Patents

Literature

46results about How to "Affect subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactor

ActiveCN101007254AAvoid chippingAvoid wear and tearChemical/physical processesNuclear engineeringLife time

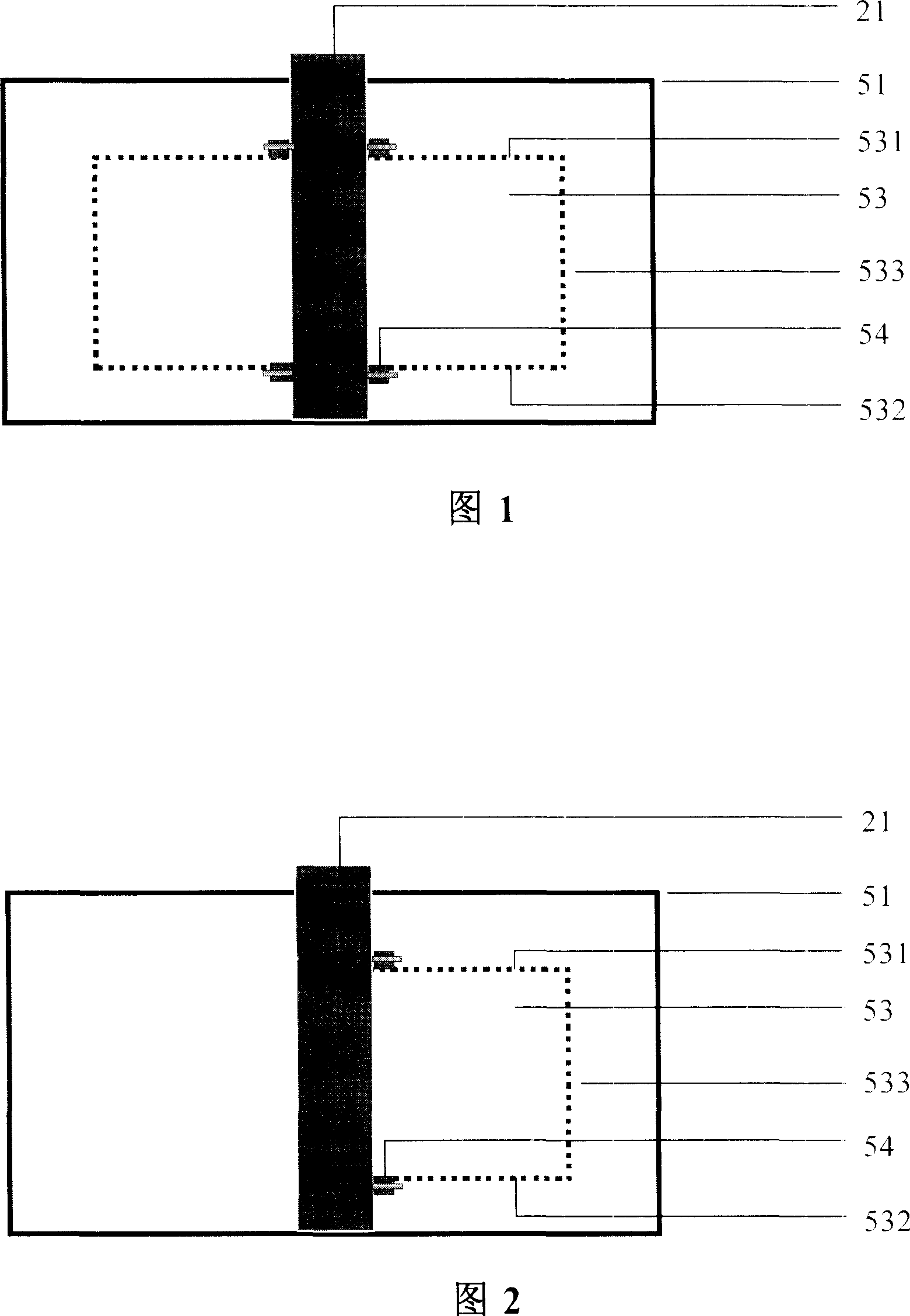

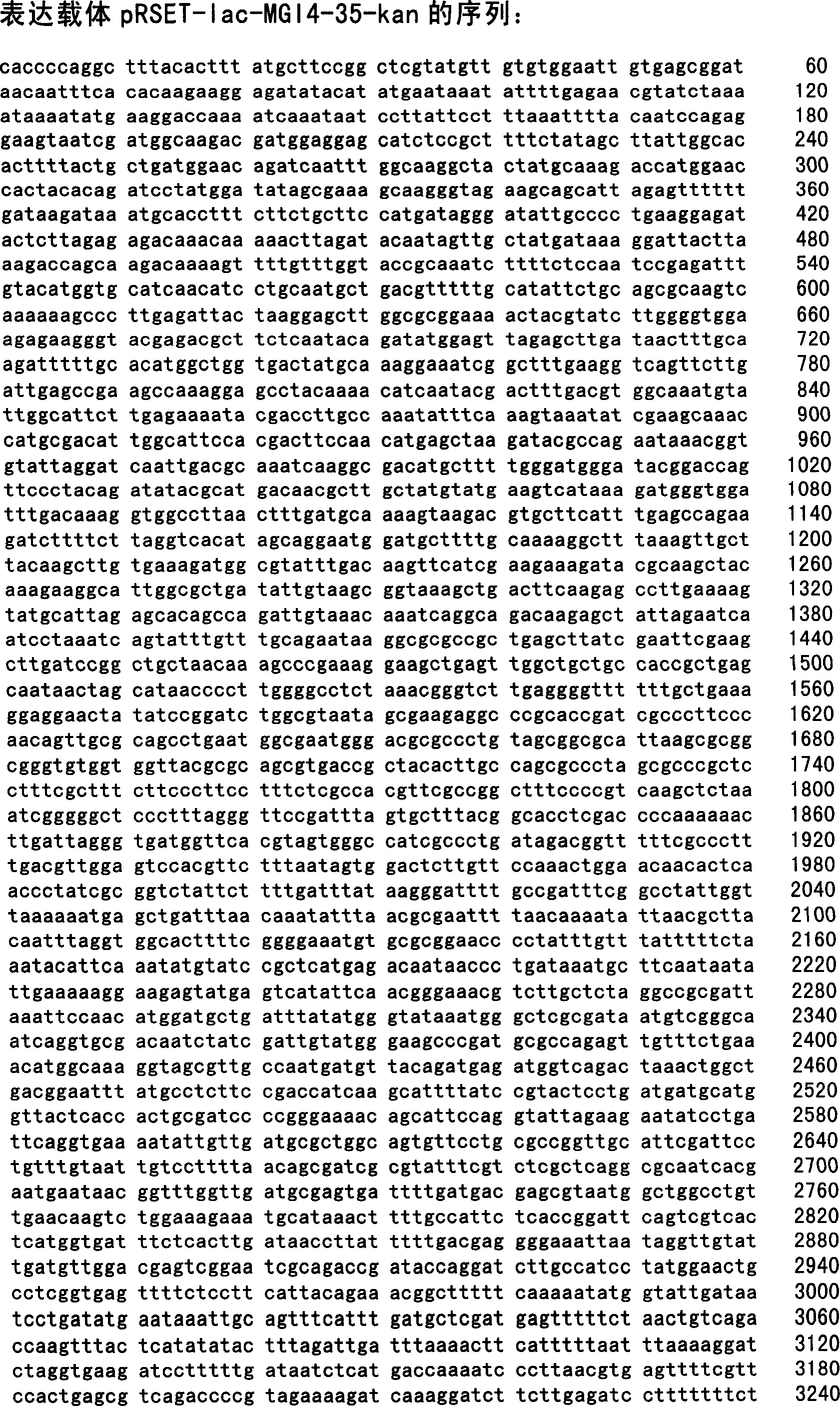

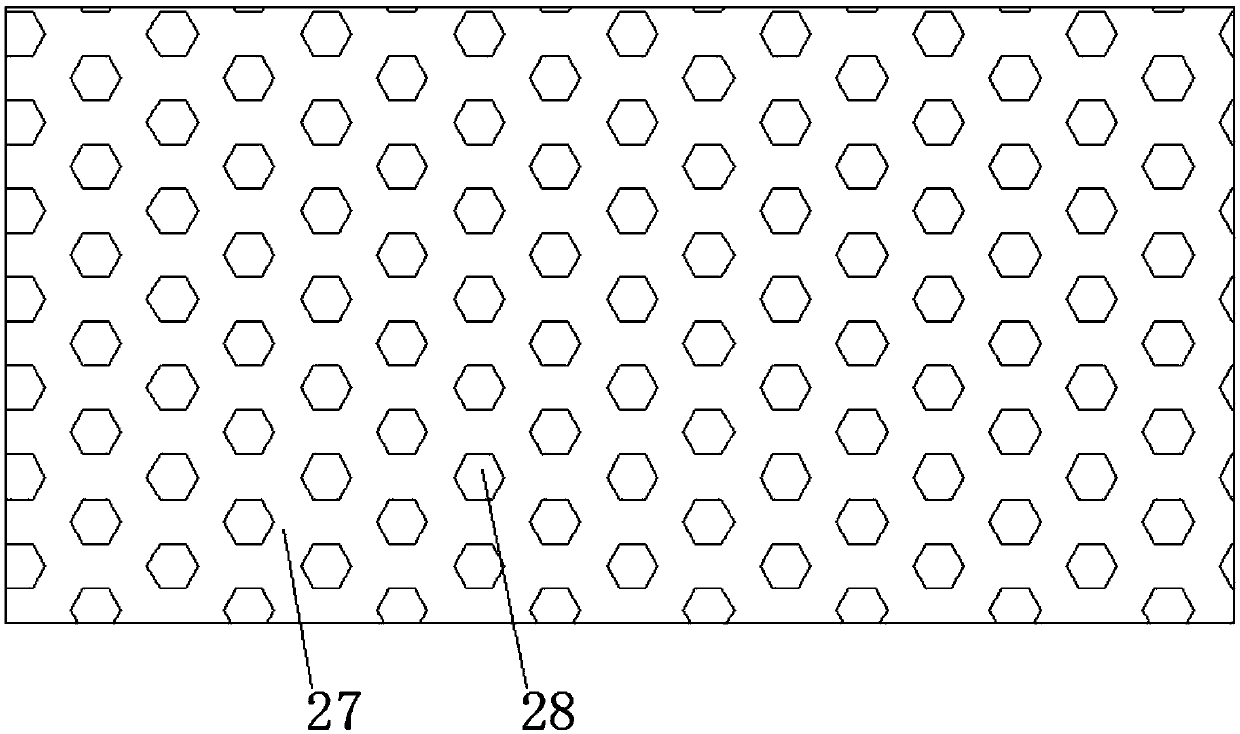

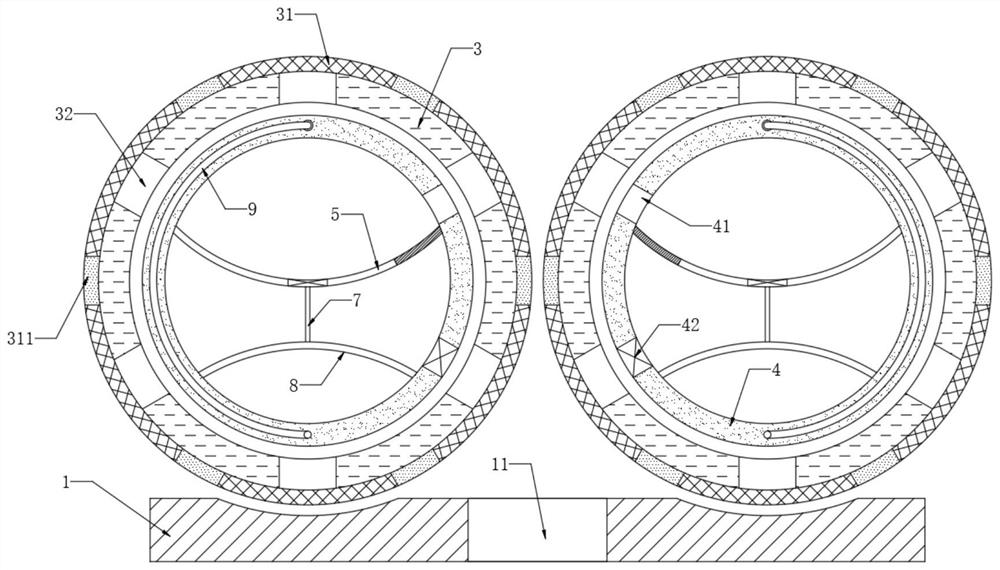

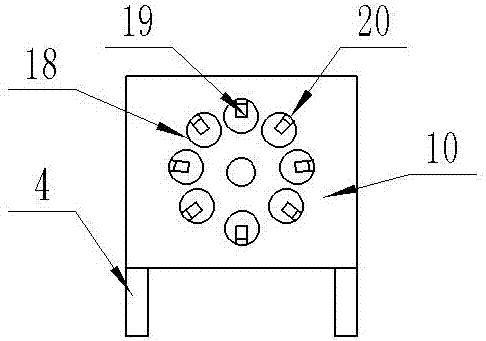

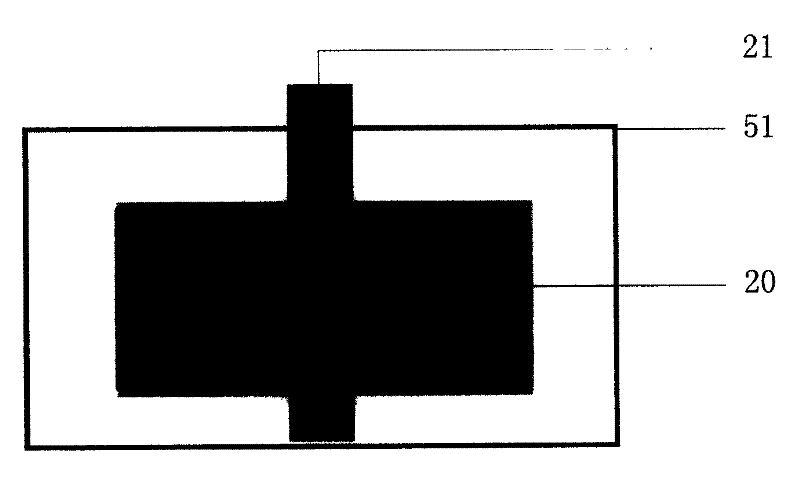

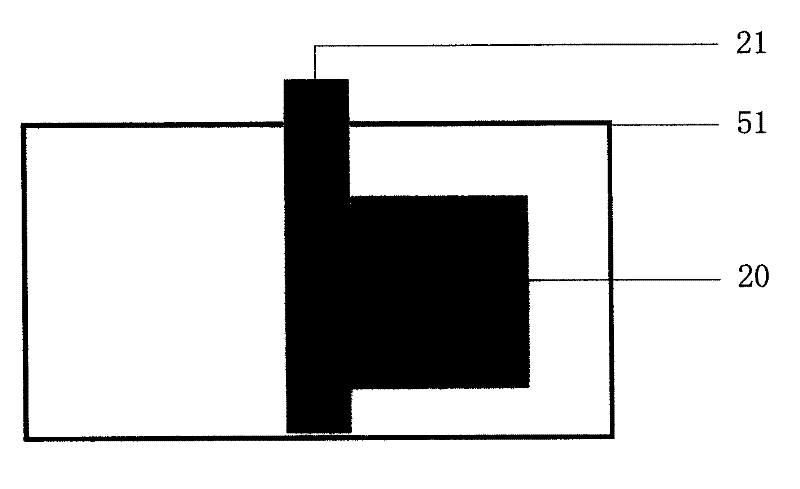

The invention discloses a reactor which reaction media is liquid, the reactor includes at least one reaction tank, said reaction tank includes tank body and revolution axis which is installed in the tank and can rotate, said reaction tank also includes a container fixed on said axis, the whole outer wall of said container is equipped with holes which can penetrate reaction liquid and gas. The reactor provided by the invention can prevent the vitality of activator decline, extend life time of activator and has characteristics of high exchange efficiency, adequate reaction and wide application range.

Owner:BIORIGHT WORLDWIDE

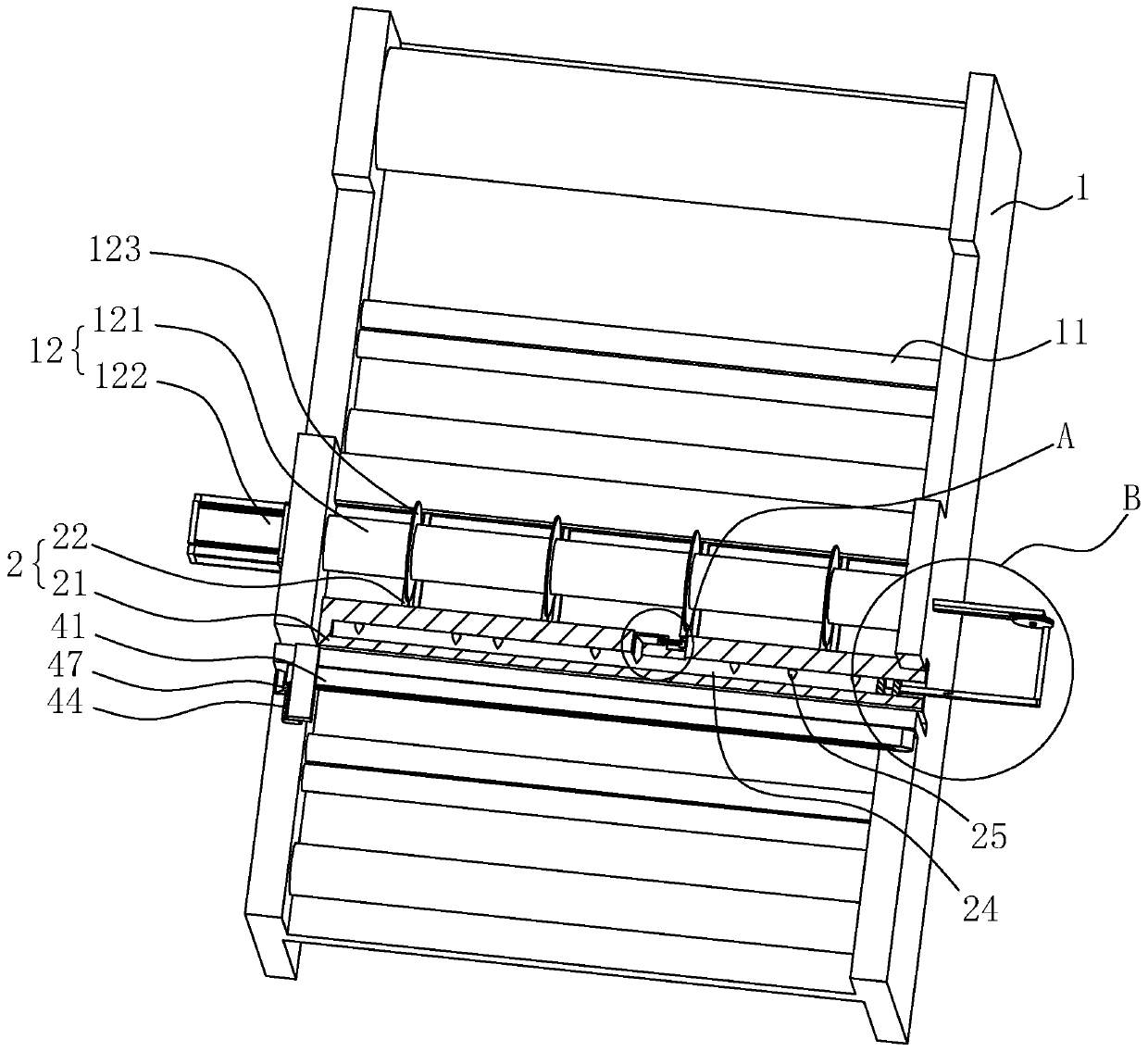

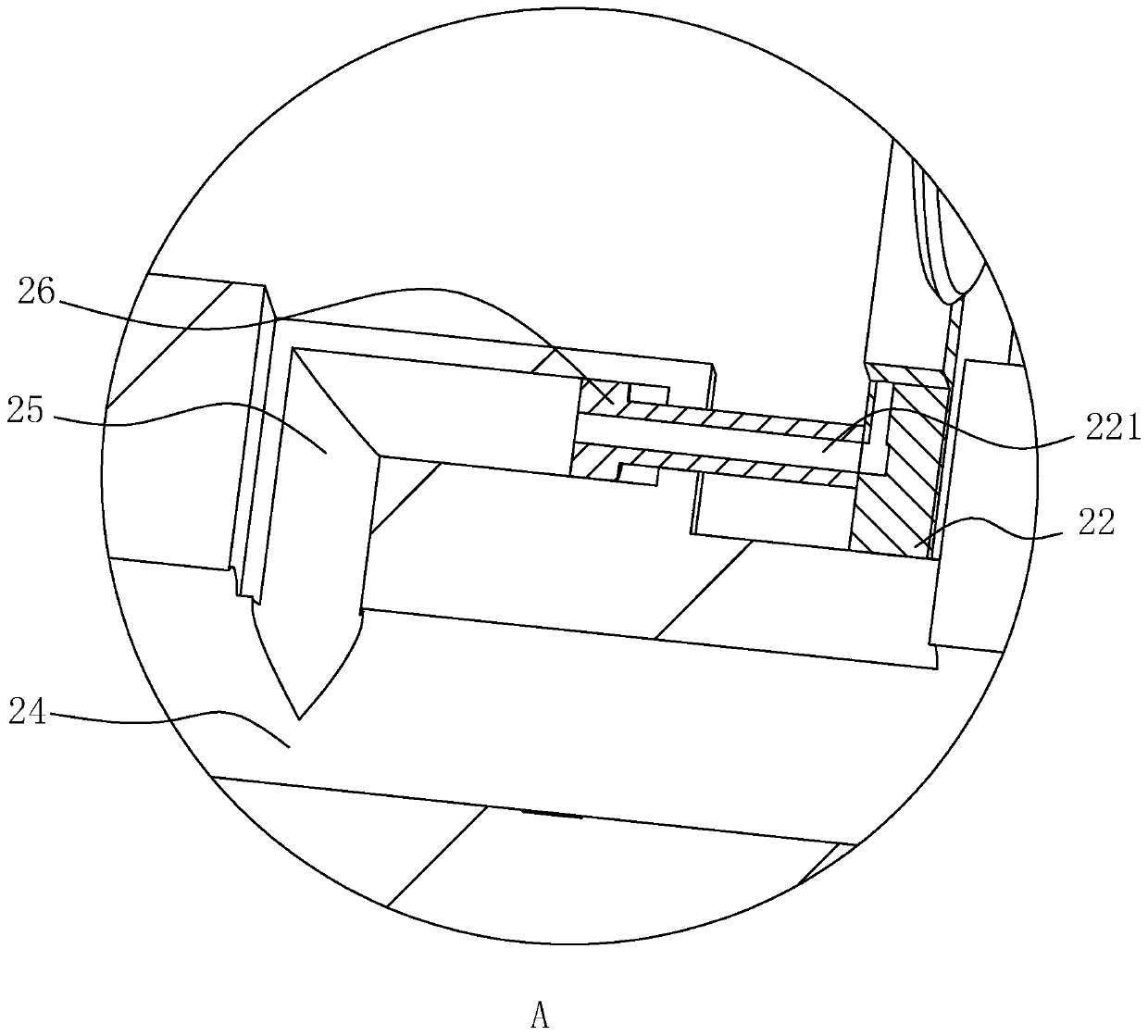

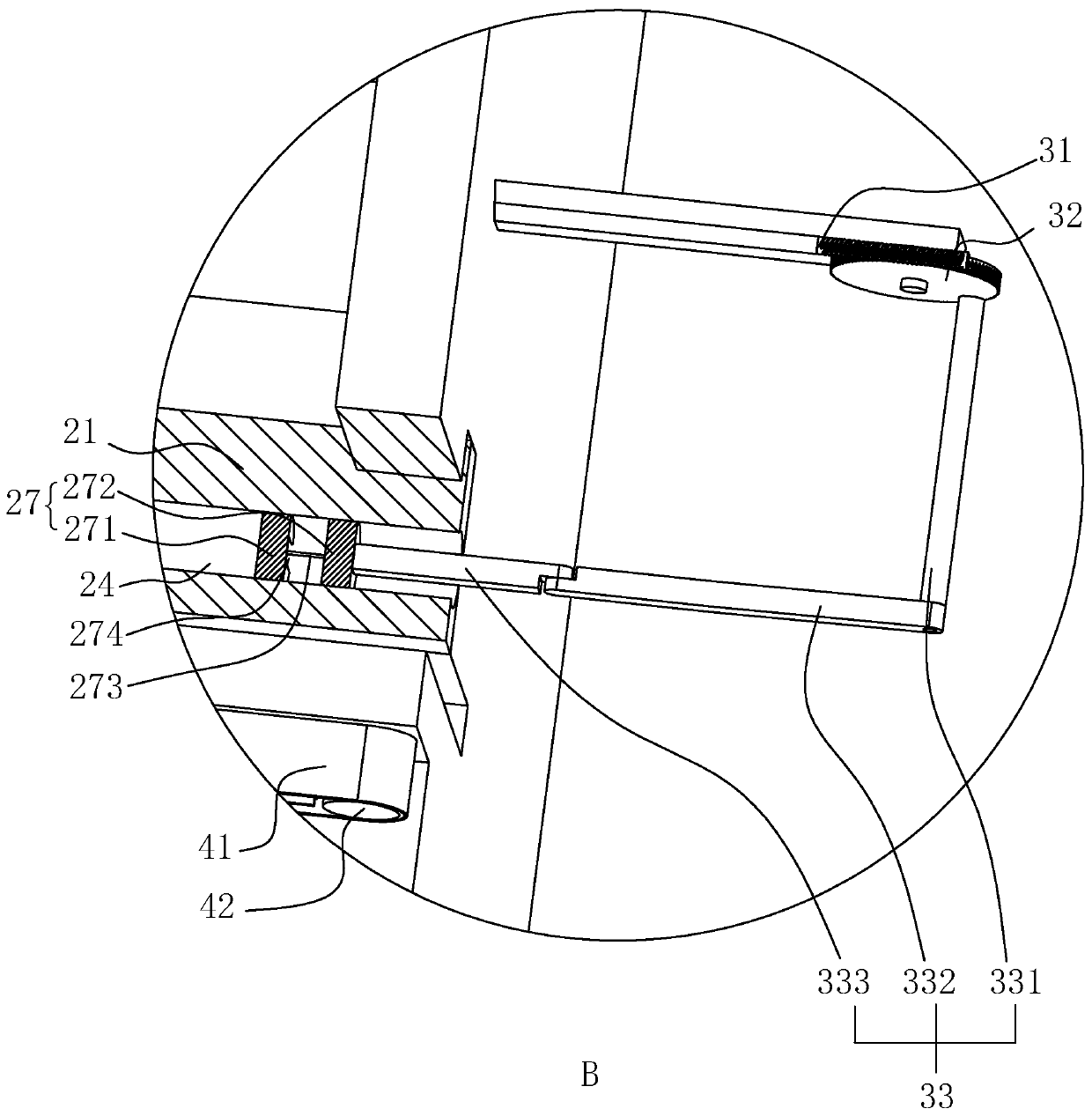

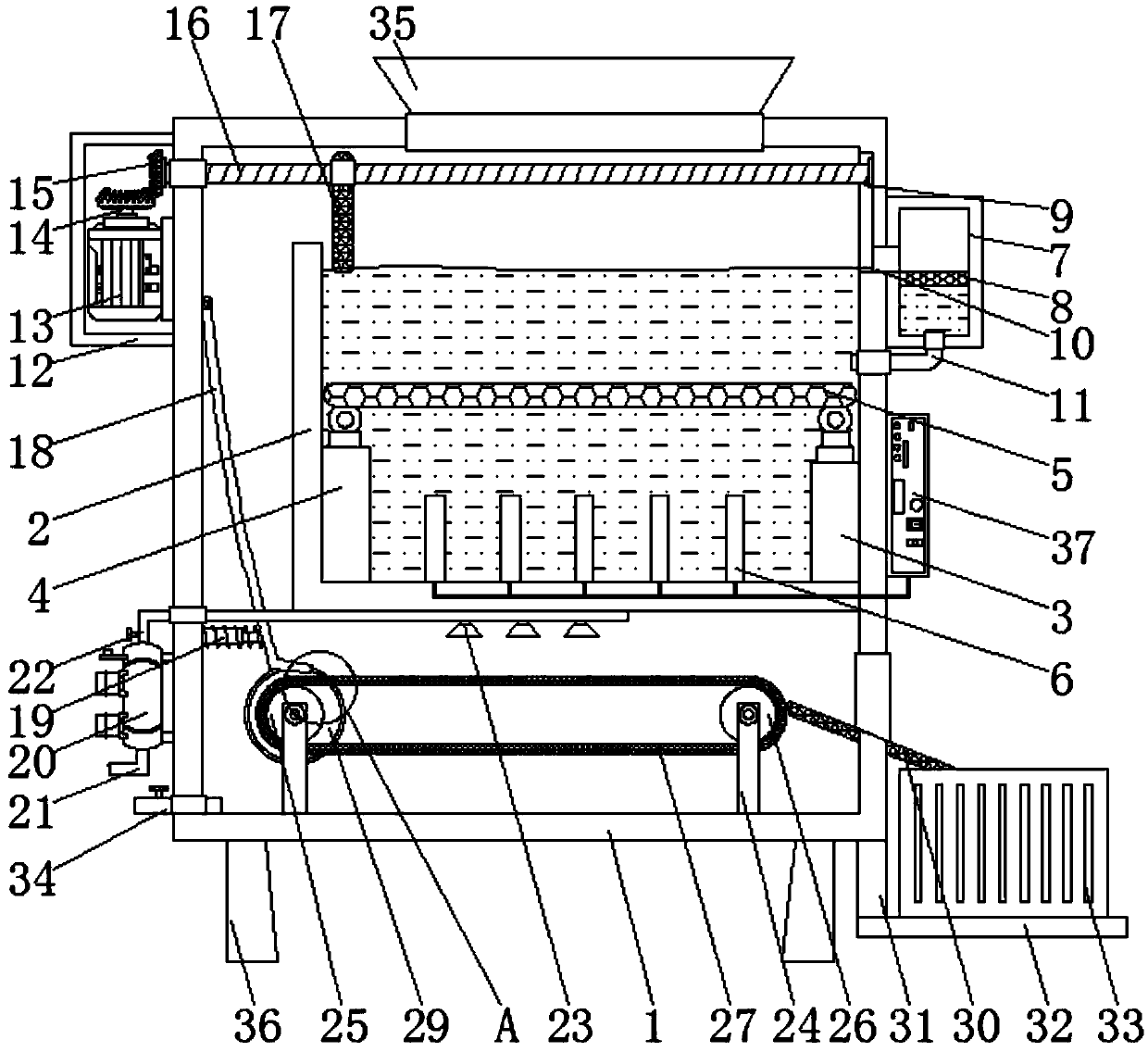

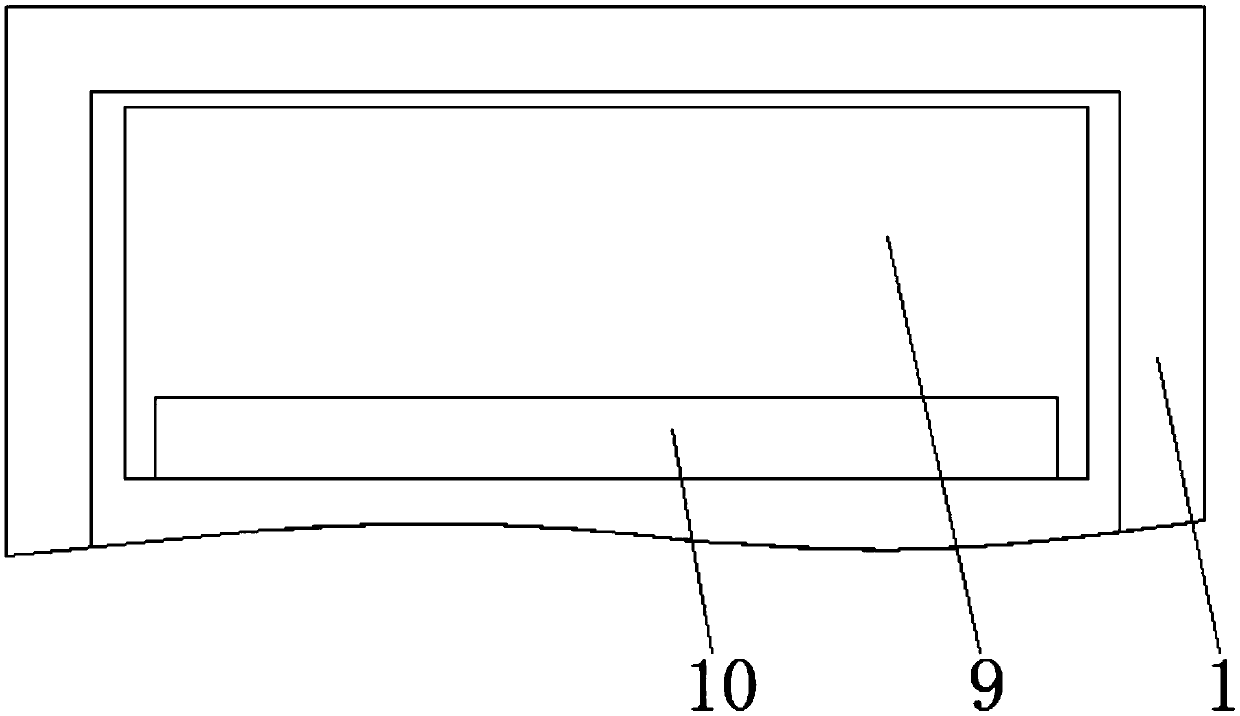

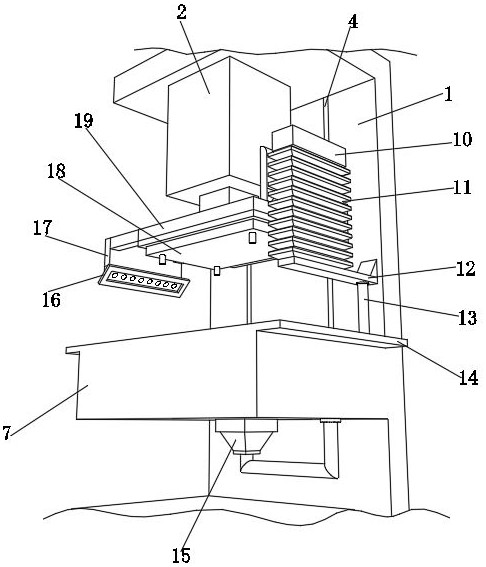

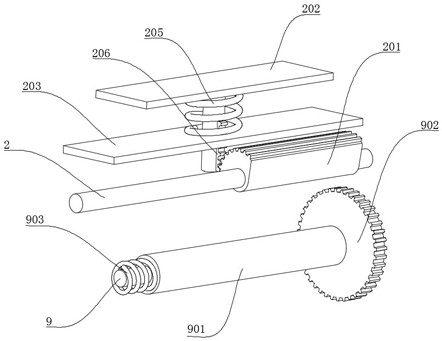

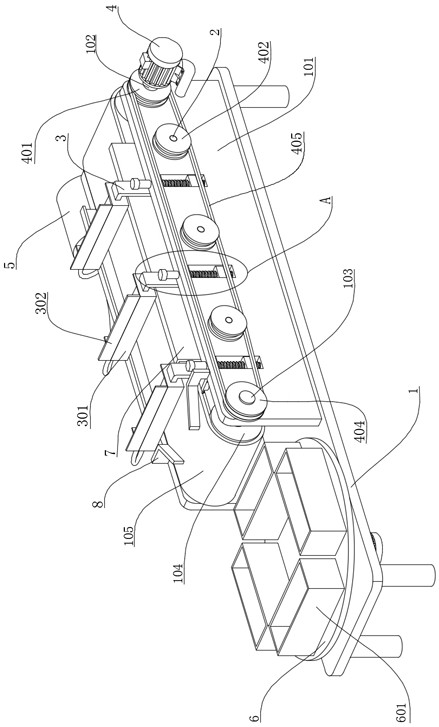

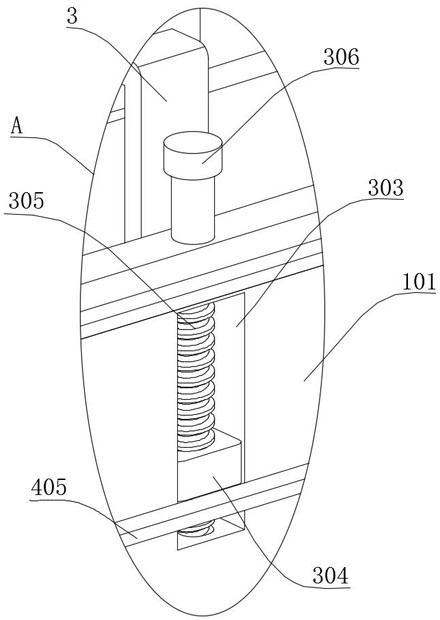

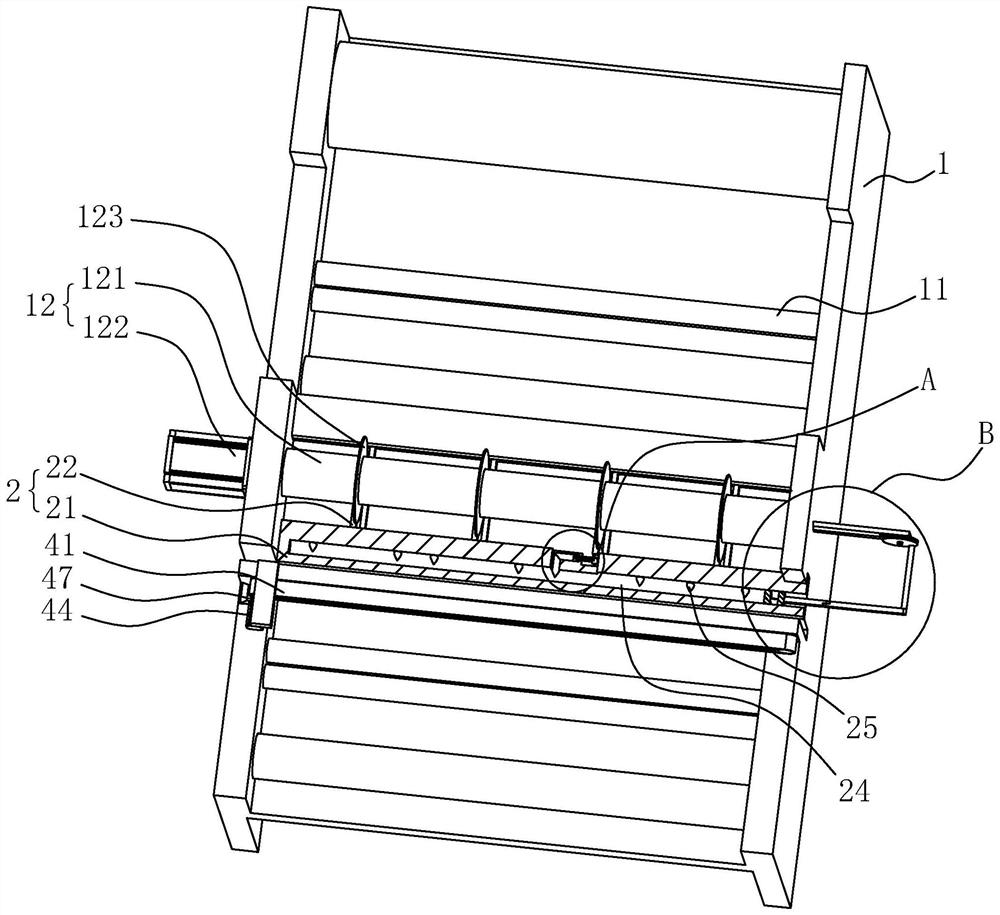

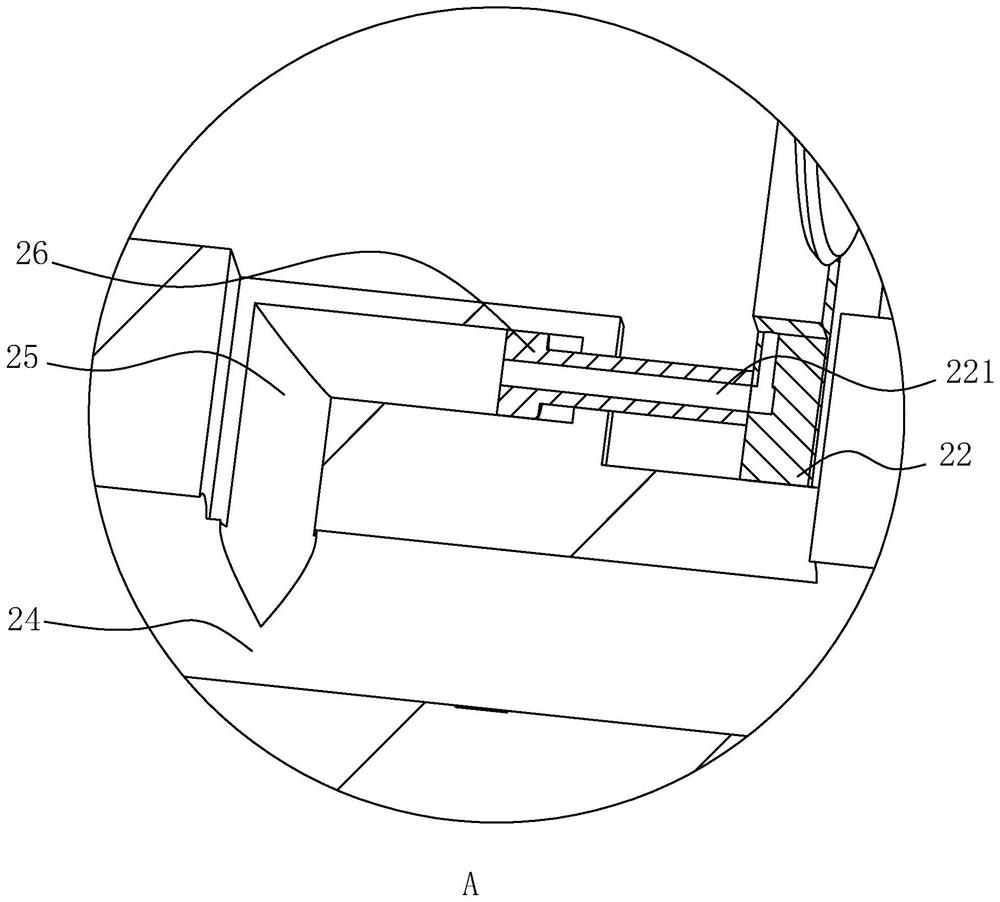

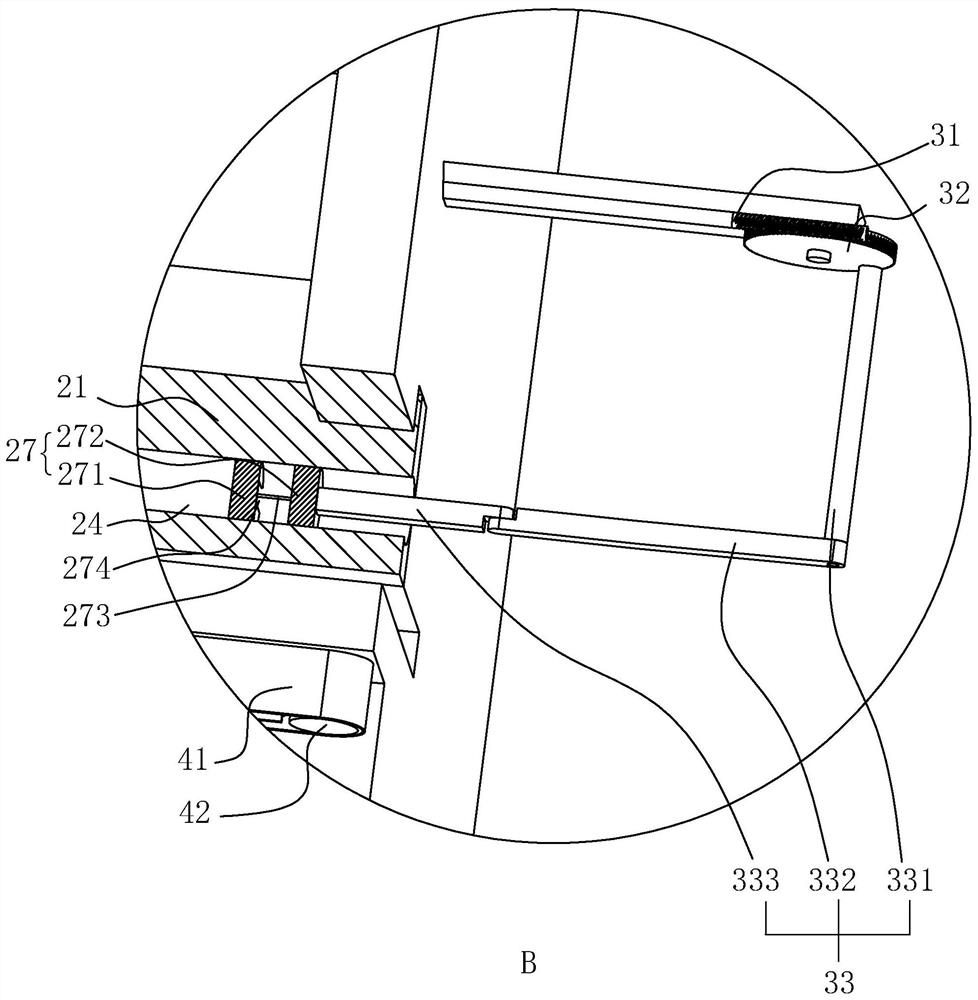

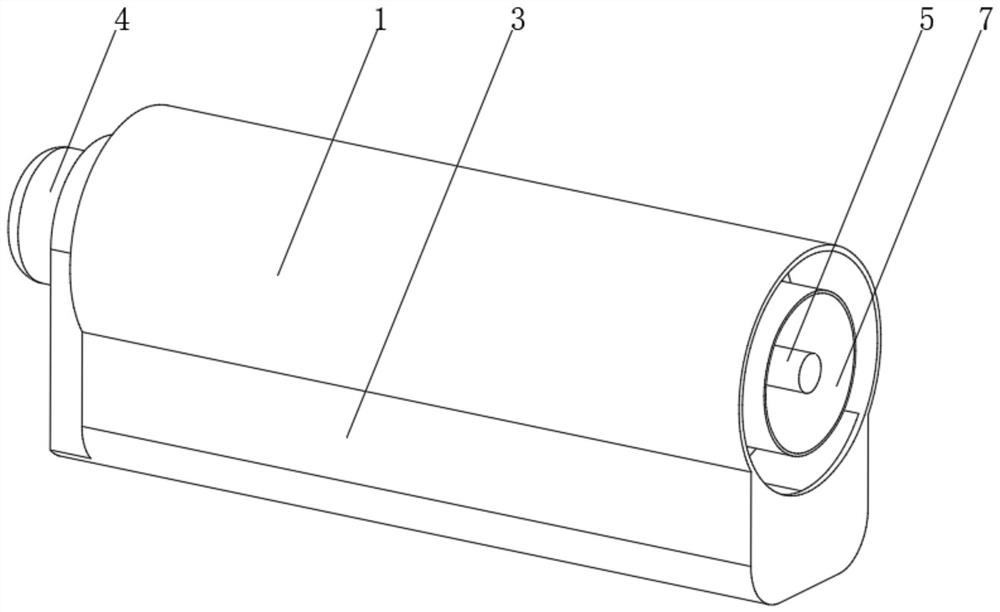

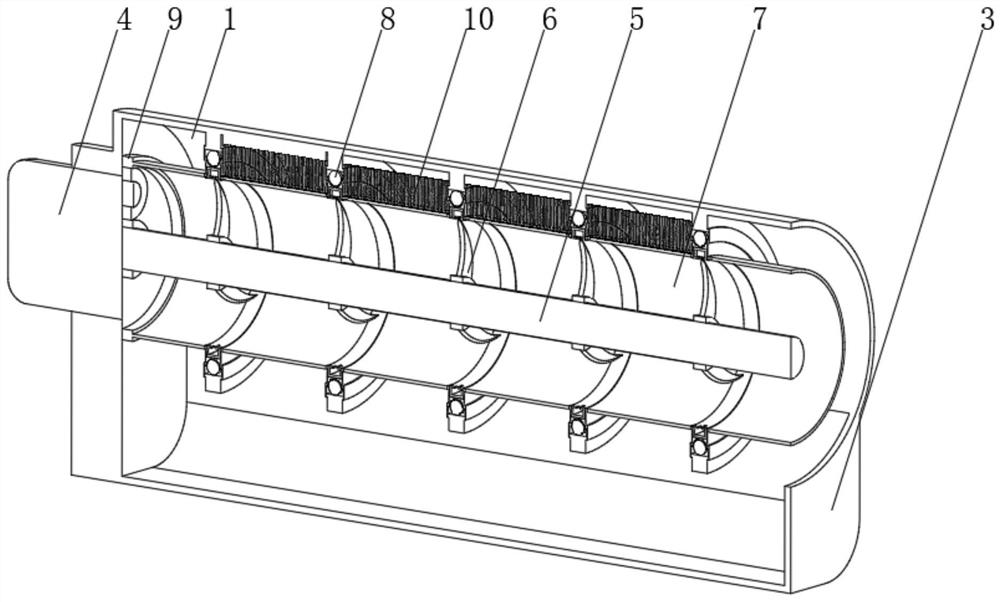

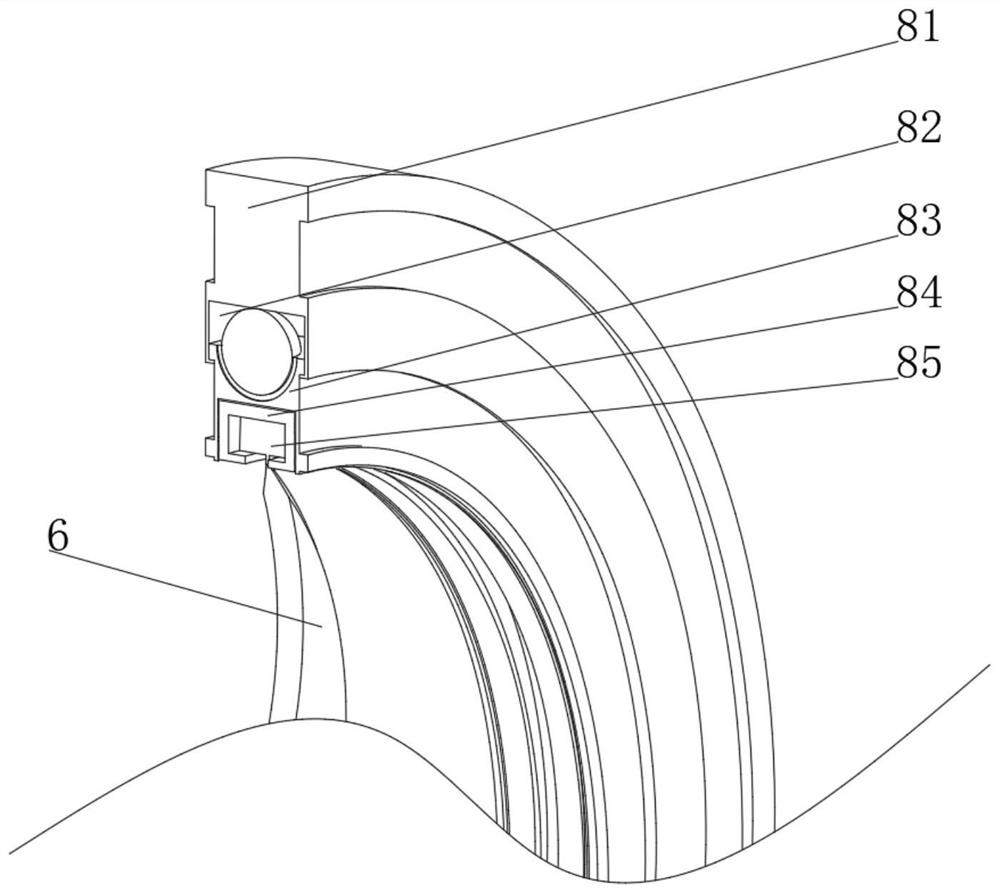

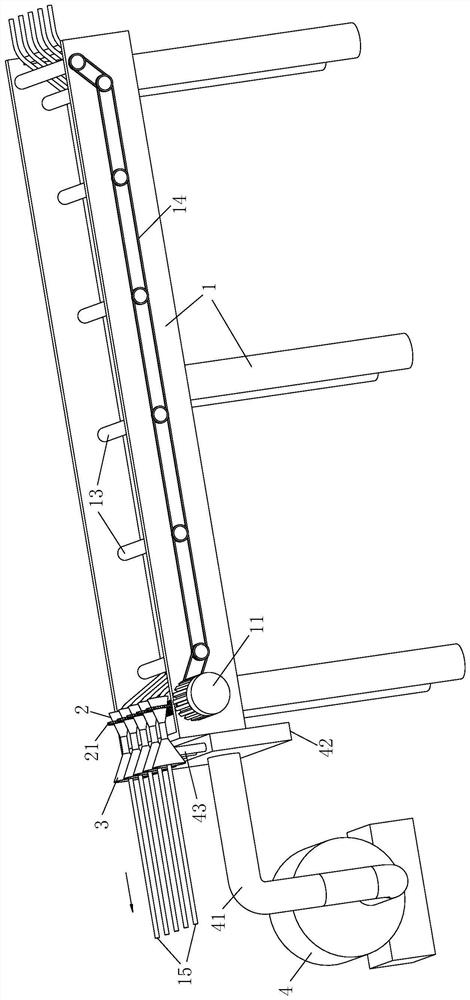

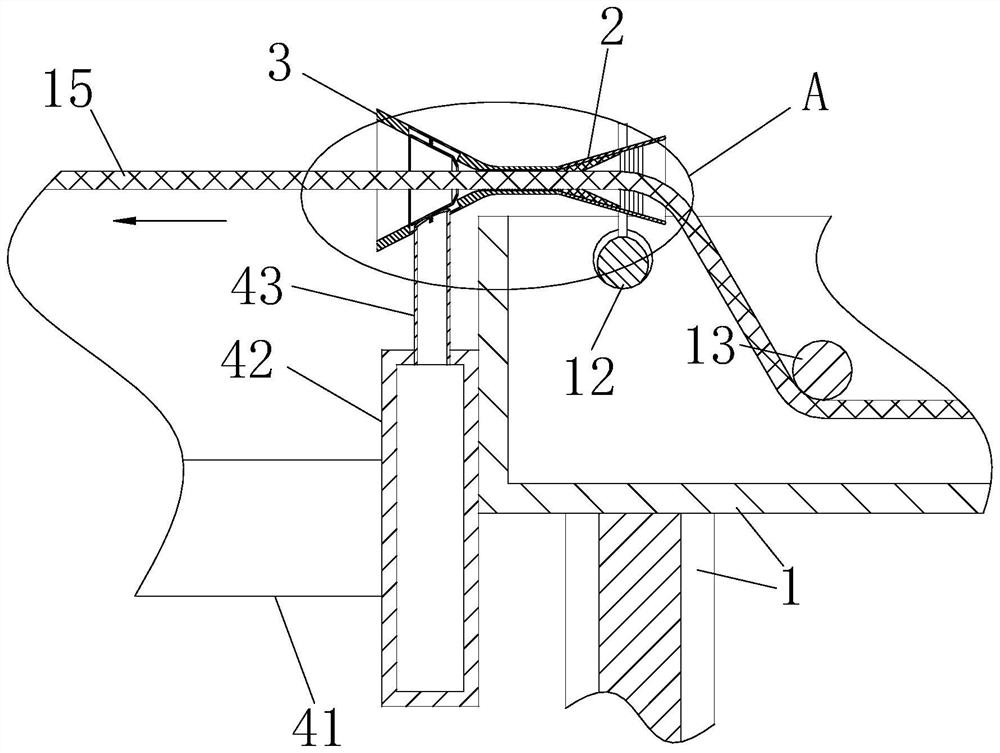

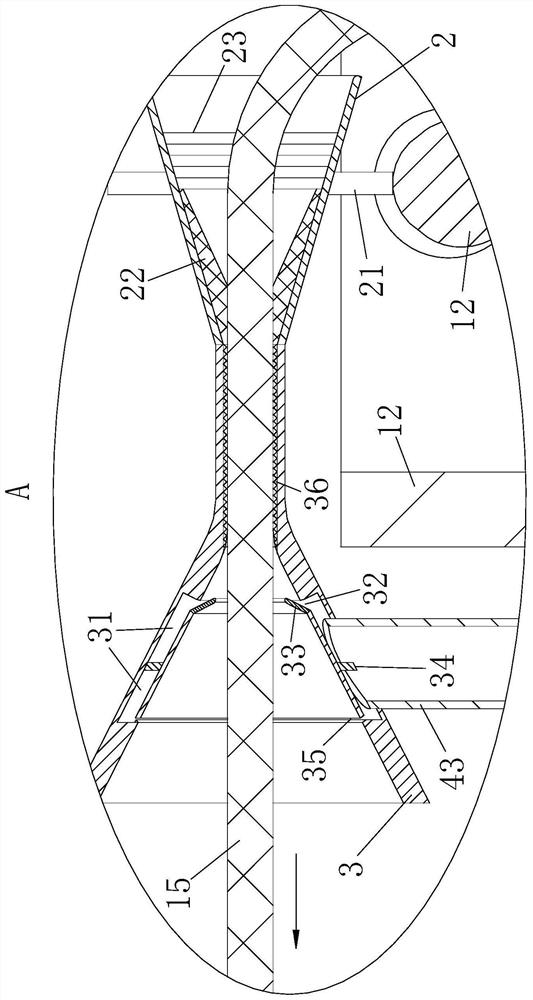

Slitting system of galvanized pull-ring strip

ActiveCN110919070AEasy to cutLess prone to glitchesShearing machinesOther manufacturing equipments/toolsRatchetElectric machinery

The invention discloses a slitting system of a galvanized pull-ring strip, and relates to the field of machining of pull-rings of ring-pull cans. According to the technical scheme, the slitting systemis characterized by comprising a machine tool, a transmission roller and a cutting mechanism are arranged on the machine tool, the cutting mechanism comprises a cutting roller and a cutting motor, acircular cutter is arranged on the cutting roller, the machine tool is provided with a trimming mechanism and a driving mechanism, the trimming mechanism comprises a trimming piece and a trimming strip, the trimming strip is provided with a knife grinder, an oil cavity and a piston channel, the trimming strip is provided with a movable plug, the trimming piece is provided with a driving piston, and the machine tool is provided with a cleaning mechanism for cleaning up cut scrap iron. Through the trimming mechanism, the circular cutter can be kept sharp so as to more easily cut off a galvanizedcoiled strip, no burrs can easily appear, and the cutting quality is high; by arranging a piston rod, a driving pawl and a ratchet wheel, the service life of the knife grinder is long; and by arranging the cleaning mechanism, scrap iron can hardly be left on the surface of the galvanized coiled strip to influence the subsequent machining of the galvanized coiled strip.

Owner:杭州泰迪包装材料有限公司

Cleaning device for grape processing

The invention discloses a cleaning device for grape processing and relates to the technical field of cleaning. The cleaning device comprises a protection box, a cleaning tank is fixedly connected on the left side of the inner wall of the protection box, a first electric rod and a second electric rod are fixedly connected on two sides of the inner-wall bottom of the cleaning tank respectively, a filter plate is rotatably connected at the top of each of the first electric rod and the second electric rod, an ultrasonic converter is arranged at the inner-wall bottom of the cleaning tank, an impurity removing box is fixedly connected on the right side of the protection box, a filtering layer is fixedly connected in the middle between two sides of the inner wall of the impurity removing box, a filter groove is formed in the top of the right side of the inner wall of the water tank, a water tank is communicated at the bottom of the right side of the inner wall of the filter groove, and a power box is fixedly connected at the top of the left side of the protection box. The cleaning device is efficient and thorough in cleaning process; grape is avoided receiving squeezing force and being damaged, so that cleaning efficiency is improved substantially, cleaning effect is improved, and quality of products processed by the grape is improved.

Owner:ZONGYANG COUNTY BAIYUN ECOLOGICAL GARDEN

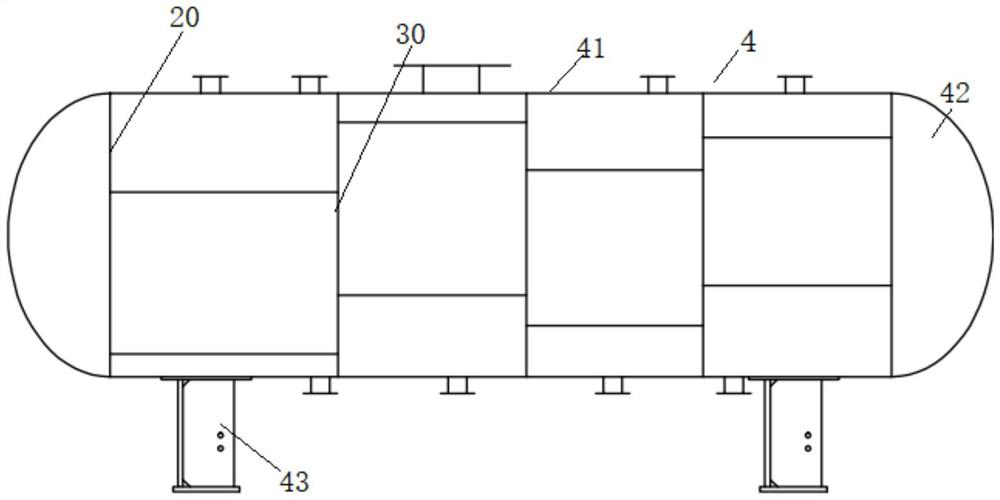

Device for polishing welding seam inside pressure vessel

InactiveCN112917299AEasy to install and disassembleEasy to follow upEdge grinding machinesGrinding carriagesPolishingStructural engineering

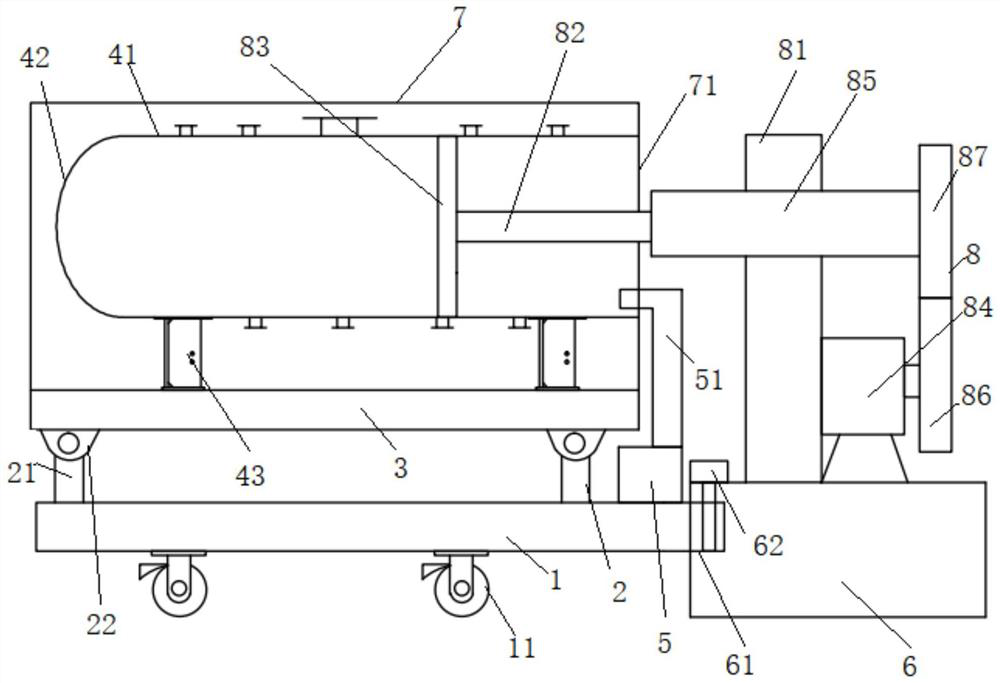

The invention provides a device for polishing a welding seam inside a pressure vessel. The device comprises a moving base; a first angle adjusting device, wherein the first angle adjusting device is arranged at the upper end of the moving base; a mounting base, wherein the mounting base is arranged at the working end of the upper end of the first angle adjusting device, the to-be-polished pressure vessel is mounted at the upper end of the mounting base, and a dust suction device is further connected to the mounting base or the moving base. a fixed base, wherein the fixed base is located on one side of the moving base, and the moving base is provided with a limiting block used for being inserted into a limiting groove in the fixed base and locked through a locking piece; a sealing cover, wherein the sealing cover is detachably connected to the upper end of the mounting base, a first opening is formed in the side, close to a sealing head, of the sealing cover, a sealing door capable of being opened or closed is connected to the first opening, and a dust suction pipe of the dust suction device is connected to the sealing cover; and a polishing device, wherein the polishing device is installed at the upper end of the fixed base, and the polishing end of the polishing device extends into the pressure vessel to be polished from the first opening. By arranging the automatic polishing device, automatic polishing is achieved, workers are prevented from entering the vessel for polishing, and the device is safe, environmentally friendly and high in polishing efficiency.

Owner:湛立宁

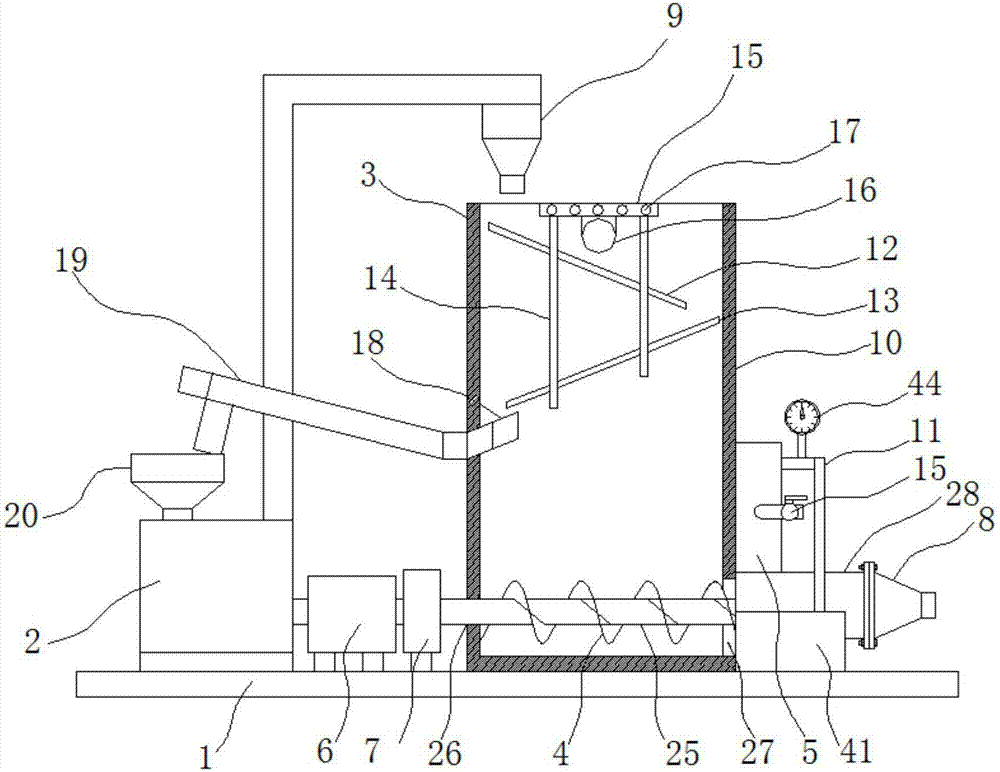

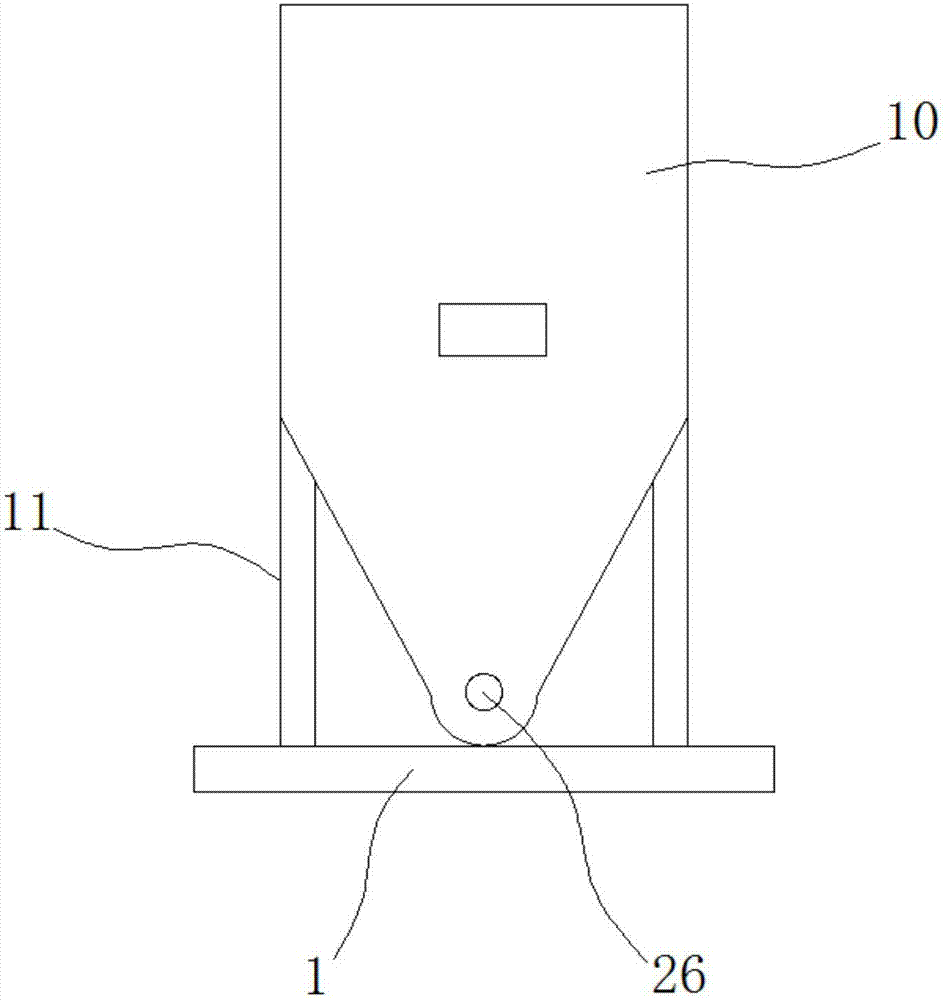

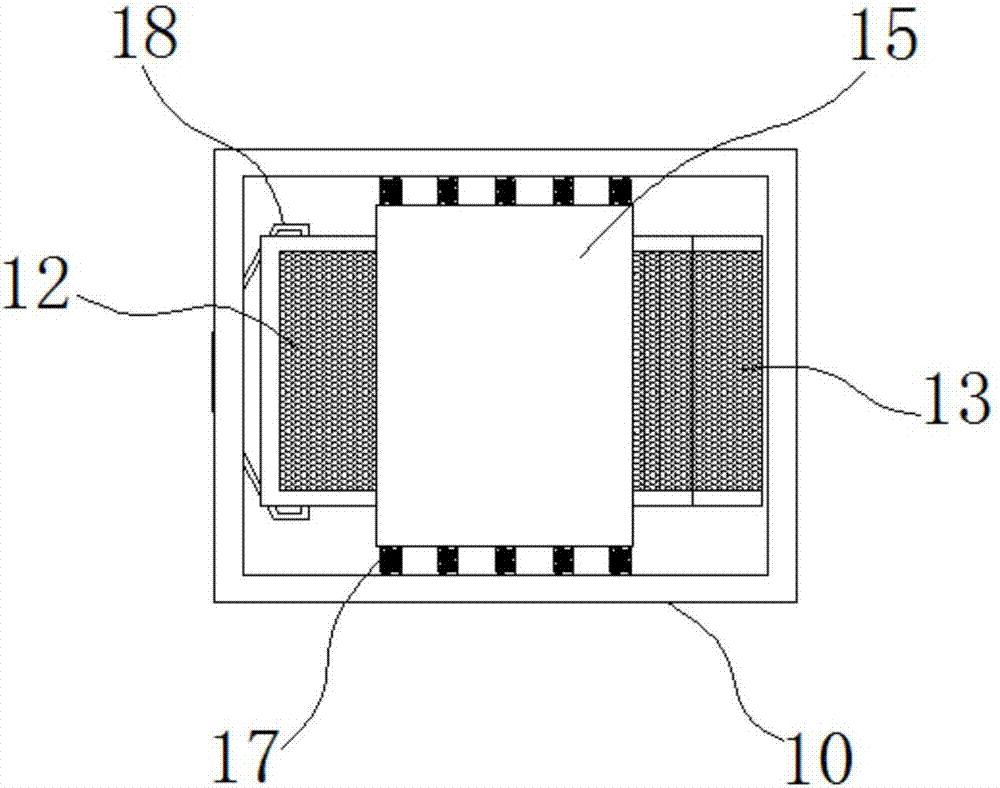

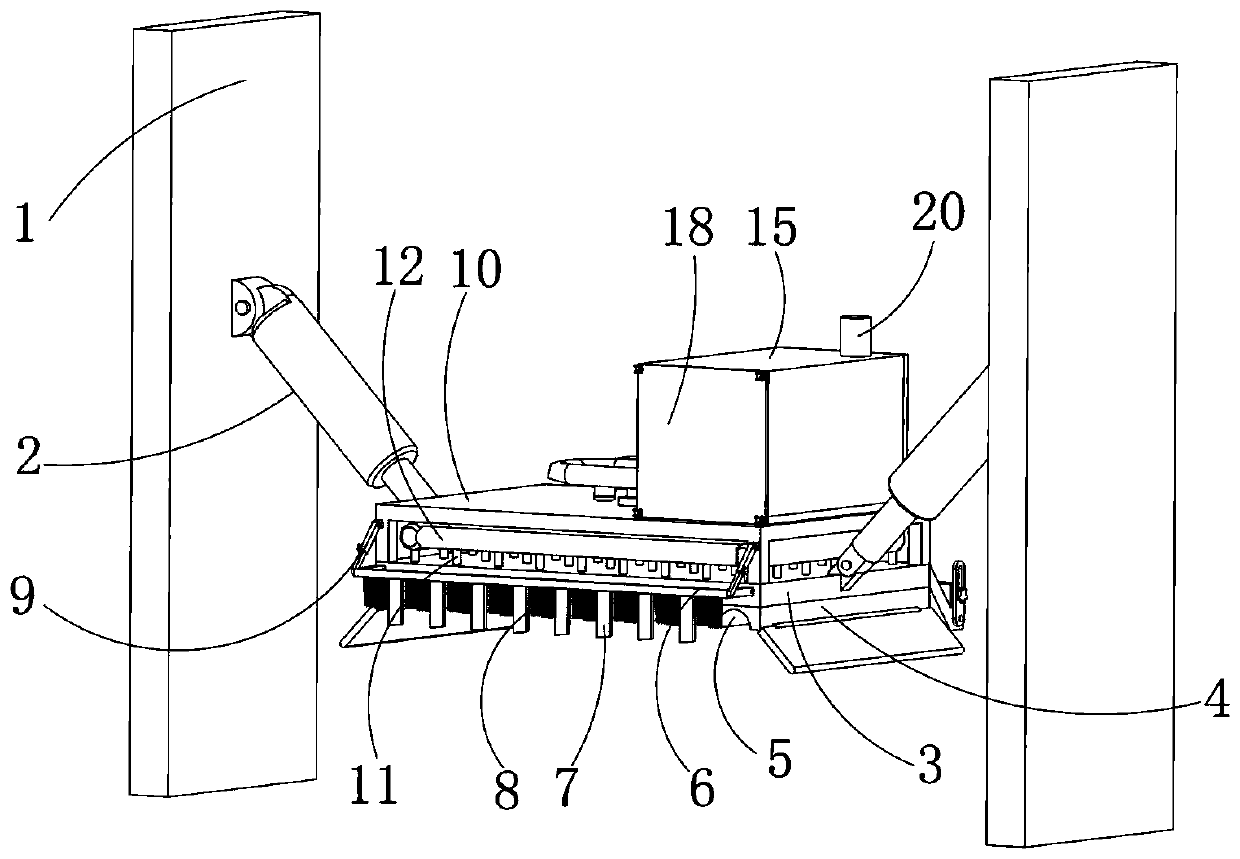

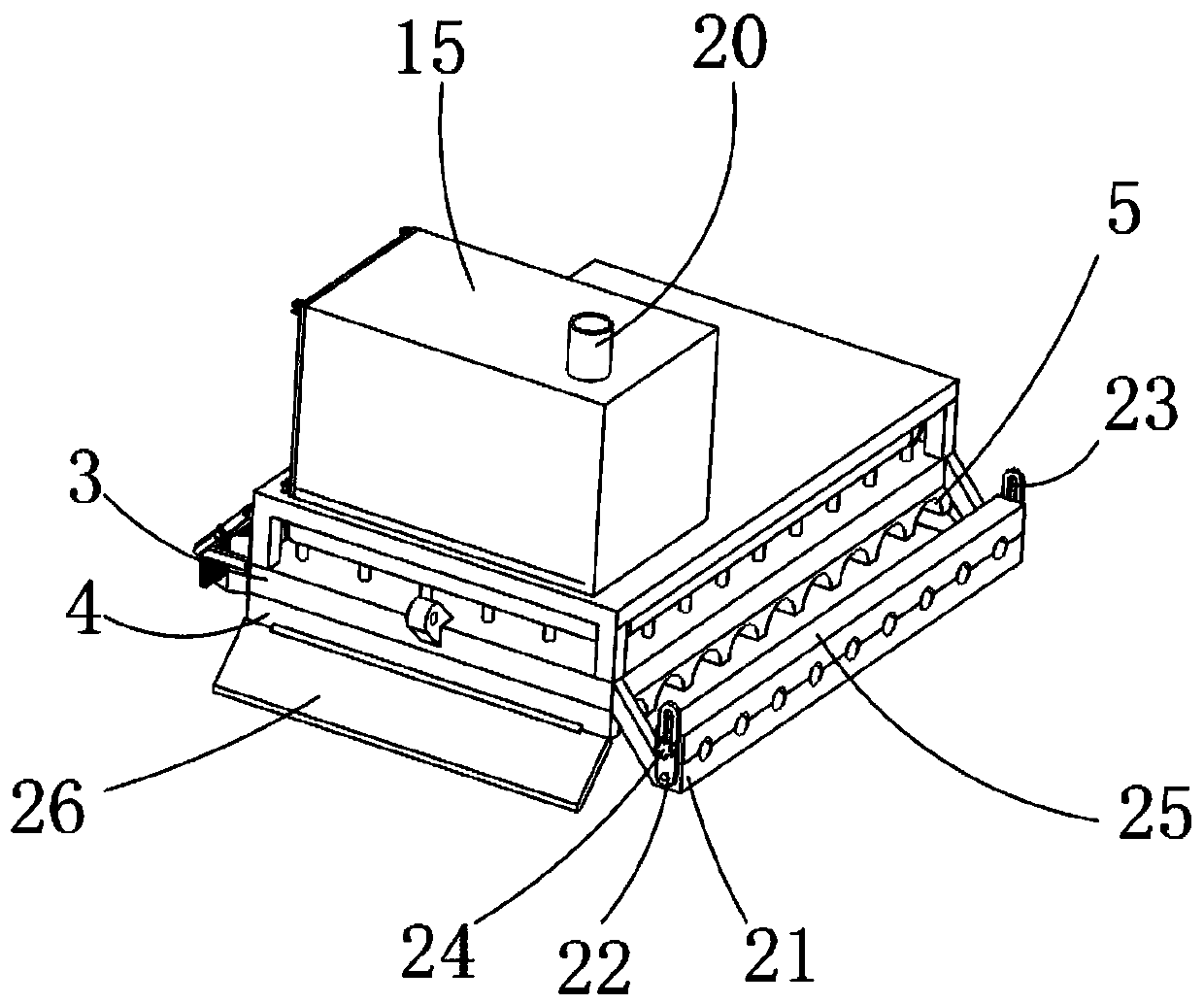

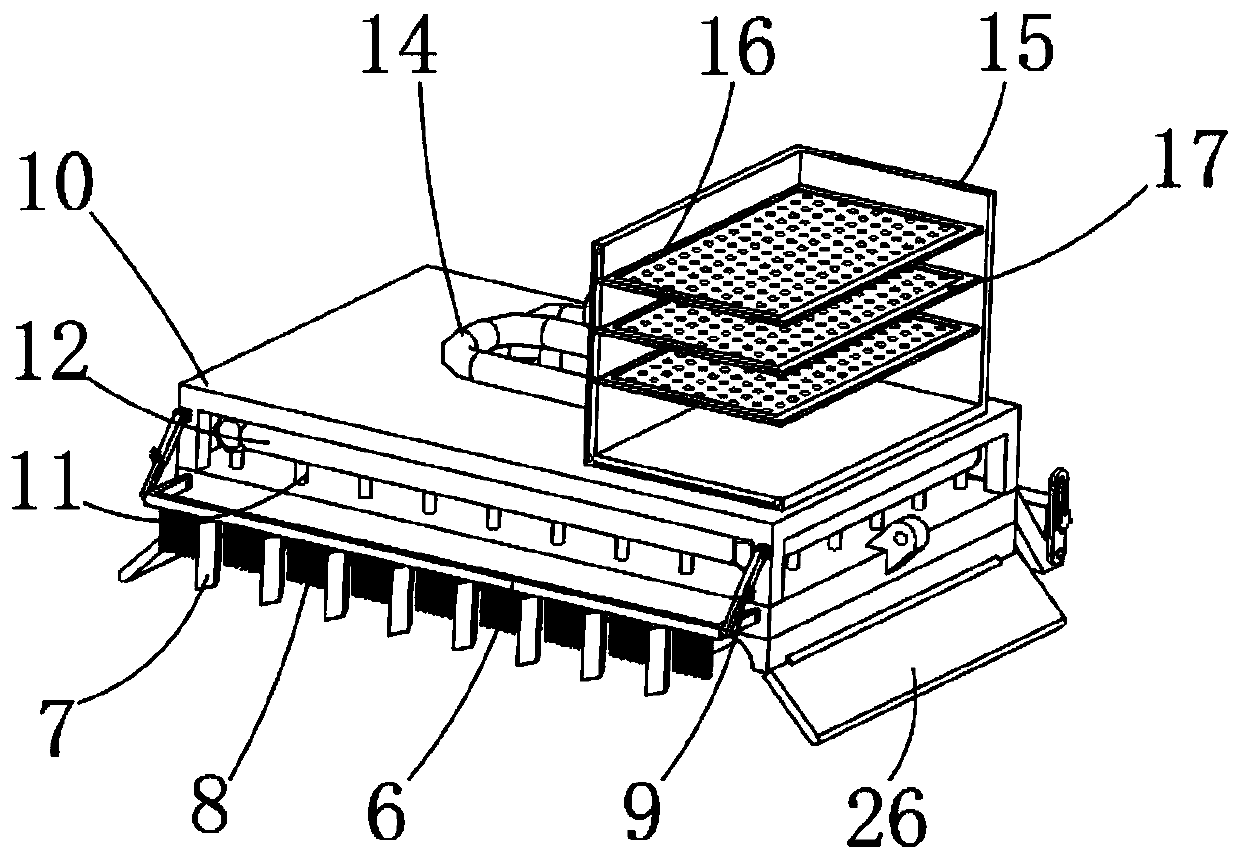

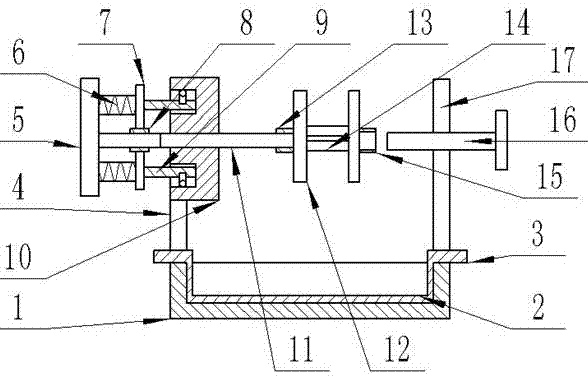

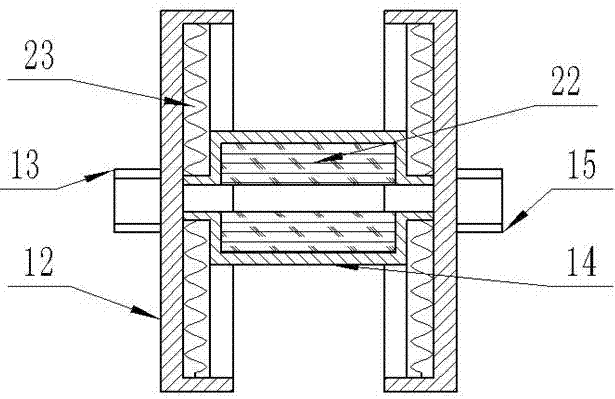

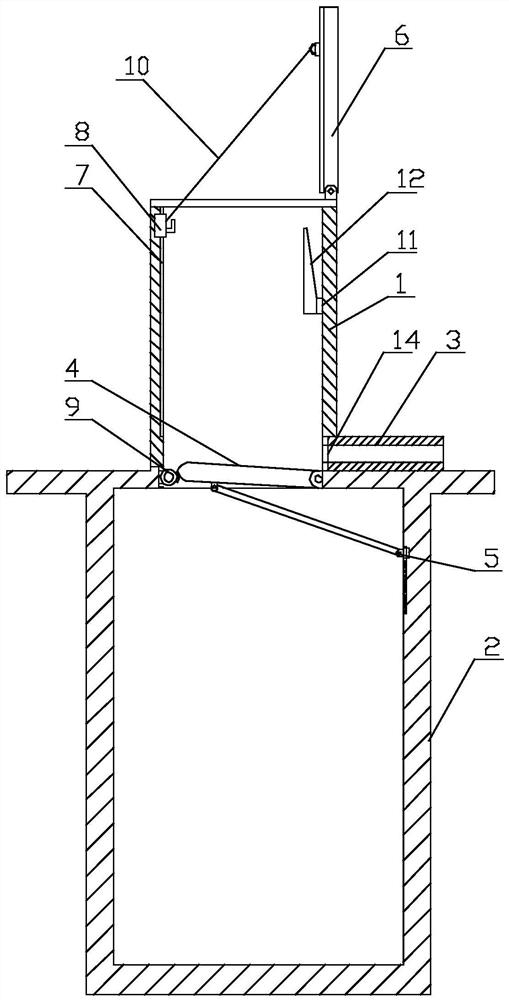

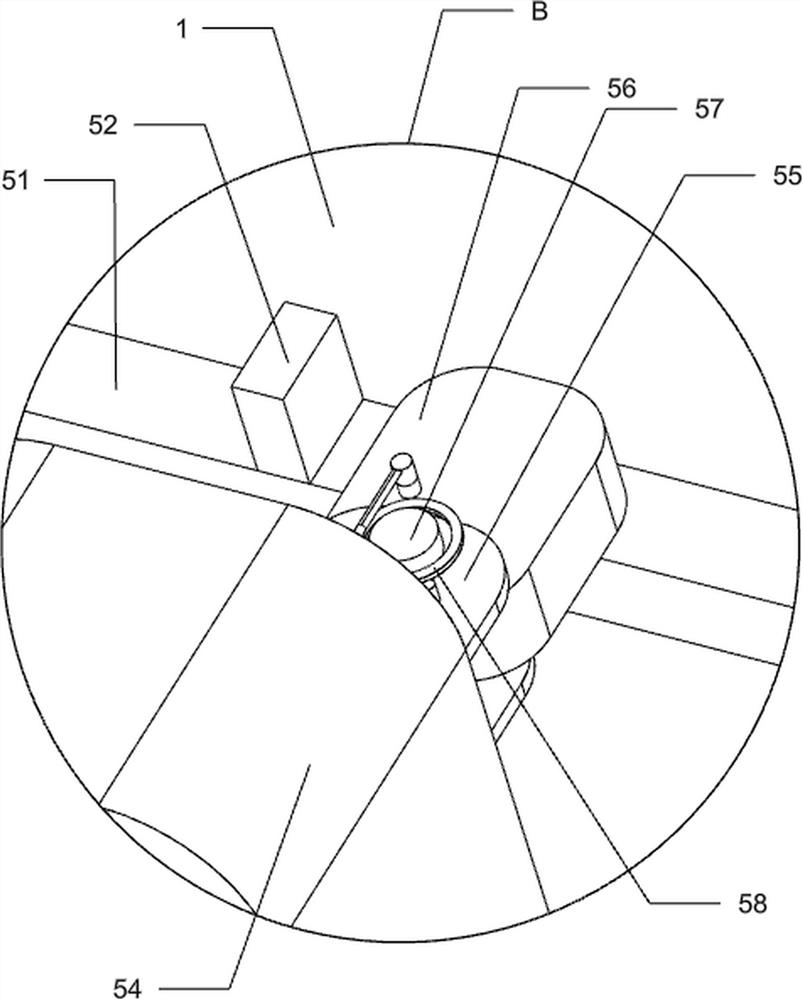

Rice noodle processing equipment

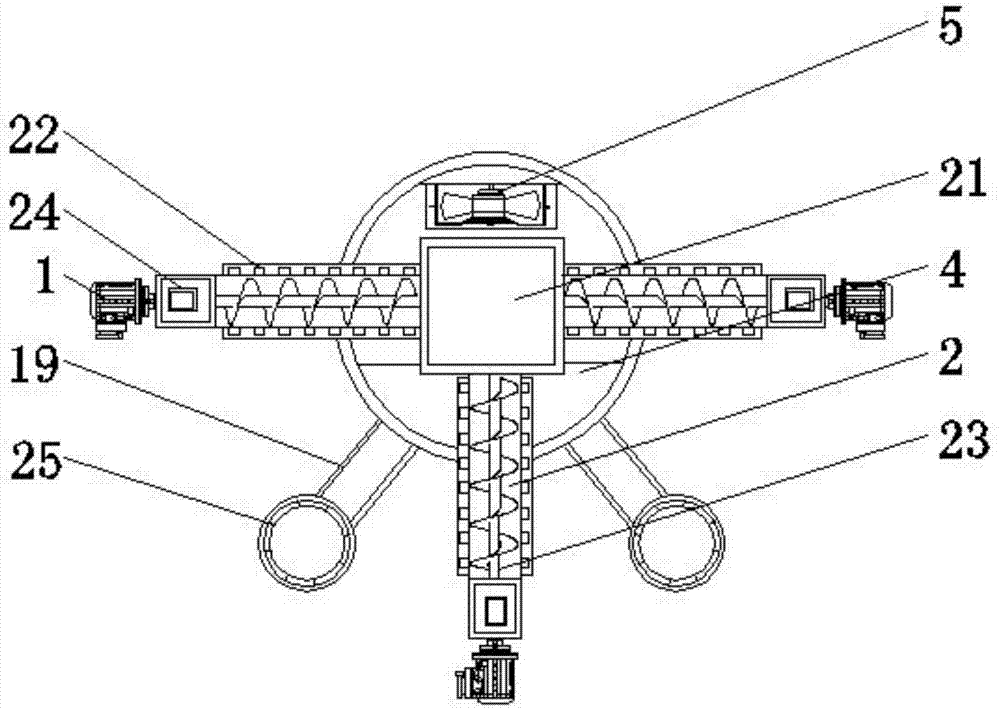

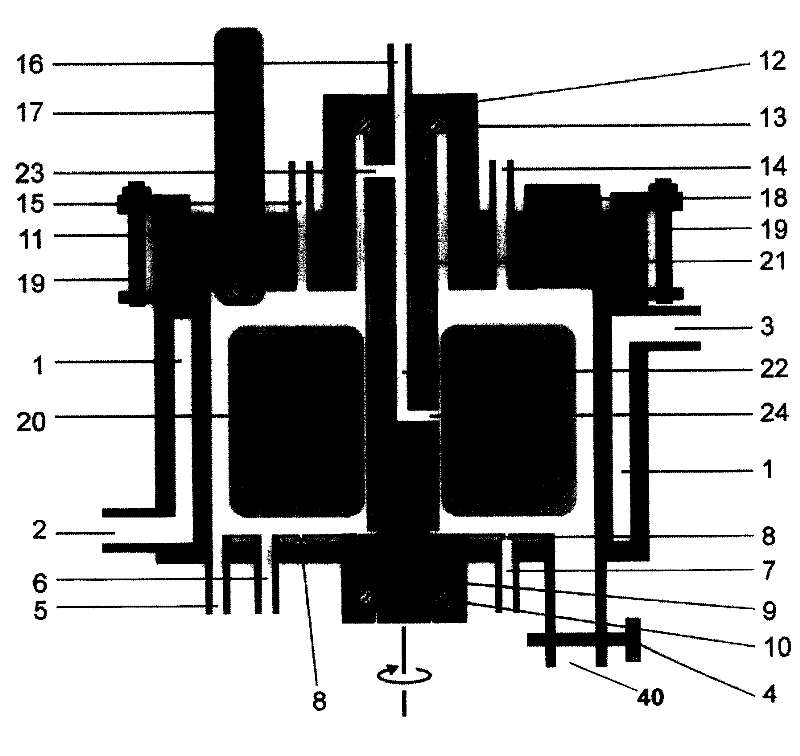

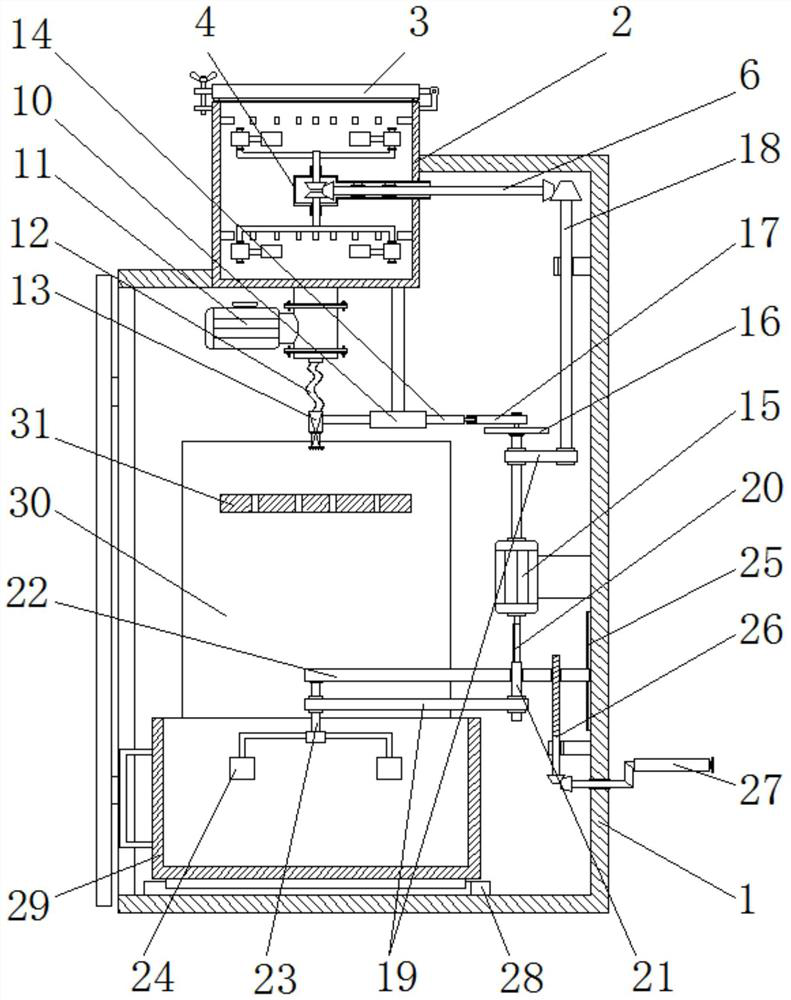

InactiveCN107467485AAffect subsequent processingQuality improvementSievingScreeningDrive shaftReducer

The invention discloses rice noodle processing equipment. The rice noodle processing equipment comprises a grinding mechanism, a screening mechanism, a conveying mechanism and an air exhaust mechanism which are arranged on a base, wherein a double-shaft motor is arranged at one side of the grinding mechanism, a first driving shaft of the double-shaft motor is connected with a roll shaft of a grinding roll in the grinding mechanism, a second driving shaft of the double-shaft motor is connected with an input shaft of a speed reducer, an output shaft of the speed reducer is connected with the conveying mechanism, the conveying mechanism penetrates through the screening mechanism and is connected with a conical discharging head, the discharge end of the grinding mechanism is connected with a cyclone unloading device, the cyclone unloading device is arranged over the screening mechanism, and the air exhaust mechanism is arranged at the upper side of the conveying mechanism and is communicated with the conveying mechanism. The rice noodle processing equipment disclosed by the invention has the advantages of being capable of completely grinding rice so as to improve the quality and taste of rice noodles, and capable of controlling the quantity of air entering rice flour to be in a reasonable interval so as to improve the quality of finished products of the rice noodles after the rice flour is processed.

Owner:香格里拉市穗源食品有限公司

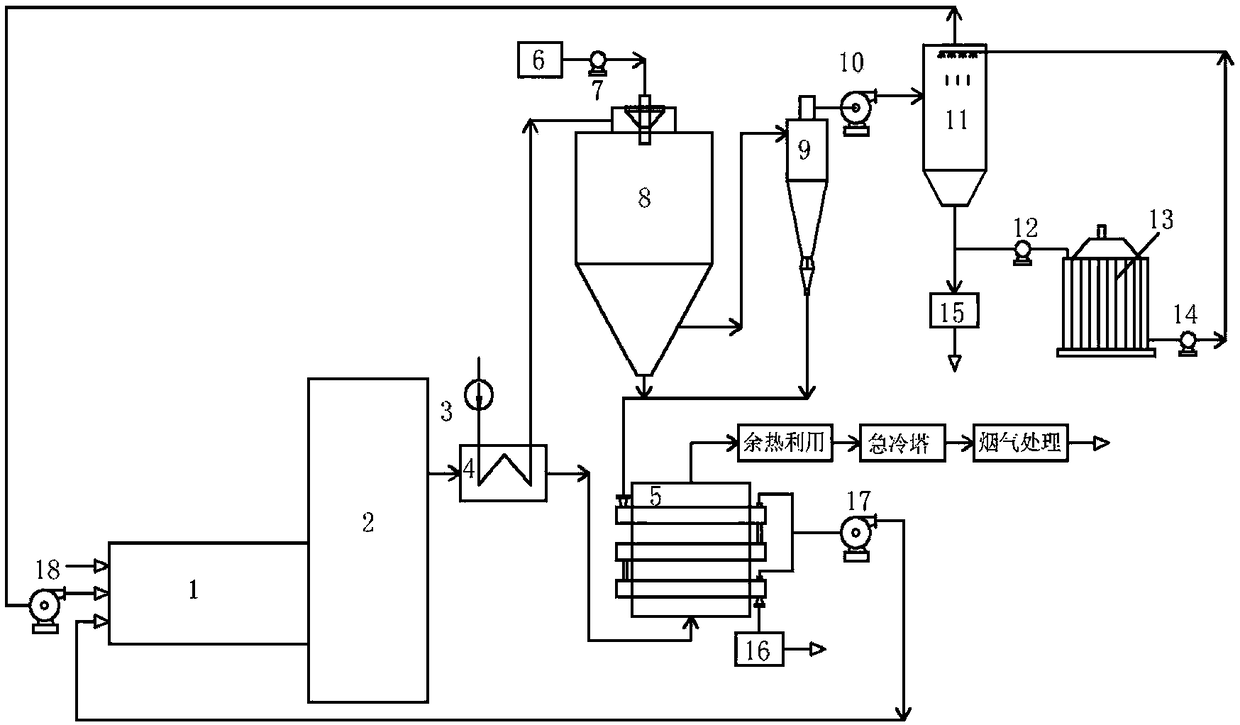

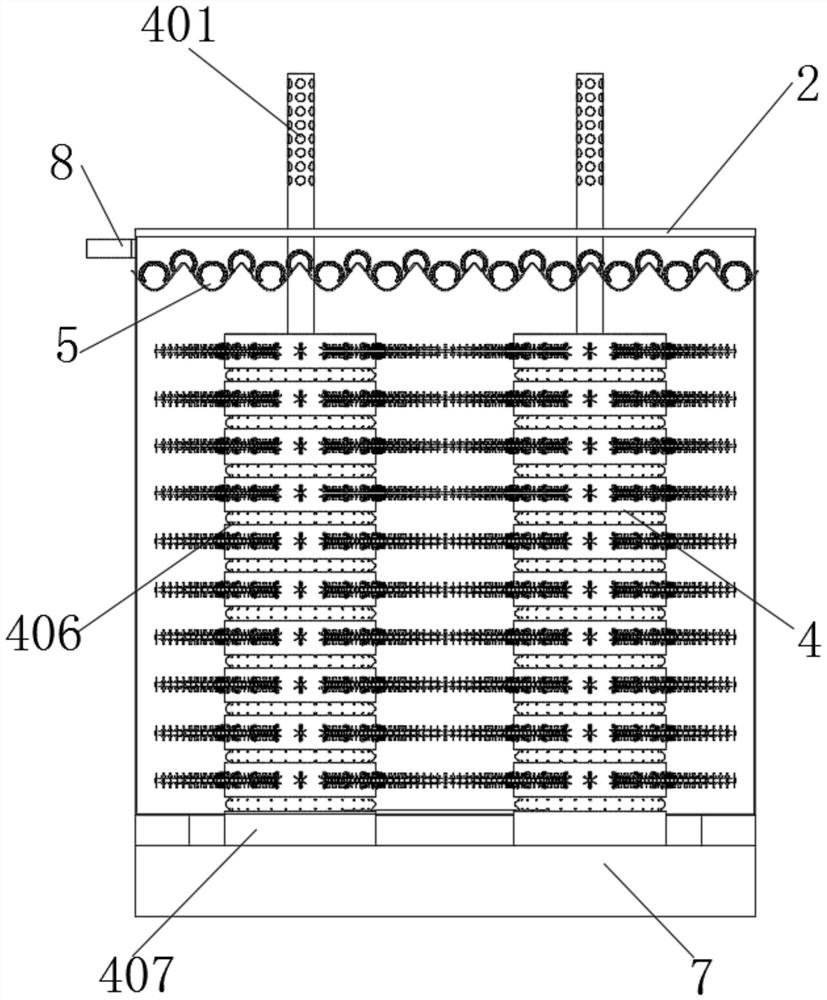

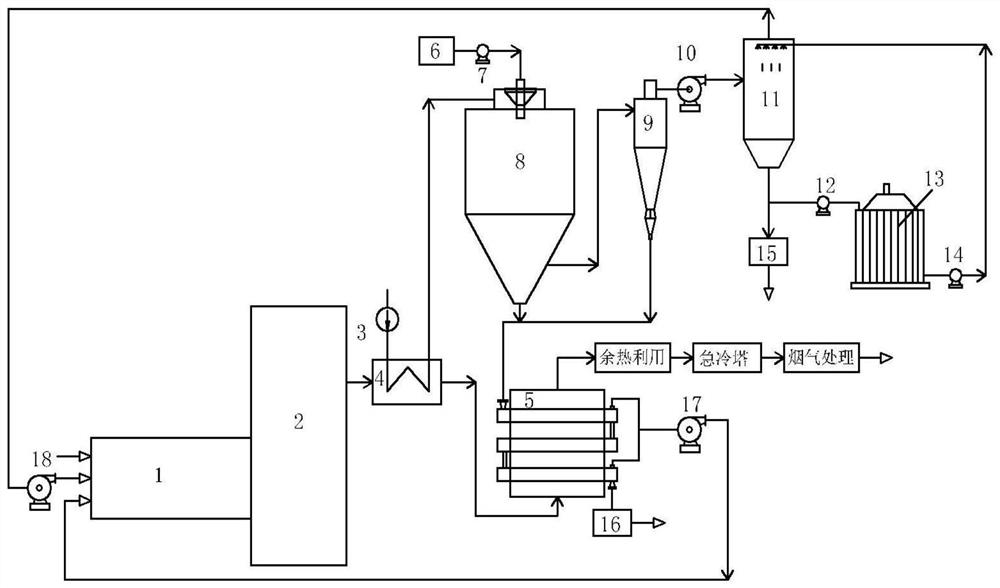

Treatment method and system for demineralization and pyrolysis of salt-containing organic waste liquid

ActiveCN108479088AAchieve separationSave energyEvaporator accessoriesCombustion technology mitigationCombustion chamberFlue gas

The invention discloses a treatment method and system for demineralization and pyrolysis of salt-containing organic waste liquid. The method comprises the following steps: (a) air preheating; (b) spray drying; (c) separation and recovery; and (d) pyrolysis. The treatment system for demineralization and pyrolysis of salt-containing organic waste liquid comprises an incinerator, a gas-gas heat exchanger connected with the outlet of a rear secondary combustion chamber of the incinerator, a tubular pyrolysis reactor connected with the flue gas outlet of the gas-gas heat exchanger, an atomization tower connected with the air outlet of the gas-gas heat exchanger, and a cyclone dust collector connected with the gas-solid mixture outlet of the atomization tower. The treatment method and system ofthe invention can utilize the residual heat of flue gas to avoid the problems of softening, coking, flue clogging, heat exchanger clogging and the like of salt sprayed into the waste liquid of the incinerator by the salt-containing organic waste liquid; at the same time, the treatment of the salt-containing organic waste liquid can be separated from the whole process, and no influence is exerted on original process.

Owner:SOUTHEAST UNIV

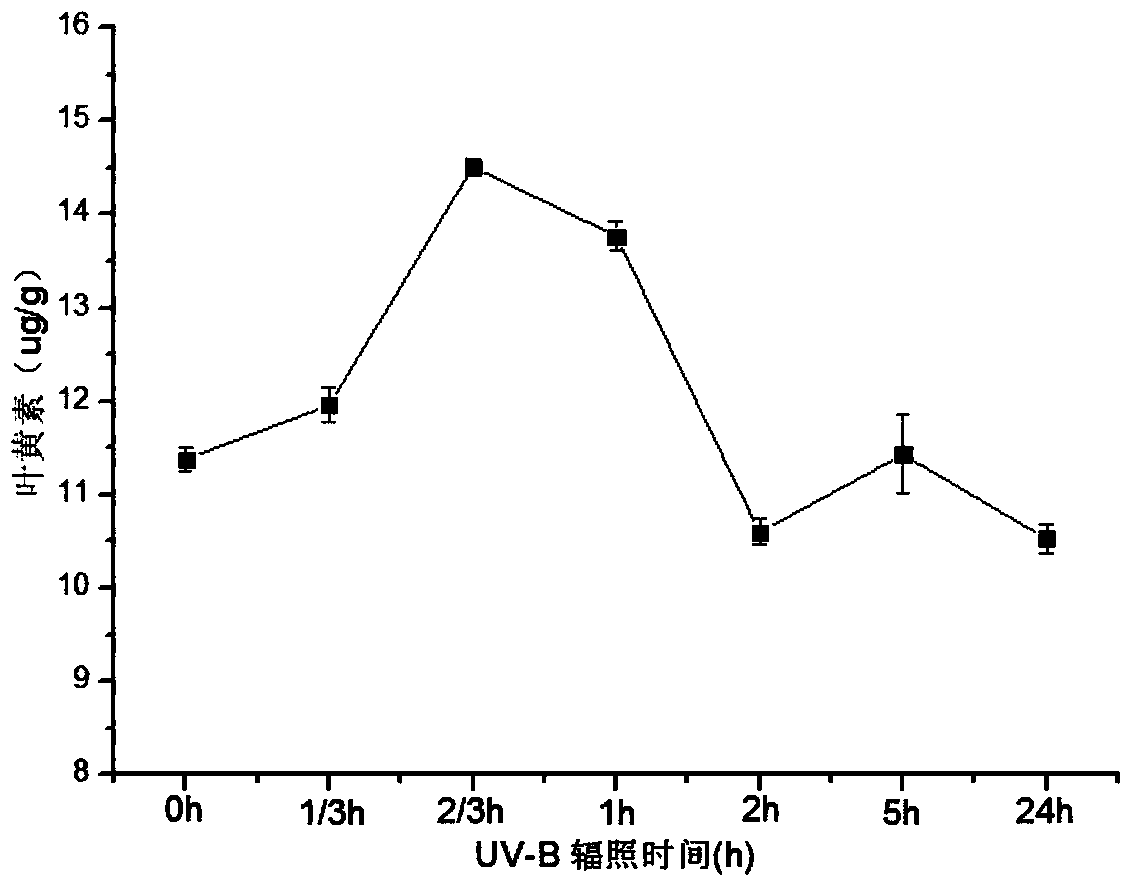

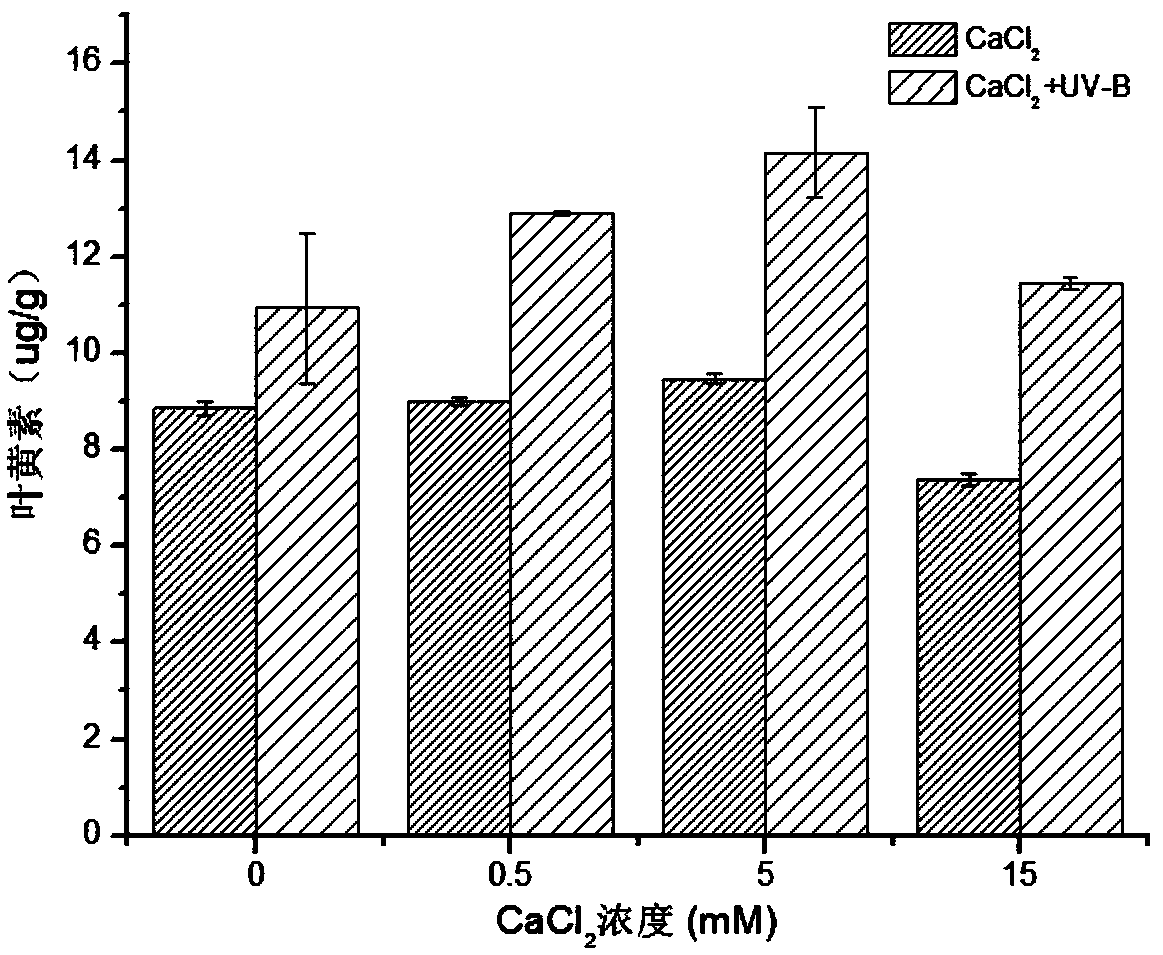

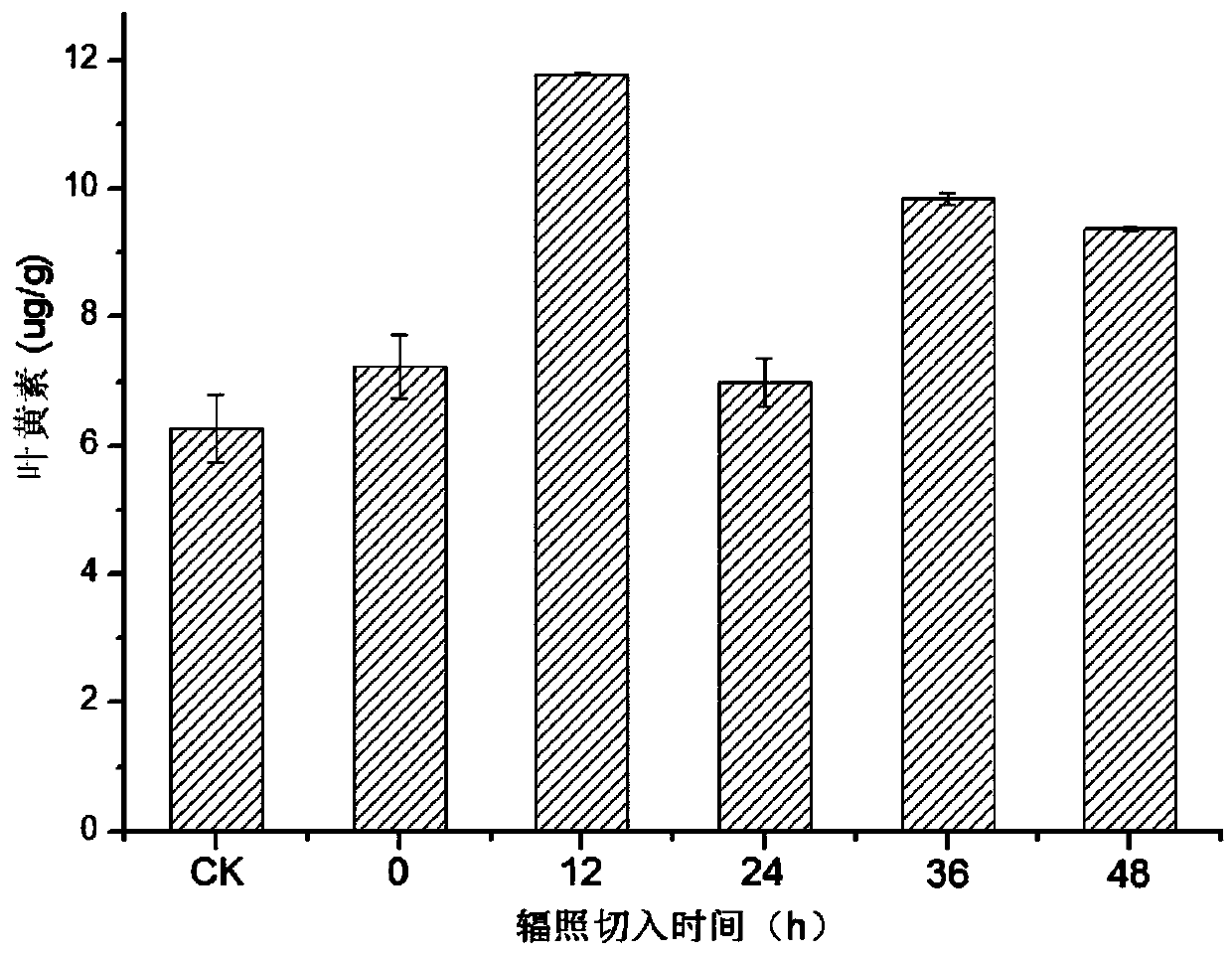

Method for enriching lutein with germinated corn, product thereof and application

The invention relates to the field of development and utilization of biological resources, in particular to a method for enriching lutein with germinated corn, a product thereof and application. The method provided in the invention includes: taking corn grains with germination ability as the raw materials, conducting seed soaking in a calcium ion solution and dark culture, and then performing UV-Birradiation treatment. Determination shows that the method provided by the invention can improve the lutein content of germinated corn by 40% or more.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

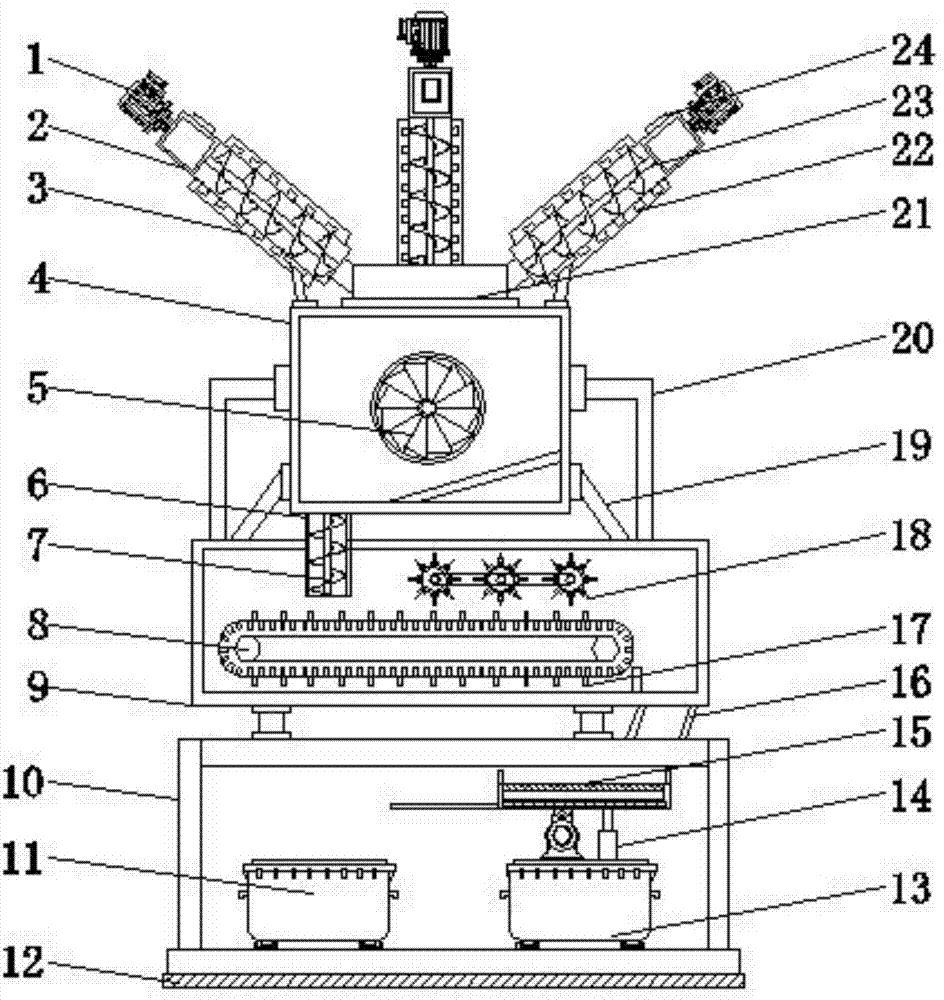

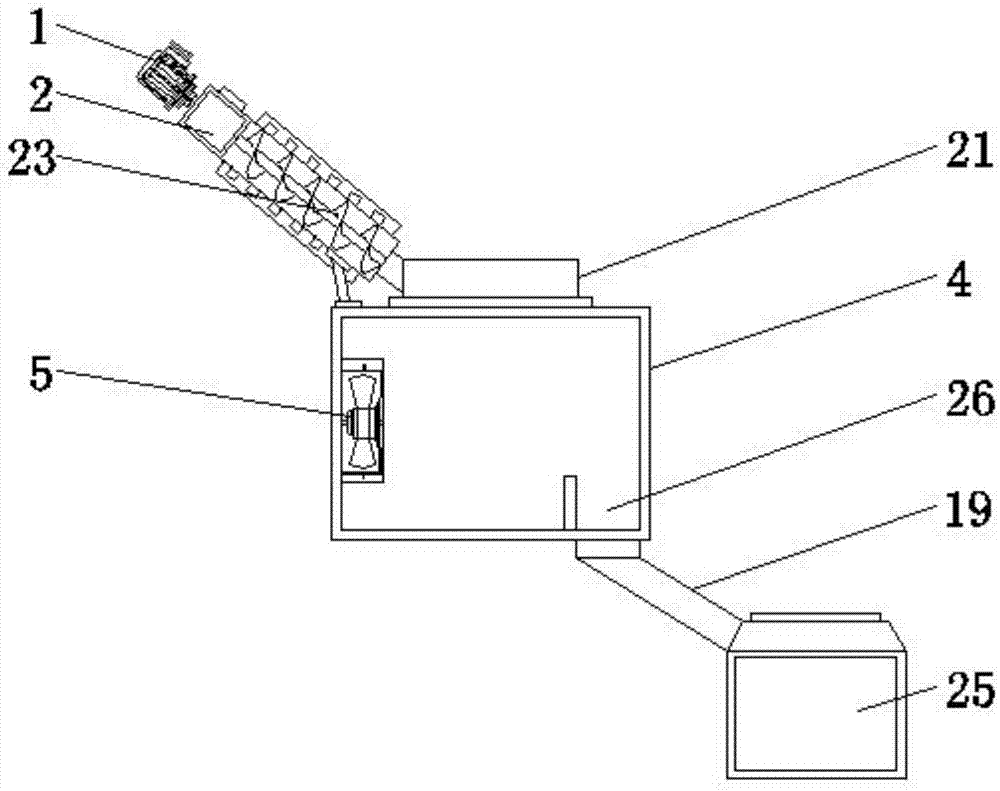

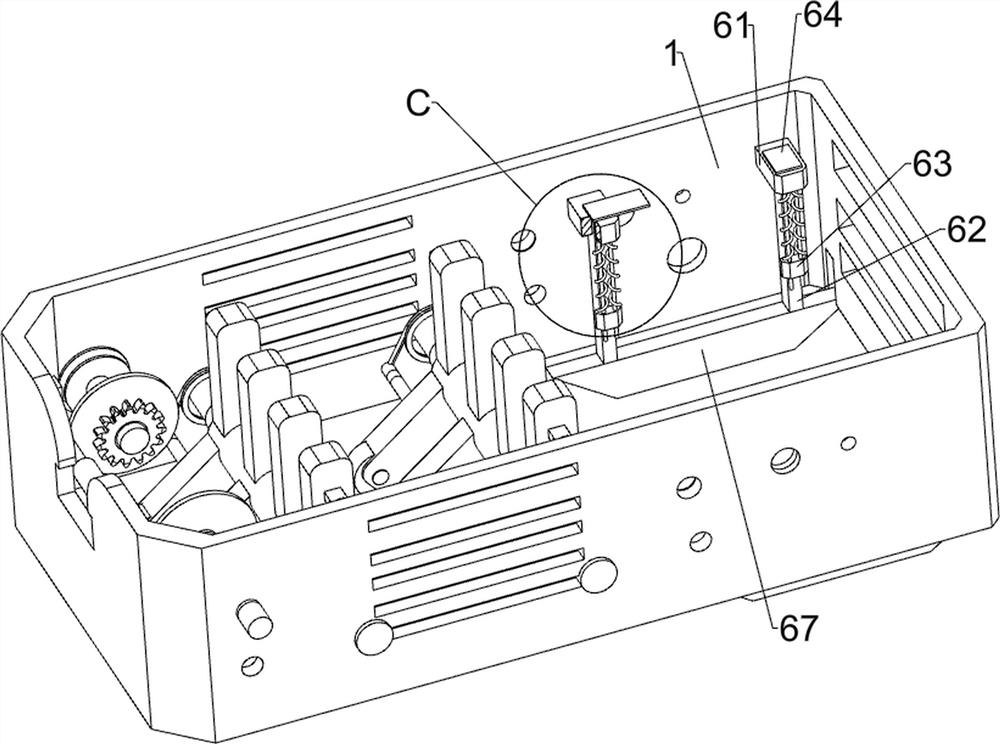

Health care product traditional Chinese medicine boat-fruited scaphium seed brewing device

InactiveCN107350158AAffect subsequent processingAffect qualityGas current separationCleaning using toolsMotor driveElectric machinery

The invention relates to a health care product traditional Chinese medicine boat-fruited scaphium seed brewing device. The device comprises a first impurity removal tank, a fan, a second impurity removal tank and a base. The second impurity removal tank is mounted above the base through a fixed seat. A conveyor belt is horizontally mounted at the lower end of the interior of the second impurity removal tank. Three rotary shafts are horizontally mounted in the second impurity removal tank and located above the conveyor belt. The rotary shafts are all provided with brushes. The first impurity removal tank is mounted above the second impurity removal tank through fixed steel frames. Through installation of the first impurity removal tank, the fan, pipelines, the second impurity removal tank, the conveyor belt, limiting plates, the rotary shafts, the brushes, a third driving motor, a fourth driving motor and a third material collection tank, the device winnows out leaves or other light impurities contained in collected boat-fruited scaphium seeds through the fan in advance; the third driving motor and the fourth driving motor drive the conveyor belt and rotary shafts to rotate correspondingly to realize brush away dust and other attachment on the surfaces of the boat-fruited scaphium seeds.

Owner:韩凤华

Non-woven fabric melt-blowing processing method based on double-roller receiving device

PendingCN111663247AAvoid condensationEfficient productionNew-spun product collectionUltrasonic/sonic fibre treatmentNonwoven fabricMechanical engineering

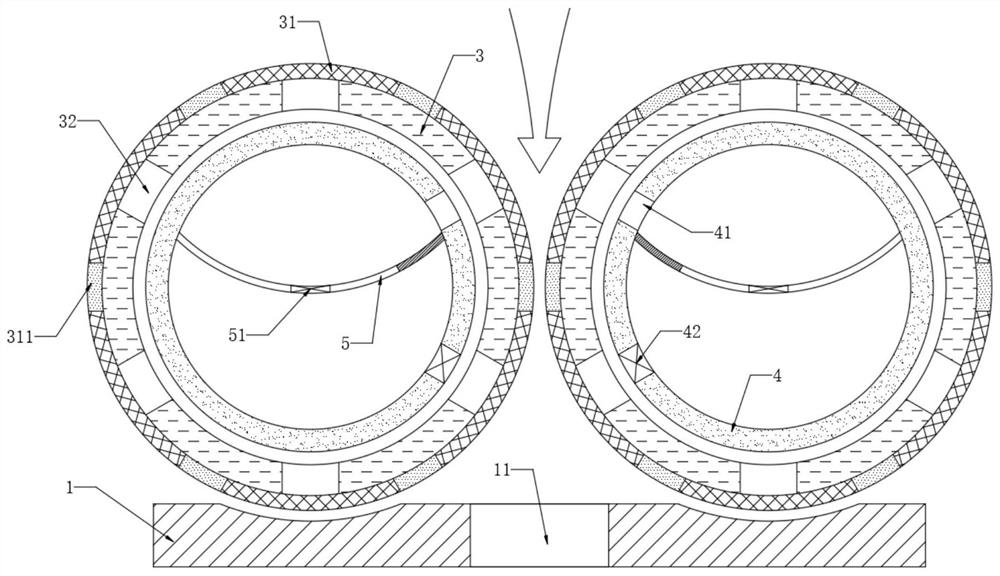

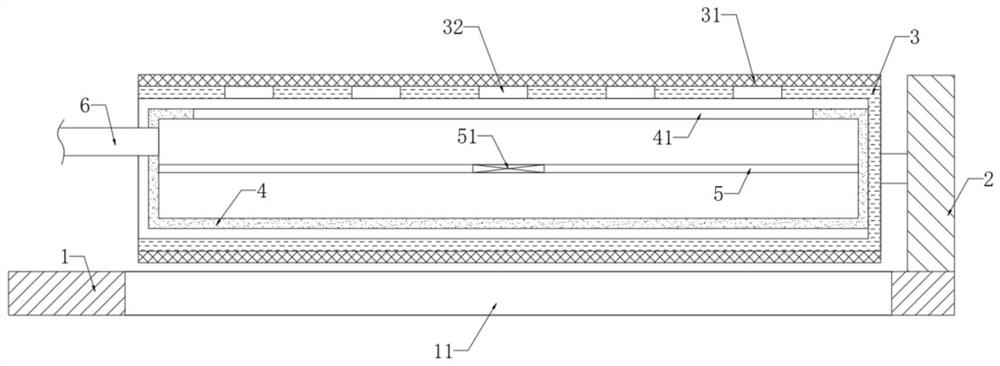

The invention discloses a non-woven fabric melt-blowing processing method based on a double-roller receiving device. The non-woven fabric melt-blowing processing method comprises the following steps of S1, pretreating a melt; S2, conveying the melt; S3, heating the melt; S4, drafting the melt to form a trickle and carrying out cooling; and S5, forming a net, namely blowing the cooled and formed superfine fibers to the double-roller receiving device. The double-roller receiving device involved in the non-woven fabric melt-blowing processing method comprises a base, wherein a discharge opening is formed in the upper end of the base; the upper end of the base is fixedly connected with a pedestal; two rollers are rotationally connected to the side wall of the pedestal; and a driving componentfor driving the rollers to rotate is arranged on the pedestal. According to the non-woven fabric melt-blowing processing method disclosed by the invention, negative pressure airflow is always distributed on opposite sides of the two rollers, so that the melt is only attached to the opposite sides of the two rollers and can be rapidly extruded and formed by the rollers, the melt is prevented from being condensed on the rollers, materials are saved, and the non-woven fabric with excellent quality can be efficiently produced.

Owner:李双双

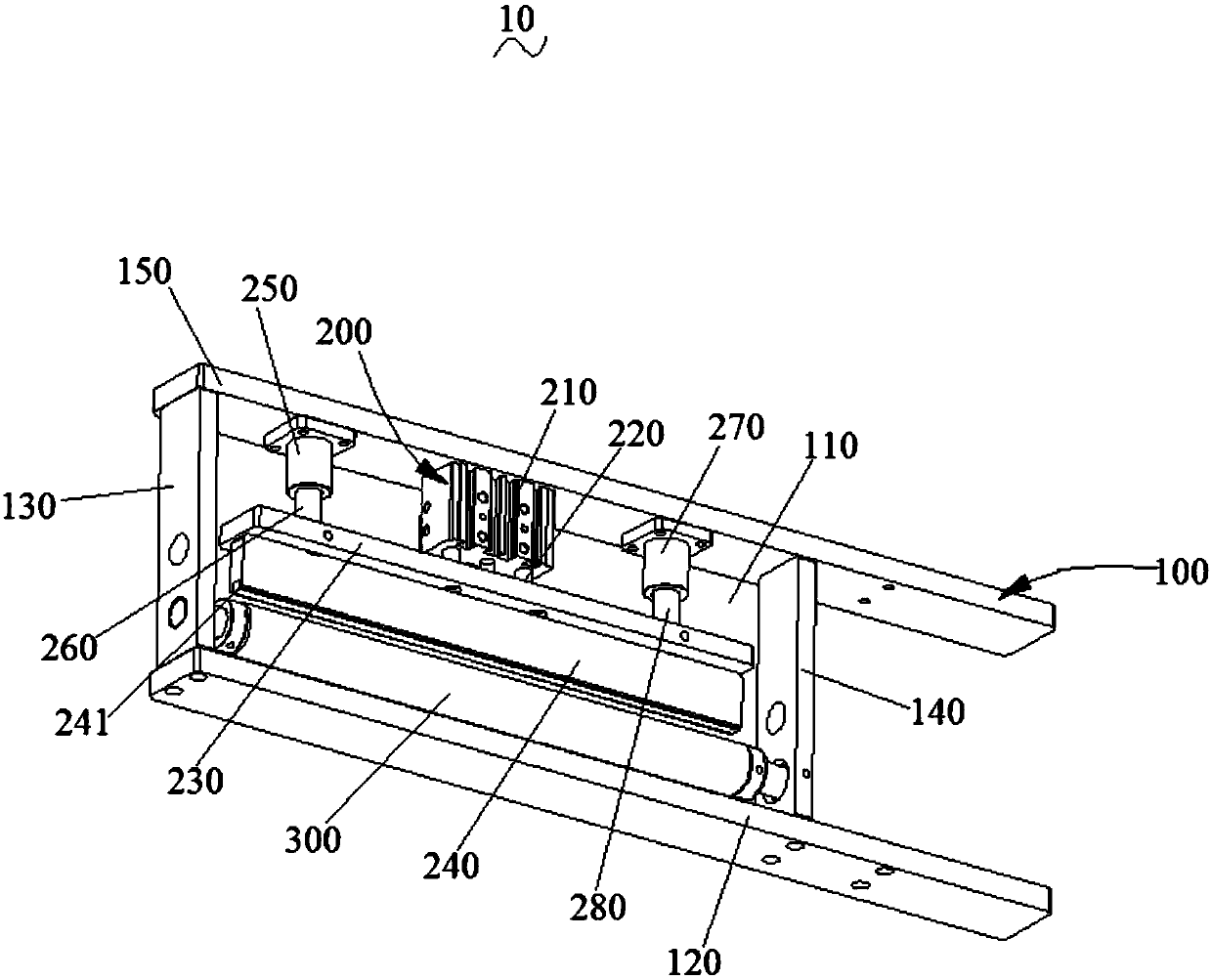

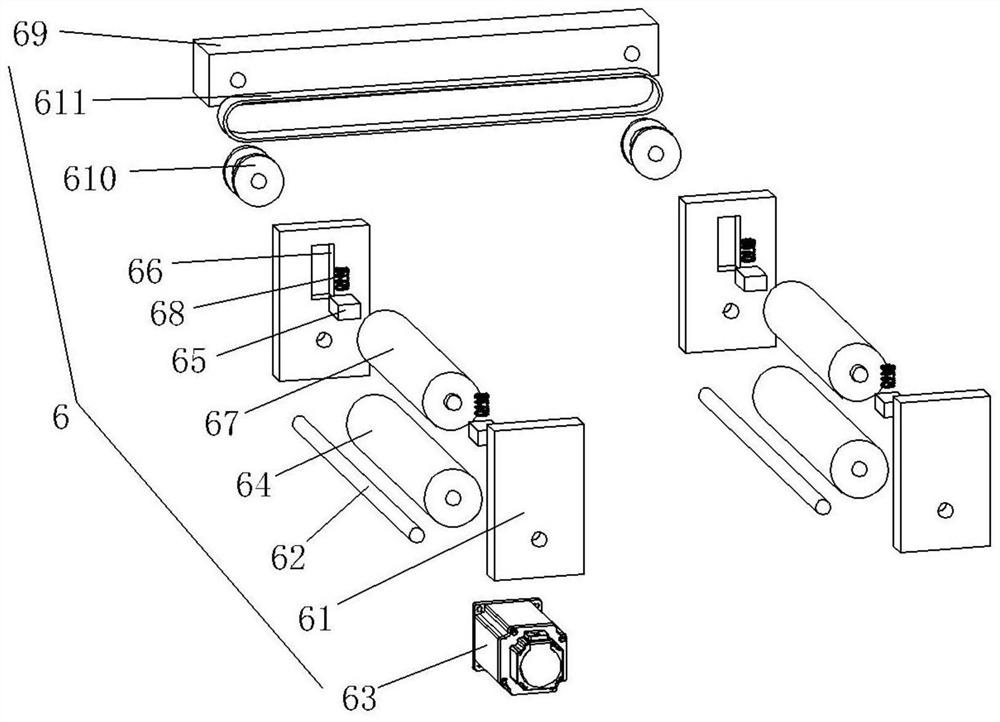

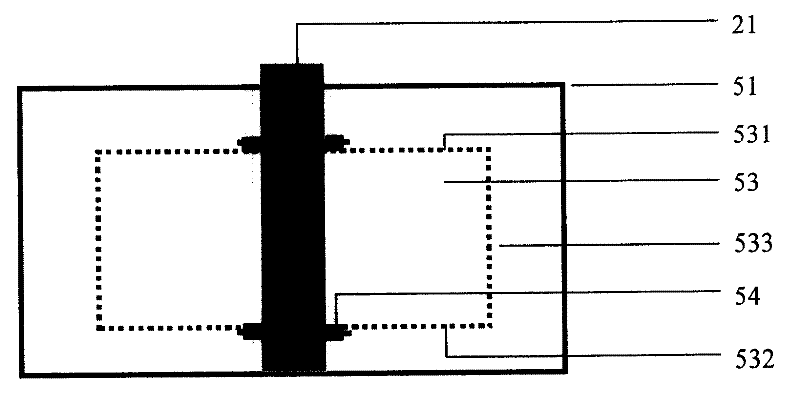

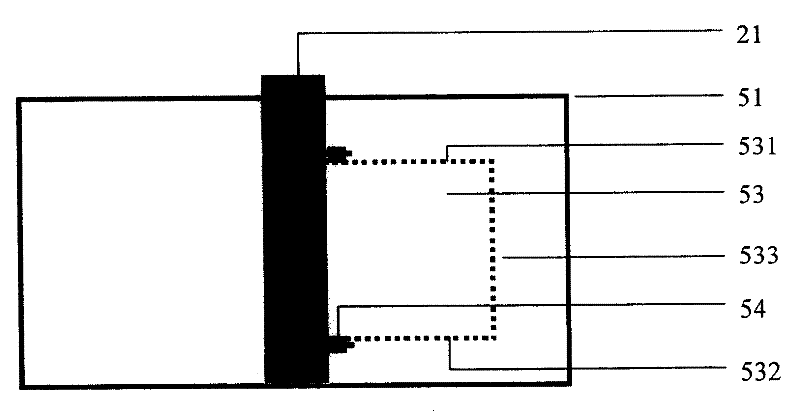

Fabric clamping mechanism

The invention discloses a cloth clamping mechanism, which comprises: an installation frame, a driving device and a roller. The installation frame has a storage chamber, the driving device and the roller are accommodated in the storage chamber, and the driving device compresses or loosens the roller. The installation frame includes: a fixed plate, a first support plate, a second support plate and an installation plate, one end of the first support plate is connected to one end of the fixed plate, the other end of the first support plate is connected to one end of the installation plate, and one end of the second support plate It is connected with the other end of the fixing plate, and the other end of the second support plate is connected with the other end of the installation plate. The cloth pressing mechanism of the present invention realizes the pressing of the cloth on the machine after cutting through the provided installation frame, driving device and roller, so as to prevent the cloth on the machine from being loose due to the tension force, which affects the subsequent processing.

Owner:郑建灵

Computer case punch forming device and using method thereof

InactiveCN113305198AAvoid stuckAffect normal stampingDispersed particle filtrationStripping-off devicesStructural engineeringMechanical engineering

The invention discloses a computer case punch forming device and a using method thereof, relates to the technical field of punching devices, and aims to solve the problem that after punching of an upper die is finished, a case plate on a lower die is easily lifted up in the upward moving process. The device specifically comprises a mounting frame, a warning lamp is arranged on the outer wall of the top of the mounting frame, a hydraulic push rod is arranged on the inner wall of the top of the mounting frame, a stand column is arranged on the inner wall of the bottom of the mounting frame, and a control panel is arranged on the outer wall of one side of the stand column. The using method of the device specifically comprises the steps that a plate is placed on an electric conveying plate, and the electric conveying plate is controlled by the control panel to drive the plate to one side of a supporting table. An extrusion block, an air bag, a first air guide pipe, a second air valve and an adsorption plate are arranged, after the plate is punched, a pressing plate moves upwards through the hydraulic push rod to be reset, at the moment, a connecting rod pushes the extrusion block to move upwards, and therefore the air bag is stretched.

Owner:京山亿捷电脑有限公司

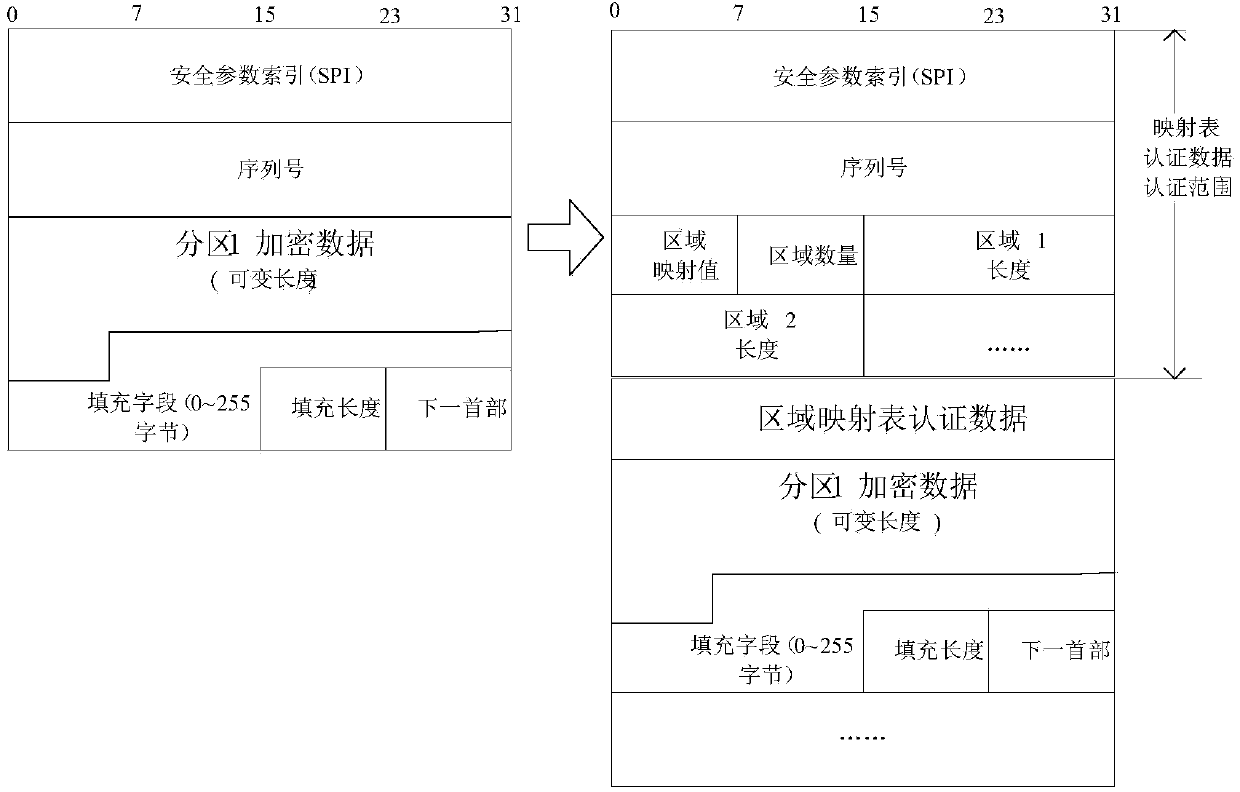

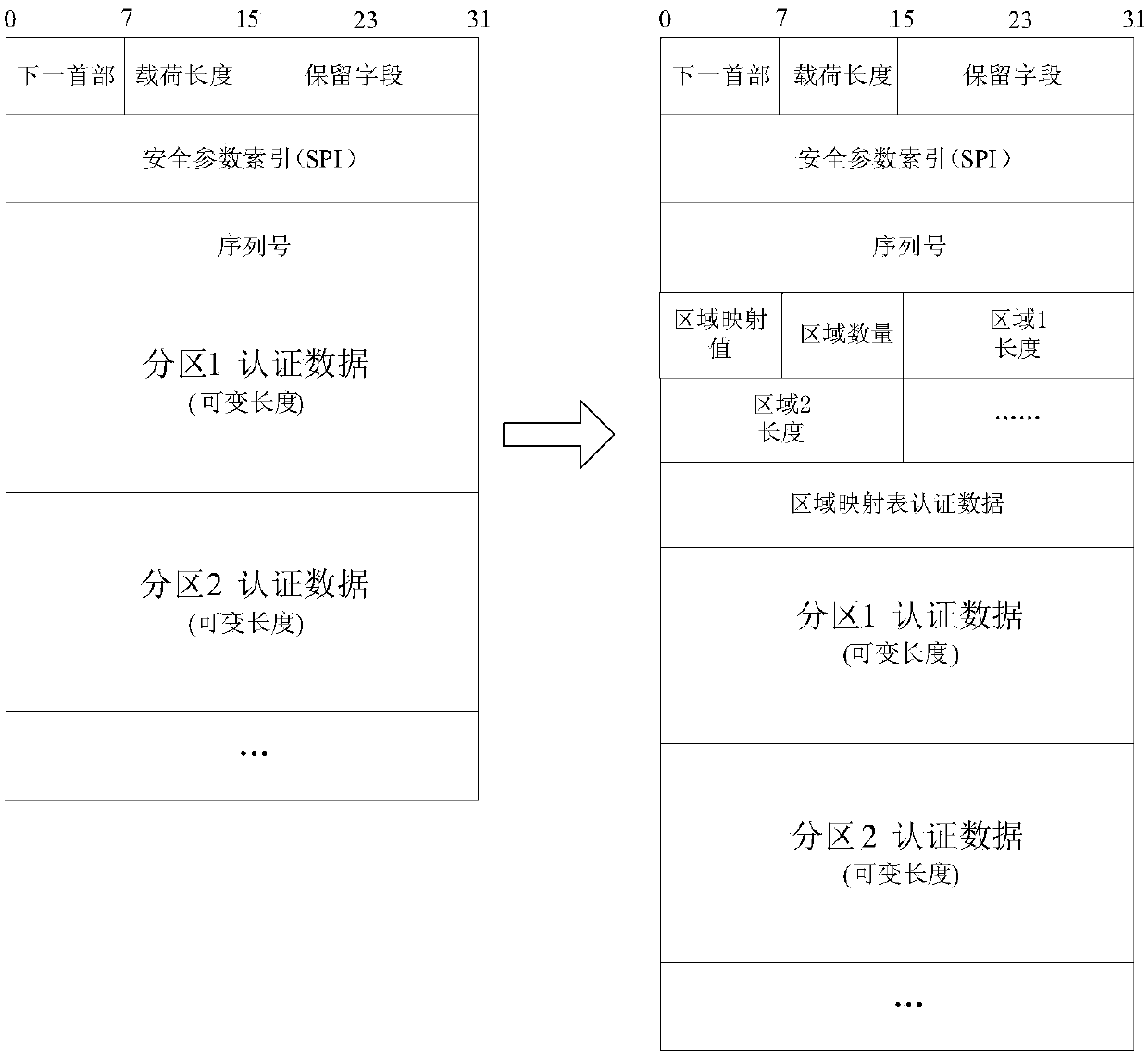

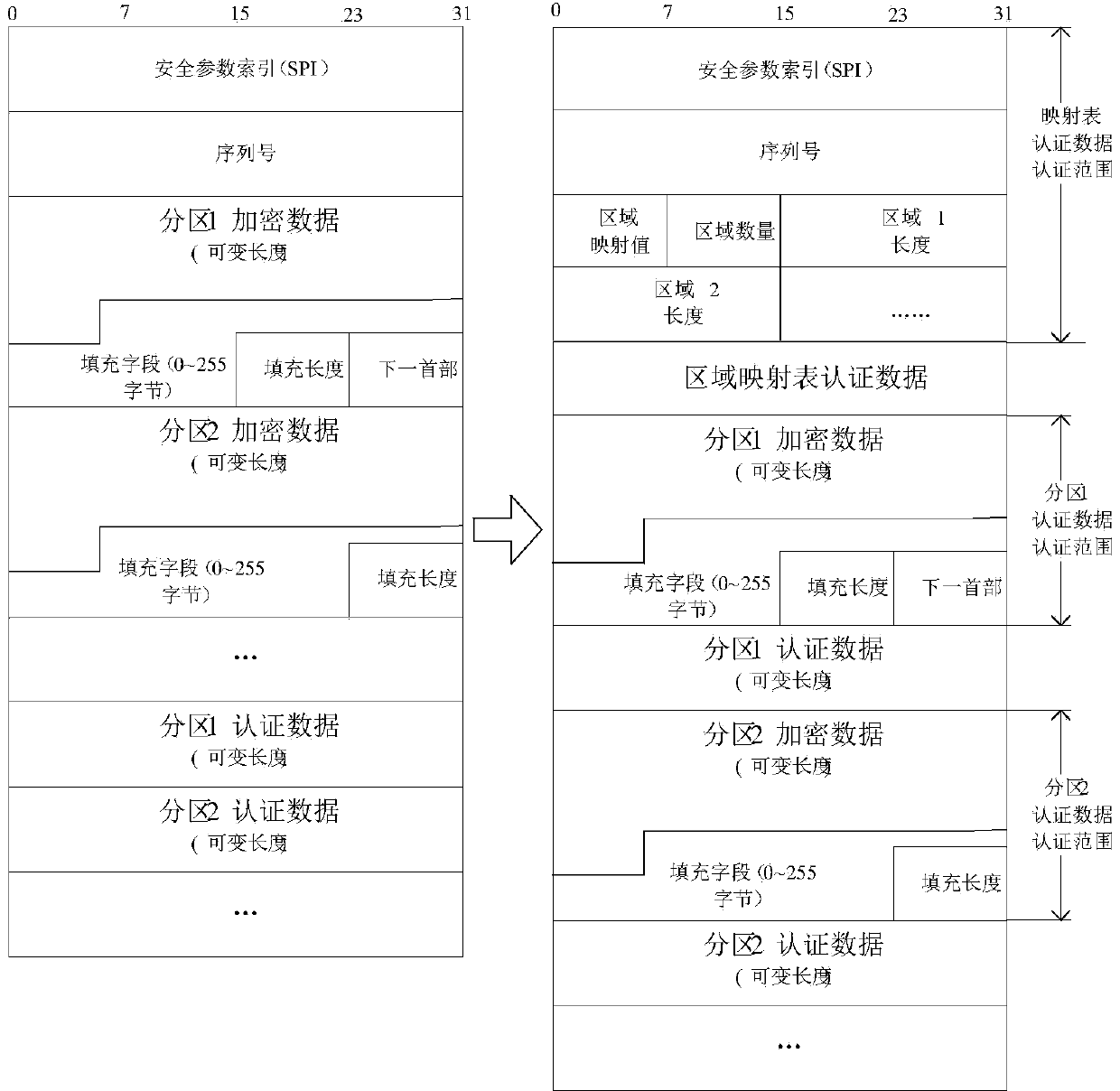

Multi-layer IPSec dynamic partition table design method used for satellite channel

ActiveCN104202311AImprove processing efficiencyFix fixityError preventionEnd to end securityPerformance enhancement

The invention provides a multi-layer IPSec dynamic partition table design method used for a satellite channel. The conflict between fixed size partition of data and performance enhancement technology on the satellite channel is solved by realizing dynamic partitioning. According to the method, the sending end nodes of data can decide the size of data partitioning according to the type of data application, a sending end can dynamically adjust the size of portioning, but IPSec segment treatment is not carried out invariably according to the inherent partitioning size in compound security association. By realizing dynamic partitioning for the data, an existing static mapping mode through a partition table in the compound security association is changed. According to the method, the flexibility of IPSec end-to-end security technology is greatly enhanced.

Owner:PLA UNIV OF SCI & TECH

Impurity-removal flow-guiding-type scutching device for textile production

InactiveCN110578198AFluffy cotton threadEasy to cleanDispersed particle filtrationFibre cleaning/openingPre treatmentCotton thread

The invention discloses an impurity-removal flow-guiding-type scutching device for textile production. Telescoping hydraulic cylinders are movably connected with the inner sides of columns, an installing plate is hinged to one ends of the telescoping hydraulic cylinders, and an installation frame is hinged to one end of the installation plate; rhombic combing plates are uniformly arranged at the bottom of the installation frame, bristle brushes are fixedly connected with the portions, corresponding to the two sides of each rhombic combing plate, of the bottom of the installation frame, adjusting telescoping rods are rotatably connected with the two ends of the top of the installation frame, and one ends of the adjusting telescoping rods are rotatably connected with a supporting frame. According to the impurity-removal flow-guiding-type scutching device for textile production, through the rhombic combing plates, before entering cotton washing equipment, weaving threads can be combed, sothat the twined weaving threads are separated from one another, and the weaving threads are prevented from being pulled apart; before entering the cotton washing equipment, the weaving threads can bepretreated by the bristle brushes, so that the cotton threads are fluffier, and convenience is provided for subsequent cleaning; the acting force of the bristle brushes to the weaving threads is adjusted by the adjusting telescoping rods through control over the installation frame, so that it is avoided that the weaving threads are broken due to too high stress.

Owner:CHANGXING BAOFU WEAVING

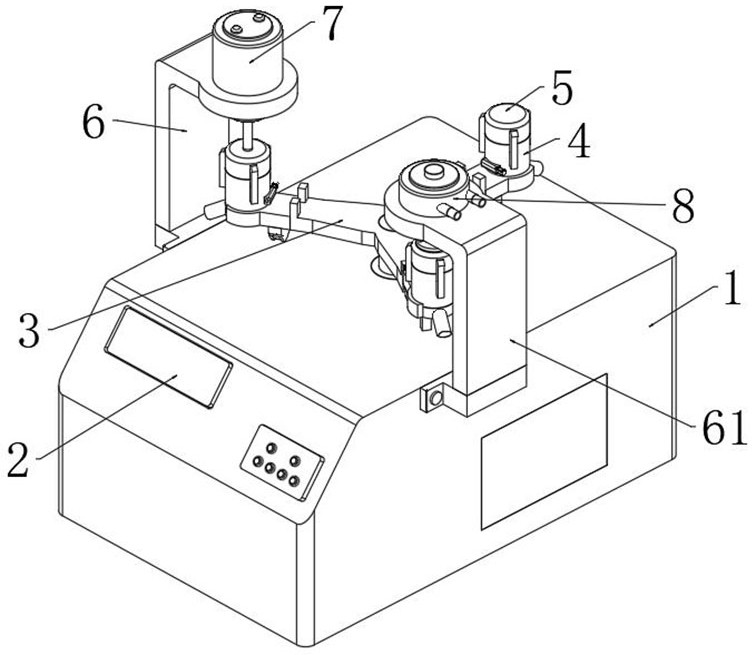

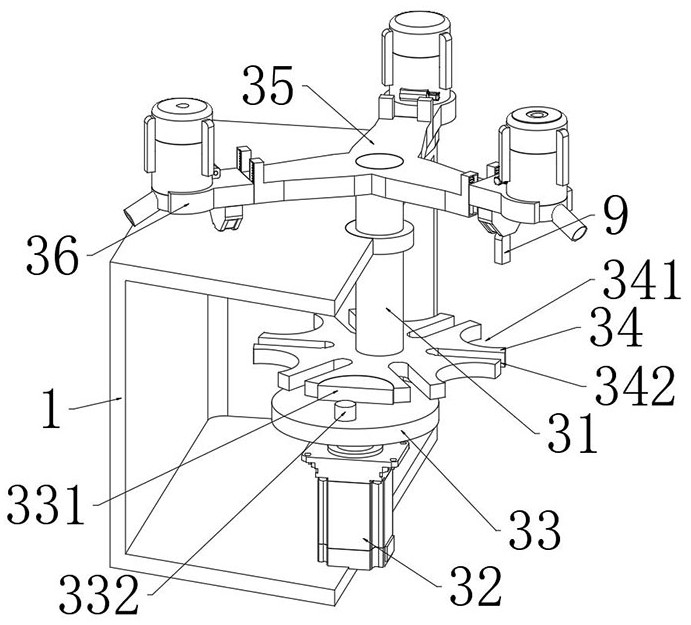

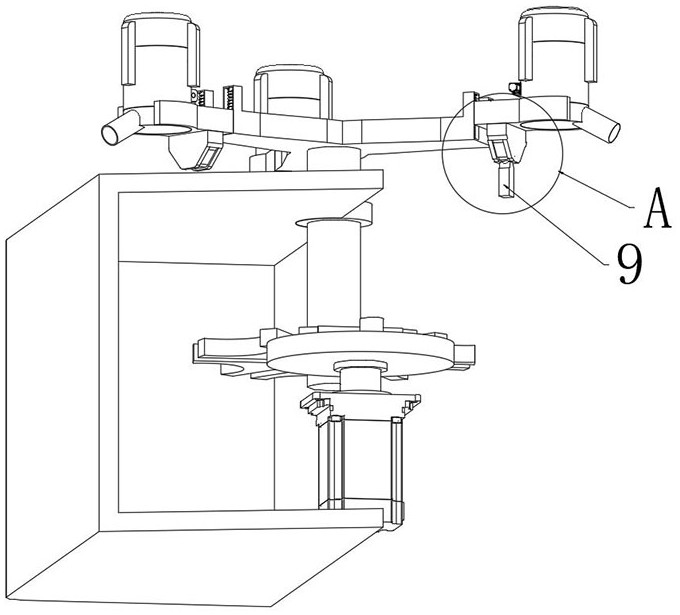

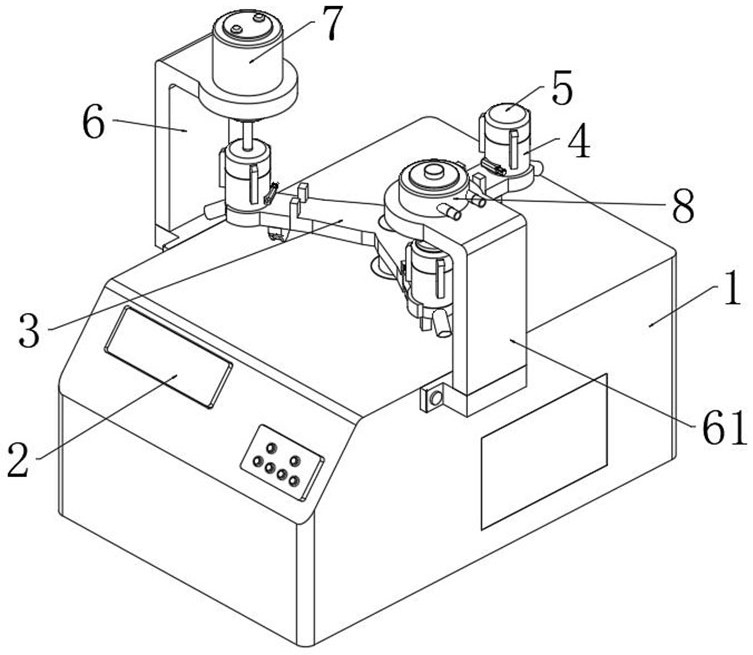

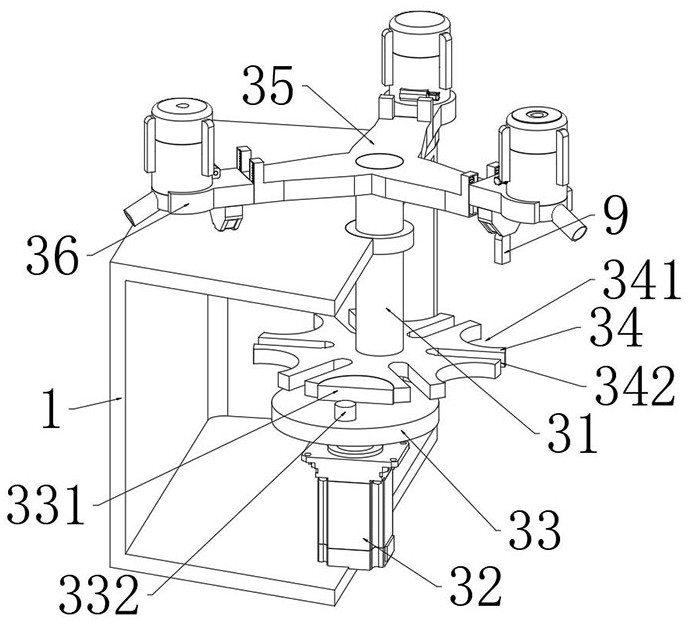

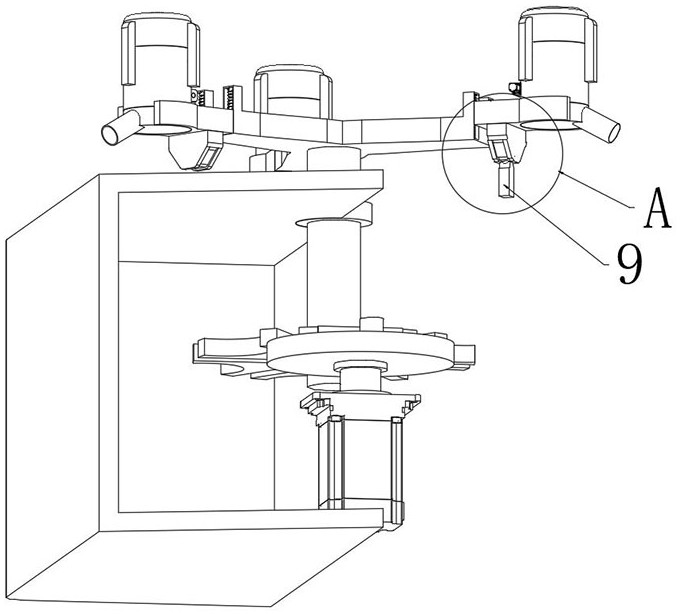

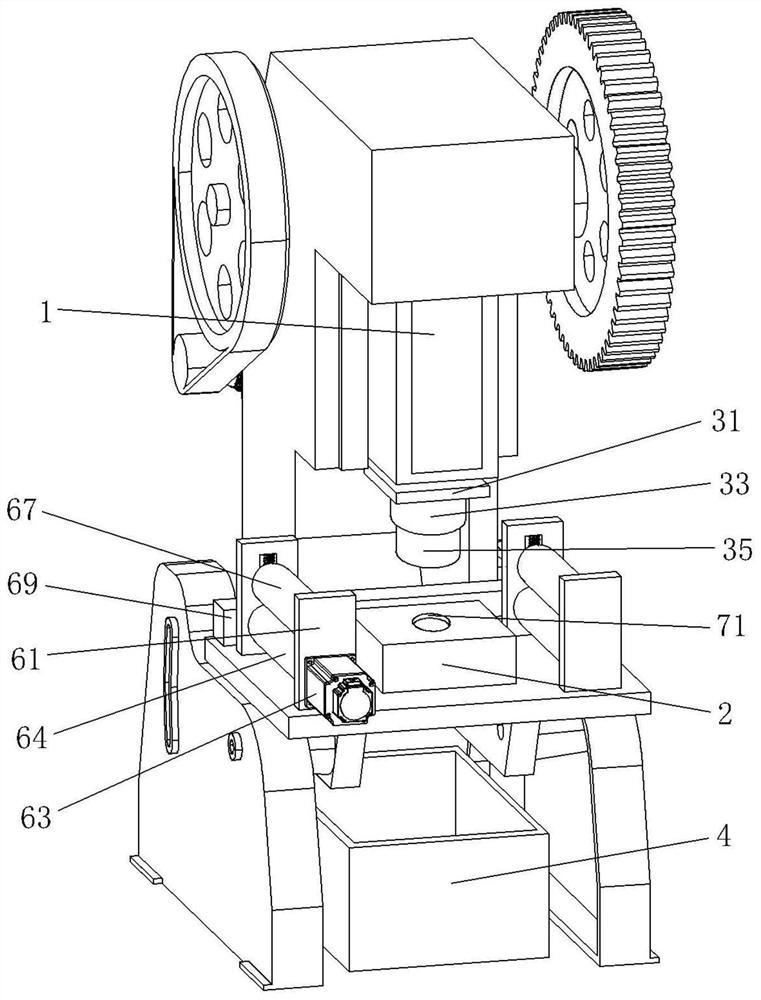

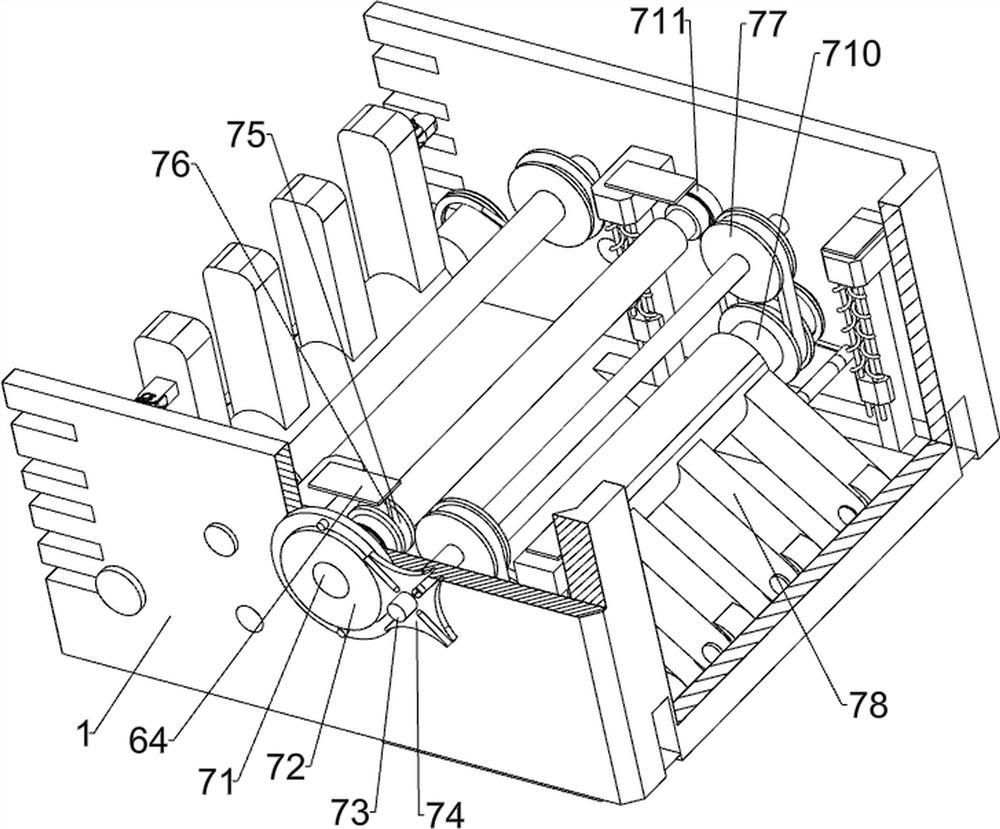

Multifunctional machine tool equipment for metal machining

ActiveCN113547375AAffect subsequent processingEasy to processPositioning apparatusMetal working apparatusMetal machiningEngineering

The invention discloses multifunctional machine tool equipment for metal machining, and belongs to the technical field of metal machining. The multifunctional machine tool equipment comprises a machine tool bottom frame, a control panel is arranged on one side of the machine tool bottom frame, a driving assembly is arranged in the middle of the machine tool bottom frame, a clamping assembly is fixedly clamped on the driving assembly, a to-be-machined metal part is movably arranged to the top of the clamping assembly in a clamped mode, and a first supporting arm is fixedly installed on the outer wall of the side, adjacent to the control panel, of the machine tool bottom frame. According to the multifunctional machine tool equipment, by arranging a scrap cleaning assembly and providing cooling airflow, waste scraps in a metal part hole site are effectively subjected to airflow clearing, the waste scraps are prevented from influencing follow-up machining of the metal part hole site, and the hole site is cooled through the cooling airflow, so that subsequent machining of the metal part is facilitated, the machining effect of the metal part is improved, the functionality of the whole machine tool equipment is improved, the waste scraps cleared through the airflow are blown into a scrap slowing frame through a scrap slowing pipe to be treated in a centralized mode, and the clearing effect of the waste scraps is effectively improved.

Owner:佛山市顺德区炜煌精密五金制品有限公司

Jade clamping device convenient to rotatably adjust

InactiveCN107009799AAvoid breakingSmooth rotationOther artistic work equipmentsJewelleryActive clampLeft direction

The invention provides a jade clamping device that is easy to rotate and adjust, belonging to the field of jewelry processing, comprising a bottom box and a fixed clip frame; the front and rear ends of the left side plate of the bottom box are vertically fixed with support rods; the two A square block is fixed between the upper ends of the support rods; the middle of the square block is horizontally penetrated by a rotating shaft and is in a left-right direction; there are two fixed clip frames, which exist symmetrically on the left and right; the fixed clip frames are sandwiched between There is a movable clip frame and the movable clip frame exists symmetrically up and down; the two movable clip frames of the present invention are used to clamp the jade that needs to be processed; the rubber pad is used to prevent the movable clip frame from directly contacting and clamping the jade to cause breakage; when the jade needs to be clamped and placed , the upper and lower movable clamping frames are pulled open, causing the first spring to compress, and the jade is stuck between the two movable clamping frames. Under the action of the resilience of the first spring, the two movable clamping frames clamp the jade; There is a gap between the initial positions of the two movable clamping frames, which is convenient for the processor to separate the two movable clamping frames.

Owner:龚俏枚

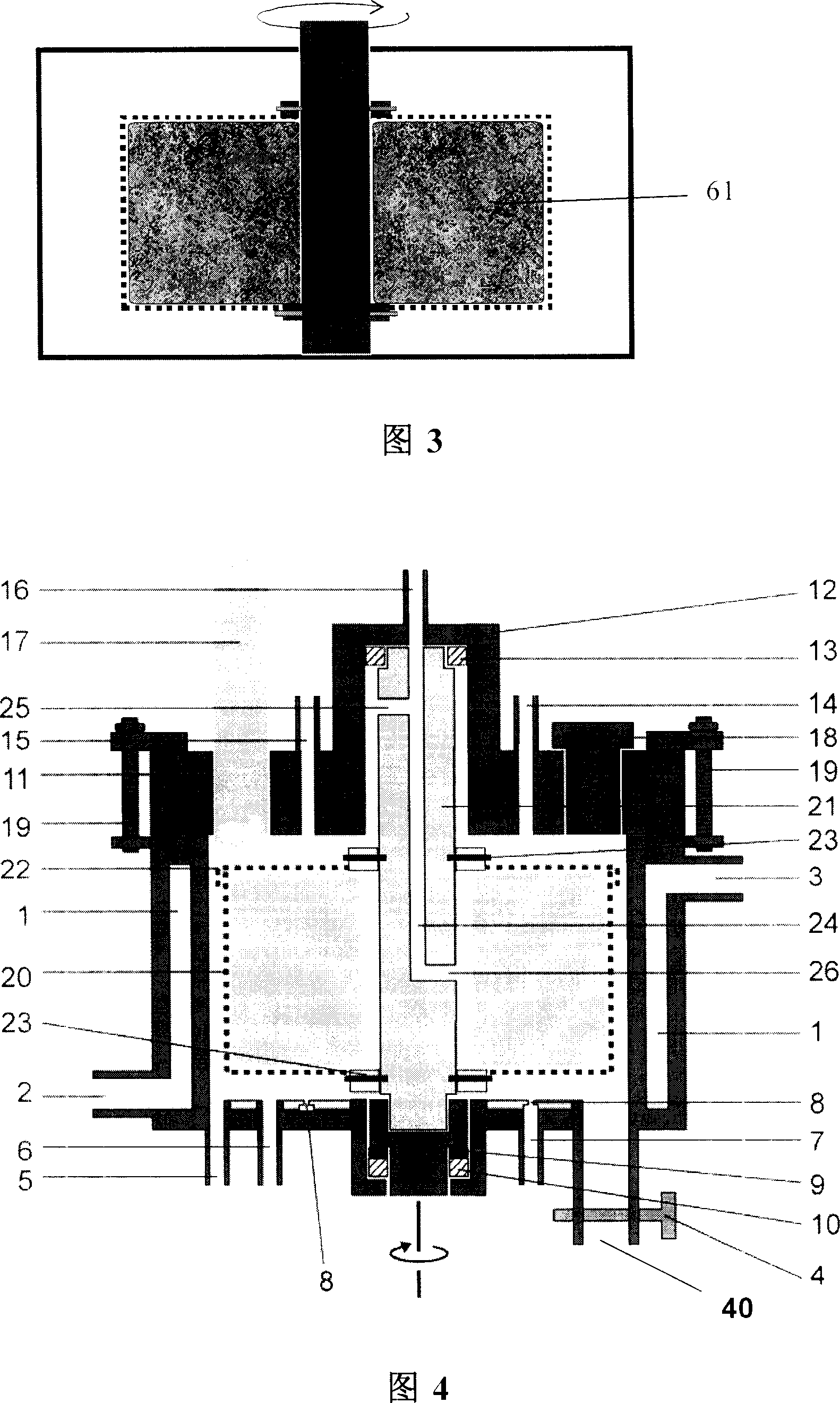

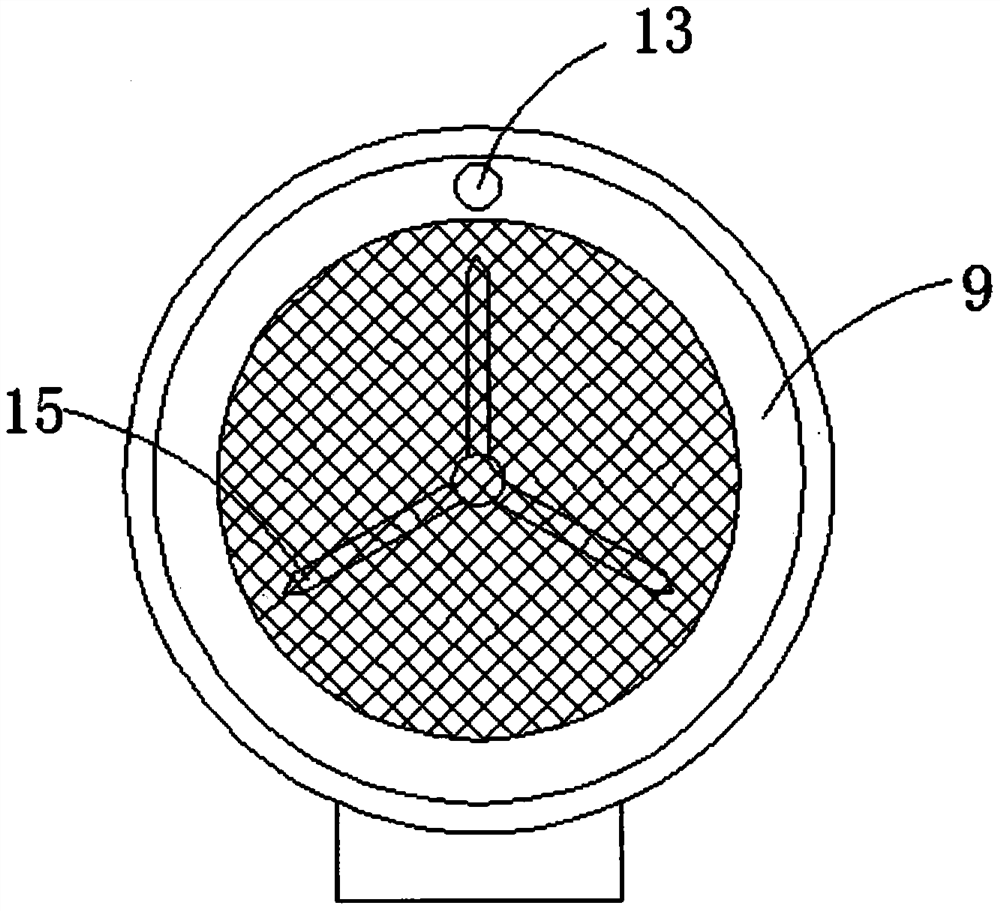

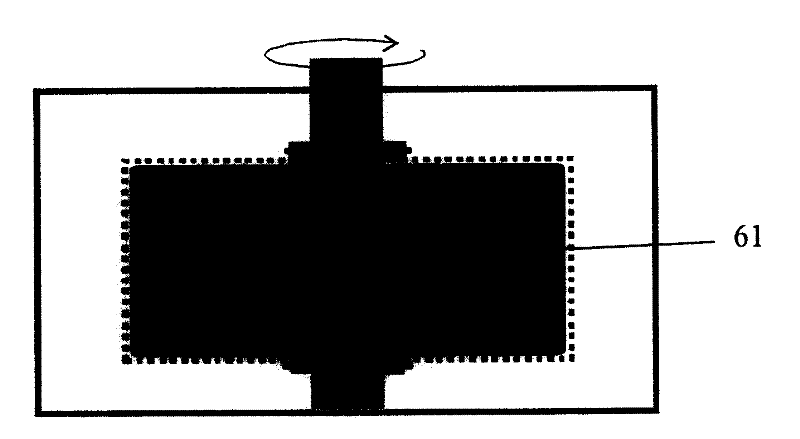

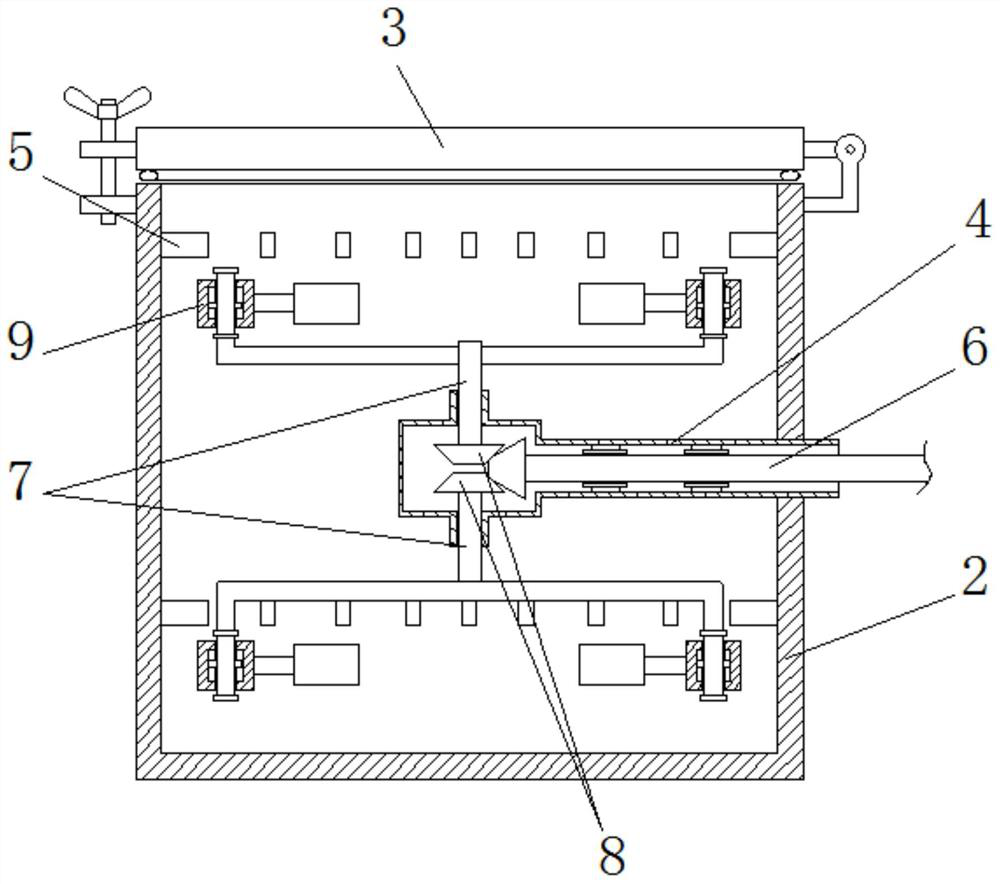

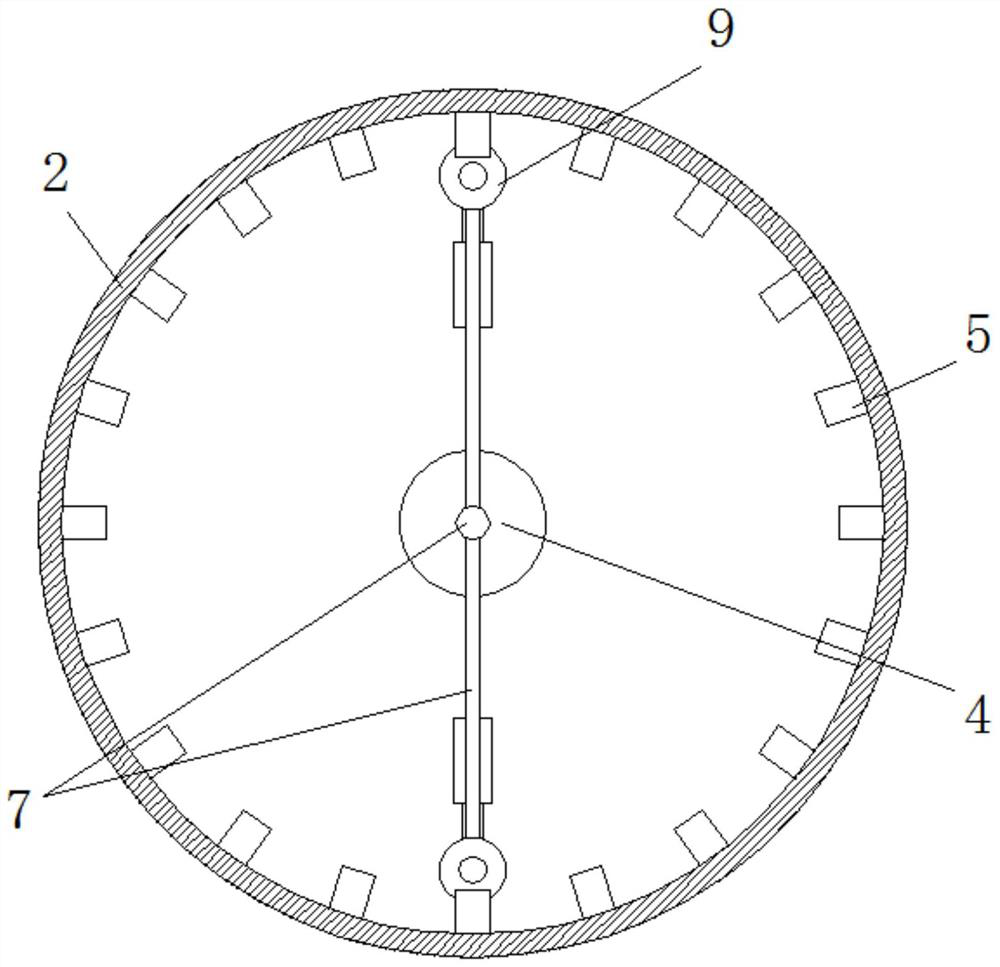

Reactor

ActiveCN101007256BWith centrifugal stirring functionAvoid chippingChemical/physical processesEngineeringVitality

The invention discloses a reaction which includes at least one reaction tank, said reaction tank includes tank body and rotating rotation axle installed in tank body, said rotation axle is fixed with solid phase catalyst, said solid phase catalyst has holes which can penetrate reaction liquid and gas, the solid phase catalyst also can be uses as a stirrer when rotates with the rotate axle. The reactor provided in the invention can prevent the vitality of catalyst decline, prolong the life tine of catalyst and has characteristics of high exchange efficiency, adequate reaction and wide application range.

Owner:BIORIGHT WORLDWIDE

A kind of multifunctional machine tool equipment for metal processing

ActiveCN113547375BAffect subsequent processingEasy to processPositioning apparatusMetal working apparatusCold airMetal machining

The invention discloses a multifunctional machine tool equipment for metal processing, which belongs to the technical field of metal processing, and comprises a machine tool bottom frame, a control panel is arranged on one side of the machine tool bottom frame, and a drive assembly is arranged in the middle of the machine tool bottom frame. A clamping component is fixed on the drive assembly, the top movable clamp of the clamping component is provided with a metal piece to be processed, and a first arm is fixedly installed on the outer wall of one side of the bottom frame of the machine tool adjacent to the control panel. In the present invention, by setting the chip cleaning assembly and the cooling air flow, the waste chips in the holes of the metal parts are effectively cleaned by air flow, preventing the waste chips from affecting the subsequent processing of the holes of the metal parts, and the holes are cooled by the cold air flow, so that Subsequent processing of metal parts improves the processing effect of metal parts and improves the functionality of the entire machine tool equipment. The waste chips cleaned by the air flow are blown into the chip relief frame through the chip relief pipe for centralized treatment, which effectively improves the cleaning of waste chips Effect.

Owner:佛山市顺德区炜煌精密五金制品有限公司

Medicinal material cleaning machine based on flotation method

InactiveCN112934837AAffect processingEasy to cleanCleaning using toolsCleaning using liquidsMedicinal herbsStructural engineering

The invention provides a medicinal material cleaning machine based on a flotation method, and relates to the technical field of medicinal material processing. The medicinal material cleaning machine based on the flotation method comprises a shell, a cover plate, feeding plates, a cleaning mechanism, a filtering mechanism, discharging plates, a driving device and a water inlet pipe; the cover plate is arranged at the top end of the shell and movably connected with the top end of the shell; the feeding plates are arranged on the two sides of the upper portion of the middle of the shell and rotationally connected with the shell; the cleaning mechanism is arranged at the bottom end in the shell; the cleaning mechanism is used for cleaning soil on radix salviae miltiorrhizae and tiny root hair; the cleaning mechanism is rotationally connected with the bottom end of the inner wall of the shell; the filtering mechanism is movably connected to the position, close to the top end, in the shell; the discharging plates are rotationally connected to the two sides, close to the bottom end, of the shell; the driving device is fixedly connected to the bottom end of the shell; and the water inlet pipe is fixedly connected to the lower portion of the left end of the shell. The medicinal material cleaning machine based on the flotation method solves the problem that a large amount of tiny root hair of radix salviae miltiorrhizae is doped in the radix salviae miltiorrhizae after the radix salviae miltiorrhizae is cleaned.

Owner:张华军

Salt-containing organic waste liquid desalination pyrolysis treatment method and system

ActiveCN108479088BAchieve separationSave energyEvaporator accessoriesCombustion technology mitigationGas solidCombustion chamber

The invention discloses a treatment method and system for demineralization and pyrolysis of salt-containing organic waste liquid. The method comprises the following steps: (a) air preheating; (b) spray drying; (c) separation and recovery; and (d) pyrolysis. The treatment system for demineralization and pyrolysis of salt-containing organic waste liquid comprises an incinerator, a gas-gas heat exchanger connected with the outlet of a rear secondary combustion chamber of the incinerator, a tubular pyrolysis reactor connected with the flue gas outlet of the gas-gas heat exchanger, an atomization tower connected with the air outlet of the gas-gas heat exchanger, and a cyclone dust collector connected with the gas-solid mixture outlet of the atomization tower. The treatment method and system ofthe invention can utilize the residual heat of flue gas to avoid the problems of softening, coking, flue clogging, heat exchanger clogging and the like of salt sprayed into the waste liquid of the incinerator by the salt-containing organic waste liquid; at the same time, the treatment of the salt-containing organic waste liquid can be separated from the whole process, and no influence is exerted on original process.

Owner:SOUTHEAST UNIV

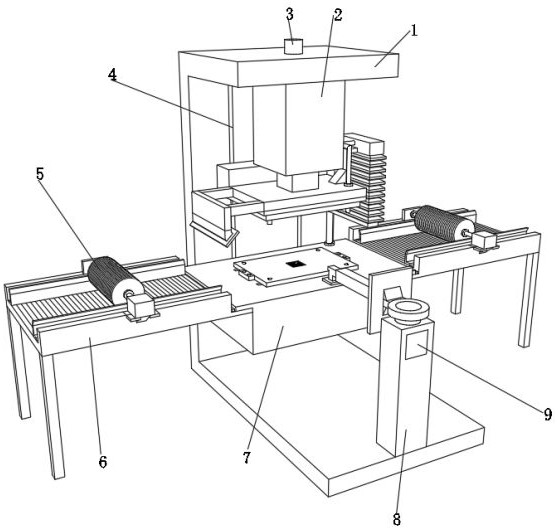

Continuous stamping and discharging equipment

InactiveCN112719113ASmooth feedingGuarantee the quality of blankingMetal-working feeding devicesPositioning devicesMachiningIndustrial engineering

The invention discloses continuous stamping and discharging equipment. The equipment comprises a stamping machine main body, a lower stamping die, an upper stamping assembly, a collecting box, a conveying mechanism and a stripping mechanism; the lower stamping die is fixedly arranged at the top end of a workbench of the stamping machine main body; the upper stamping assembly is arranged at the top end of the inner side of the stamping machine main body; the collecting box is arranged at the bottom end of the stamping machine main body, a through hole is formed in the top end of the workbench of the stamping machine main body, and the through hole is located over the collecting box; the conveying mechanism is arranged at the top end of the workbench of the stamping machine main body; and the stripping mechanism is arranged in an inner cavity of the lower stamping die. According to the continuous stamping and discharging equipment, by arranging the upper stamping assembly, a workpiece can be extruded and fixed before being stamped, so that stable stamping and discharging is carried out on the workpiece in the conveying process, the discharging quality of the workpiece is guaranteed, it is guaranteed that the stamped and separated workpiece smoothly enters the collecting box, and therefore, the workpiece is prevented from being taken out by a stamping block to influence subsequent machining.

Owner:金楚迪

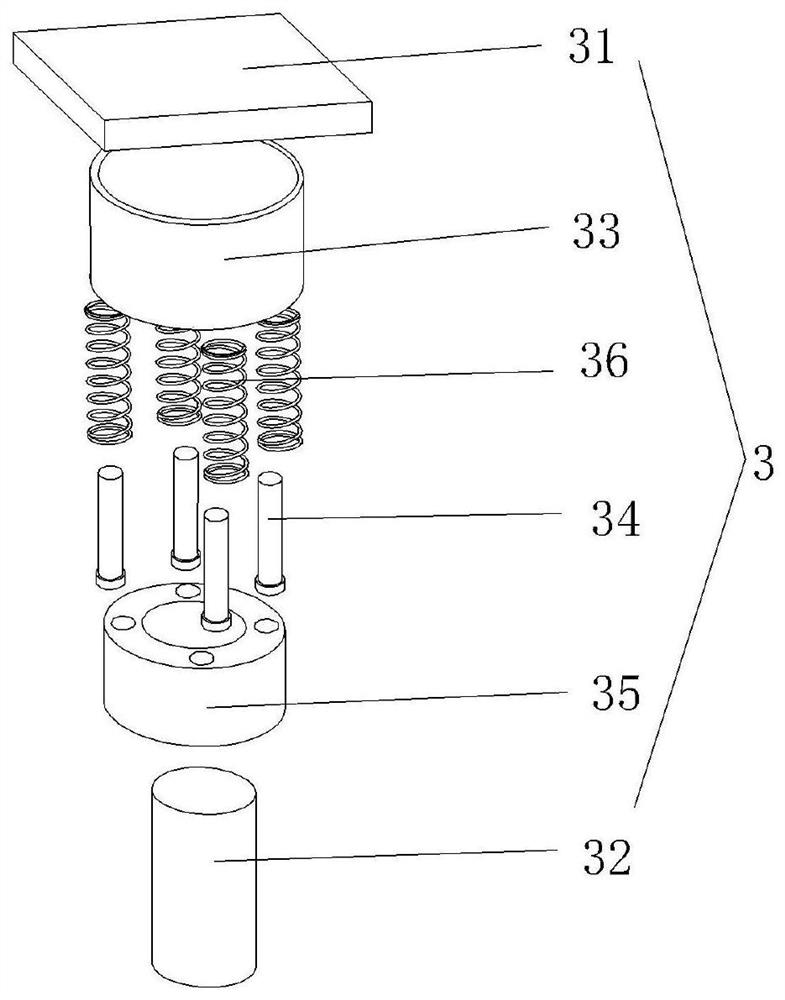

Centralized wet garbage collection equipment capable of removing liquid

InactiveCN112623564AAffect subsequent processingRefuse receptaclesBags openingBin bagGarbage collection

The invention discloses centralized wet garbage collection equipment capable of removing liquid. An overground putting drum is located above an underground collection box, a putting cavity and a liquid-discharging cavity which communicate from top to bottom in sequence are formed in the overground putting drum, a sliding rail and a bag-breaking part are arranged on an inner wall of the putting cavity, a hook is slidingly installed on the sliding rail through a sliding base, the sliding base is connected with a drum cover through a connection rope, the bottom of the liquid-discharging cavity communicates with a collection space through a garbage inlet, and a liquid-discharging opening is formed in a side wall of the liquid-discharging cavity. Wet garbage is put into the overground putting drum in bags, in falling processes, the plastic bags are broken, the plastic bags remain on the hook in a putting channel, wet garbage falls onto a box cover, liquid is discharged through the liquid-discharging opening, udder the gravity action, and the garbage subjected to liquid filtering pushes the box cover to open the box cover downwards, and then falls into the collection space which is underground, so that on one hand, the garbage bags are prevented from being mixed to affect subsequent treatment of the wet garbage, and on the other hand, the liquid contained in the wet garbage is filtered out in advance, so that effects of the garbage off-odour to the environment are reduced.

Owner:阜阳莱纳环保科技有限公司

A conveyor for jujube processing

ActiveCN113499994BAvoid accumulationAvoid Manual SortingCleaningDirt cleaningInterference fitEngineering

The invention discloses a jujube processing conveyor, comprising an operation table, the upper surface of the operation table is fixedly connected with two vertical plates, and the two vertical plates are connected with a main shaft, a secondary shaft and three vertical plates through bearings through and rotating through. A rotating rod, a section of the main shaft and the secondary shaft located between the two vertical plates is an interference fit with a rotating roller, the two rotating rollers cooperate with a conveyor belt, and the rotating rod is located between the two vertical plates. An arc-shaped block is in interference fit between the two vertical plates, and three mounting plates are fixedly connected between the two vertical plates. The advantages are: compared with the prior art, the present invention can automatically remove defective jujubes under the condition that the jujubes are not dropped or piled up during transportation, avoids manual removal, greatly reduces labor intensity, and improves At the same time, it can prevent dust and debris from being transported together, and ensure the product quality of jujube.

Owner:江苏蜜心枣业有限公司

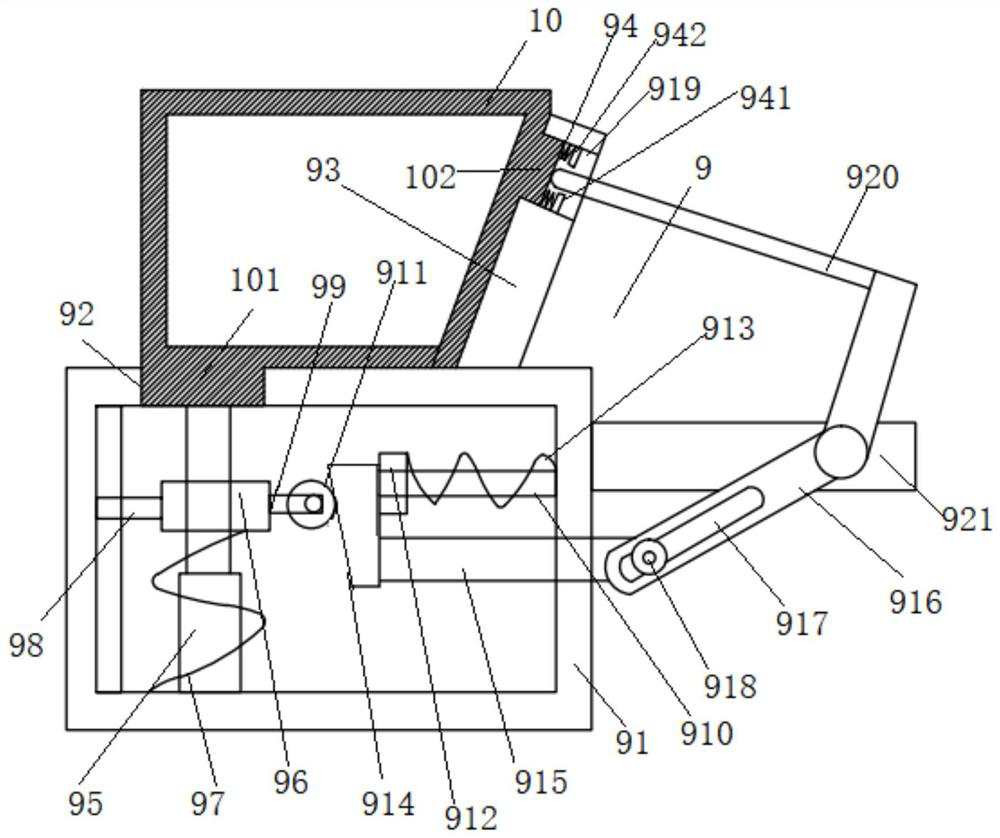

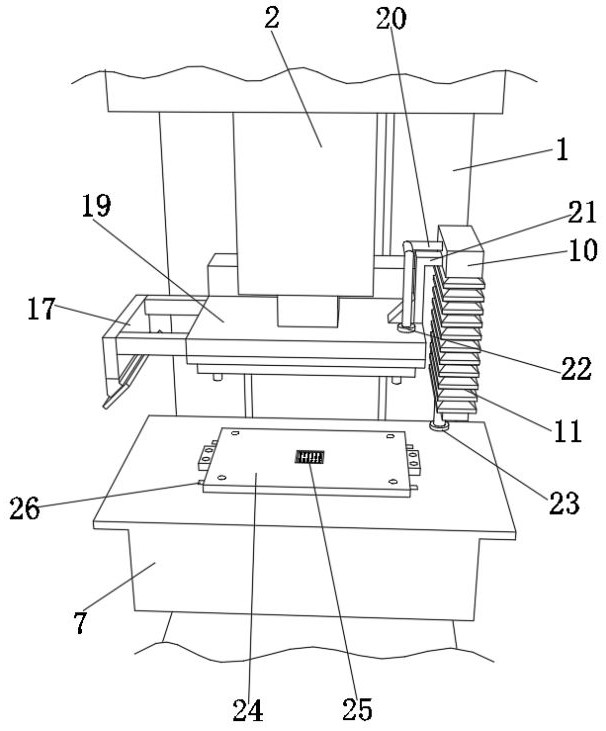

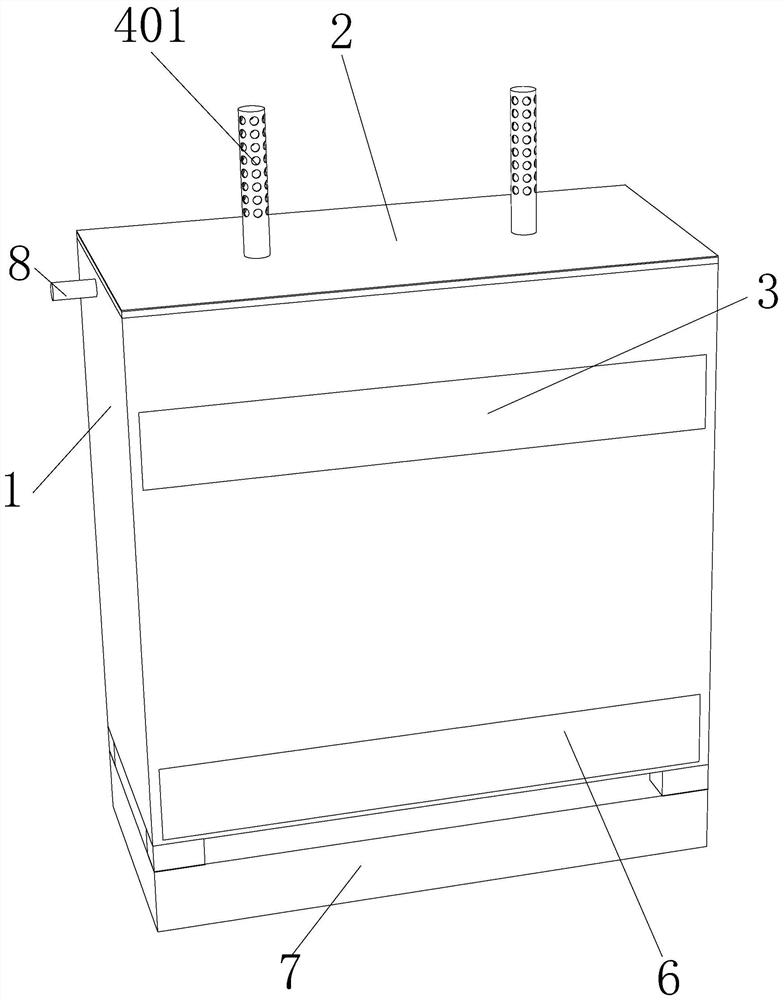

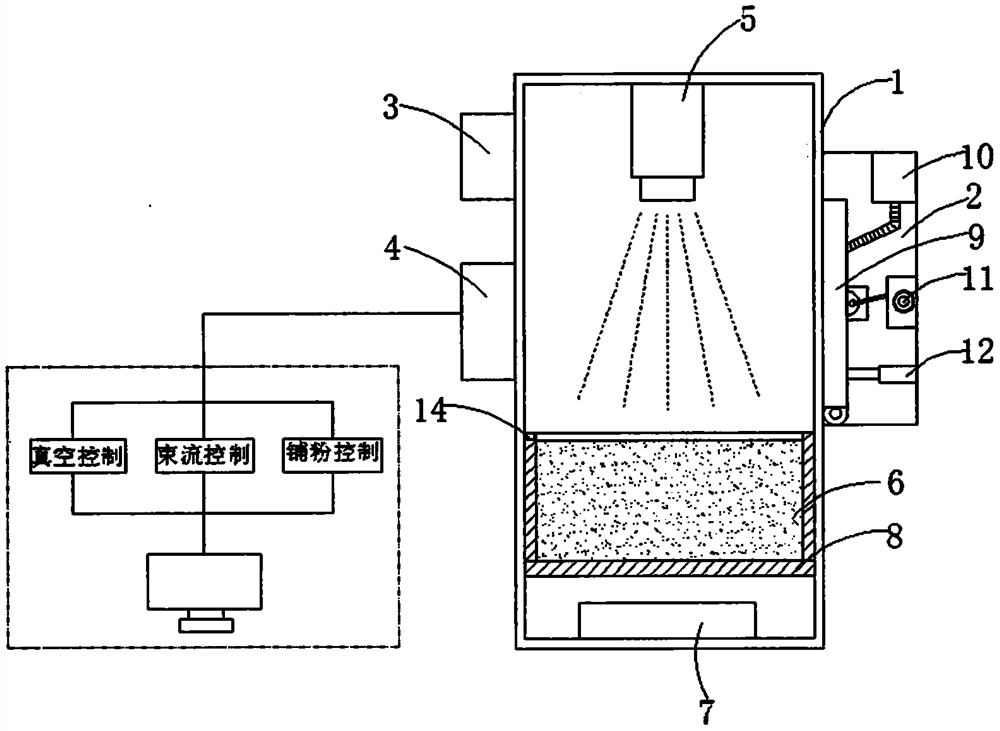

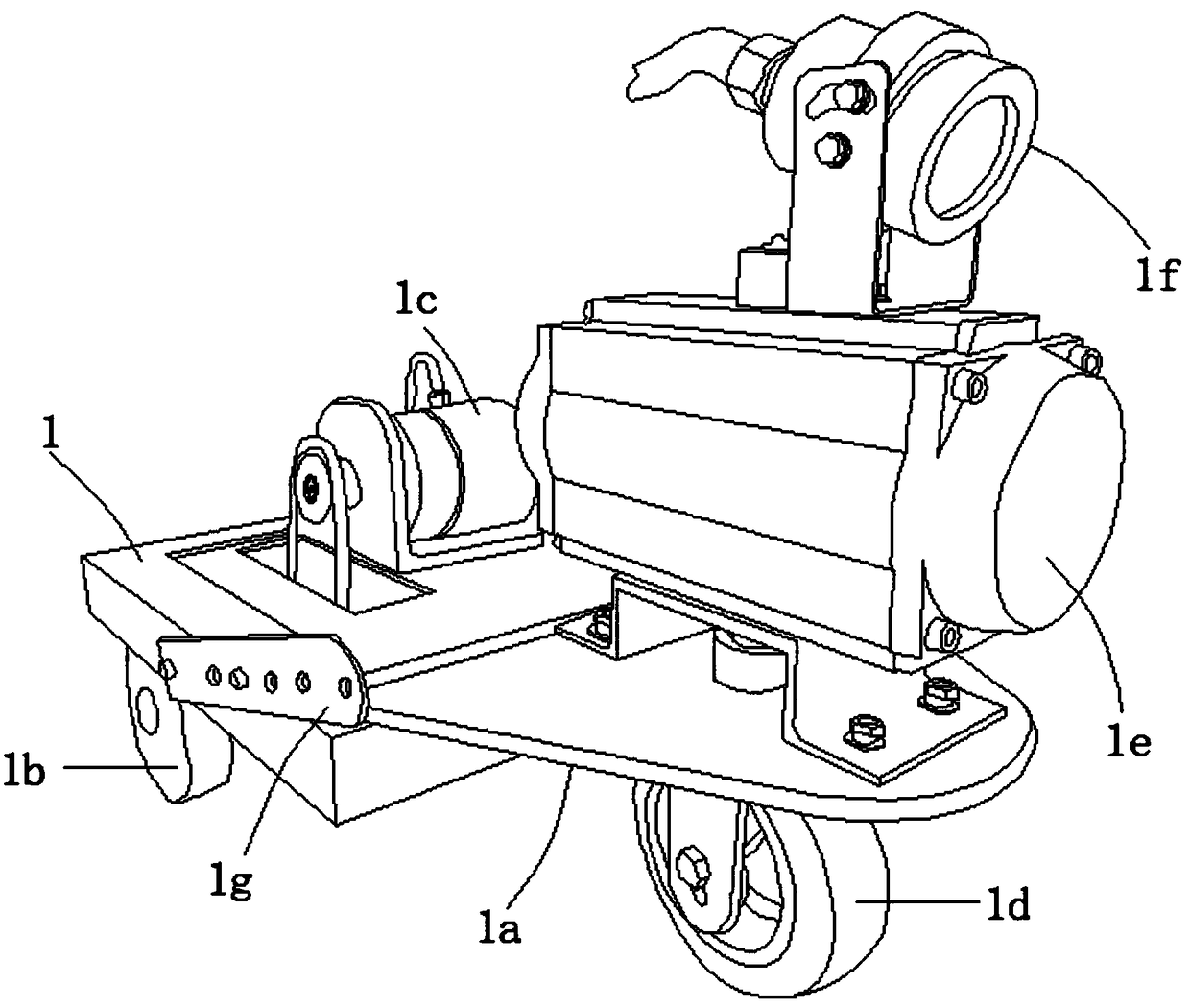

An electron beam powder rapid prototyping system

ActiveCN110328363BPrecise powder placementPowder evenlyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringRapid prototyping

The invention relates to the technical field of electron beam powder rapid prototyping, in particular to an electron beam powder rapid prototyping system and an operation method, including a body, a vacuum pump and a controller are installed and fixed on one side outside the body, and the other side outside the body The powder spreading box is installed and fixed on the side, the top of the inner wall of the body is equipped with an electron gun, the bottom of the body is fixed with a ventilating plate frame, a fan is installed under the ventilating plate frame, and the inside of the ventilating plate frame is a molding cavity, and the powder spreading box One side of the powder spreading board is installed with a right-angle hinge, and the middle part of the back side of the powder spreading board is connected and fixed by a pull rope and a retracting rope device, and the inner cavity of the powder spreading board is connected to the output end of the powder pump in the powder bin through the connecting pipe. connected, and the powder outlet side of the powder spreading board is provided with a powder outlet grid, and the powder outlet grid is rotated and equipped with a scraper. Powder is flying throughout the unit.

Owner:河北敬业增材制造科技有限公司

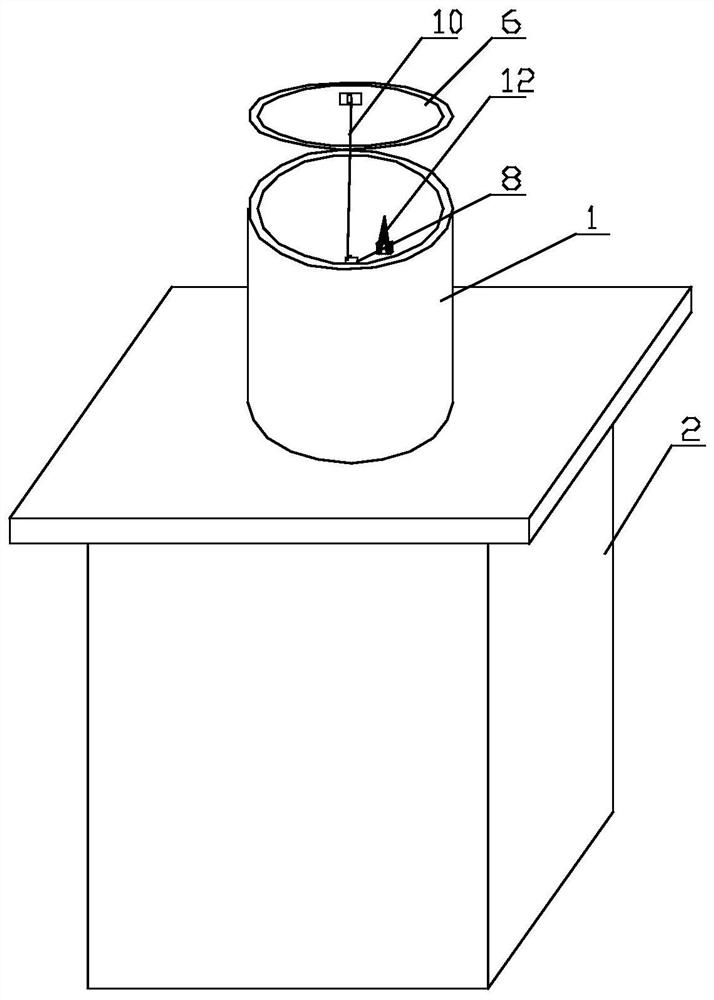

Ceramic tile knocking equipment for building

ActiveCN114278065AAvoid knockout effectsKnock really goodBuilding constructionsCeramic materials productionStructural engineeringMechanical engineering

The invention relates to ceramic tile knocking equipment, in particular to ceramic tile knocking equipment for buildings. According to the ceramic tile knocking equipment for the building, the ceramic tiles can be knocked to be compact, the tilted ceramic tiles can be pressed to be compact, and knocking is not affected. Ceramic tile knocking equipment for building comprises a shell, rollers, rotating shafts and the like, the rotating shafts are rotatably connected between the left sides of the lower portions of the front side and the rear side of the shell and between the right lower sides of the front side and the rear side in a penetrating mode, and the rollers are fixedly connected to the front ends and the rear ends of the rotating shafts. A driving mechanism is pulled to be adjusted to a proper position firstly, then the driving mechanism is pushed to drive the device to move rightwards, a rolling wheel rotates forwards to drive a rotating shaft to rotate forwards, the rotating shaft rotates forwards to drive the driving mechanism to operate, the driving mechanism operates to drive a beating mechanism to operate, and the beating mechanism operates to drive rubber to swing up and down to beat a ceramic tile. And the shell further drives the limiting mechanism to operate to compact the tilted ceramic tile, so that the ceramic tile can be compacted, and the tilted ceramic tile can be prevented from influencing compacting.

Owner:陕西铜川煤矿建设有限公司

A slitting system for galvanized pull ring strip material

ActiveCN110919070BEasy to cutLess prone to glitchesShearing machinesOther manufacturing equipments/toolsRatchetElectric machinery

The invention discloses a slitting system of a galvanized pull-ring strip, and relates to the field of machining of pull-rings of ring-pull cans. According to the technical scheme, the slitting systemis characterized by comprising a machine tool, a transmission roller and a cutting mechanism are arranged on the machine tool, the cutting mechanism comprises a cutting roller and a cutting motor, acircular cutter is arranged on the cutting roller, the machine tool is provided with a trimming mechanism and a driving mechanism, the trimming mechanism comprises a trimming piece and a trimming strip, the trimming strip is provided with a knife grinder, an oil cavity and a piston channel, the trimming strip is provided with a movable plug, the trimming piece is provided with a driving piston, and the machine tool is provided with a cleaning mechanism for cleaning up cut scrap iron. Through the trimming mechanism, the circular cutter can be kept sharp so as to more easily cut off a galvanizedcoiled strip, no burrs can easily appear, and the cutting quality is high; by arranging a piston rod, a driving pawl and a ratchet wheel, the service life of the knife grinder is long; and by arranging the cleaning mechanism, scrap iron can hardly be left on the surface of the galvanized coiled strip to influence the subsequent machining of the galvanized coiled strip.

Owner:杭州泰迪包装材料有限公司

Dirty oil separation and purification device and method

PendingCN109384275AAffect subsequent processingFatty/oily/floating substances removal devicesLiquid separationOil separationOil content

The invention provides a dirty oil separation and purification device and method, relates to the technical field of sewage treatment, and aims to solve the problems of low dirty oil extraction efficiency and low sewage treatment efficiency. The dirty oil separation and purification device comprises an underwater trolley, a dosing system and a sewage purification system, wherein an extraction pipeline is mounted on the underwater trolley; the extraction pipeline is connected with a sludge pump; the sludge pump is connected with the sewage purification system through a sludge pipeline; the dosing system is connected with the sewage purification system through a dosing pipeline; and the suction hole of the extraction pipeline faces a water level. The underwater trolley is moved to an area with a high oil content and few sludge, sewage and dirty oil can be directly sucked into the sewage purification system for treatment, and the dirty oil extraction efficiency and the water purification efficiency can be improved.

Owner:四川天宜石油化工工程有限公司

Reactor

ActiveCN101007254BAvoid chippingAvoid wear and tearChemical/physical processesNuclear engineeringVitality

The invention discloses a reactor which reaction media is liquid, the reactor includes at least one reaction tank, said reaction tank includes tank body and revolution axis which is installed in the tank and can rotate, said reaction tank also includes a container fixed on said axis, the whole outer wall of said container is equipped with holes which can penetrate reaction liquid and gas. The reactor provided by the invention can prevent the vitality of activator decline, extend life time of activator and has characteristics of high exchange efficiency, adequate reaction and wide application range.

Owner:BIORIGHT WORLDWIDE

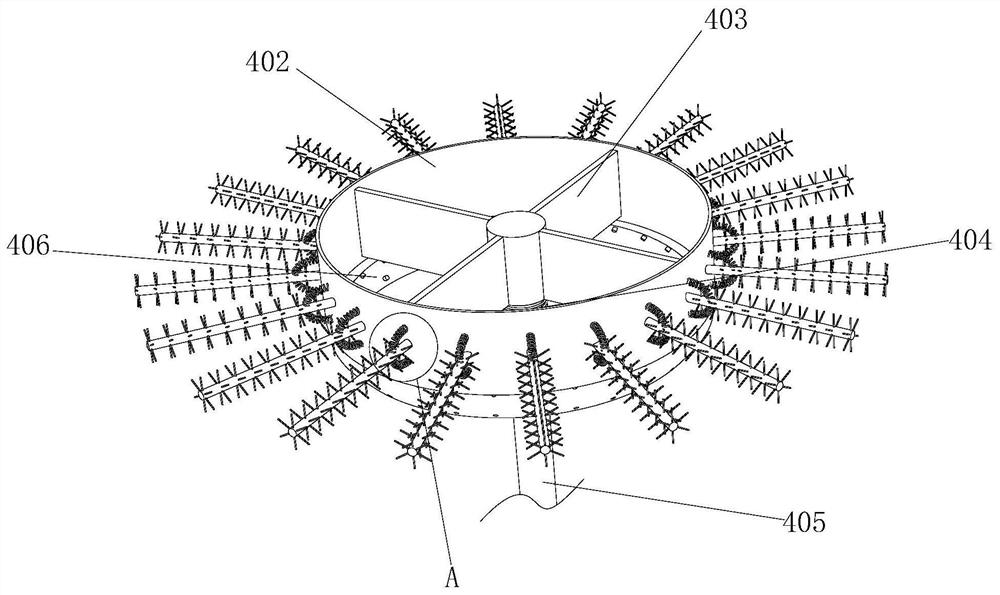

Biomass energy particle preparation device

InactiveCN113877694AEasy to control the maximum diameterAffect subsequent processingSievingScreeningDrive shaftGear wheel

The invention discloses a biomass energy particle preparation device, which specifically comprises an outer fixed cylinder, the bottom of the outer fixed cylinder is provided with a storage shell, and one end of the outer fixed cylinder is provided with a driving device; a driving shaft, wherein one end of the driving shaft is connected with the driving device, a plurality of groups of cutting knives are arranged on the outer side of the driving shaft, and the cutting knives are uniformly distributed on the driving shaft; a screen cylinder which is connected with the outer fixed cylinder through a rotating device, an inner gear ring is arranged at one end of the screen cylinder, and the end, close to the inner gear ring, of the driving shaft is in transmission connection with the inner gear ring through a gear set; and a cleaning device which is arranged on the inner wall of the outer fixed cylinder. The invention relates to the technical field of biomass energy. According to the biomass energy particle preparation device provided by the invention, the maximum diameter of cut particles can be conveniently controlled, the situation that follow-up machining is affected by particles with the large diameter in the particles is avoided, blockage caused by material accumulation during cutting can be avoided, the failure rate is low, and the machining efficiency is high.

Owner:李冠群

A polyurethane spraying device

ActiveCN112642620BReduce recycling efficiencyNot easy to recycleSpraying apparatusElectric machineStructural engineering

Owner:宁波耀众模塑科技有限公司

Plastic master batch processing and preparing system

The invention belongs to the technical field of plastic master batch processing equipment, and particularly relates to a plastic master batch processing and preparing system which comprises a body, a wire material, a motor, a worm gear, a roller shaft and a dehumidification mechanism. A wire enters the body and then makes contact with cooling liquid, the wire is solidified after being cooled, the motor drives the roll shaft in the body to rotate synchronously through the belt in the rotating process, and therefore the wire in the body can be effectively prevented from making contact with the same position of the roll shaft for a long time; when the wire material located in the body moves towards the front end of the body after being cooled, the dehumidification mechanism is used for removing moisture adhering to the surface of the wire material, the structure is simple, use is convenient, the effect of removing moisture on the outer surface of the wire material can be effectively improved, and meanwhile the wire material can be conveniently and rapidly removed. And by using the dehumidification mechanism, the energy loss and waste of the dehumidification mechanism in the process of removing the moisture on the outer surface of the line material can be effectively reduced, so that the energy-saving effect is achieved.

Owner:聂卫兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com