Biomass energy particle preparation device

A preparation device and biomass energy technology, applied in grain processing, solid separation, sieving and other directions, can solve the problems of inconvenient processing, different particle sizes for cutting, and many accumulated materials, etc. The effect of bending offset and high machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

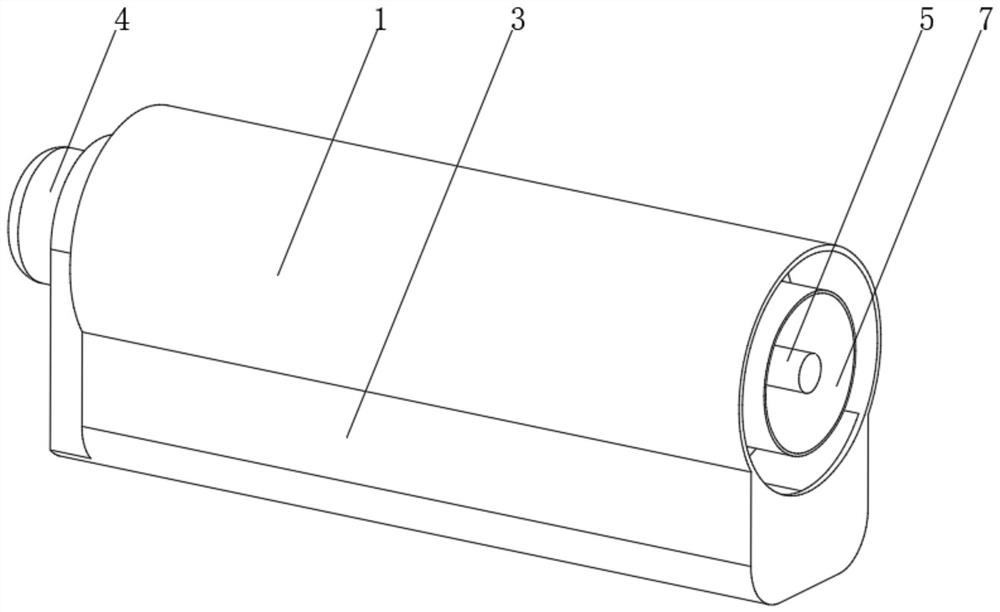

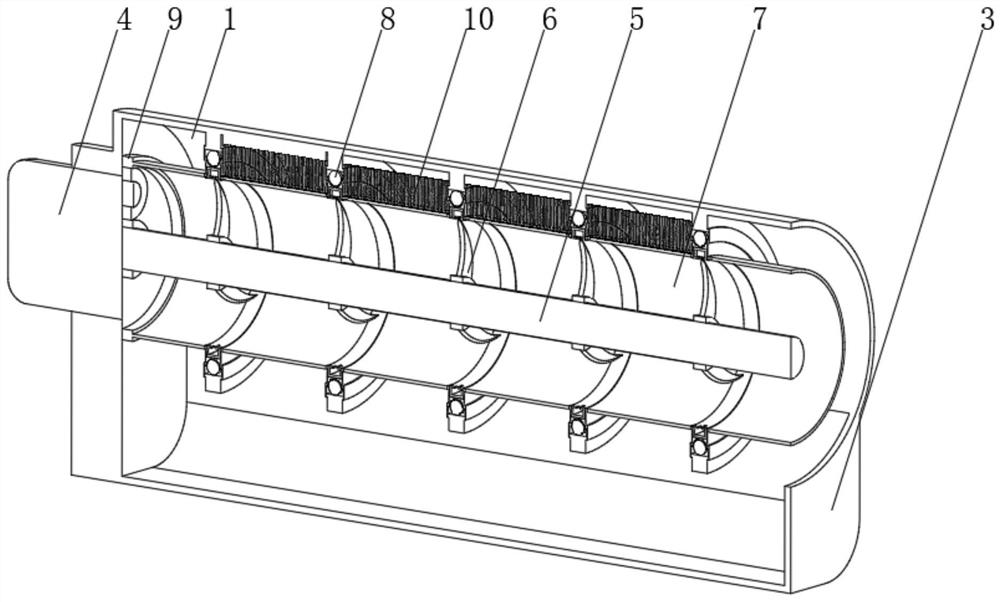

[0040] see Figure 1-4 , the present invention provides a technical solution: a biomass particle preparation device, specifically comprising:

[0041] An external fixing cylinder 1, the bottom of the external fixing cylinder 2 is provided with a storage shell 3, and one end of the external fixing cylinder 2 is provided with a driving device 4;

[0042] Drive shaft 5, one end of the drive shaft 5 is connected to the drive device 4, the outside of the drive shaft 5 is provided with cutting knives 6, and the cutting knives 6 are arranged in multiple groups and evenly distributed on the drive shaft 5;

[0043] Screen cylinder 7, the screen cylinder 7 is connected with the external fixed cylinder 2 through the rotating device 8, the inner gear 9 is arranged at one end of the screen cylinder 7, and the end of the drive shaft 5 close to the inner gear 9 passes through the gear set and the inner gear 9 transmission connection;

[0044] A cleaning device 10, the cleaning device 10 is...

Embodiment 2

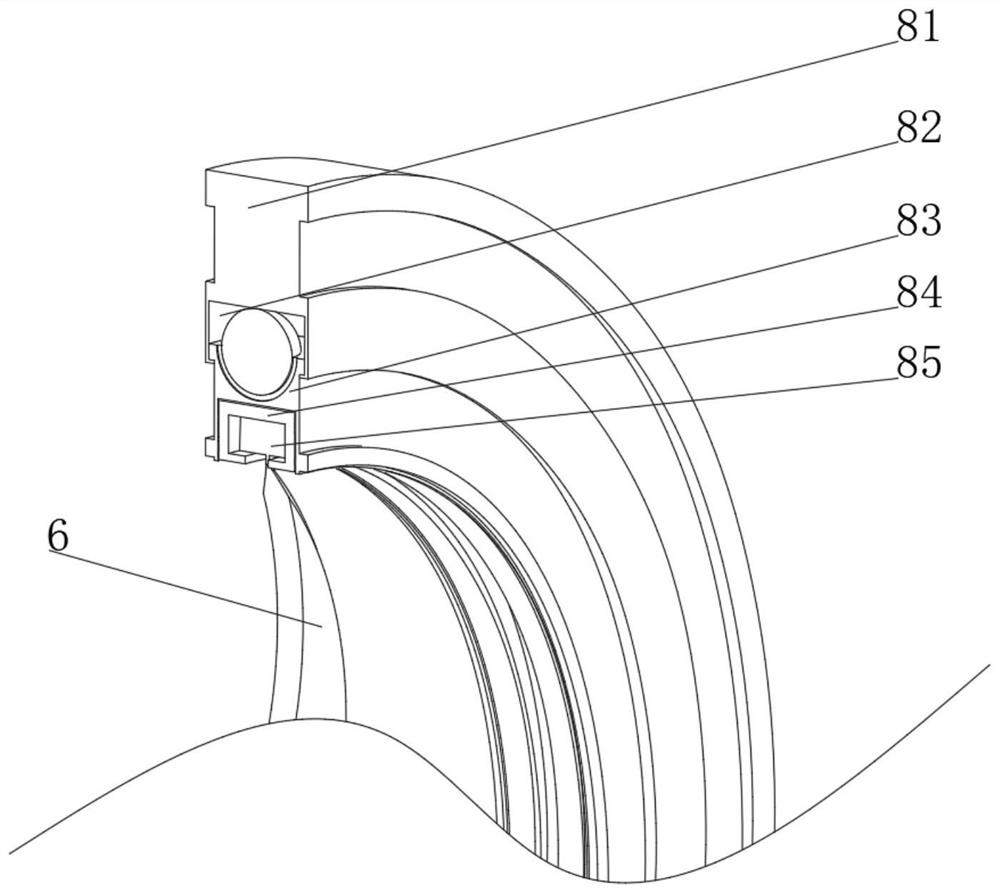

[0049] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: the cleaning device 10 includes:

[0050] Cleaning brush 101, the top of the cleaning brush 101 is fixed on the inner wall of the outer fixed cylinder 1, and the bottom of the cleaning brush 101 is closely attached to the surface of the screen cylinder 7

[0051] A tup 102, one end of the tup 102 is fixed on the inner wall of the outer fixed cylinder 1 through a rotating support 103, and the tup 102 can rotate around the rotating support 103;

[0052] Spring leaf 104, the spring leaf 104 is fixed on the inner wall of the outer fixing cylinder 1, and the bottom of the spring leaf 104 is fixedly connected with the end of the hammer head 102 away from the rotating support 103;

[0053] A rotating ring 105, the rotating ring 105 is sleeved on the hammer head 102 and can rotate on the hammer head 102, and the outer side of the rotating ring 105 is provided with a spherical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com