Hardware-in-the-loop test system for vehicle FOTA function automatic verification

A technology of automatic verification and test system, applied in the field of vehicle testing, can solve the problems of long test cycle, lack of complete automation, low test efficiency, etc., and achieve the effect of flexible upgrade methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

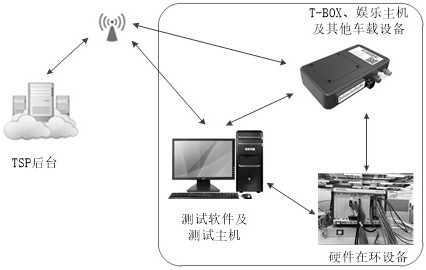

[0016] see figure 1 , the present embodiment provides a hardware-in-the-loop testing system for automatic verification of vehicle FOTA functions, which is used for automatic verification of remote online upgrade functions of vehicle ECU units and related functional logic. The hardware-in-the-loop test system can simulate the signals required by the vehicle controller, collect the signals sent by the vehicle controller, and perform conversion operations with the TSP background API through the automated software interface, so that the vehicle ECU controller can compare the real-time model with the cloud platform. Functional closed-loop control. The hardware-in-the-loop test system has the following functions: verify the data link in the FOTA upgrade process, perform basic function verification on the upgraded controller software, support the FOTA stress test and stability test of related parts, generate and Send test report.

[0017] Including TSP background, on-board equipmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap