Reactor

A technology of reactors and reaction tanks, applied in the field of reactors, can solve the problems of shortened service life, large bed pressure drop, difficult feeding and gas ventilation, etc., to avoid fragmentation and wear, avoid vitality decline, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] Example 1. Suspension agitation damages the immobilized enzyme carrier

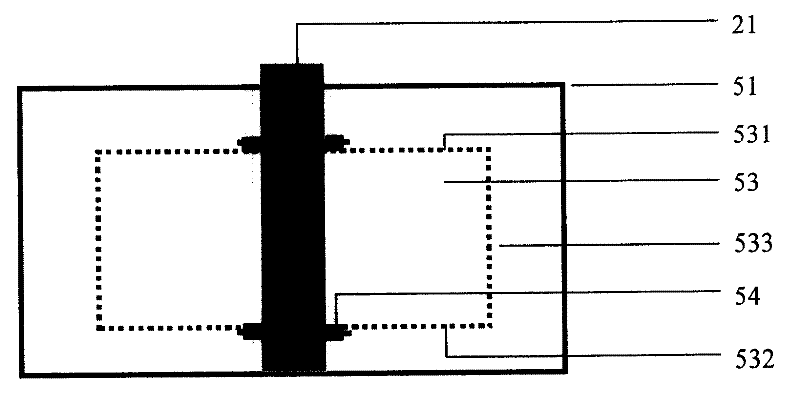

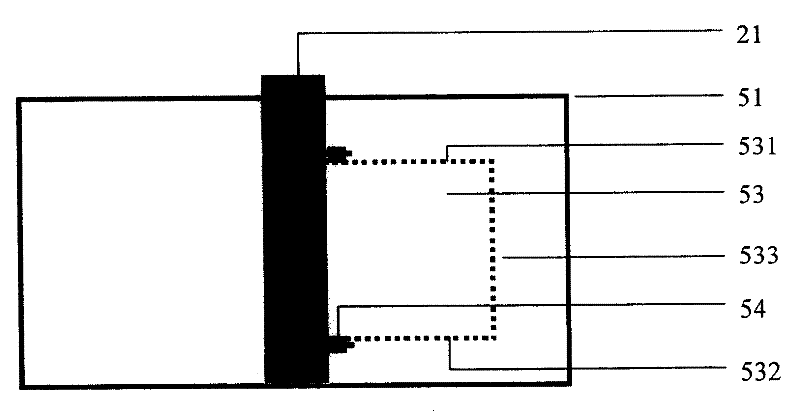

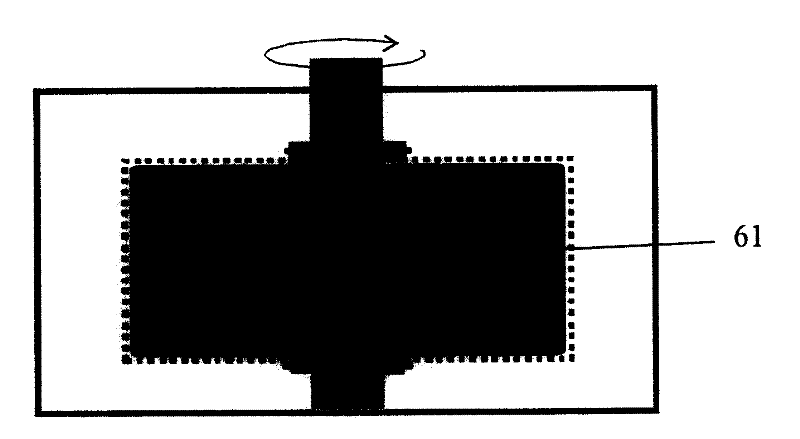

[0057] use Figure 4 In the shown reactor, the currently widely used granular immobilized enzyme resin carrier Sepabeads EC-EP (Grazu V, Abian O, Mateo C, Batista-Viera F, Fernandez-Lafuente R, Guisan JM.Biotechnol Bioeng.2005, 90:597-605; Grazu V, Abian O, Mateo C, Batista-Viera F, Fernandez-LafuenteR, Guisan JM.Biomacromolecules.2003, 4:1495-1501) and granular immobilized glucose isomerase, respectively Stirring (that is, as mentioned above, the granular immobilized enzyme resin carrier and the immobilized glucose isomerase are respectively loaded into the container 53, and the container 53 follows the rotating shaft 21 for centrifugal rotation to obtain the stirring effect) and suspension stirring test, comparing the resin The degree of damage to the carrier. Sepabeads EC-EP was purchased from Italy Resindion S.R.L company. Granular immobilized glucose isomerase was purchased from Sigma (St. ...

example 2

[0064] Example 2. The whole piece of open-pore immobilized cells is used as a stirring paddle for continuous stirring reaction to prepare high fructose syrup [1]

[0065] Glucose isomerase catalyzes the reaction that converts glucose into fructose. The vector pRSET-lac-MGI4-35-kan expressing glucose isomerase was prepared as follows. PCR primers were designed according to the sequence of pGEMT-Easy (Promega), specifically: upstream primer RBS-NdeI: 5'-CATATGTATATCTCCTTCTTGTGTGAAATTG-3'; downstream primer RBS-AlwNI: 5'-CAGTGGCTGCTGCCAGTGGCGATAAGTC-3'. Using pGEMT-Easy (Promega) as a template, PCR was performed with the above primers, and a 755bp product was amplified. The PCR conditions were: 50ng pGEMT-Easy (Promega), 0.4 μM RBS-NdeI, 0.4 μM RBS-AlwNI, 50 μM dATP, 50 μM dTTP, 50 μM dCTP, 50 μM dGTP, 20 mM Tris-HCl (pH 8.8), 10 mM KCl, 10 mM ( NH 4 ) 2 SO 4 , 2mM MgSO 4 , 0.1% Triton X-100, 2.5 U Pfu DNA polymerase (Promega), and the reaction volume was adjusted to 50 μL ...

example 3

[0072] Example 3. The whole piece of open-pore immobilized cells is used as a stirring paddle for continuous stirring reaction in series to prepare high fructose syrup

[0073] The preparation of the glucose isomerase-immobilized cell sheet, the determination of its activity, its installation on the reaction tank, the operation of the isomerization reaction and the reaction tank, etc. basically refer to Example 2. In this example, 50 grams of glucose isomerase-immobilized cell sheets were prepared, and the enzyme activity was 5,298 units / gram. Using 2 such as Figure 4 In the shown reaction tanks, reaction tank I and reaction tank II, 23.5 grams of immobilized cell sheet belts with a specific activity of 5,298 units / g were filled in the grid tray 20 respectively, and reacted separately, and the operation was the same as that of Example 2. When the flow rate of the reaction tank I was recorded at 7.1 g / min, the optical rotation (22°C) was -8.68 (equivalent to 48.68% fructose c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com