Ceramic tile knocking equipment for building

A technology for building and ceramic tiles, applied in the direction of construction and building structure, can solve the problems of uneven force, broken tiles, etc., and achieve the effect of avoiding the residual agglomeration of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

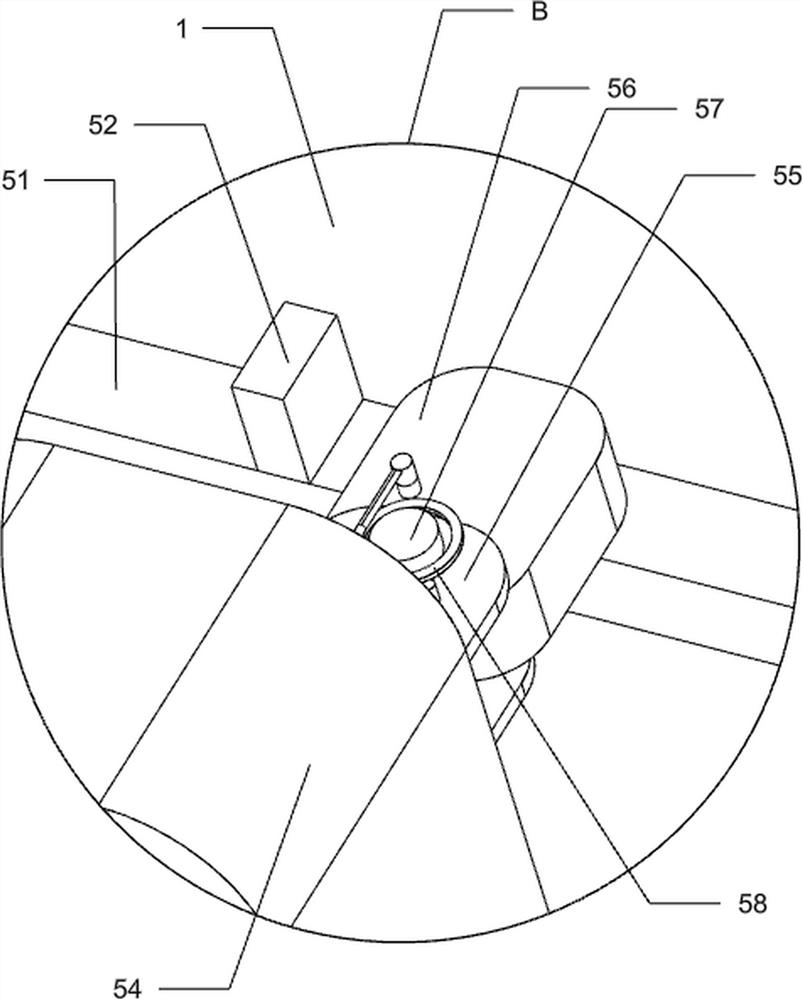

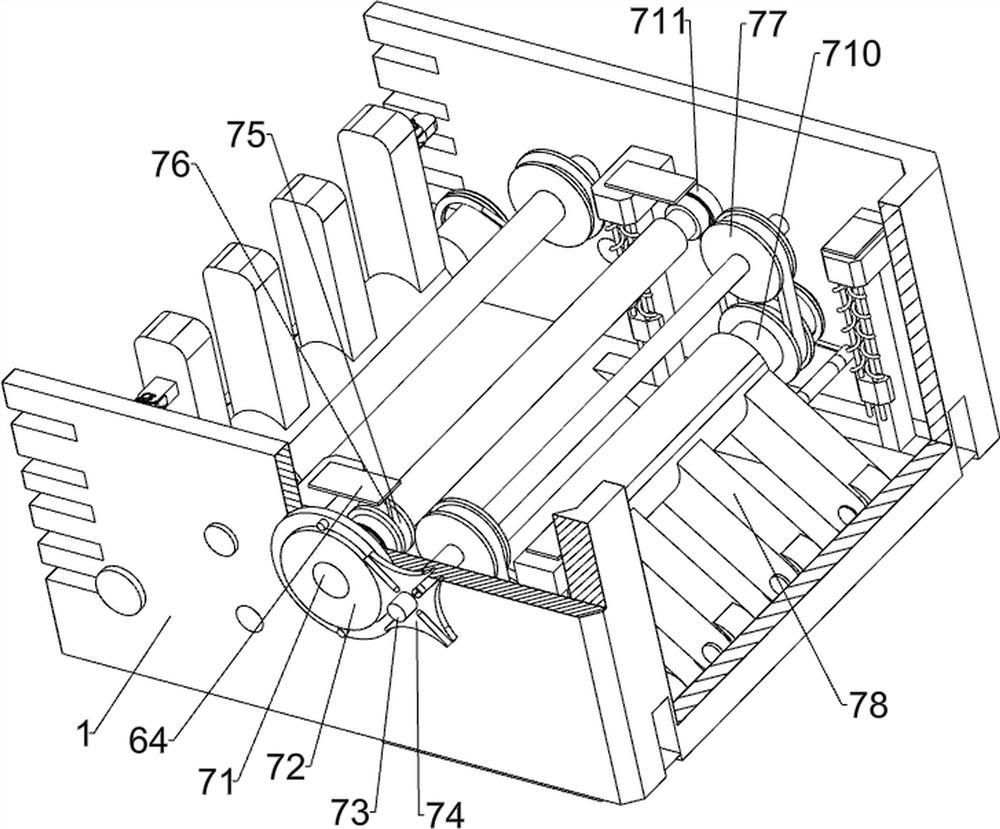

[0037] A building tile knocking in the equipment, including housing 1, roller 2, rotating shaft 21, rubber wheel 3, drive mechanism 4, and knocking mechanism 5, see Figure 1 - Figure 8 As shown, the pendant-shaped shaft 21 between the lower left side of the lower portion of the housing 1 and the front and rear side of the front and rear side, and the front and rear ends of the rotating shaft 21 are mounted by the welding connection. 2, left A drive mechanism 4 is mounted between the side shaft 21 and the inner side of the housing 1, the drive mechanism 4 is used to provide power, and the drive mechanism 4 and the housing 1 are mounted with a knocking mechanism 5, and the mounting mechanism 5 is rotated on the mounting of the mounting. The rubber wheel 3, when the hit mechanism 5 operates the rubber wheel 3, the rubber wheel 3 is tried to the tile.

[0038] The drive mechanism 4 includes a gear shaft 42, a column gear 43, a hollow rod 44, a bushing 45, a connecting rod 46, a first ...

Embodiment 2

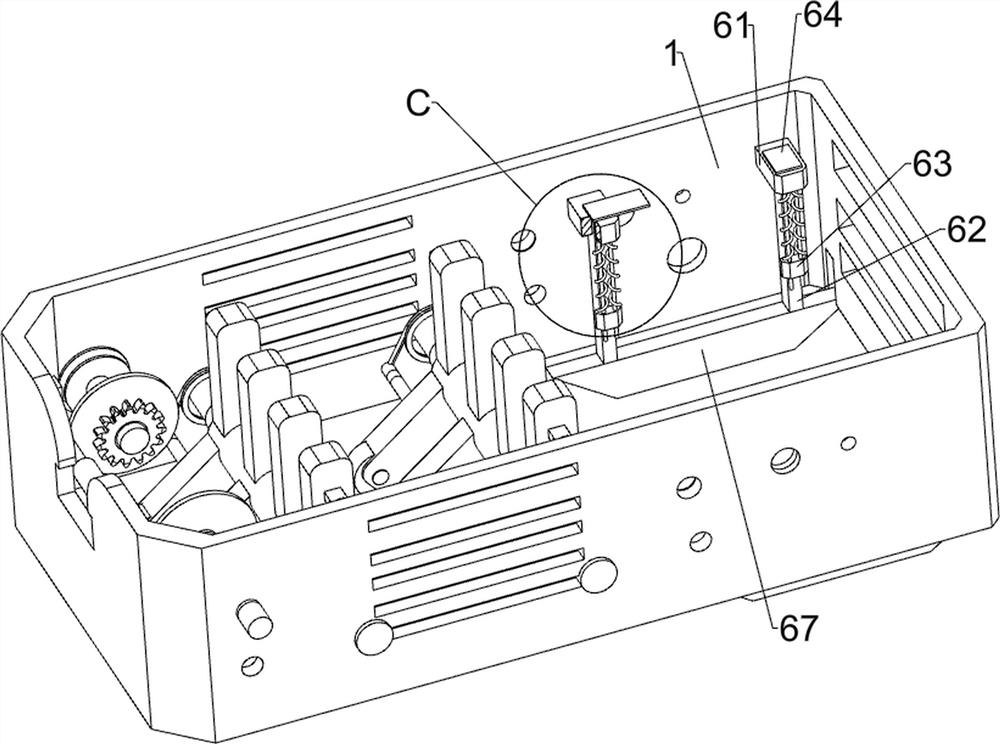

[0044] Based on Example 1 and Example 2, a finite mechanism 6 includes a restricted block 61, a standing plate 62, a mounting block 63, a restricted plate 64, a guide post 65, a second column spring. 66 and ladder block 67, see figure 1 , figure 2 , Figure 9 and Figure 10 As shown, two fixed blocks 61 are mounted by the upper and rear sides of the housing 1, and the mid-pull type, the mid-fixing type, and the top portion of the fixed block 61 is limited to the top of the plate 62. The seat plate 64, the front side two sets of stands are fixed between the trapezoidal block 67, and when the casing 1 drives the ladder block 67 to move to the right, the trapezoidal block 67 can achieve the tiles of the tiles, the front side fixed The bottom side of the block 61 is attached to the front side of the bottom side of the rear fixed block 61 by the welding connection by welding, and the two guide column 65 on each of the fixed block 61 has a mounting block. 63. The upper right side of the m...

Embodiment 3

[0049] Based on Example 1 and Example 2, there is also a scraper mechanism 8, a scraping mechanism 8 includes a finite frame 81, a rotating rod 82, a second belt assembly 83, and a scraper plate 84, see figure 1 , figure 2 and Figure 14 As shown, the finish frame 81 is mounted by the lower portion of the outer left side surface of the housing 1, and the rotation of the rotating rod 82 is rotated between the front and rear two-side limit frame 81, the rotor rod 82 The circumferential uniform intervals are mounted by the welded connection, and when the squeegee plate 84 is rotated, the wiper plate 84 can realize the concrete scraping on the tile, and the front and rear of the rotating rod 82 respectively A second belt assembly 83 is connected between the front and rear sides of the left side shaft 21, and the second belt assembly 83 consists of two pulley and the flat belt, one of which is fixed to the rotating rod 82 and the other pulley fixing sleeve is on the left side. On the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com