Computer case punch forming device and using method thereof

A stamping forming, computer technology, applied in the field of stamping devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

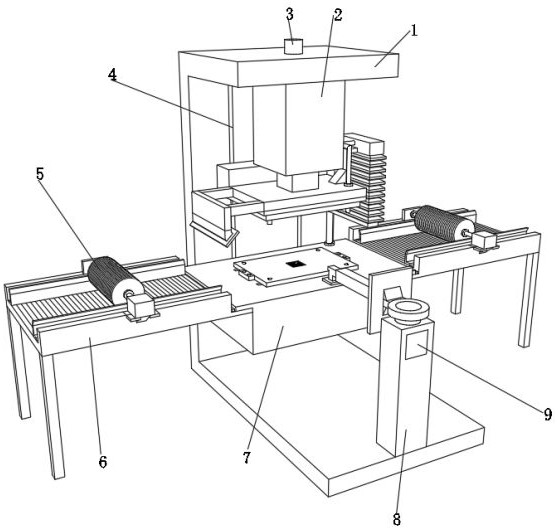

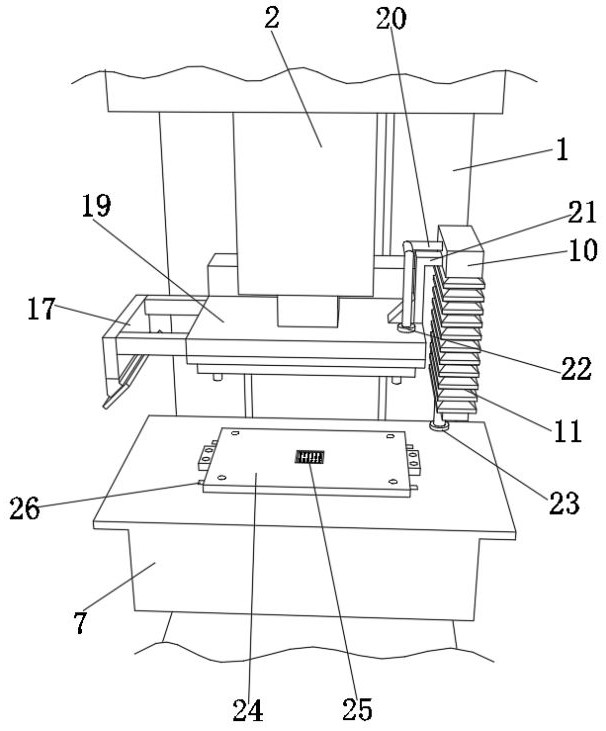

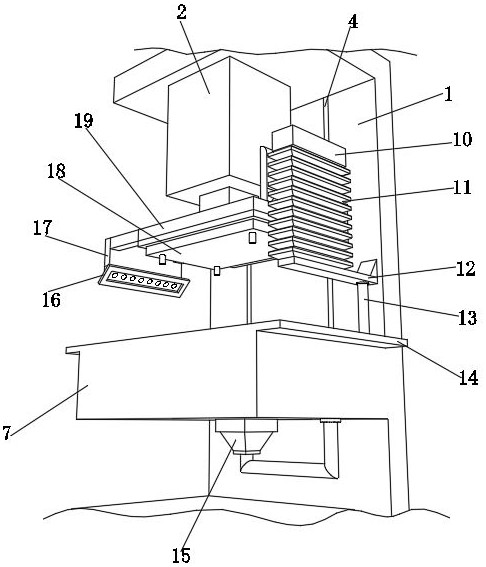

Embodiment 1

[0042] A stamping and forming device for a computer case, such as Figure 1-9 As shown, it includes an installation frame 1, the top outer wall of the installation frame 1 is provided with a warning light 3, the top inner wall of the installation frame 1 is provided with a hydraulic push rod 2, the bottom inner wall of the installation frame 1 is provided with a column 8, and the outer wall of one side of the column 8 is provided with a The control panel 9 and the outer wall on one side of the column 8 are provided with a manipulator mechanism, and the inner wall on one side of the installation frame 1 is provided with a support platform 7 . Two electric transmission plates 6 are arranged on the outer walls of both sides of the support table 7, the output shaft of the hydraulic push rod 2 is provided with a pressing plate 19, the outer wall of the bottom of the pressing plate 19 is provided with an upper mold 18, the outer wall of the top of the pressing plate 19 is provided wi...

Embodiment 2

[0055] A method for using a stamping and forming device for a computer case, such as Figure 1-9 shown, including the following steps:

[0056] S1: Place the plate on the electric conveying plate 6, and control the electric conveying plate 6 through the control panel 9 to drive the plate to the side of the support table 7;

[0057] S2: Control the mechanical arm mechanism through the control panel 9 to grab the plate on the electric transfer plate 6, and place the plate on the lower mold 24 located on the outer wall of the top of the support table 7;

[0058] S3: Control the hydraulic push rod 2 through the control panel 9 to push the pressure plate 19 down, and drive the upper mold 18 at the bottom of the pressure plate 19 to stamp the plate on the top of the lower mold 24;

[0059] S4: After the stamping is completed, the control panel 9 controls the hydraulic push rod 2 to reset, and controls the manipulator mechanism to grab the plate on the top of the lower mold 24;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com