An electroplating clamping device for production and processing of hollow parts of fitness equipment

A fitness equipment and clamping device technology, which is applied in the field of electroplating clamping devices for the production and processing of hollow parts of fitness equipment, can solve the problems of deformation of hollow parts, high use limitations, and affecting the quality of hollow parts, and achieve good support The effect of fixing, reducing the separation distance, and ensuring tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Please refer to Figures 1 through 8 :

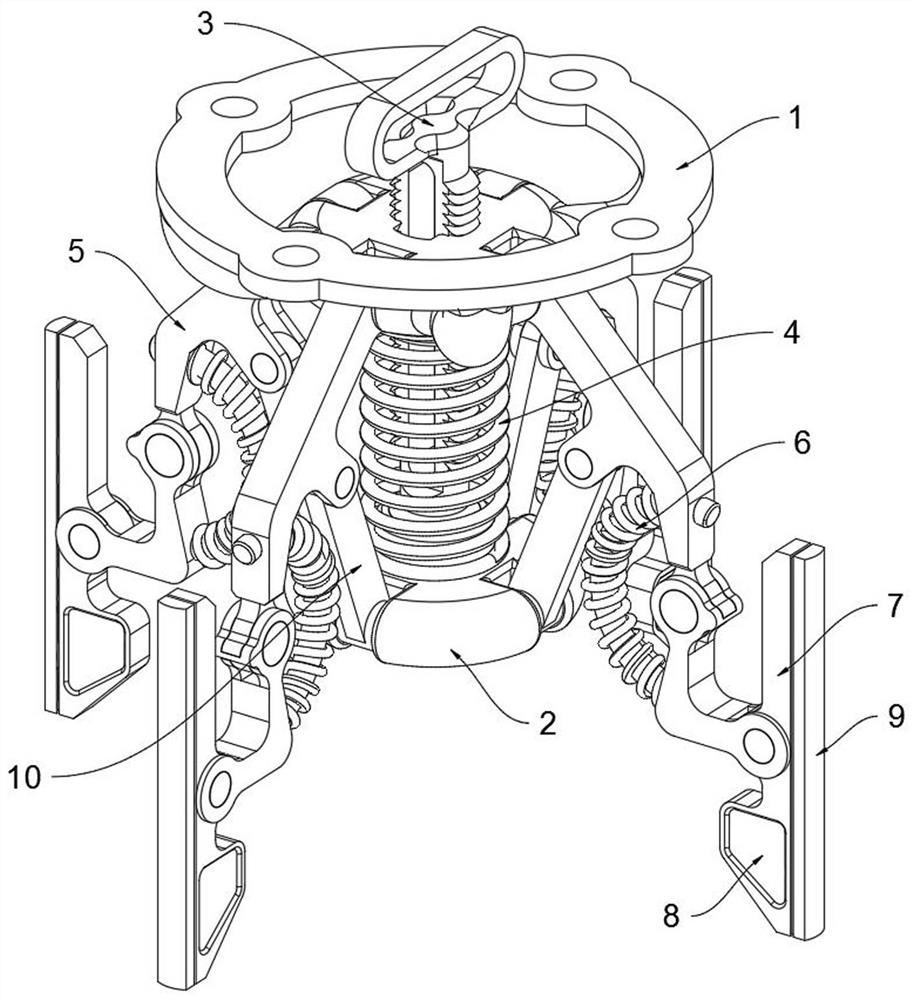

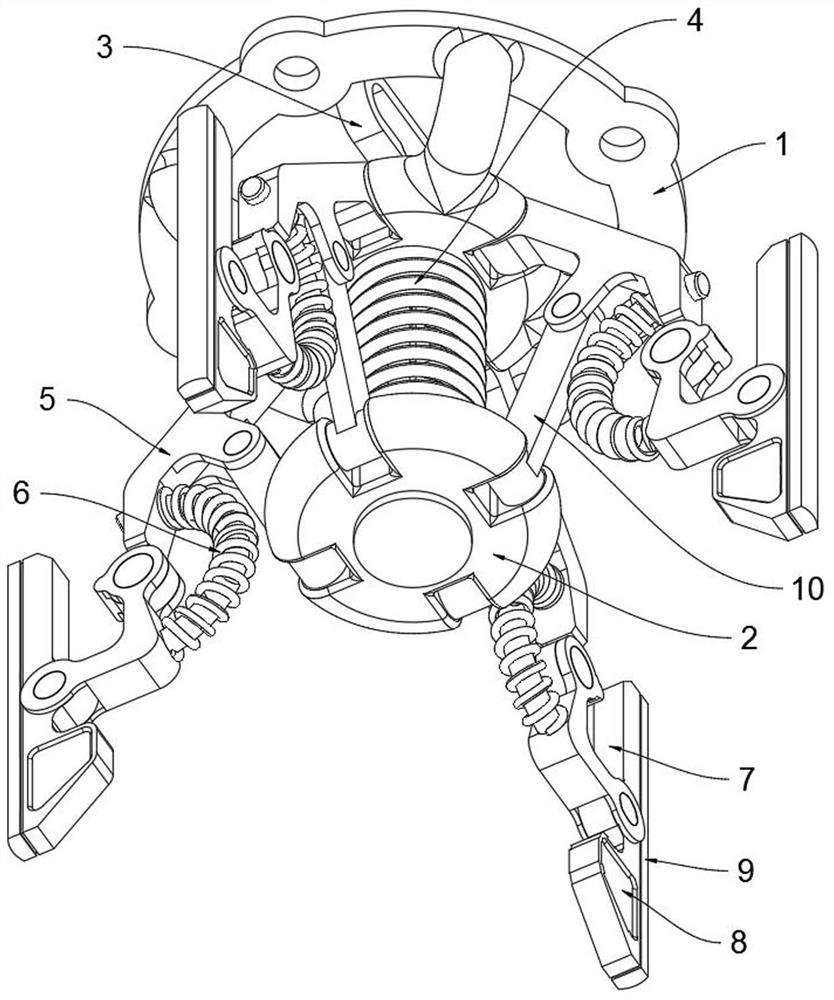

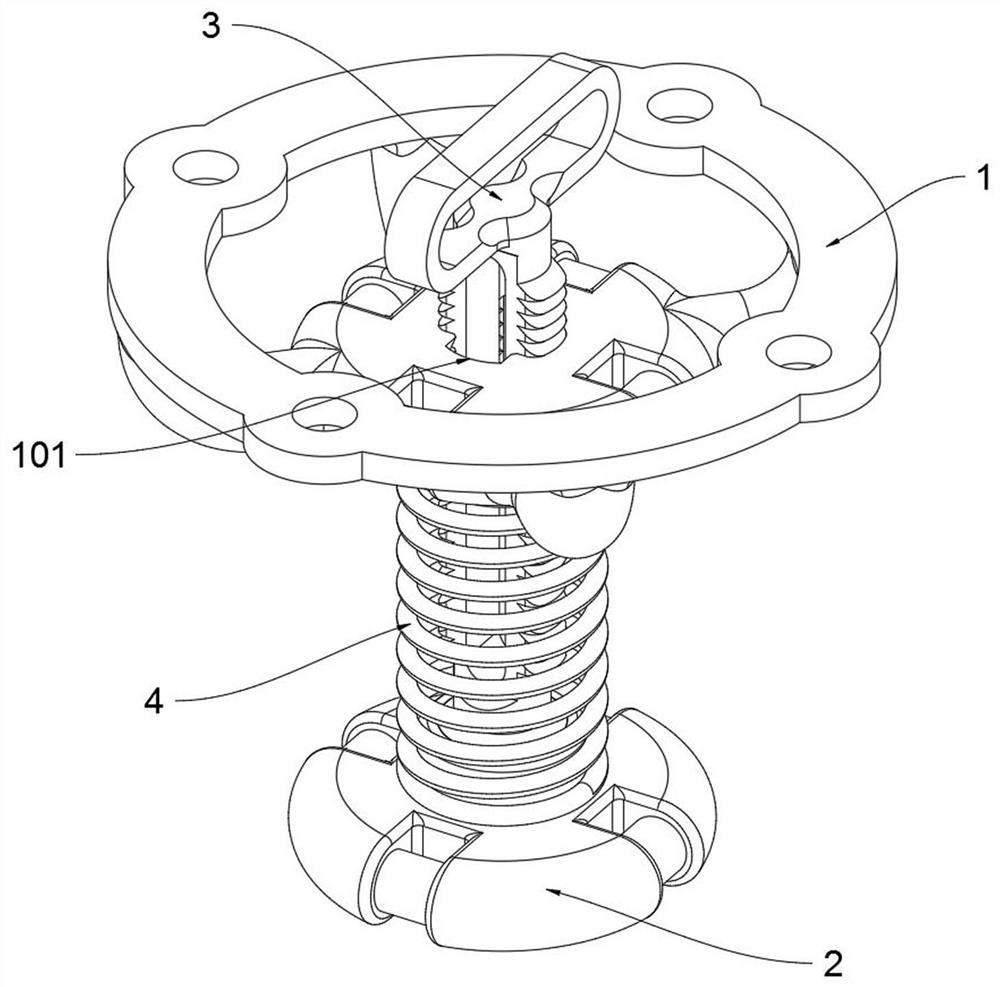

[0051] The present invention proposes a fitness equipment hollow parts production processing electroplating clamping device, comprising: fixed top seat 1, movable base 2 and tie rod 3;

[0052] Fixed top base 1 bottom is connected with four poles 5; movable base 2 is located at the bottom of fixed top 1, movable base 2 top is connected to four connecting rods 10 in a wrap-around manner, and linkage 10 is connected to pole 5, and the movable base 2 is connected to the fixed top seat 1 by connecting rod 10 and pole 5; tie rod 3 is hollow inside, the top of tie rod 3 is connected to the inside of fixed top 1, and the bottom end of the tie rod 3 is rotated inside the movable base 2; the pole 5 is set up in total, and the pole 5 is connected to the clamp spring 6, The bottom end of the pole 5 is connected to the movable rod 7, and the outer side of the movable rod 7 is equipped with anti-slip rubber strip 9; the top of the pole 5 is connec...

Embodiment 2

[0060] Pole 5 includes: ejector 501 and basebar 502;

[0061] The top of the ejector rod 501 is connected to the fixed top seat 1 rotation, the ejector rod 501 is connected to the connecting rod 10 rotation, and the ejector 501 is opened with an arc sliding hole 5011 inside;

[0062] The top of the bottom bar 502 is connected to the bottom end of the ejector 501, the bottom bar 502 and the ejector 501 rotation angle is 0 ~ 120 degrees, and the outer side of the bottom bar 502 is provided with an arc slider 5021, the arc slider 5021 slide is connected to the arc slide hole 5011, the curved slider 5021 external set has a clamping spring 6, and the top of the clamping spring 6 is attached to the outside of the top rod 501;

[0063] Using the above technical scheme, when the pole 5 drives the movable rod 7 to expand outward, the bottom rod 502 is affected by the reverse thrust of the hollow parts to rotate inward, the clamping spring 6 applies thrust to the bottom rod 502, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com