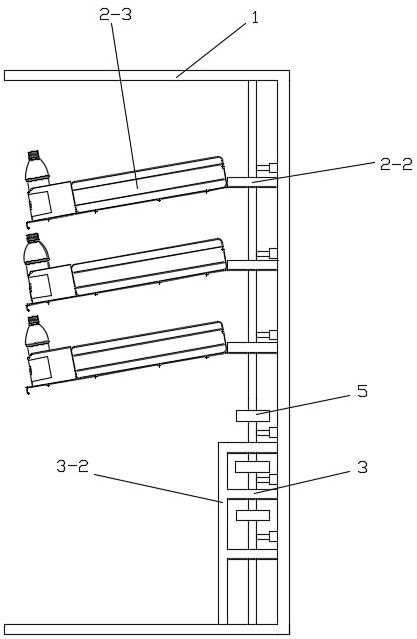

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Such as Figure 1-7 As shown, a replenishing mechanism for a post-replenishment type freezer includes a cabinet body 1, a plurality of display layers 2 are arranged in the cabinet body 1, and several display layers 2 are located at different levels of the cabinet body 1, and the display layers 2 are formed There are several display positions 2-1; a horizontally arranged material preparation layer 3 is arranged below the display layer 2, and the number of the material preparation layer 3 is consistent with the number of the display layer 2; the material preparation layer 3 is a hollow structure, and the material preparation layer 3 The first inner comb teeth 3-1 are formed in the hollow structure; the feed plate 5 consistent with the number of the stock layer 3 is also provided in the cabinet body 1, and the size of the feed plate 5 is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com