Non-woven fabric melt-blowing processing method based on double-roller receiving device

A technology of receiving device and processing method, which is applied in the direction of melt spinning, nonwovens, textiles and papermaking, etc., can solve the problems affecting the processing efficiency of nonwovens, uneven thickness of nonwovens, and rotation resistance of drums, etc., and achieve saving Material, avoid condensation, increase the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

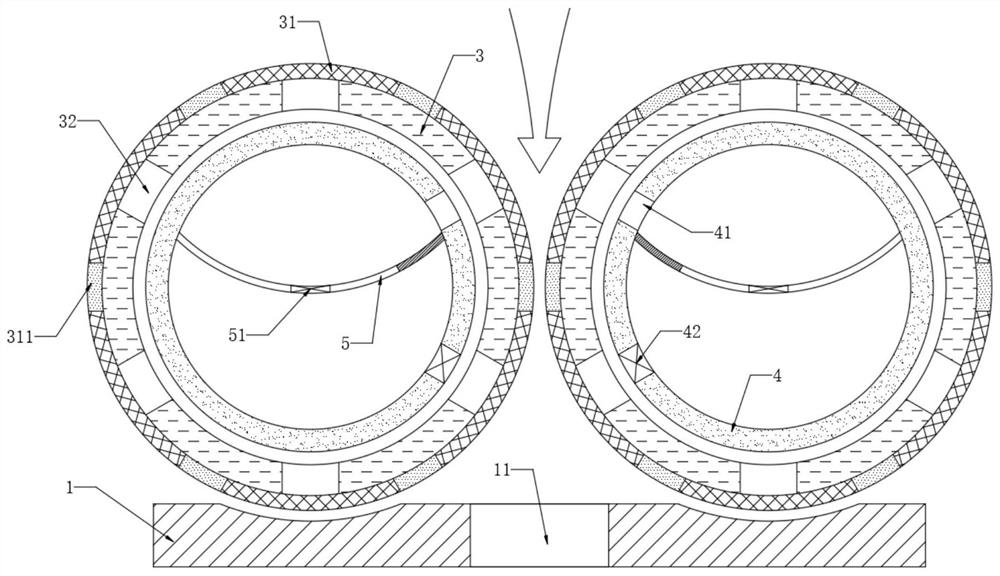

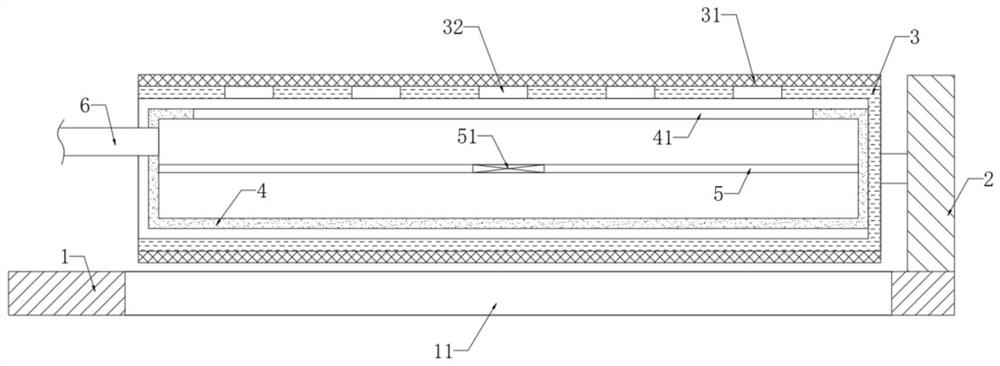

[0027] A non-woven fabric melt-blown processing method based on a double-drum receiving device, comprising the following steps:

[0028] S1, melt pretreatment, dry and pre-crystallize the processed raw materials, and put the dried processed raw materials into the hopper of the conveying equipment;

[0029] S2. Conveying the melt, conveying the melt in the conveying equipment to the die, and filtering through a multi-layer fine-mesh metal screen during the conveying process to remove impurities;

[0030] S3, heating the melt, heating the polymer melt to a molten state, extruding it from the spinneret hole of the die, and expanding it;

[0031] S4. Draw a thin stream of melt and cool it. When the melt is extruded from the spinneret hole, high-speed hot airflow is introduced on both sides of the die head, which can pull the fluid melt into a thin stream, and the outside of the die head is mixed with traction cooling Air flow, so that the thin flow of melt is rapidly cooled and f...

Embodiment 2

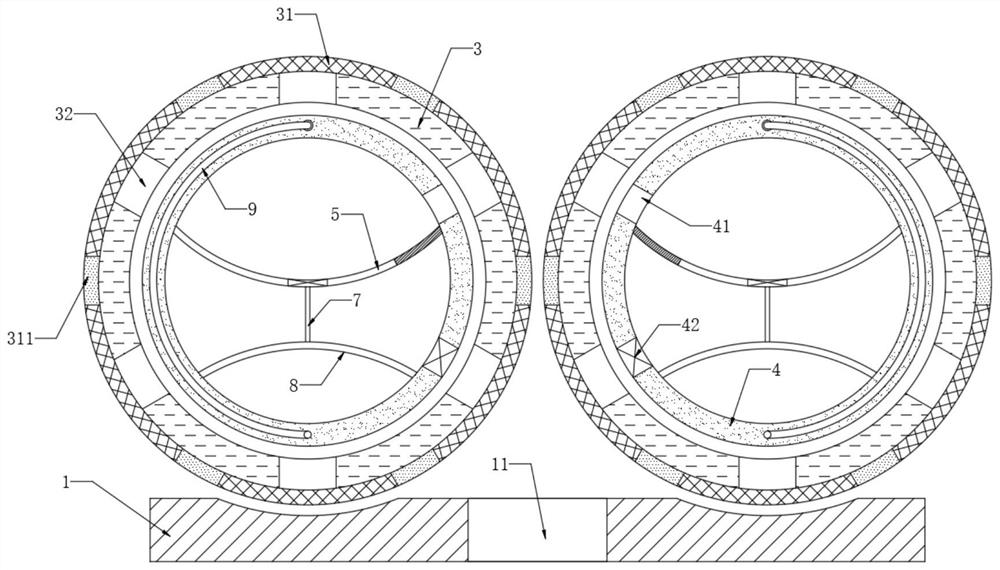

[0044] The inner bottom of the hollow mandrel 4 is embedded with a plurality of magnetic shape memory alloy strips 8, and the magnetic shape memory alloy strips 8 and the elastic pieces 5 are fixedly connected by the connecting rod 7, and the inner wall of the hollow mandrel 4 is embedded with a magnetic shape memory alloy. The alloy strip 8 is coupled to a coil 9, and the coil 9 is coupled in the power supply circuit of the drive member.

[0045] In this implementation, the elastic piece 5 will drive the connecting rod 7 to vibrate up and down continuously during the up and down vibration process, and force the magnetic shape memory alloy strip 8 to continuously deform, which can cause the internal magnetic moment arrangement of the magnetic shape memory alloy strip 8 to change, making the magnetic shape memory alloy strip 8 change. As the magnetic induction intensity of the magnetic shape memory alloy strip 8 changes continuously, the magnetic flux in the coil 9 changes conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com