Dirty oil separation and purification device and method

A technology of water purification device and waste oil, which is applied in the direction of separation method, liquid separation, water/sewage treatment, etc., and can solve the problems affecting the treatment efficiency of sewage and waste oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

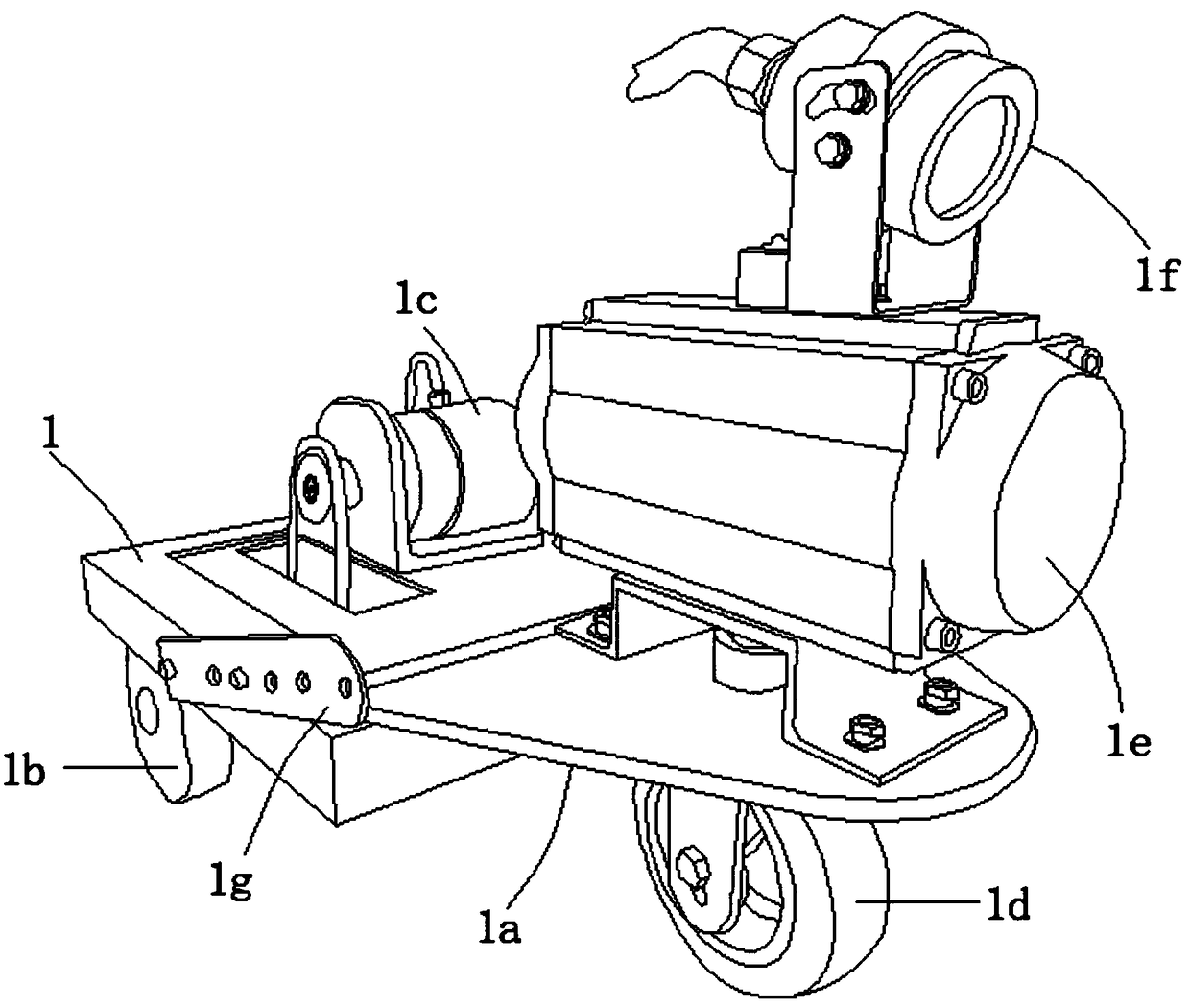

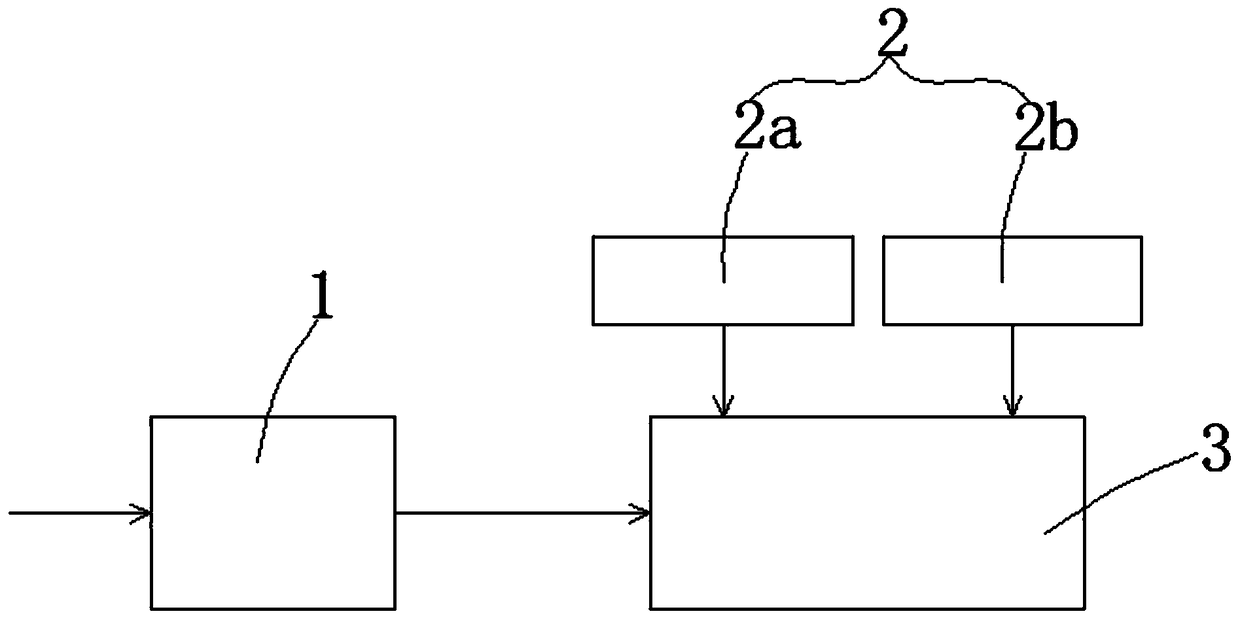

[0038] The waste oil separation and water purification device has the advantages of high efficiency in extracting waste oil and high efficiency in water purification, such as figure 1 , figure 2 As shown, specifically set to the following structure:

[0039] Including underwater car 1, dosing system 2, sewage purification system 3.

[0040] The underwater car 1 includes a base 1a made of a stainless steel plate, the base 1a is equipped with driving equipment for driving the underwater car back and forth, and the base 1a is equipped with a steering wheel for realizing the left and right steering of the underwater car. The equipment has a support 1g on one side of the base 1a, and an extraction pipeline for sucking sewage and dirty oil is installed on the support 1g. The suction port of the extraction pipeline is set towards the water surface, and the extraction pipeline can be a water hose. Cargo bellows. The extraction pipeline is connected with a mud pump, the mud pump is...

Embodiment 2

[0048] This embodiment provides a method for separating dirty oil and purifying water based on the above structure, comprising the following steps:

[0049] Step S1: Place the underwater car on the bottom of the pool, and control the underwater car to walk on the bottom of the pool to reach the predetermined area;

[0050] Step S2: Start the mud pump to extract the waste oil through the extraction pipeline and pump it to the dissolved air flotation machine;

[0051] Step S3: Add the stirred inorganic flocculant to the dissolved air flotation machine through the first dosing tank for conditioning, and stir in the first dosing tank for 15 minutes in advance;

[0052] Step S4: Add the stirred organic flocculant to the dissolved air flotation machine through the second dosing tank for conditioning, and stir in the second dosing tank for 30 minutes in advance;

[0053] Step S5: stirring the inorganic flocculant and the organic flocculant evenly in the dissolved air flotation machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com