A slitting system for galvanized pull ring strip material

A technology for endless belts and galvanized coils, applied in shearing devices, metal processing equipment, manufacturing tools, etc., which can solve the problems of poor quality galvanized strips, easy wear and dullness of circular cutting knives, and many burrs on the edges of galvanized strips, etc. problems, to achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

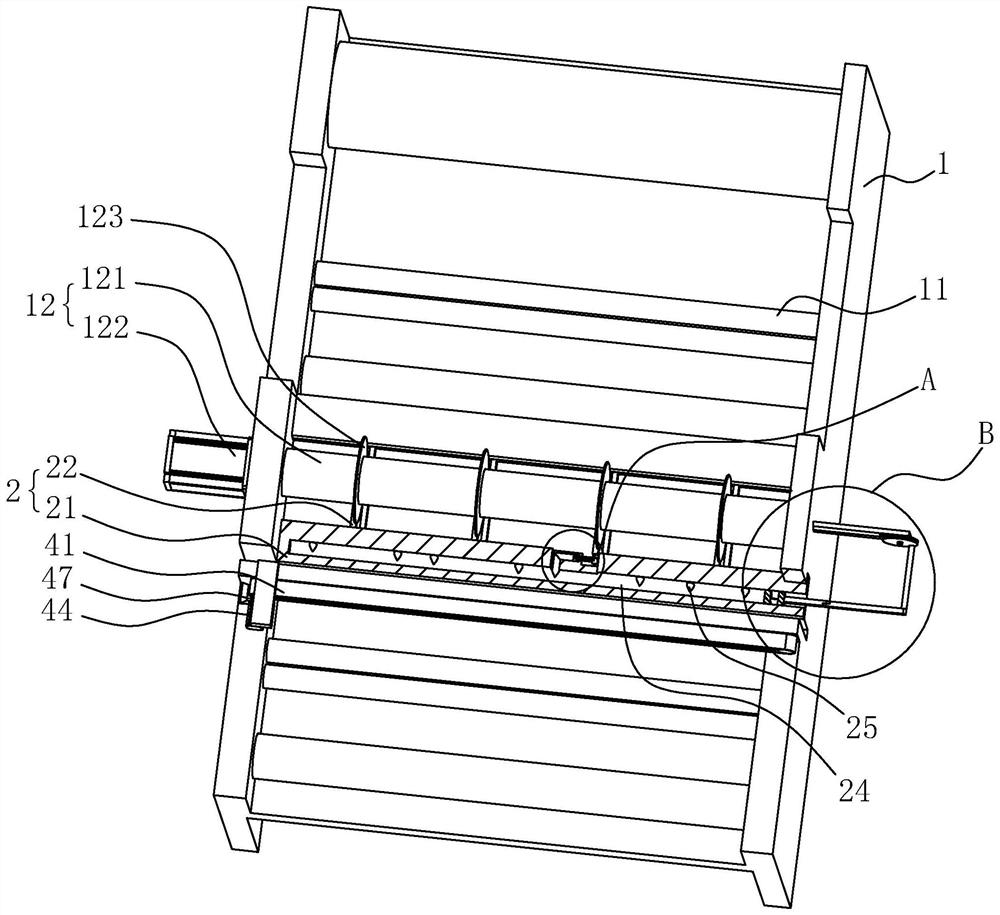

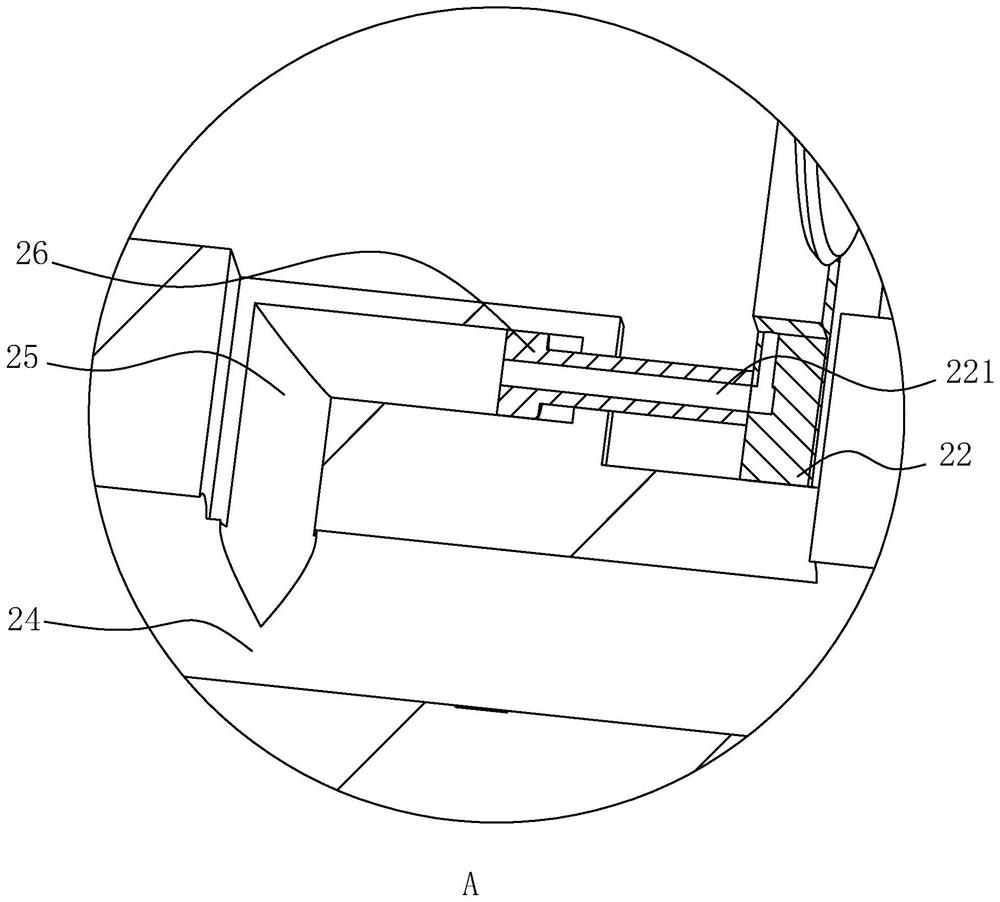

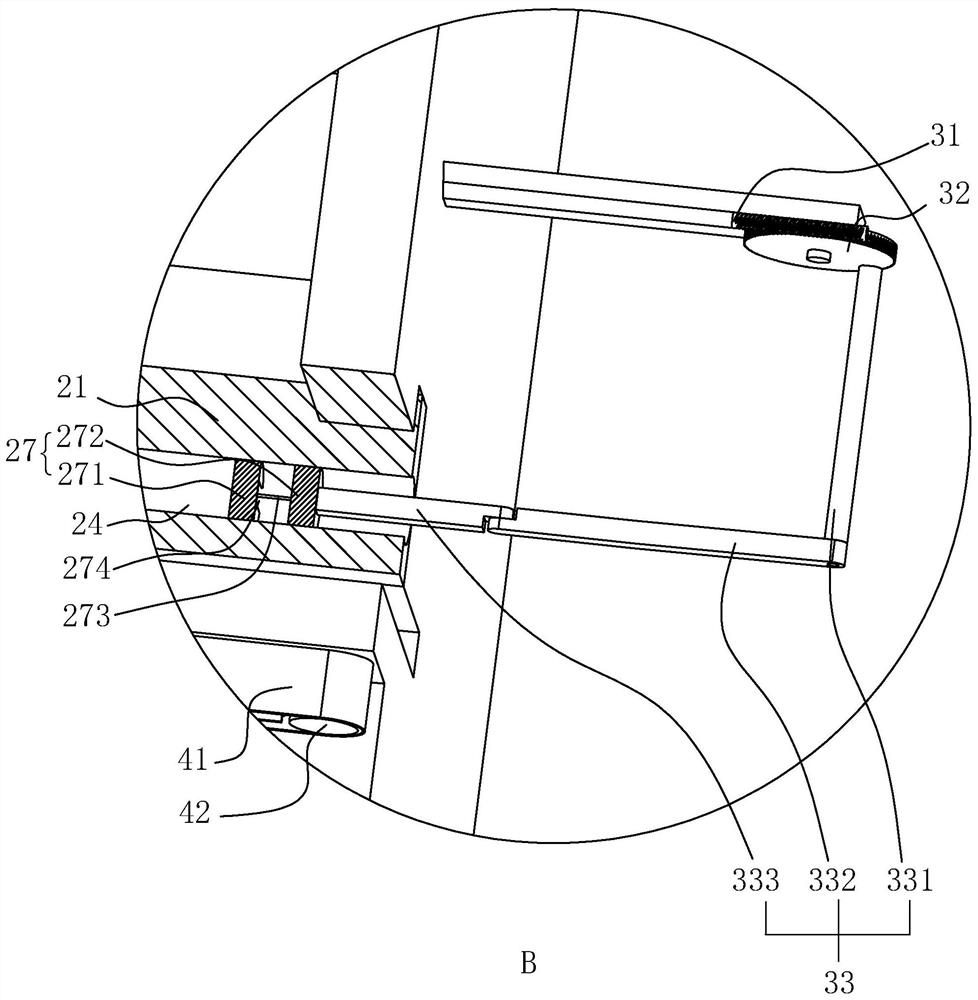

[0035] refer to figure 1 and figure 2 , is the slitting system of a kind of galvanized ring strip material disclosed in the present invention, comprises rectangular lathe 1, and lathe 1 is provided with the transmission roller 11 that is used to transmit galvanized coil strip, cutting mechanism 12 in rotation, and transmission roller 11 is driven by motor Drive to rotate, the transmission direction of transmission roller 11 is along the transmission direction of machine tool 1, and cutting mechanism 12 comprises cutting roller 121, the cutting motor 122 that drives cutting roller 121 to rotate, and the axial direction of cutting roller 121 is along the width direction of machine tool 1, and cutting roller 121 A circular cutting knife 123 is fixed coaxially, the cutting roller 121 is rotationally connected with the machine tool 1 , the motor shaft of the cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com